Motor drive multi-shaft combined mechanical arm system

A motor-driven, robotic arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as movement restrictions, high production costs, and unreasonable movement modes of robotic arm devices, achieving a wide range of applications and reducing replacement. the effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

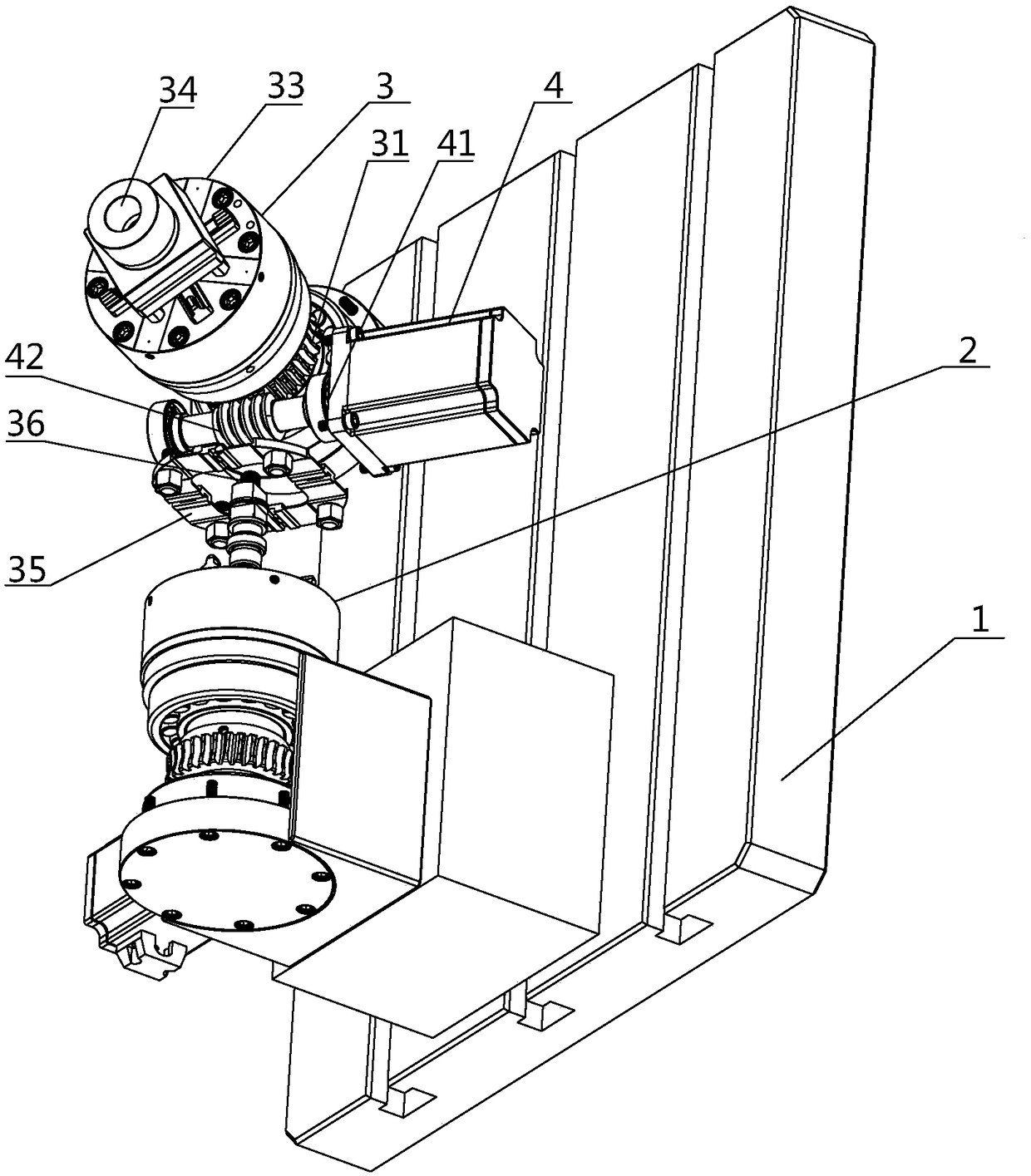

[0036] Such as Figure 1-3 As shown, the motor-driven multi-axis combined manipulator system described in Embodiment 1 of the present invention, the purpose of the implemented technical means is to solve the problem of traditional manipulator equipment when single-axis or multi-axis work is required. In addition, the replacement of the matching single-axis or multi-axis manipulator leads to the technical problem that the multi-axis work cannot be achieved through the single-axis manipulator. Rotation and position adjustment, therefore, the technical solution implemented by the present invention firstly includes a vertical fixed frame 1 arranged vertically.

[0037] Analyze the structure of the vertical fixed rack 1 set above:

[0038] The implemented fixed frame 1 adopts equipment with a single-axis mechanical arm or is fixedly equipped with a vertical direction single-axis mechanical arm 2 on the basis of traditional mechanical arm equipment. At the same time, in order to co...

Embodiment 2

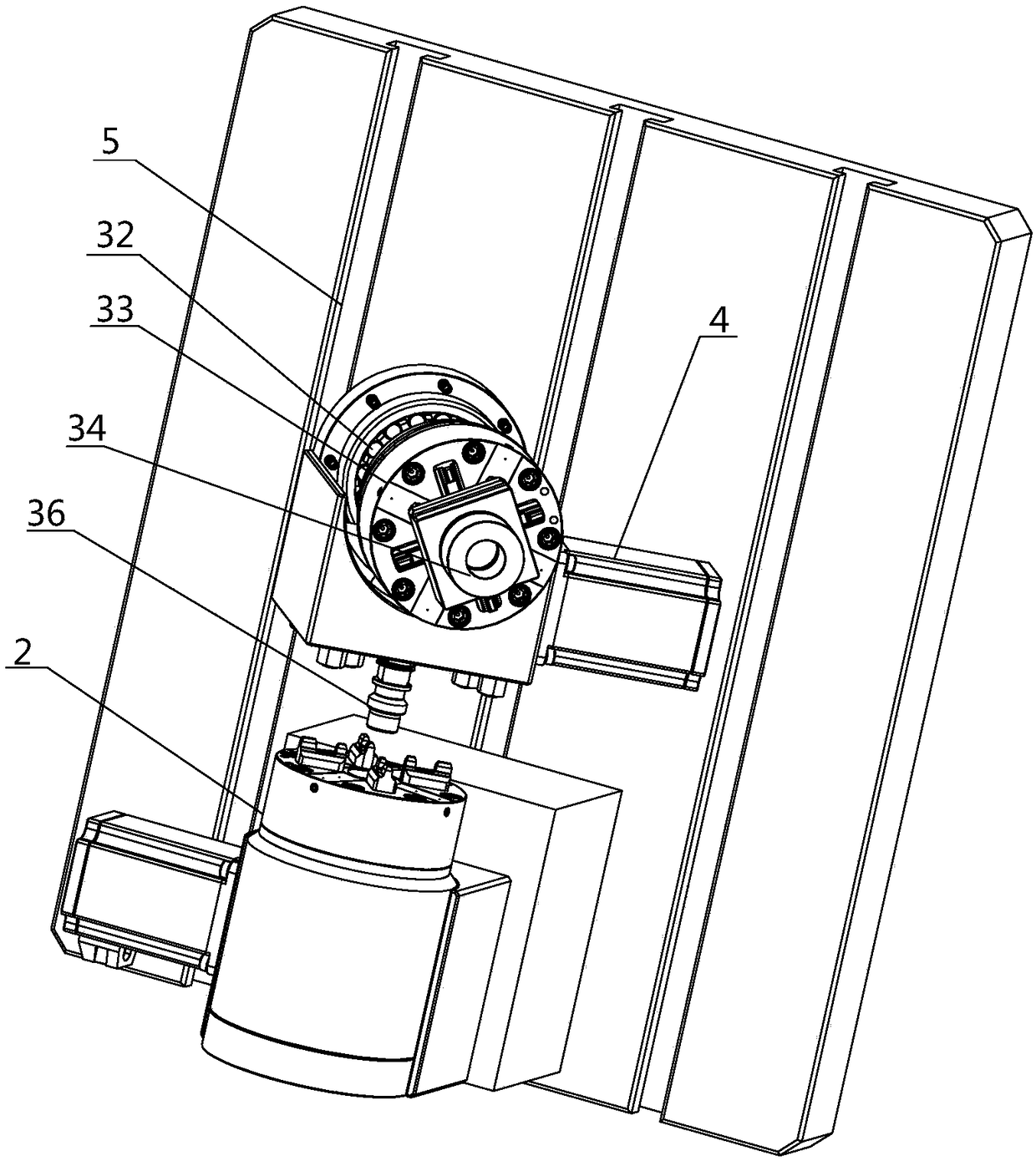

[0044] Such as Figure 1-3 As shown, the motor-driven multi-axis combined manipulator system described in Embodiment 2 of the present invention is a modification made on the basis of Embodiment 1. It belongs to the same concept as the technical solution implemented in Embodiment 1 and solves the same problem. Technical problem, the technical means implemented is to connect different shapes of mechanical arm components at the connection port of the horizontal single-axis mechanical arm 3, and realize the rotation within 360° with the rotation of the gear 31. At the same time, due to the vertical direction The single-axis mechanical arm 2 and the horizontal single-axis mechanical arm 3 are flexibly connected, so that the horizontal single-axis mechanical arm 3 can adjust its position through rotation in the vertical space.

[0045] Further, there are several rails 5 on the implemented fixed frame 1 that allow the vertical single-axis manipulator 3 to slide in the vertical direct...

Embodiment 3

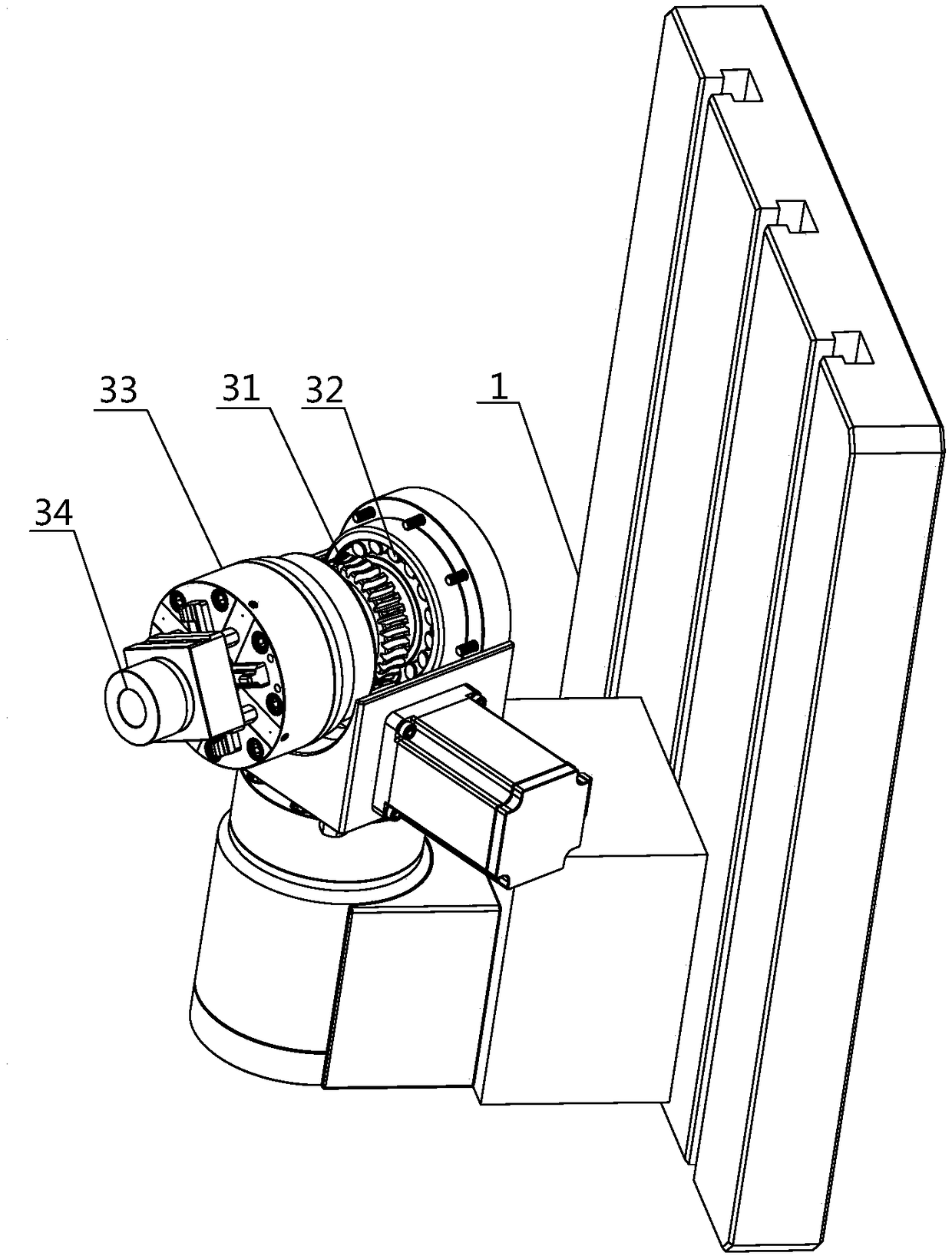

[0049] Such as Figure 1-3 As shown, the motor-driven multi-axis combined manipulator system described in Embodiment 3 of the present invention is a modification based on Embodiment 1 and Embodiment 2, and is the same as the technical solution implemented in Embodiment 1 and Embodiment 2. It belongs to the same idea and solves the same technical problem. The implemented technical means is that the outer end surface of each single-axis manipulator has a connecting shaft hole for connecting another added single-axis manipulator, and the rotating shaft installed through the connecting shaft hole The assembly turns another added single-axis robotic arm.

[0050] Correspondingly, the horizontal single-axis mechanical arm is connected to different numbers of vertical or horizontal single-axis mechanical arms, and every two single-axis mechanical arms are connected through the connecting shaft hole and the rotating shaft assembly, thereby forming any Combined multi-axis combined rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com