Preparation and application methods of lignin-based flame retardant

A technology based on lignin and an application method is applied in the field of preparing lignin-based flame retardant polyurethane, which can solve the problems of small impact on material mechanical properties, human health and environmental hazards, etc., and achieves improved compatibility, good impact resistance, and mechanical properties. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of phosphorus-containing lignin-based flame retardant

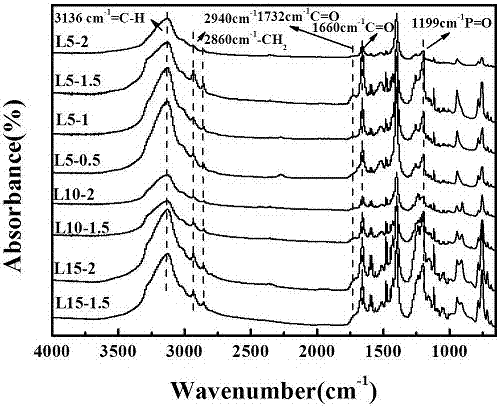

[0036] Weigh 1.36g of lignin, disperse it in 2ml of N,N-dimethylformamide (DMF), stir to disperse the lignin evenly, then add 4.2g of hexamethylene diisocyanate (HDI) and stir until it is evenly dispersed , put it into an oil bath at 80°C and keep stirring, react for 12 minutes until the system becomes viscous, set the oil bath temperature to 125°C, add 21.6g DOPO, continue stirring for 20 minutes until the system is viscous, take out the reaction product, and dry it at 80°C 12 hours, pulverized to obtain phosphorus-containing lignin-based flame retardant L5-2, its FTIR characterization results are as follows figure 1 shown.

[0037] (2) Preparation of flame retardant polyurethane

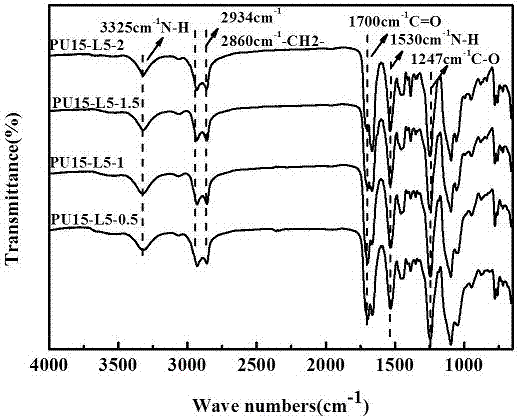

[0038] Add 15ml of N,N-dimethylformamide (DMF), 10g of polyethylene glycol (PEG200), and 10g of hexamethylene diisocyanate (HDI) into a 250ml three-necked flask, and stir until uniform. Put it in an oil bath, react at...

Embodiment 2

[0040] (1) Preparation of phosphorus-containing lignin-based flame retardant

[0041] Weigh 1.43g of lignin and disperse it in 3ml of N,N-dimethylformamide (DMF). Stir to disperse the lignin evenly. Then add 5.55g of hexamethylene diisocyanate (HDI) and stir until dispersed. Evenly, put it in an oil bath at 80°C and keep stirring, react for 15 minutes until the system becomes viscous, set the temperature of the oil bath at 125°C, add 21.6g DOPO, continue stirring for 12 minutes until the system is viscous, take out the reaction product, and bake at 80°C Dry for 24 hours and pulverize to obtain phosphorus-containing lignin-based flame retardant L5-1.5, and its FTIR characterization results are as follows: figure 1 shown.

[0042] (2) Preparation of flame retardant polyurethane

[0043] Add 15ml of N,N-dimethylformamide (DMF), 10g of polyethylene glycol (PEG200), and 10g of hexamethylene diisocyanate (HDI) into a 250ml three-necked flask, and stir until uniform. Put it in an ...

Embodiment 3

[0045] (1) Preparation of phosphorus-containing lignin-based flame retardant

[0046] Weigh 1.58g of lignin and disperse it in 4ml of N,N-dimethylformamide (DMF). Stir to disperse the lignin evenly, then add 8.41g of hexamethylene diisocyanate (HDI) and stir until evenly dispersed. , placed in an oil bath at 80°C and continuously stirred, and reacted for 18 minutes. When the system becomes viscous, set the oil bath temperature to 120°C, add 21.6g DOPO, continue to react for 12 minutes and stir until the system is viscous, take out the reaction product, dry at 80°C for 20 hours, and pulverize to obtain phosphorus-containing lignin-based flame retardant L5- 1. The FTIR characterization results are as follows figure 1 shown.

[0047] (2) Preparation of flame retardant polyurethane

[0048] Add 15ml of N,N-dimethylformamide (DMF), 10g of polyethylene glycol (PEG200), and 10g of hexamethylene diisocyanate (HDI) into a 250ml three-necked flask, and stir until uniform. Put it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com