Weather-proof halogen-free flame retardant insulation polyurea coating

A weather-resistant, polyurea technology, used in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., to achieve the effects of simple construction, good self-leveling, and wide practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

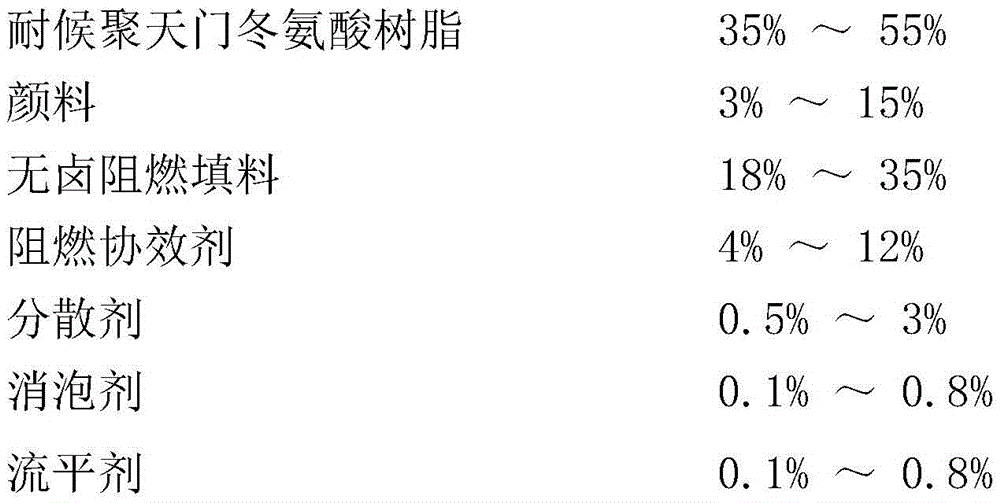

[0038] Example 1: According to the following Table 1, a weather-resistant, halogen-free, flame-retardant insulating polyurea coating was prepared, and the test results of coating film properties are shown in Table 8.

[0039] Table 1

[0040]

Embodiment 2

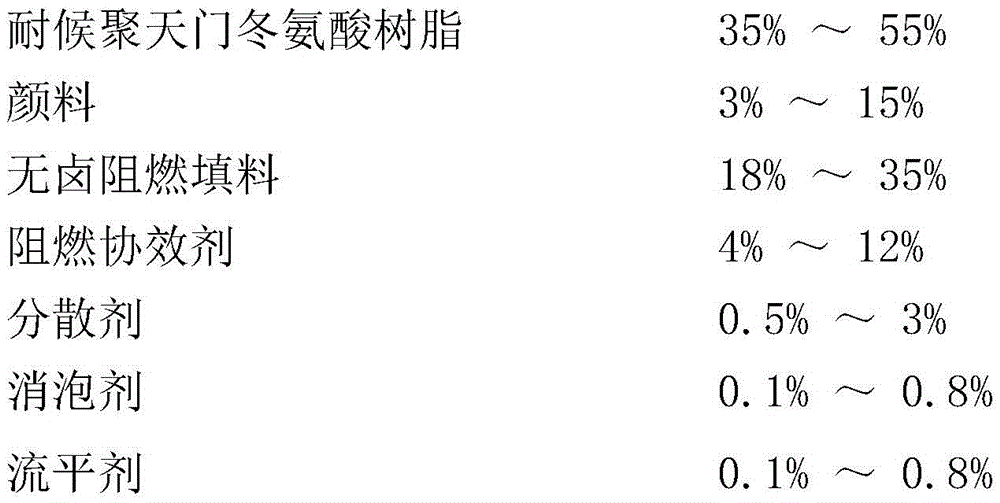

[0041] Example 2: A weather-resistant, halogen-free, flame-retardant insulating polyurea coating was prepared according to the following Table 2, and the test results of coating film properties are shown in Table 8.

[0042] Table 2

[0043]

Embodiment 3

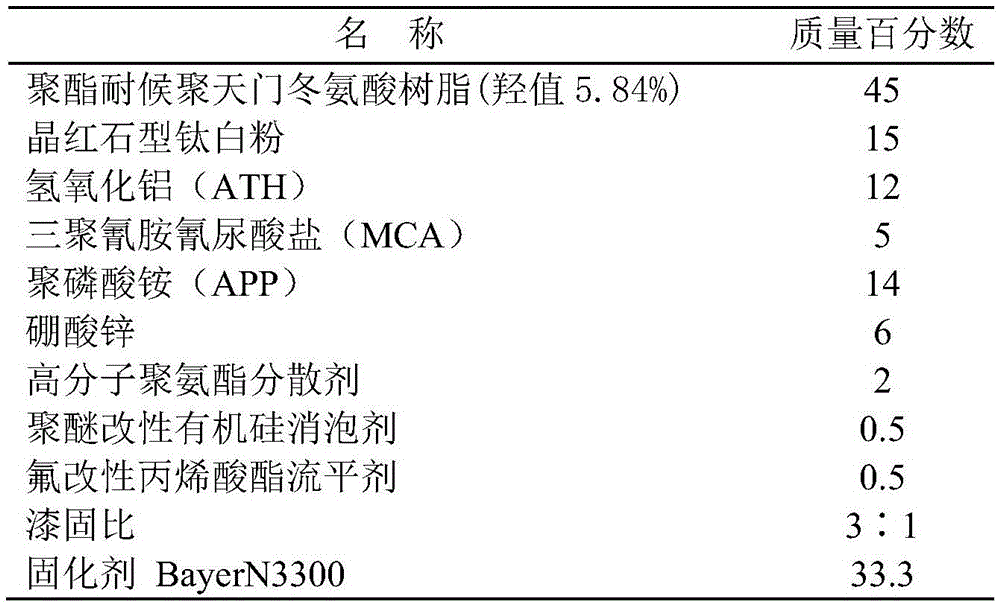

[0044]Example 3: According to the following Table 3, a weather-resistant, halogen-free, flame-retardant insulating polyurea coating was prepared, and the test results of coating film properties are shown in Table 8.

[0045] table 3

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com