Precursor of hollow positive electrode material and preparation method thereof

A positive electrode material and precursor technology, which is applied in the field of hollow positive electrode material precursor and its preparation, can solve the problems of inability to meet the requirements of high output power and high cycle characteristics of power batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

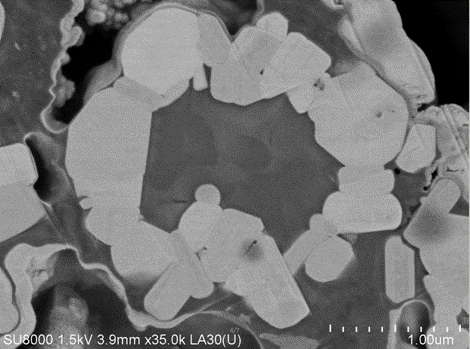

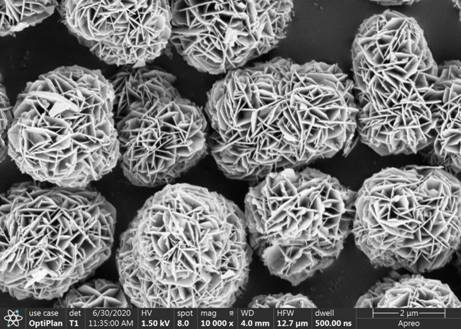

Image

Examples

Embodiment 1

[0044] Prepare a ternary metal salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a total metal concentration of 2mol / L, the molar ratio of nickel, cobalt, and manganese is 50:20:30, and prepare a 2mol / L sodium hydroxide solution. Add pure water into the reaction kettle with a volume of 300L, control the temperature at 70°C, adjust the pH to 11.70 with lye, and continuously feed nitrogen into the reaction kettle.

[0045] During the reaction process of stage I, inject the ternary metal salt solution into the reactor at a flow rate of 60mL / min, control the reaction temperature at 70°C, enter the reaction of stage II after the pH value of the solution drops to 9.50, and start injecting sodium hydroxide Solution, maintain the pH value of the solution within the range of 9.50±0.02, after 6 hours of reaction, increase the flow rate of the ternary metal salt solution to 120mL / min, after 12 hours, increase the flow rate of the ternary metal salt solution to 18...

Embodiment 2

[0049] Prepare a ternary metal salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a total metal concentration of 2mol / L, the molar ratio of nickel, cobalt, and manganese is 50:20:30, and prepare a 2mol / L sodium hydroxide solution. Add pure water into the reaction kettle with a volume of 300L, control the temperature at 70°C, adjust the pH to 11.50 with lye, and continuously feed nitrogen into the reaction kettle.

[0050] During the reaction process of stage I, inject the ternary metal salt solution into the reaction kettle at a flow rate of 60mL / min, control the reaction temperature at 70°C, enter stage II reaction after the pH value of the solution drops to 8.90, and start injecting sodium hydroxide solution , maintain the pH value of the solution within the range of 8.90±0.02, after 6 hours of reaction, increase the flow rate of the ternary metal salt solution to 100mL / min, after 10 hours, increase the flow rate of the ternary metal salt solution to ...

Embodiment 3

[0052] Prepare a ternary metal salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a total metal concentration of 2mol / L. The molar ratio of nickel, cobalt, and manganese is 35:35:30, and prepare a 2mol / L sodium hydroxide solution. Pure water was added to a reaction kettle with a volume of 100 L, the temperature was controlled at 65° C., the pH was adjusted to 11.70 with lye, and nitrogen gas was continuously introduced into the reaction kettle.

[0053] During the reaction process of stage I, inject the ternary metal salt solution into the reaction kettle at a flow rate of 40mL / min, control the reaction temperature at 70°C, enter stage II reaction after the pH value of the solution drops to 8.90, and start injecting sodium hydroxide solution , maintain the pH value of the solution within the range of 9.8±0.02, after 6 hours of reaction, increase the flow rate of the ternary metal salt solution to 80mL / min, after 12 hours, increase the flow rate of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com