Anti-reflection anti-dazzle liquid for LED glass lampshade and preparation method of anti-reflection anti-dazzle liquid

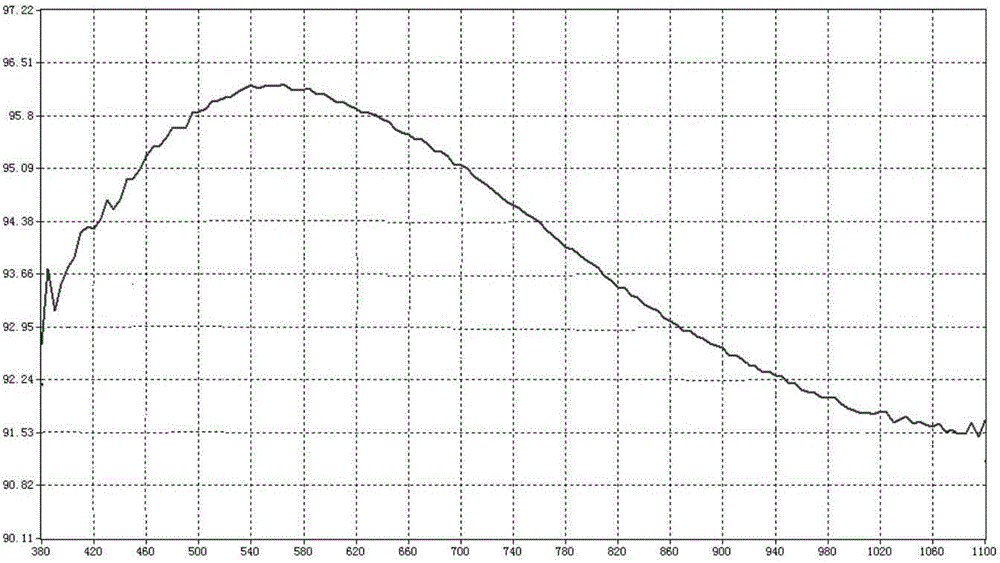

A technology of LED glass and lampshade, applied in the coating and other directions, can solve the problems of the glass surface structure is not fine enough, cannot withstand high temperature, and the yield is low, and achieves the effect of fine surface structure, good light transmittance, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An anti-reflection and anti-glare liquid for LED glass lampshades. The anti-reflection and anti-glare liquid for LED glass lampshades is prepared by compounding silica nano-sol and micron-sized silica emulsion, comprising the following steps:

[0022] (1) Preparation of silica nano-sol: disperse 3060g tetraethyl silicate in 4200g ethanol solvent, add 0.2N 2-amino-2-methyl-1-propanol solution, stir and react at 4°C for 24 hour, after the reaction finished, the reaction solution was carried out by rotary evaporation to prepare 3200g silica nano-sol;

[0023] (2) Preparation of micron-sized silica emulsion: disperse 15 g of micron-sized silica particles with a particle size of 0.4 μm in 300 g of propylene glycol methyl ether solvent, add 0.5 g of silicone surfactant, and perform mechanical stirring for 2 hours to prepare Obtain micron silica emulsion;

[0024] (3) Preparation of anti-reflection and anti-glare liquid for LED glass lampshade: add the micron-sized silica emu...

Embodiment 2

[0026] An anti-reflection and anti-glare liquid for LED glass lampshades. The anti-reflection and anti-glare liquid for LED glass lampshades is prepared by compounding silica nano-sol and micron-sized silica emulsion, comprising the following steps:

[0027] (1) Preparation of silica nano-sol: disperse 2300g tetraethyl silicate and 1200g trimethyl methylsilicate in 4000g ethanol solvent, add 0.2N 2-amino-2-methyl-1-propanol The solution was stirred and reacted at 25°C for 25 hours. After the reaction, the reaction solution was subjected to rotary evaporation to prepare 4600g of silica nano-sol;

[0028] (2) Preparation of micron-sized silica emulsion: disperse 15 g of micron-sized silica particles with a particle size of 4 μm in 300 g of propylene glycol methyl ether solvent, add 0.5 g of silicone surfactant, and perform mechanical stirring for 2 hours to prepare Micron silica emulsion;

[0029] (3) Preparation of anti-reflection and anti-glare liquid for LED glass lampshade:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com