High brightness flame retardant decorative film

A decorative film and bright technology, applied in the field of PVC film functional materials, can solve the problems of specular gloss attenuation, mechanical properties and fluidity affecting high gloss, and it is difficult to ensure the durability of specular gloss, etc., to achieve high specular gloss, size Good stability and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

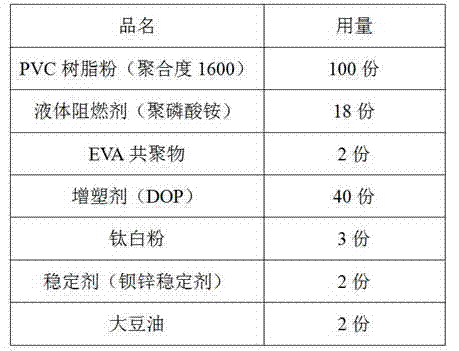

[0016] Ingredients (as shown in Table 1) → first add liquid functional additives to PVC resin powder, stir at 75°C to 80°C, then add powder functional additives, stir evenly at 95°C to 100°C, then enter banburying (temperature 165°C ℃~170℃)→2-roll rolling wheel to continue plasticizing→filtering (temperature 160℃)→four-roll calendering (185℃~190℃)→mirror embossing once (liquid silicone wheel, temperature 100℃, pressure 25Kg, speed 12m / min)→mirror non-stick lamination process (laminate the front of two decorative films, and control the peeling load at about 60cN / 5cm)→cooling→coiling→packaging. During this period, the control speed was 40 m / min.

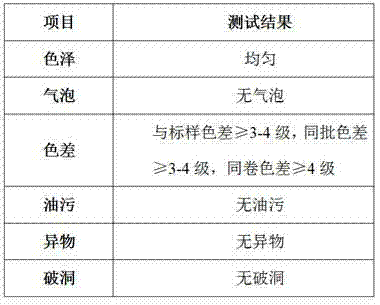

[0017] Table 2 and Table 3 respectively list the test results of the appearance quality and internal quality of the product, indicating that the decorativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com