High-effective bio-based flame-retarding agent containing furan ring, and synthesis method and application of the flame-retarding agent

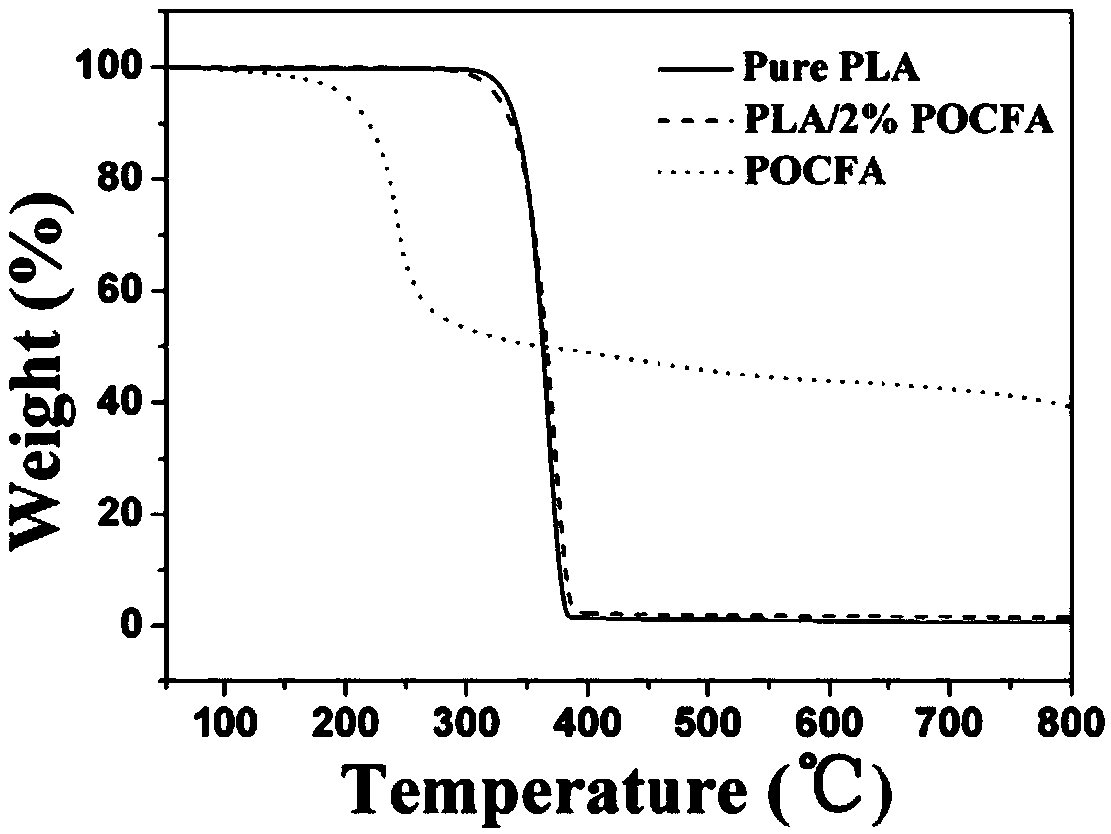

A furan ring and bio-based technology, which is applied in the field of high-efficiency furan ring-containing bio-based flame retardants and their synthesis, can solve the problems of low flame retardant efficiency, high toxicity, and environmental hazards, and achieve high flame retardant efficiency and improved mechanical properties. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) In a 250mL three-necked round-bottomed flask equipped with magnetic stirring, disperse 0.30mol of methylfurylamine and 0.40mol of triethylamine into 100ml of acetonitrile solution and stir evenly;

[0052] 2) Add 0.10mol of phosphorus oxychloride to 50mL of acetonitrile solution and stir evenly;

[0053] 3) Slowly drop the acetonitrile solution containing phosphorus oxychloride into the acetonitrile solution containing furanmethylamine and triethylamine in an ice-water bath and nitrogen atmosphere with a constant pressure dropping funnel, and the dropping time is controlled within 2 hours. After the dropwise addition, react at room temperature for 2 h, then raise the temperature to 50° C. and continue to react for 6 h.

[0054] 4) After the reaction, remove the white precipitate by filtration, remove the solvent by rotary evaporation, add ethyl acetate for dissolution, wash 5 times with deionized water, and remove the ethyl acetate by rotary evaporation to obtain a y...

Embodiment 2

[0059] In an ice-water bath and a nitrogen atmosphere, add 0.30 mol of methylfuranamine and 0.60 mol of triethylamine in chloroform to a 250 mL three-necked round-bottomed flask equipped with magnetic stirring. After stirring evenly, use a constant pressure dropping funnel to The chloroform solution of 0.50mol phosphorus oxychloride was slowly dropped into the flask, and the dropping time was controlled at 0.5h. After the dropwise addition, react at room temperature for 4 h, then raise the temperature to 80° C. and continue to react for 4 h. After the reaction was completed, it was washed with deionized water for 5 times, and the solvent was removed by rotary evaporation to obtain a light yellow solid product, the structural formula of which was shown in Formula 1.

Embodiment 3

[0061] In an ice-water bath and a nitrogen atmosphere, add 0.30 mol of furan methanol and 0.30 mol of pyridine in a 1,4-dioxane solution into a 250 mL three-neck round bottom flask equipped with magnetic stirring. The 1,4-dioxane solution of phosphorus oxychloride (0.1mol) was slowly dropped into the flask through the funnel, and the dropping time was controlled at 1.5h. After the dropwise addition, react at room temperature for 2 h, then raise the temperature to 50° C. and continue to react for 6 h.

[0062] After the reaction, the white precipitate was removed by filtration, the solvent was removed by rotary evaporation, washed 5 times with deionized water, and vacuum-dried to obtain the dark brown target product, whose structural formula is shown in formula 2:

[0063]

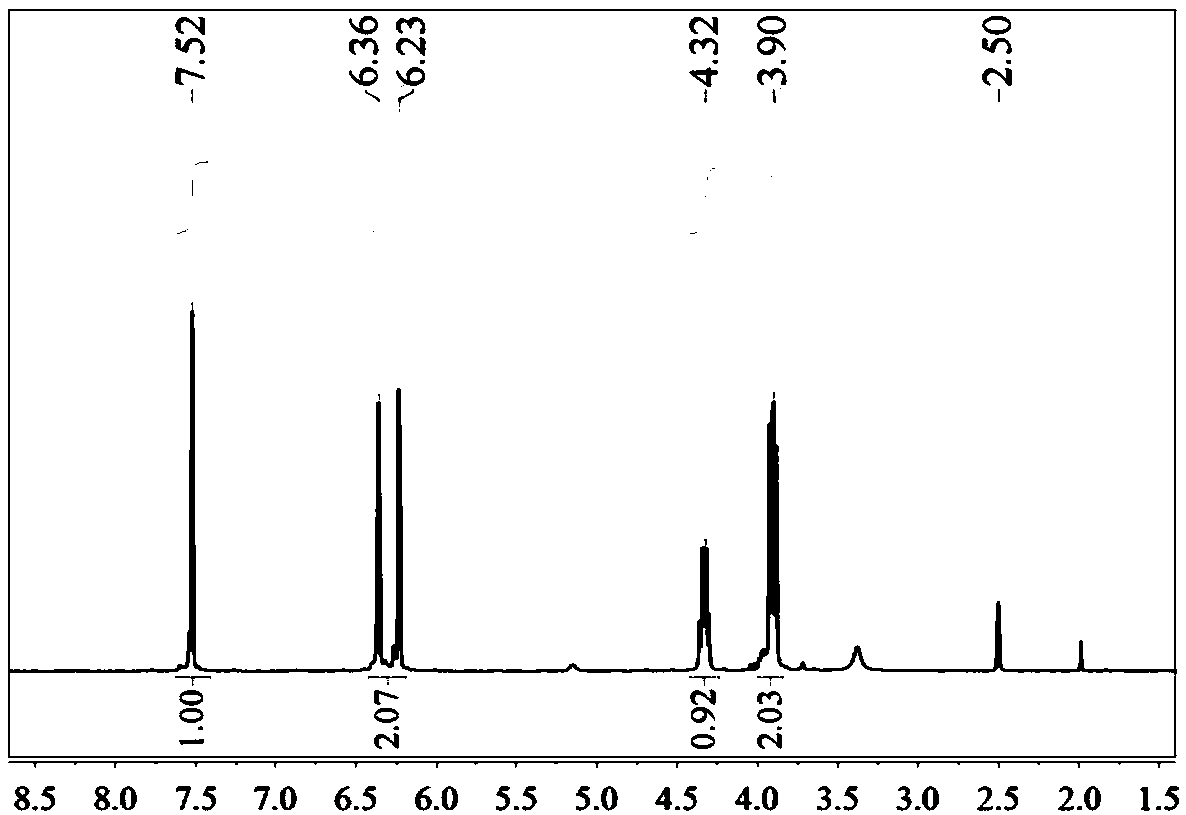

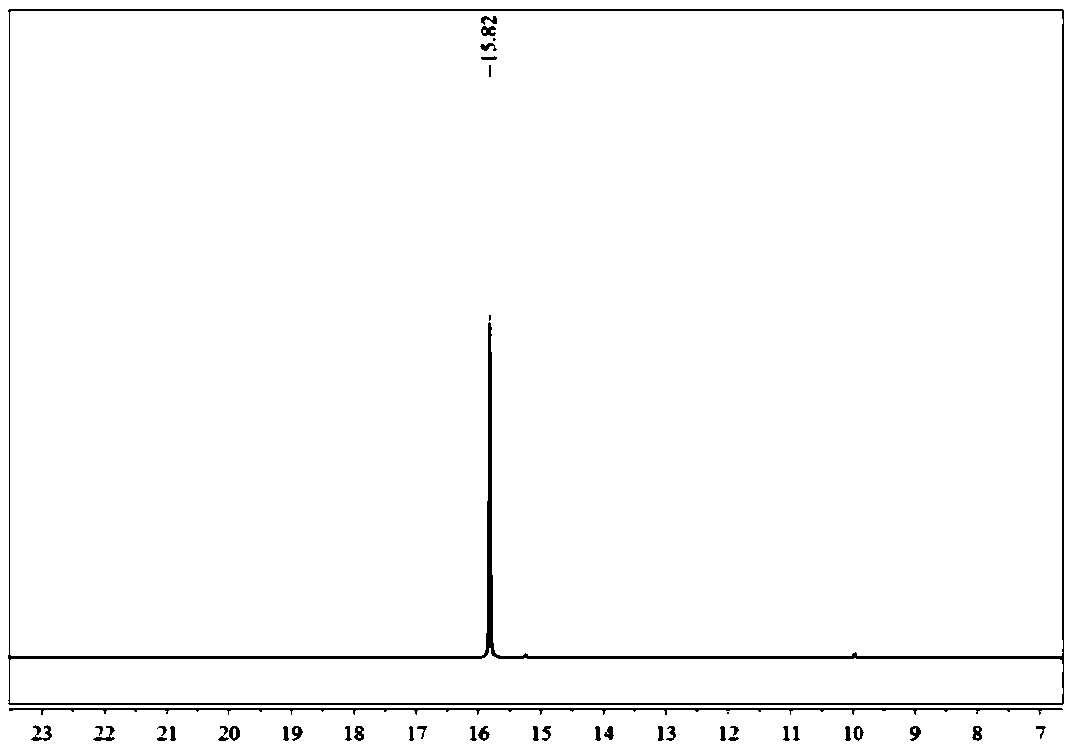

[0064] The compound prepared above can prove that the structure shown in the above formula has been obtained by proton nuclear magnetic spectrum, phosphorous nuclear spectrum and infrared spectrum. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com