Coat, LED lampshade using it, and PC material

A technology for LED lampshades and coatings, applied in the direction of coatings, lampshades, polyester coatings, etc., can solve problems such as insufficient astigmatism, insufficient light transmission efficiency, no high light transmittance, high astigmatism, etc., to achieve improved The effect of light angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A coating, comprising the following components (measured by mass fraction): 1-15% of spherical organosilicon powder, 0-5% of square barium sulfate, 0-15% of inorganic filler, 20-90% of resin, 0-40% of the solvent, 0-5% of the auxiliary agent and 0-5% of the color-changing agent.

Embodiment 2

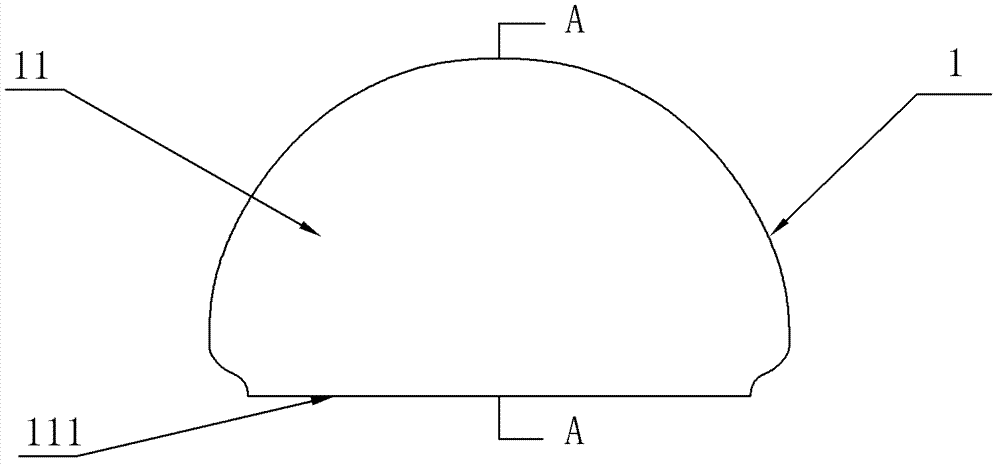

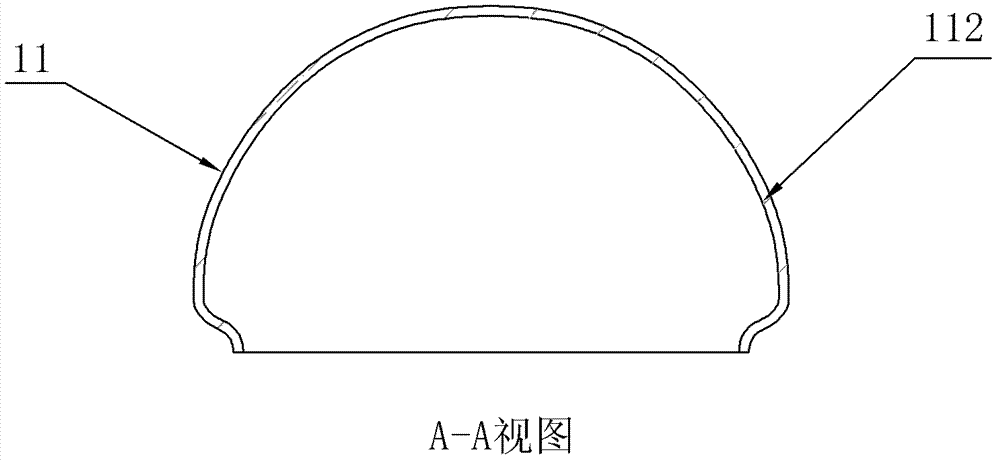

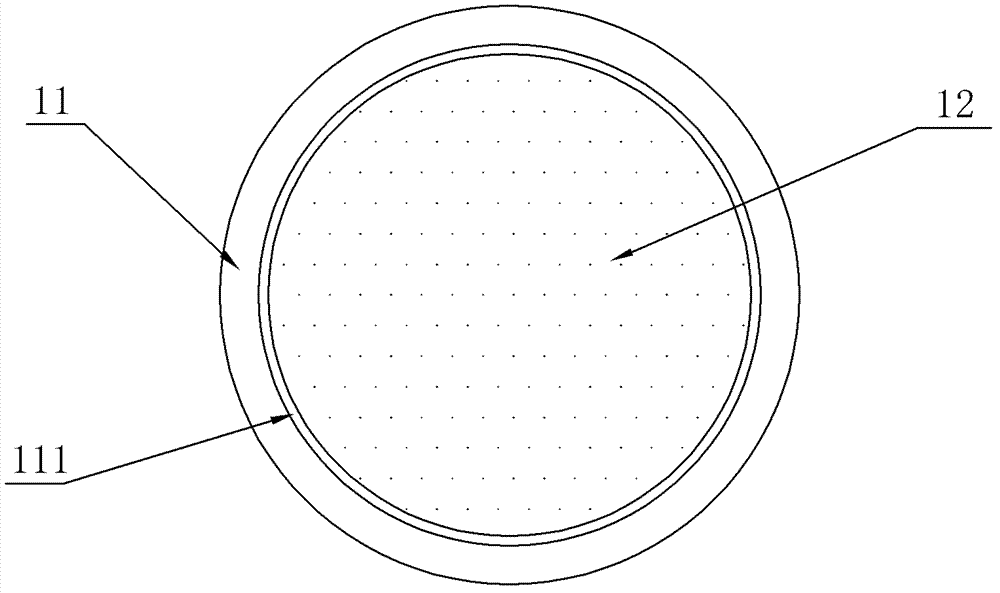

[0027] Coated LED lamp shades such as figure 1 , figure 2 as well as image 3 shown, where figure 1 An overall view of the LED lampshade provided by Embodiment 2 of the present invention, figure 2 A cross-sectional view of LED lampshade A-A provided for Embodiment 2 of the present invention, image 3 The bottom view of the LED lampshade provided by Embodiment 2 of the present invention. The coating 12 of the LED lampshade includes the following components (measured by mass fraction): 10% of the spherical silicone micropowder and 90% of the resin.

[0028] The coating 12 is applied on the LED lampshade 1 by manual pouring, specifically: pour the coating 12 from the opening 111 of the lampshade main body 11 of the LED lampshade 1 onto the inner surface 112 of the lampshade main body 11, and shake it from side to side Then pour it out, and then bake it at 60° C. for 20 minutes to obtain the LED lampshade 1 of this embodiment.

[0029] The LED lampshade 1 of this embodimen...

Embodiment 3

[0031] Coated LED lampshade, the coating includes the following components (measured by mass fraction): 10% of spherical silicone micropowder, 5% of square barium sulfate and 85% of resin.

[0032] The coating is applied on the LED lampshade by mechanical pouring, specifically: turn the LED lampshade upside down, spray the coating onto the inner wall of the lampshade from bottom to top, smooth it naturally for 3~10 minutes, and then bake it at 180°C After 10 minutes, the LED lampshade of this embodiment was obtained.

[0033] The LED lampshade of this embodiment has uniform light transmission, white and clear, and the filament inside cannot be seen after being powered on.

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

| beam angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com