Improvement to methods for continuous production of acetic acid and/or methyl acetate

A kind of technology of methyl acetate and acetic acid, applied in the improvement field of continuous production of acetic acid and/or methyl acetate, can solve problems such as no one has proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] Embodiment 1 (comparative example)

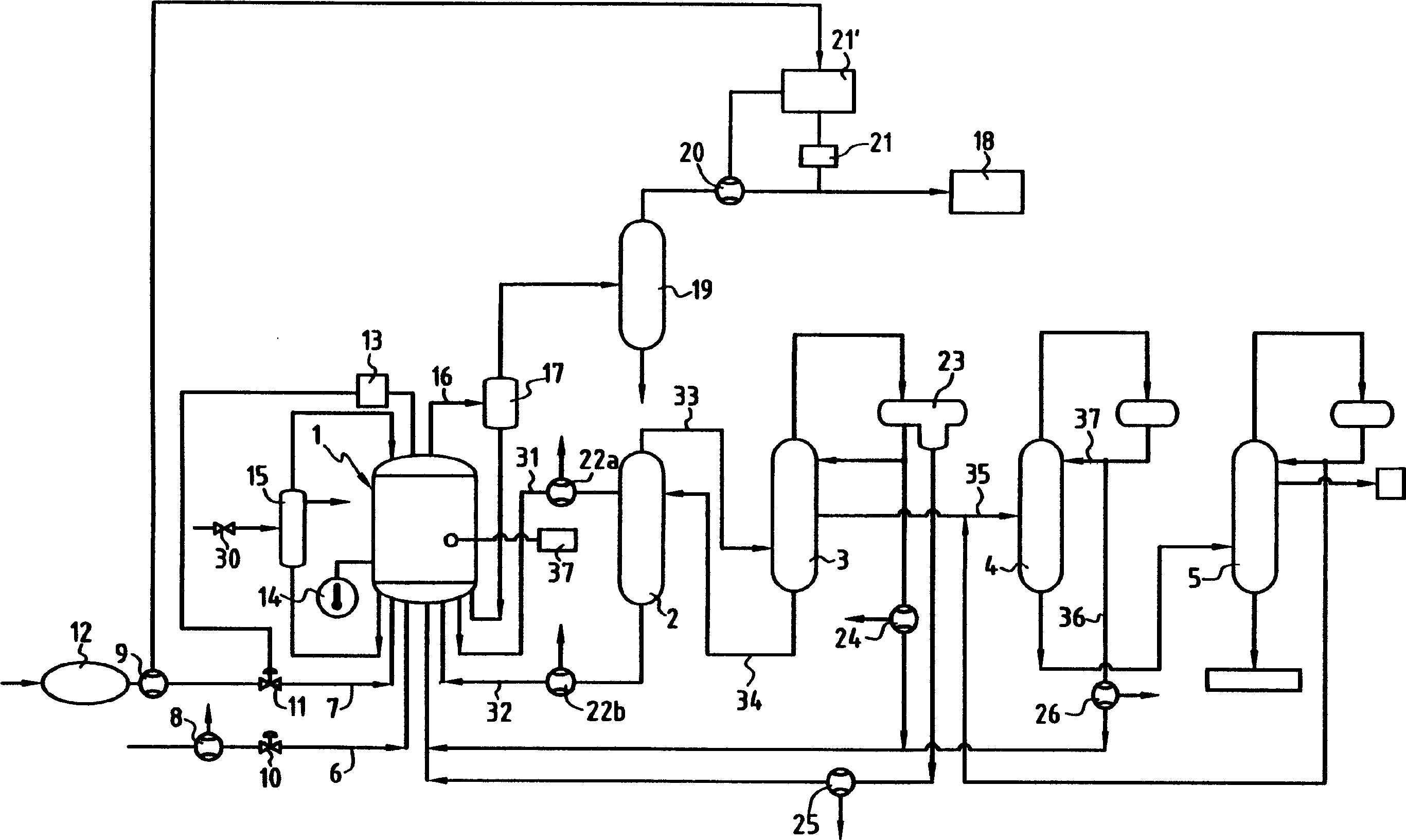

[0125] In this example, acetic acid is produced by the liquid phase carbonylation of methanol with carbon monoxide in the apparatus shown in Figure 1 in the presence of a homogeneous catalyst system.

[0126] The carbonylation reaction was carried out at a total pressure of 29 bar absolute and a temperature of 185°C.

[0127] The water concentration was kept at a value of 14% by weight of the reaction medium.

[0128] Concentrations expressed by weight of reaction medium are as follows:

[0129] ●Water: 14%

[0130] ●Iodomethane: 10%

[0131] ●Methyl acetate: 1.75%

[0132] ●Acetic acid and catalyst: up to 100%

[0133] The production rate of acetic acid is 54.1T / h.

[0134] In the case shown in the figure, the plant comprises: a reaction zone I consisting essentially of a reactor 1, a flash zone II comprising essentially a flash evaporator 2, and a zone comprising three distillation columns 3, Purification zon...

Embodiment 2

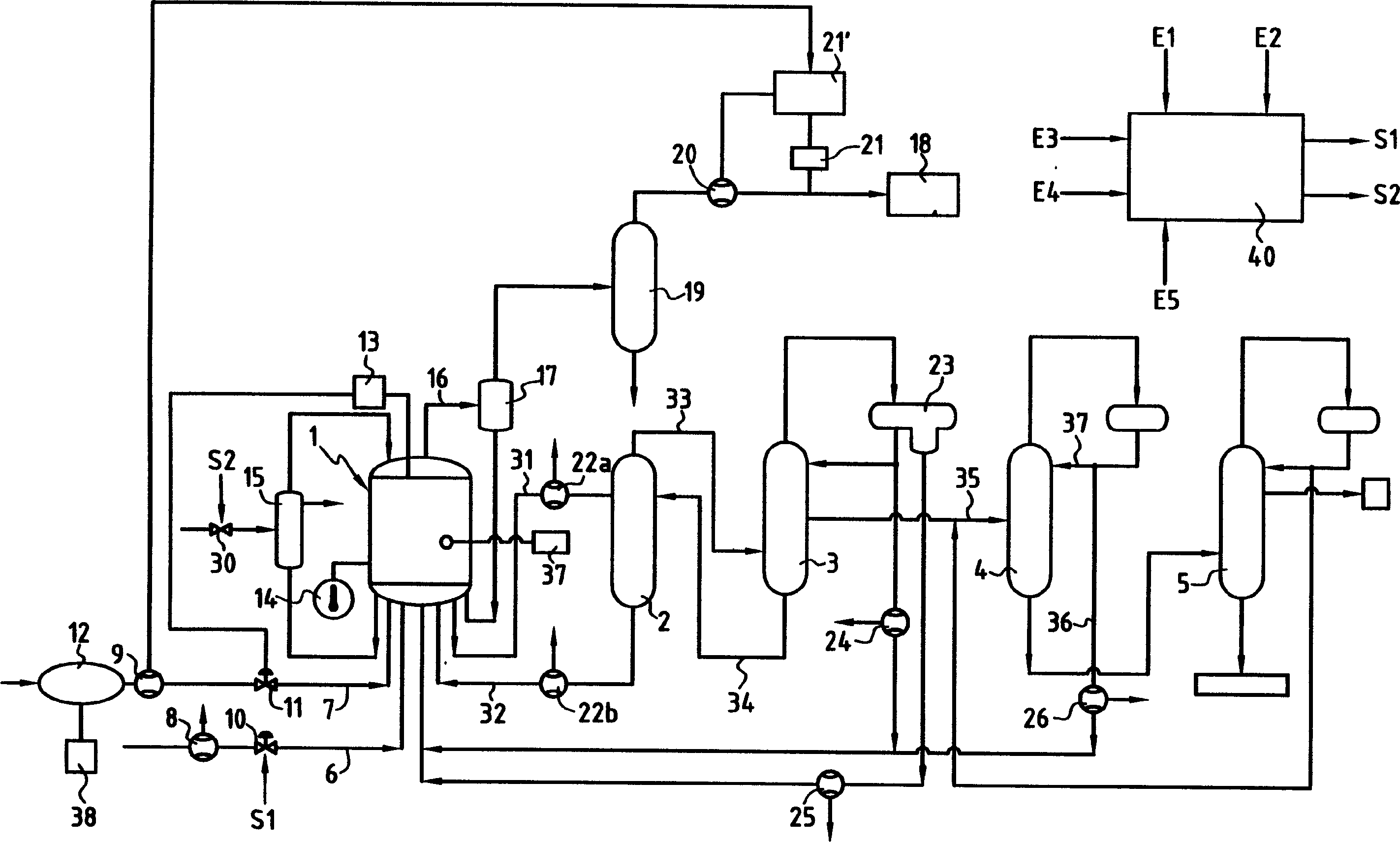

[0171] This embodiment illustrates how to implement the method of the present invention, in order to figure 2 Acetic acid is produced in the apparatus shown and under the operating conditions of Example 1.

[0172] figure 2 The arrangement shown in represents a modification of the arrangement shown in FIG. 1 and includes a multivariable predictive controller 40.

[0173] The controller 40 is programmed to adjust the target variable around the setpoint by acting on the action variable.

[0174] In this Example 2, the target variables to be adjusted were the carbon monoxide feed rate and the CO 2 selective. The action variables are the temperature in Reactor 1 and the feed rate of methanol to this reactor.

[0175] More specifically, controller 40 receives:

[0176] - the feed rate of carbon monoxide in the reactor 1 measured by the flow meter 9 at the first input E1;

[0177] - At the second input end E2, the CO of the reaction is calculated by the calculation module 21' ...

Embodiment 3

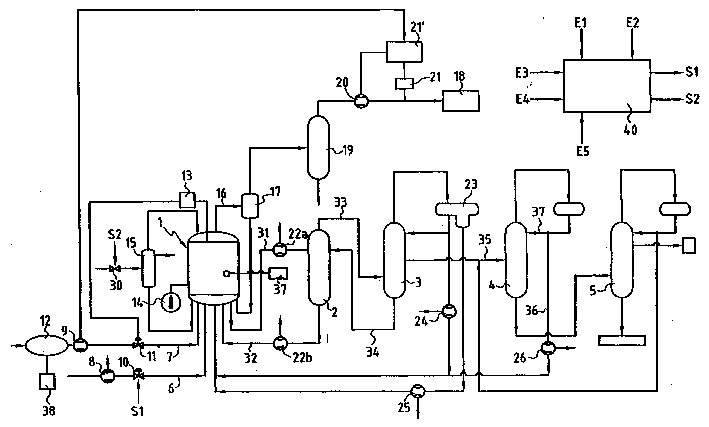

[0206] This example also refers to the industrial plant and equipment used in Example 2.

[0207] However, the controller 40 is also used in this example to control the flow of circulating liquid into the reactor 1 to the level of liquid in the reactor.

[0208] The main liquid stream entering Reactor 1 is:

[0209] ● Methanol feed rate - F1

[0210] - Recycle streams entering the reactor from Zones II and III, namely:

[0211] - circulating liquid components from the flash zone and circulating liquid from the bottom of the first distillation column - F2

[0212] - Recycle part of the aqueous liquid phase from the top of the first distillation column - F3

[0213] - Recycle organic liquid phase from the top of the first distillation column - F4

[0214] - Recycle partially condensed liquid from the top of the second distillation column - F5

[0215] The main liquid stream leaving the reactor consists of stream-F6 which enters the flash zone from the reactor.

[0216] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com