Preparation method of graphene-based thick and dense electrode

A graphene-based, graphene-based technology, applied in the field of graphene, can solve the problems of low volumetric energy density of electrochemical energy storage devices, easy agglomeration of graphene electrode materials, hindered electrolyte ion transmission, etc., to achieve rapid charge and discharge characteristics, impurity The effect of less, high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

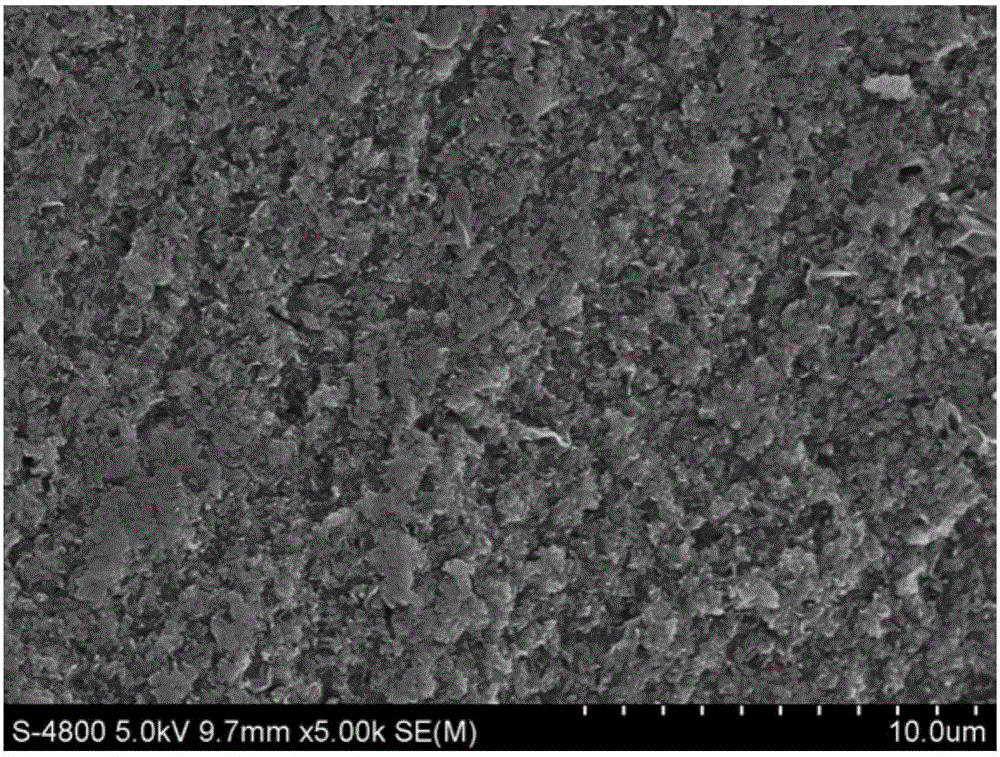

[0035] The invention provides a kind of preparation method of graphene-based thick and dense electrode, it comprises the following steps:

[0036] (1) Preparation of graphene hydrogel

[0037] It can be understood that in order to make the graphene sheets overlap and cross-link more fully to form a three-dimensional structure, the selected graphene derivatives are selected from at least one of graphene oxide, modified graphene, and porous graphene.

[0038] In an embodiment of the present invention, graphene oxide is preferred.

[0039] The reduction method includes: hydrothermal reduction, chemical reduction, and the chemical reducing agent used includes (at least one of hydrazine hydrate, urea, thiourea, hydroiodic acid, sodium citrate, and sodium bisulfite).

[0040]In an embodiment of the present invention, hydrothermal reduction is preferred among the reduction methods.

[0041] (2) Compounding of graphene and salt components

[0042] The selected salt composition shou...

Embodiment 1

[0057] (1) Preparation of graphene hydrogel

[0058] Weigh 170 mg of graphite oxide powder material prepared by the improved Hummer method, add it to 85 mL of deionized water, and ultrasonically disperse it for 2 h at a power of 200 W to obtain 2 mg·mL -1 graphene oxide hydrosol. Put the above-mentioned hydrosol in a 100mL hydrothermal kettle, heat at 180°C for 6 hours; after the hydrothermal kettle cools down, pour out the water phase to obtain a hydrothermally reduced graphene hydrogel.

[0059] (2) Compounding of graphene and salt components

[0060] Soak the above-mentioned graphene hydrogel in 20mL 0.5M zinc chloride aqueous solution for 12h, then take out the graphene hydrogel, at this time, zinc chloride is adsorbed on the graphene sheet of the hydrogel, and the graphene hydrogel The glue was dried under vacuum at 70°C for 24 hours to obtain a composite of zinc chloride and graphene.

[0061] (3) The salt component generates gas to regulate the pore structure of the ...

Embodiment 2

[0066] Embodiment 2: The concentration of the zinc chloride aqueous solution in embodiment 1 is adjusted to 0.1M, and the rest is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com