Manufacturing method of powder sintered anode foil and anode foil

A production method and technology of anode foil, applied in the direction of electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of reducing the electrostatic capacity of anode foil, affecting the mechanical properties of devices, and rearranging aluminum powder particles, so as to prevent closed cells and collapse, Prevention of overburning and proper porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

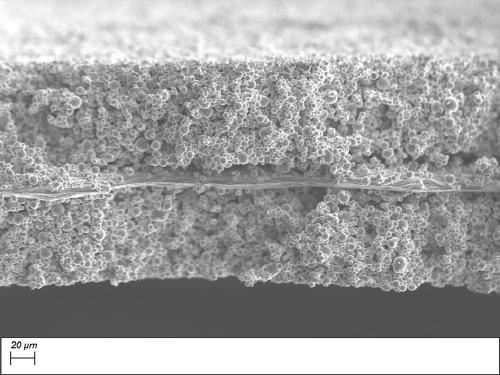

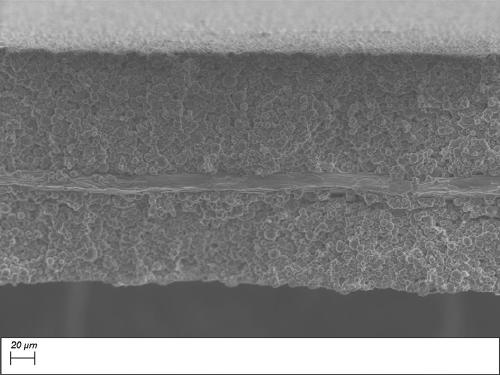

[0039] A method for making sintered anode foil, characterized in that it comprises the following steps:

[0040] 1) Put at least one of aluminum powder and aluminum alloy powder and the binder into the solvent and mix evenly; the weight ratio of aluminum powder and aluminum alloy powder to the solvent is 1:1; the solvent is acetone; the binder is epoxy resin.

[0041] 2) The uniformly mixed slurry is formed into a film on the substrate and cured; the substrate is an aluminum foil with a thickness of 40 μm. The film thickness was 80 μm. The curing is thermally cured, and the thermal curing temperature is 120°C. When forming a film, the film is formed on both sides of the aluminum foil substrate.

[0042] 3) Degrease the substrate obtained after curing; degreasing is divided into two steps: the first stage, the temperature is raised to 120°C, and kept for 90min; the second stage, the temperature is slowly raised to 350°C within 10h, and Keep warm for 50 minutes;

[0043] 4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com