PU (polyurethane) daub and preparation method thereof

A technology of polyurethane and mastic, which is applied in the field of mastic materials, can solve problems such as high brittleness, mastic that cannot meet the needs of the marine anti-corrosion field, and easy cracks in the mastic layer, so as to achieve good water resistance, improve technical application level, and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

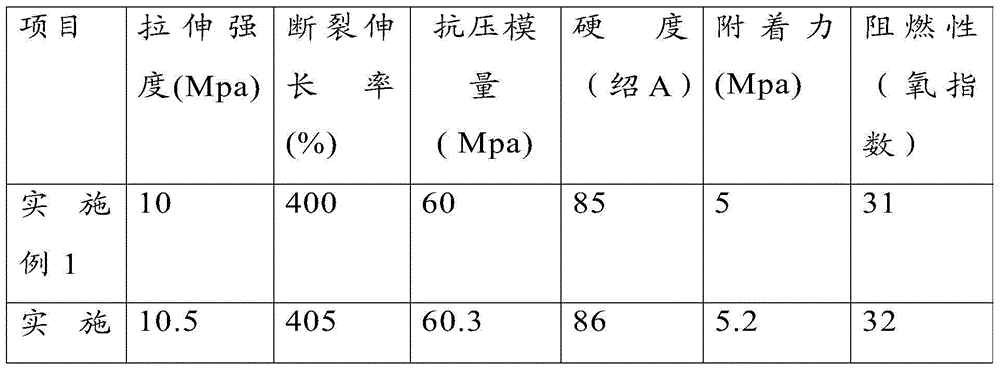

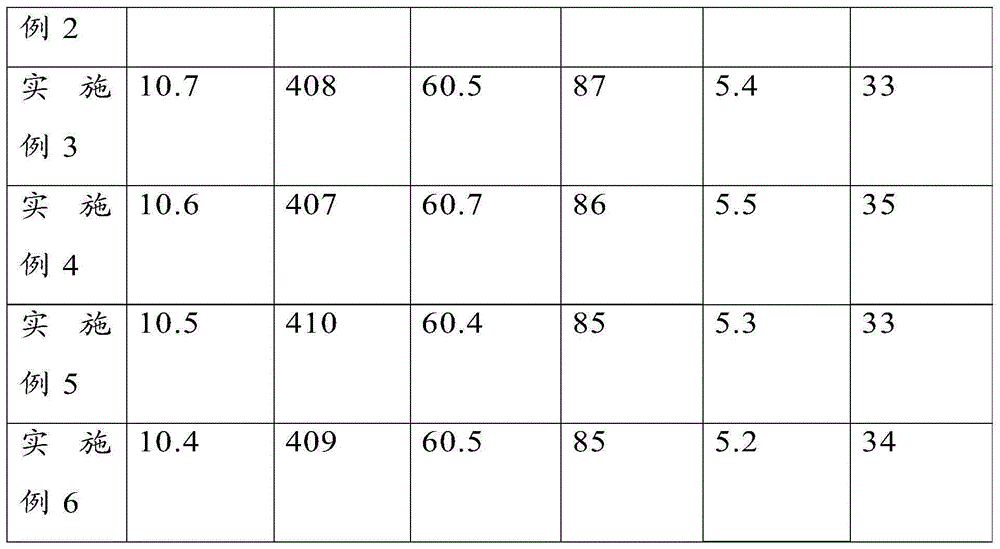

Examples

Embodiment 1

[0055] A component:

[0056] Take component A, in parts by weight, 120 parts of PTMEG200, 80 parts of MDI, 50 parts of red phosphorus flame retardant, among which, the mesh number of red phosphorus flame retardant is not less than 1500;

[0057] The A component is made by the following method:

[0058] a. Under negative pressure -0.09Mpa, add red phosphorus flame retardant and heat up to 55℃;

[0059] b. Add PTMEG200, heat up to 115℃, and dehydrate for 100min;

[0060] c. Cool down to 35°C, add MDI, heat up to 75°C, and react for 100 minutes;

[0061] d. Cool down.

[0062] B component:

[0063] Take component B, in parts by weight, PTMEG20070 parts, curing agent 40 parts, red phosphorus flame retardant 50 parts, defoaming agent 1 part, dispersant 1 part, leveling agent 1 part, surface active agent 1 part;

[0064] The B component is prepared by the following method:

[0065] a. Under negative pressure -0.09Mpa, add red phosphorus flame retardant, defoamer, dispersant, leveling agent and sur...

Embodiment 2

[0069] A component:

[0070] Take component A, in parts by weight, 130 parts of polyether glycol, 100 parts of MDI, 70 parts of aluminum hydroxide flame retardant (ATH), and the mesh number of the flame retardant is not less than 1500;

[0071] The A component is made by the following method:

[0072] a. Under negative pressure -0.09Mpa, add aluminum hydroxide flame retardant and heat up to 60℃;

[0073] b. Add polyether glycol, heat up to 120°C, and dehydrate for 120 minutes;

[0074] c. Cool down to 40°C, add MDI, heat up to 80°C, and react for 120 minutes;

[0075] d. Cool down.

[0076] B component:

[0077] Take component B, in parts by weight, 75 parts polyether glycol, 50 parts curing agent, 60 parts aluminum hydroxide flame retardant, 2 parts defoamer, 2 parts dispersant, 2 parts leveling agent, surface active 2 parts;

[0078] The B component is prepared by the following method:

[0079] a. Add aluminum hydroxide flame retardant, defoamer, dispersant, leveling agent and surface act...

Embodiment 3

[0083] A component:

[0084] Take component A, in parts by weight, 135 parts of polyethylene glycol, 110 parts of MDI, and 75 parts of magnesium hydroxide flame retardant. Among them, the mesh number of the flame retardant is not less than 1500;

[0085] The A component is made by the following method:

[0086] a. Add flame retardant under negative pressure below -0.09Mpa and heat up to 58℃;

[0087] b. Add polyethylene glycol, heat up to 120°C, and dehydrate for 130 minutes;

[0088] c. Cool down to 40°C, add MDI, heat up to 80°C, and react for 130 min;

[0089] d. Cool down.

[0090] B component:

[0091] Take component B, in parts by weight, 80 parts of polyethylene glycol, 50 parts of curing agent, 60 parts of magnesium hydroxide flame retardant, 3 parts of defoaming agent, 3 parts of dispersant, 2 parts of leveling agent, surface active 2 parts;

[0092] The B component is prepared by the following method:

[0093] a. Add flame retardant, defoaming agent, dispersant, leveling agent and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com