Construction method of spiral impact drilling device suitable for rock and soil

A construction method and drilling device technology, which are applied in the construction field of helical impact drilling devices, can solve the problems of increasing construction period, drilling inclination, and increasing engineering costs, so as to avoid deviation of drilling inclination, stable rotation frequency and transmission. System stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

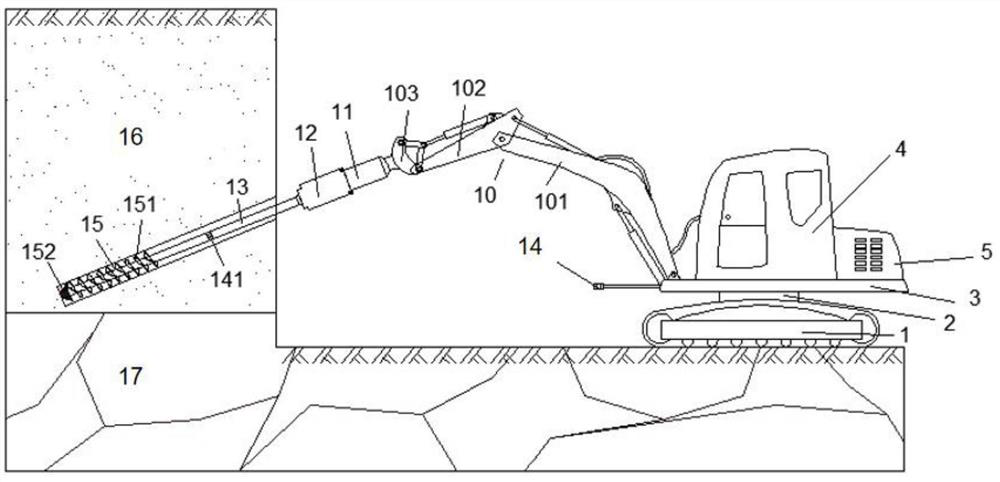

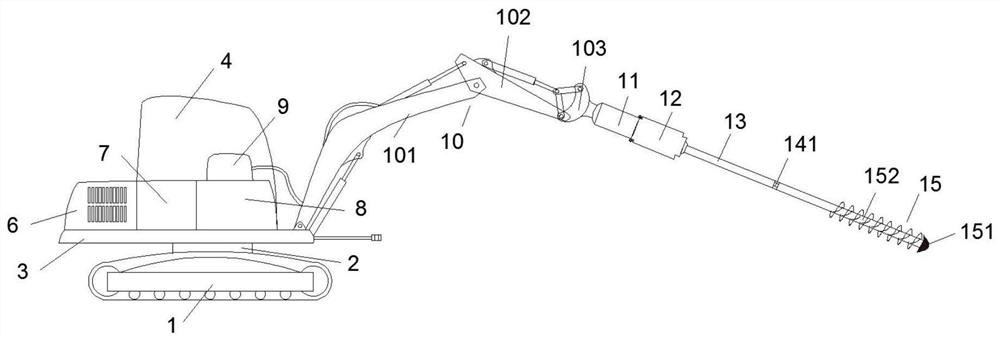

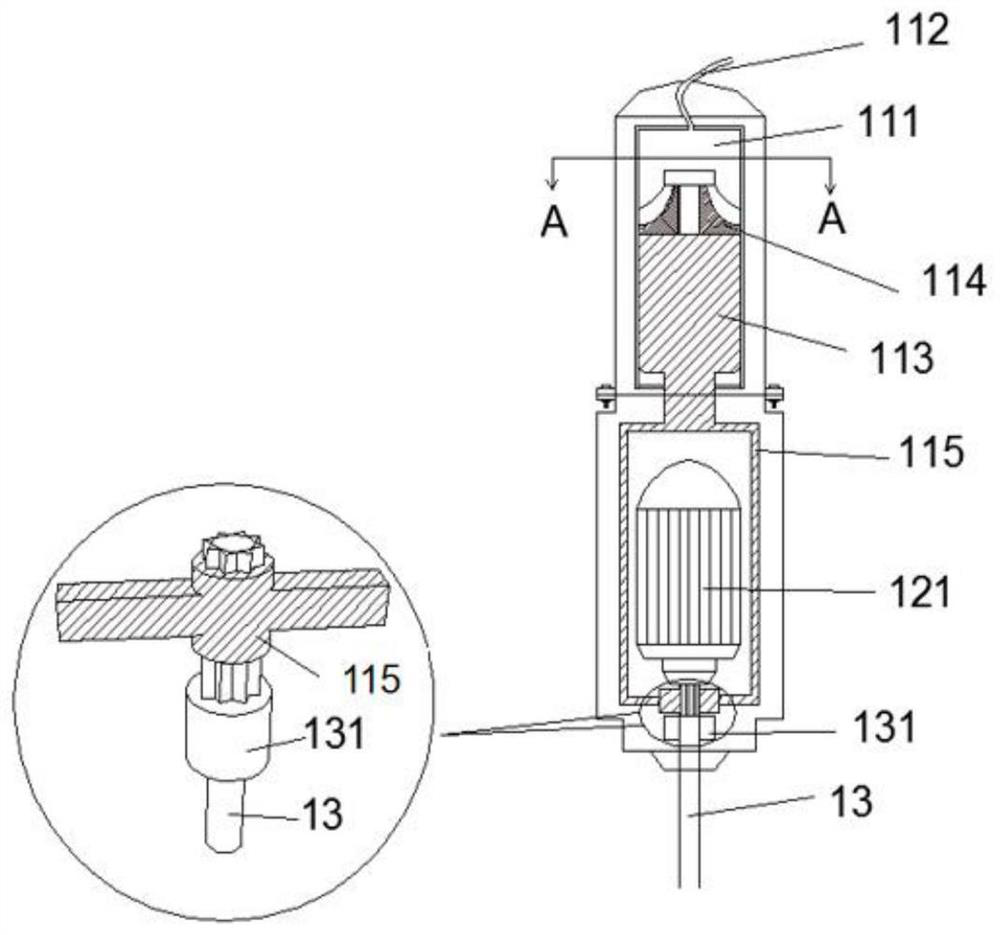

[0041] Such as figure 1As shown in -4, a construction method of a spiral percussion drilling device suitable for rock and soil, the drilling device includes a drilling rig system and a drilling rig support, and the drilling rig support includes a walking chassis mechanism 1, and the chassis mechanism 1 is equipped with a rotating Mechanism 2, the rotating mechanism 2 is provided with a working platform 3, the driving and operating room 4 is arranged on the working platform 3, the front end of the working platform 3 is provided with a boom 10, and the front end of the boom 10 is connected with the drilling system; the drilling system Including power distribution system, air pressure system 6, rock drilling parts 11, soil drilling parts 12, gears, drill pipe 13 and drill bit 15 at the bottom of the drill pipe; There is a cylinder 111, the top of the cylinder 111 is provided with an air pipe 112, the bottom of the cylinder 111 has a hole, and the cylinder 111 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com