Environment-friendly cable fireproof paint and manufacturing method thereof

A kind of fire-proof coating, environment-friendly technology, applied in the direction of fire-proof coating, insulating cables, cables, etc., can solve the problems of production, construction and storage hazards, solvent-based cable fire-proof coating hazards, complex processes, etc., to eliminate fire hazards, reduce Hazards to humans and effects of pollution on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

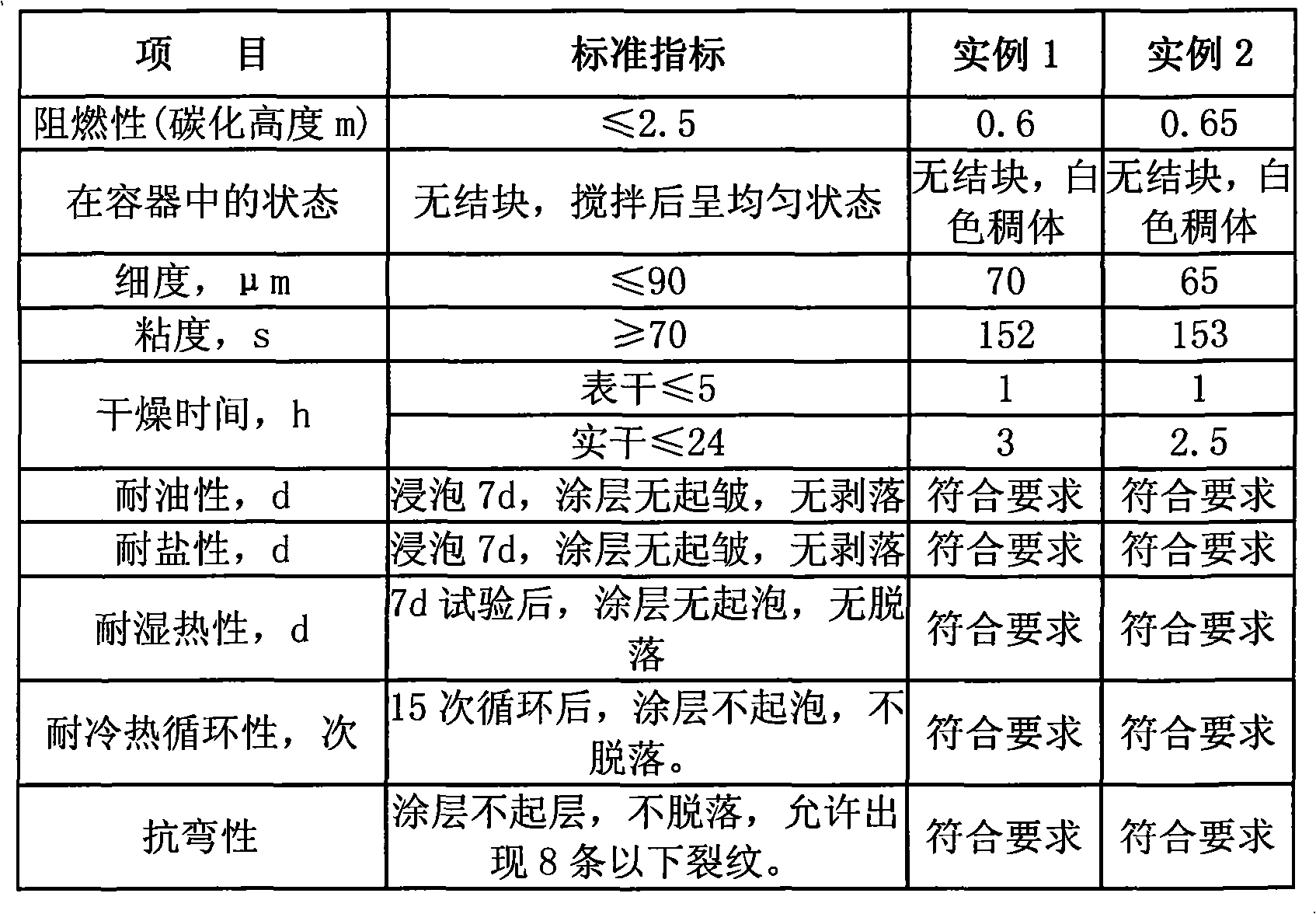

[0025] Pump 75kg of water and 200kg of elastic acrylic emulsion into a multifunctional mixer and mix them at a speed of about 200rpm. Add 100kg of aluminum hydroxide flame retardant, 25kg of melamine, 50kg of rutile titanium dioxide, 10kg of calcium carbonate, 20kg of dipentaerythritol and poly Ethylene wax 15kg, fully stirred for 3 hours, rotating speed 600rpm. Move the material to a horizontal closed sand mill for sanding, and sand while cooling. The barrel pressure in the sand mill is kept at about 0.1MPa. After sanding, move the material to a multifunctional mixer, and add it while stirring. Sodium polyacrylate 5kg, obtain environment-friendly cable fireproof coating after increasing the consistency. The physical and chemical performance indicators of the product are shown in Table 1

Embodiment 2

[0027] Pump 50kg of water and 150kg of elastic acrylic emulsion into a multifunctional mixer and mix them at a speed of about 200rpm. Add 80kg of magnesium hydroxide flame retardant, 30kg of melamine, 40kg of rutile titanium dioxide, 10kg of talcum powder, 15kg of dipentaerythritol and two Silicon oxide 10kg, fully stirred for 2.5 hours, rotating speed 600rpm. Move the material to a horizontal closed sand mill for sanding, and sand while cooling. The barrel pressure in the sand mill is kept at about 0.1MPa. After sanding, move the material to a multifunctional mixer, and add it while stirring. Polyethylene oxide 3kg, the environment-friendly cable fireproof coating can be obtained after increasing the consistency. The physical and chemical performance indicators of the product are shown in Table 1

[0028] Table 1 Physical and chemical performance indicators of environmentally friendly cable fireproof coatings

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com