Non-halogen fire retardant for terylene polyester chips and its production technology

A polyester polyester and production process technology, applied in the field of phosphate ester chemical additives, can solve the problems of unsustainable flame retardant effect, unsatisfactory external performance, complex process, etc., and achieve beautiful appearance, no yellowing in appearance, and appearance bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

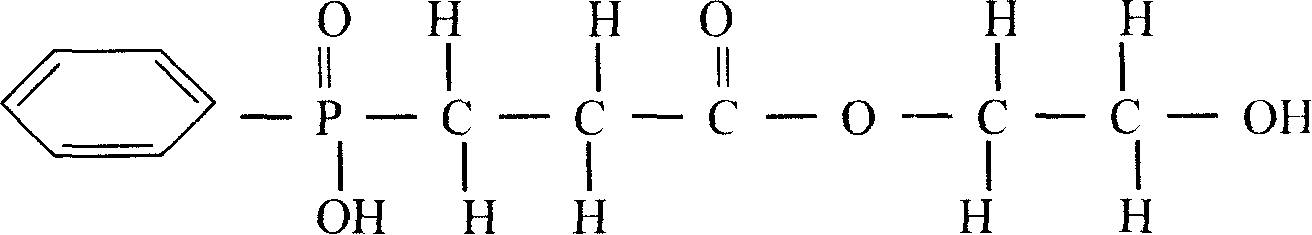

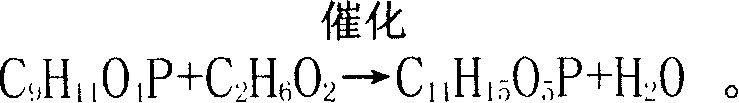

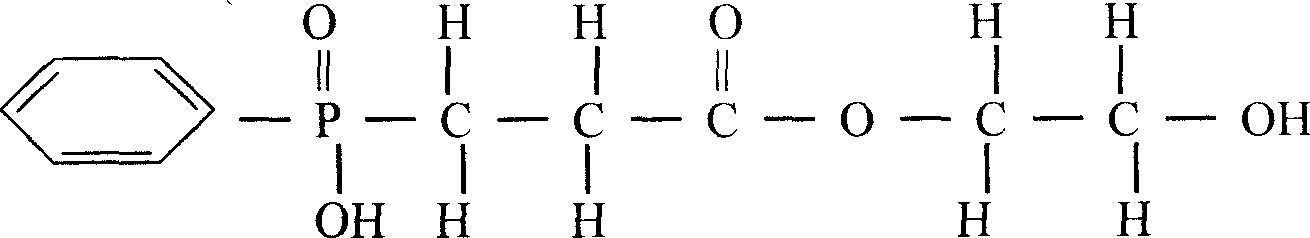

[0010] A certain amount of ethylene glycol (C 2 H 6 O 2 ), then equimolar 2-carboxyethylphenylphosphoric acid (C 9 H 11 O 1 P) Pour into ethylene glycol solvent, then add a certain amount of catalyst, stir, heat, and heat up to 250 ° C, while maintaining the pressure at the level of -0.8Mpa (vacuum), start timing from reflux, and react after 1.5 hours After the end, the light yellow liquid flame retardant is obtained, and then the temperature is rapidly lowered to 20 °C, and the material is discharged and canned in plastic drums. The storage and transportation temperature is 20-25 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com