Agricultural waste anion adsorbent and application thereof

An agricultural waste and anion technology, applied in the chemical and environmental fields, can solve the problems of high preparation temperature, complicated equipment, secondary pollution, etc., and achieve the effects of simple production process, wide source of raw materials and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1, (wheat straw) anionic adsorbent

[0023] The wheat straw stalks were cut into pieces about 10 cm in length, and the dirt and dust were washed with tap water. Wash and dry at 105°C for 24 hours; crush the wheat straw stalks, sieve them, and keep 40-100 mesh for later use.

[0024] (1) Take 15g of the above-mentioned wheat straw in a three-neck round bottom flask, add 250ml of NaOH (15wt%), stir and react at room temperature for 1h; add 100ml of epichlorohydrin, stir and react at 30°C for 3.5h; use the product Wash with deionized water and dry under vacuum at 60°C for 12 hours.

[0025] (2) Add the dried product to 120 mL of dimethylamine solution with a mass percent concentration of 40 wt %, stir and react at 30°C for 5 hours; wash the final product with deionized water, and dry it in vacuum at 60°C for 12 hours to obtain modified wheat straw Straw, ie anionic adsorbent (13 g).

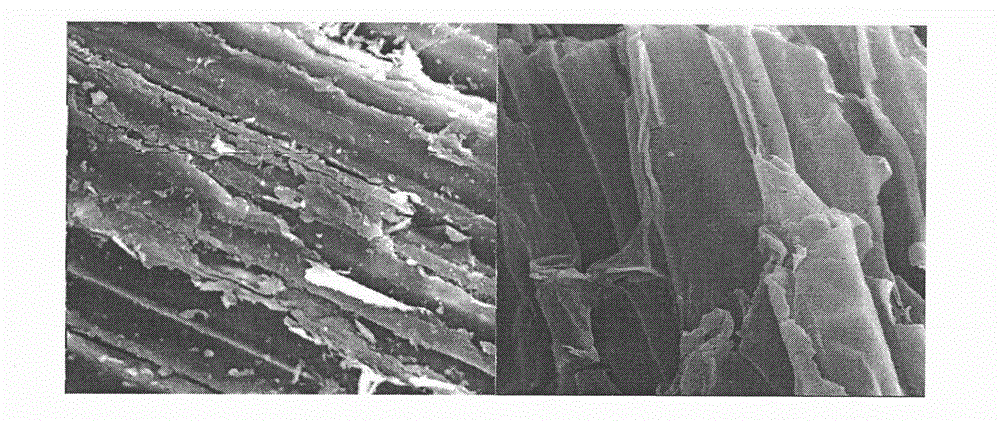

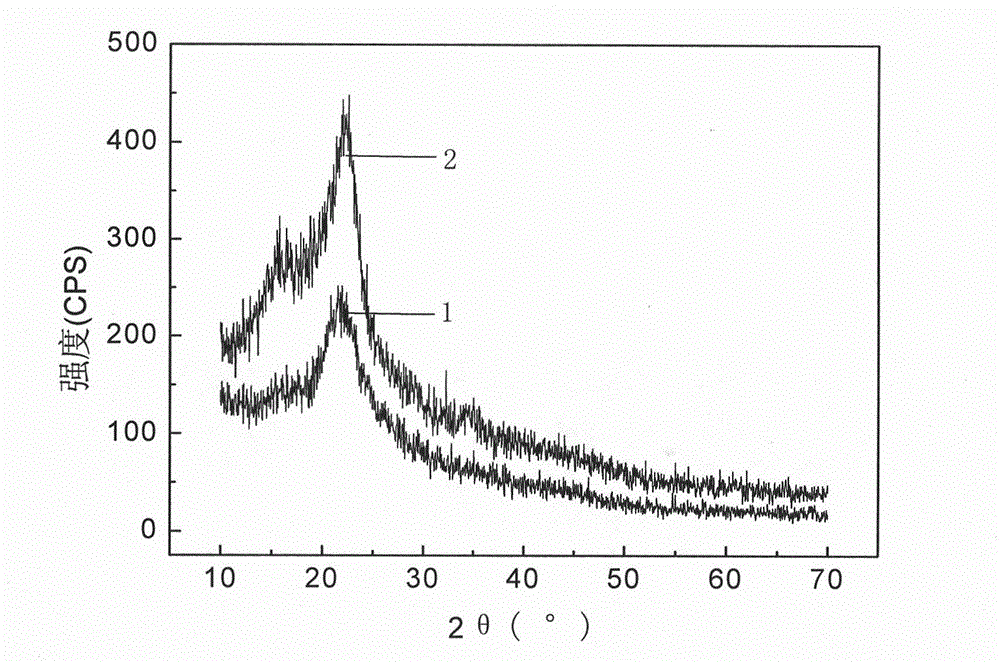

[0026] The anionic adsorbent (modified wheat straw) prep...

Embodiment 2

[0027] Embodiment 2, the application of anionic adsorbent

[0028] The anionic adsorbent of Example 1 was used to decolorize the wastewater containing anionic dyes, and the initial concentration of dyes in the wastewater was 100 mg / L.

[0029] Process 1:

[0030] At room temperature, at a vibration speed of 140r / min, use acid to adjust the pH of the wastewater to 2.0, add an anion adsorbent so that the solid-liquid ratio of the adsorbent to the dye wastewater is 1.0g / L, shake for 60min, filter, and separate out the anion adsorption dose.

[0031] Process 2:

[0032] At room temperature, at a vibration speed of 140r / min, use acid to adjust the pH of the wastewater to 4.0, add an anion adsorbent so that the solid-liquid ratio of the adsorbent to the dye wastewater is 1.2g / L, shake for 90min, filter, and separate out the anion adsorption dose.

[0033] Process 3:

[0034] At room temperature, at a vibration speed of 140r / min, use alkali to adjust the pH of the wastewater to ...

Embodiment 3

[0054] Embodiment 3, the preparation of (wheat straw) anionic adsorbent

[0055] The wheat straw stalks were cut into 9cm-long fragments, and the dirt and dust were washed with tap water. Wash and dry at 105°C for 22 hours; crush the wheat straw stalks, sieve them, and keep 40-100 mesh for later use.

[0056] (1) Take 10 g of the above-mentioned wheat straw in a three-necked round-bottomed flask, add 150 mL of NaOH (15 wt %), and stir for 1 h at room temperature; add 60 ml of epichlorohydrin, and stir for 3.5 h at 30° C; Wash with deionized water and dry in vacuum at 60°C for 10h.

[0057] (2) Add the dried product to 100 mL of dimethylamine solution with a mass percent concentration of 40 wt%, and stir and react at 30°C for 5.5h; wash the final product with deionized water, and dry it in vacuum at 60°C for 12h to obtain the modified Wheat straw straw, ie anionic adsorbent (8.5 g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com