Injectable hydrogel as well as preparation method and application thereof

A technology for injecting water and hydrogels, applied in the fields of application, pharmaceutical formulation, pharmaceutical science, etc., can solve the problems of less research on mechanical properties of adhesion properties, shorten the gelation time, promote the performance of materials, and improve the possibility of injectable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

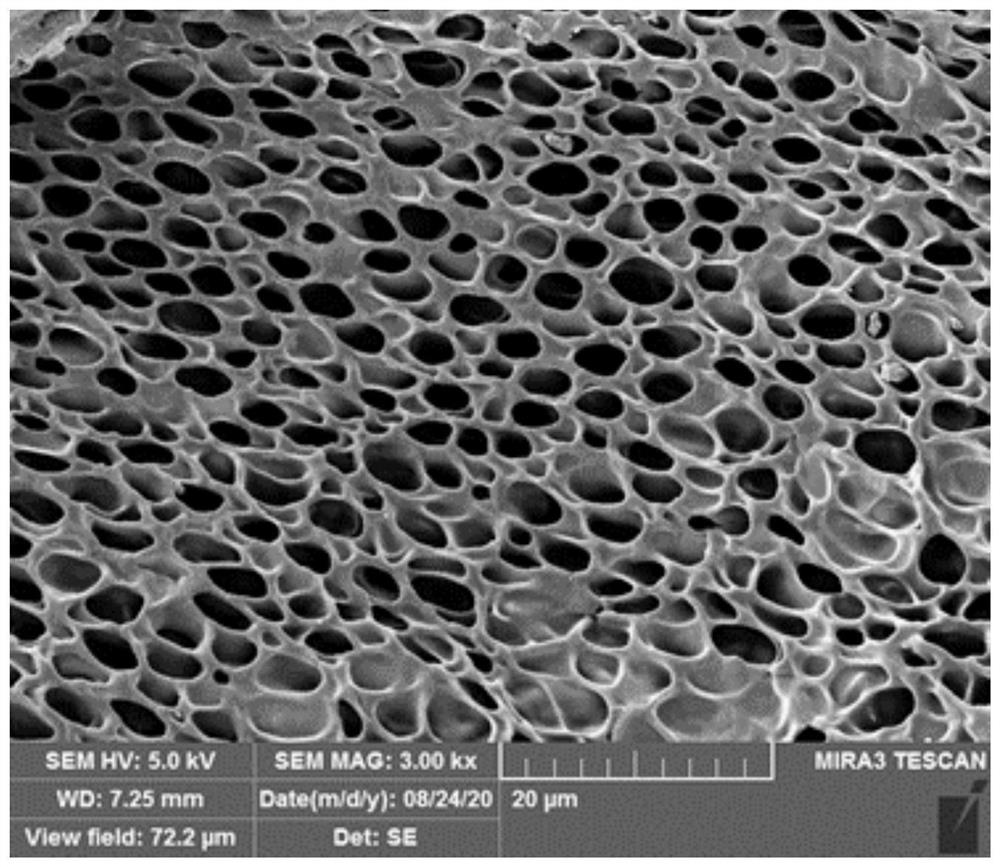

[0048] This embodiment provides an injectable hydrogel, the preparation method of which is as follows:

[0049] (1) Type A pigskin gelatin was dissolved in deionized water to prepare a gelatin solution with a mass fraction of 20 wt%, and the pH was adjusted to 8.0 using Tri buffer.

[0050] (2) Add tannic acid to (1) gelatin solution, the mass fraction of tannic acid in the gelatin solution is 2wt%, stir in 55 ℃ water bath for 6h, prepare the gelatin solution doped with tannic acid.

[0051] (3) Dilute the purified transglutaminase (TG enzyme) in PBS buffer solution to prepare TG enzyme solution, the concentration of TG enzyme is 0.5mg / mL.

[0052] (4) Mix the gelatin solution doped with tannic acid in step (2) and the TG enzyme solution in step (3) with a volume ratio of 5:1, and incubate to obtain the adhesive injectable hydrogel, and the incubation time for 1 min, and the incubation temperature is 37° C. to make it gel, and obtain the injectable hydrogel.

Embodiment 2

[0054] This embodiment provides an injectable hydrogel, the preparation method of which is as follows:

[0055] (1) Type A pigskin gelatin was dissolved in deionized water to prepare a gelatin solution with a mass fraction of 20 wt%, and the pH was adjusted to 8.0 using Tri buffer.

[0056] (2) Add tannic acid to (1) gelatin solution, the mass fraction of tannic acid in the gelatin solution is 4wt%, stir in 55 ℃ water bath for 6h, prepare the gelatin solution doped with tannic acid.

[0057] (3) Dilute the purified transglutaminase (TG enzyme) in PBS buffer solution to prepare TG enzyme solution, the concentration of TG enzyme is 0.5mg / mL.

[0058] (4) Mix the gelatin solution doped with tannic acid in step (2) and the TG enzyme solution in step (3) with a volume ratio of 5:1, and incubate to obtain the adhesive injectable hydrogel, and the incubation time for 40 s, and the incubation temperature was 37° C. to make it gel, and obtain the injectable hydrogel.

Embodiment 3

[0060] This embodiment provides an injectable hydrogel, the preparation method of which is as follows:

[0061] (1) Type A pigskin gelatin was dissolved in deionized water to prepare a gelatin solution with a mass fraction of 10 wt%, and the pH was adjusted to 7.5 using Tri buffer.

[0062] (2) Add tannic acid to (1) gelatin solution, the mass fraction of tannic acid in the gelatin solution is 1wt%, stir in 45 ℃ water bath for 10h, prepare the gelatin solution doped with tannic acid.

[0063] (3) Dilute the purified transglutaminase (TG enzyme) in PBS buffer solution to prepare TG enzyme solution, the concentration of TG enzyme is 1mg / mL.

[0064] (4) Mix the gelatin solution doped with step (2) tannic acid and step (3) TG enzyme solution with a volume ratio of 8:1, and incubate to obtain the adhesive injectable hydrogel, and the incubation time for 40 s, and the incubation temperature was 45° C. to make it gel, and obtain the injectable hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com