Patents

Literature

132results about How to "Conducive to decentralization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

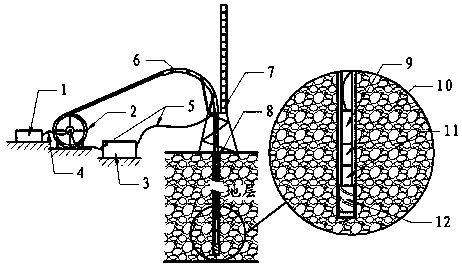

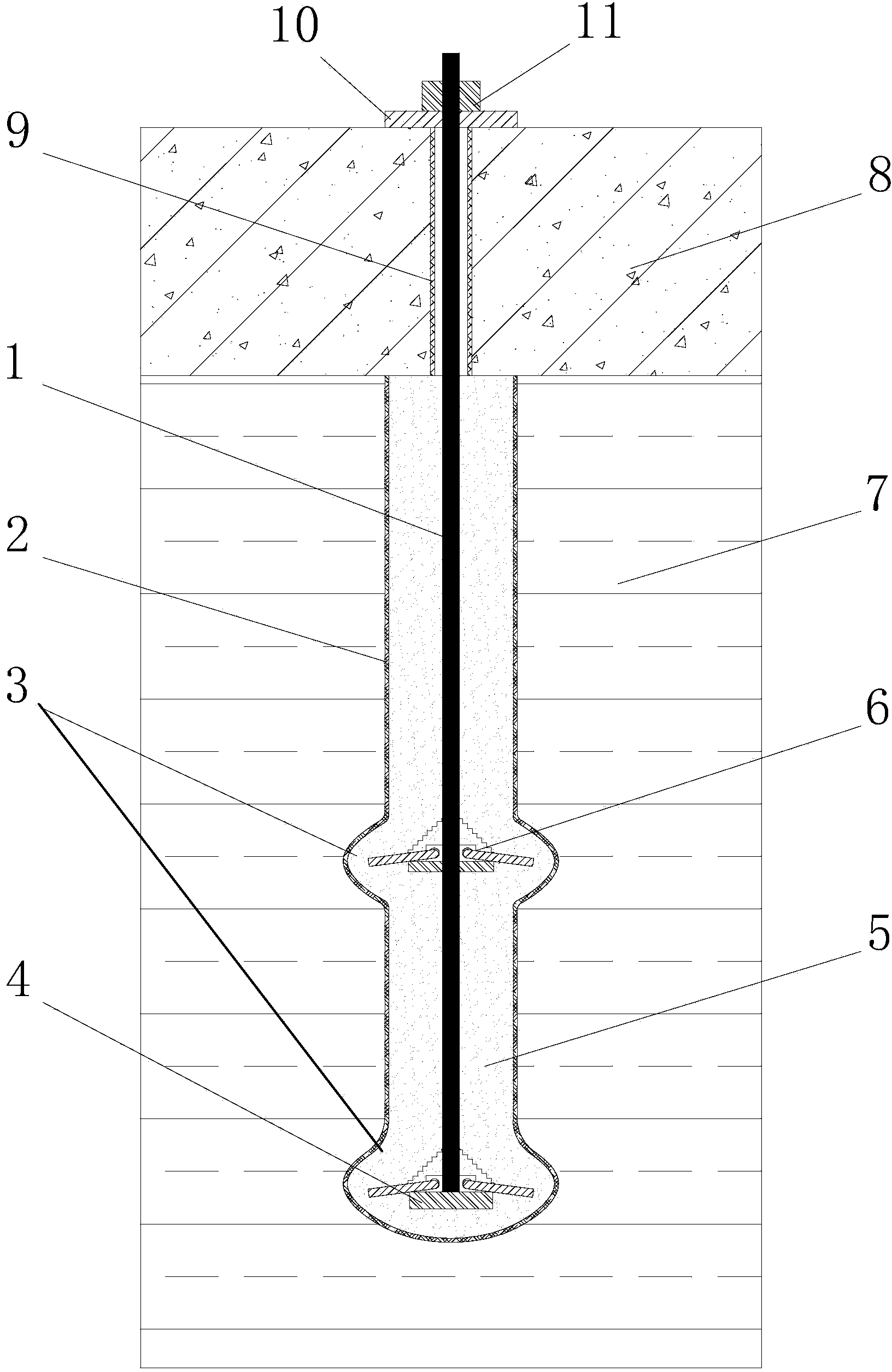

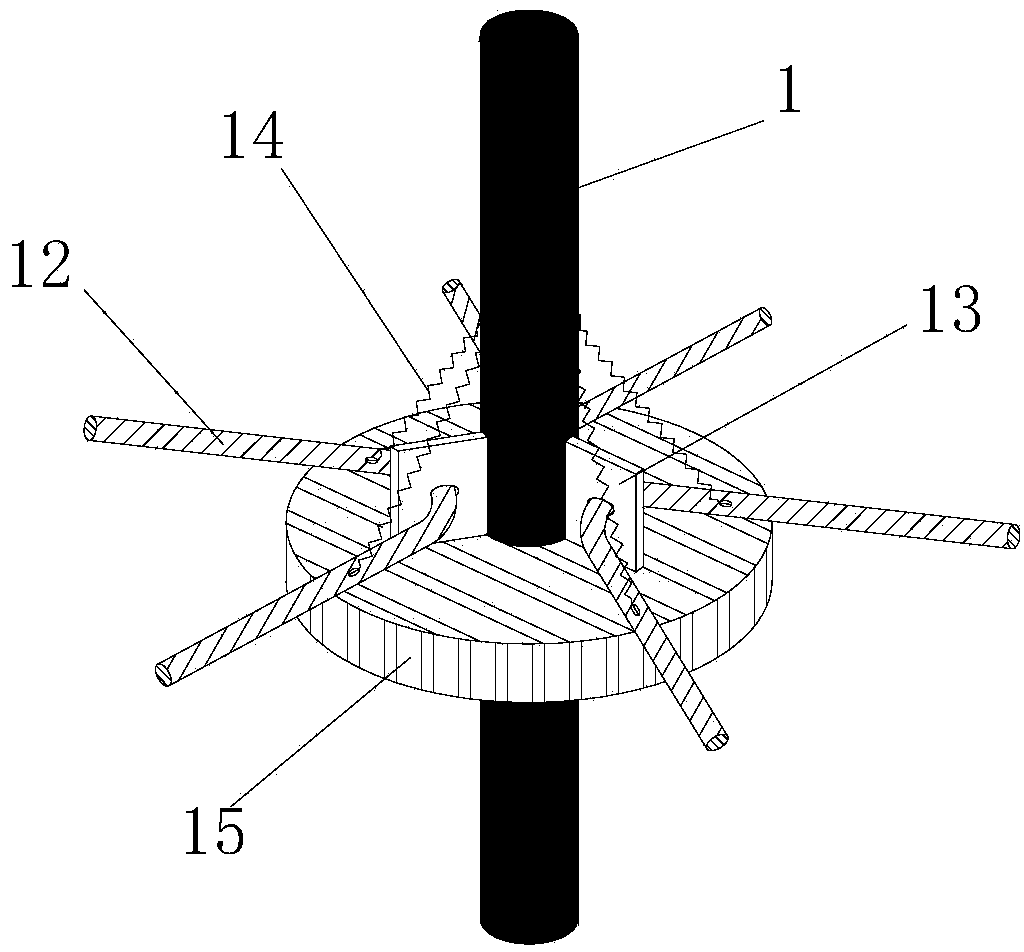

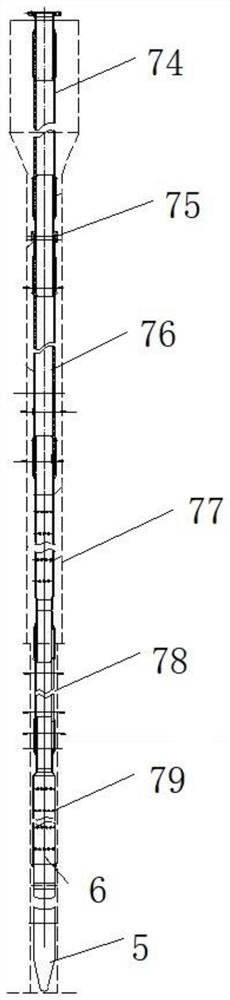

Electrode bit for coiled tubing high-voltage electrical pulse/mechanical composite drilling

ActiveCN109577864AGood technology inheritanceImprove drilling efficiencyDrill bitsDrilling machines and methodsCoaxial cableHorizontal wells

The invention relates to an electrode bit for coiled tubing high-voltage electrical pulse / mechanical composite drilling, which structurally comprises a coaxial cable, an upper connector, insulator I,a transmission key, a bit collar, insulator II, a low-voltage ground electrode, a high-voltage center electrode and the like. A traditional rock-breaking bit and an electrode bit are combined herein;the electrode bit herein is suitable for drilling of both straight wells and oriented wells (including horizontal wells); the high-voltage electrical pulse drilling and coiled tubing drilling are combined, so that cable lowering is convenient; in addition, the electrode bit has the advantages of high rock-breaking efficiency, good well wall quality, low deep well drilling cost and the like.

Owner:SOUTHWEST PETROLEUM UNIV

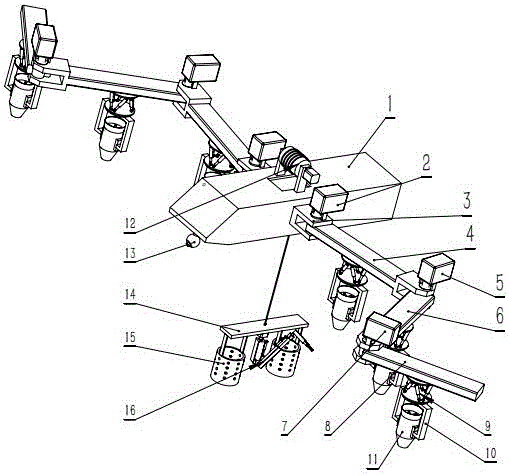

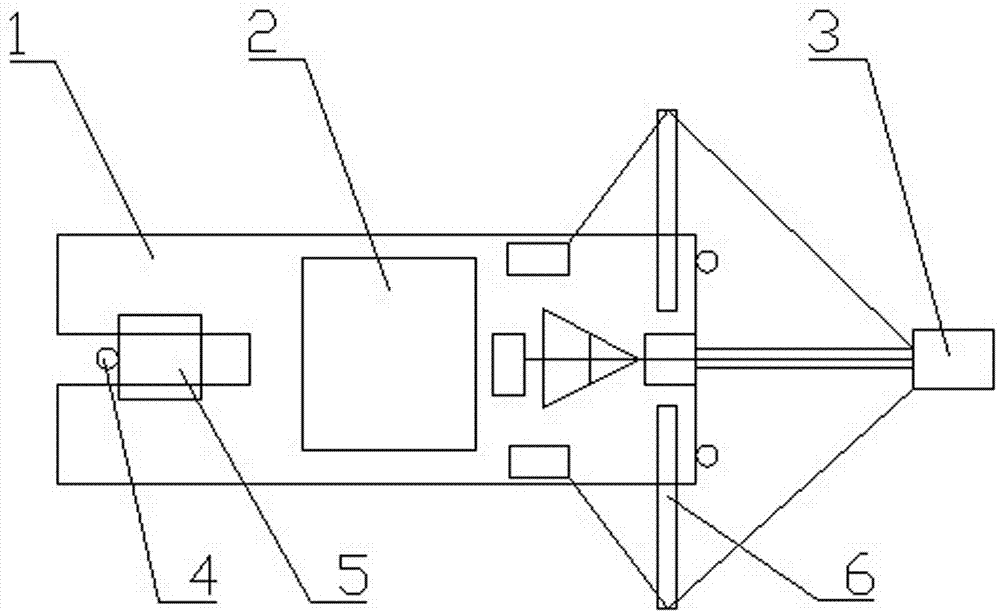

Unmanned aerial vehicle for salvage of sea garbage

ActiveCN106516078ASmall footprintConducive to decentralizationFuselagesAir-flow influencersHydraulic cylinderHydraulic motor

The invention provides an unmanned aerial vehicle for salvage of sea garbage. The unmanned aerial vehicle comprises a fuselage, a wing, four fanjets A, two hydraulic motors A, two fanjets B, a hydraulic motor B, a fanjet C, a multi-stage hydraulic cylinder, a rotary bearing and a collecting component. The unmanned aerial vehicle for salvage of the sea garbage is characterized in that the fuselage is in a pointed head cylinder shape, and the wing is arranged at the top of the fuselage; the four fanjets A are symmetrically arranged below the fuselage, the two sides of the wing are each provided with a hydraulic motor A, and the fanjet B is arranged at the end of a driving shaft of each hydraulic motor A. According to the unmanned aerial vehicle for salvage of the sea garbage, the unmanned aerial vehicle is adopted as a carrier of the collecting component, can quickly arrive at a polluted sea area, and has a larger speed advantage compared with a traditional carrier such as a ship.

Owner:河南正大航空工业股份有限公司

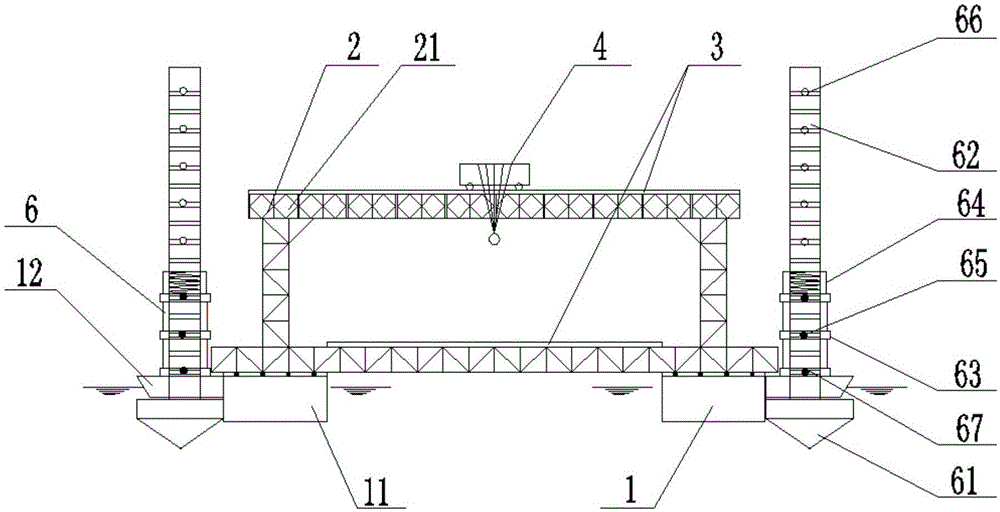

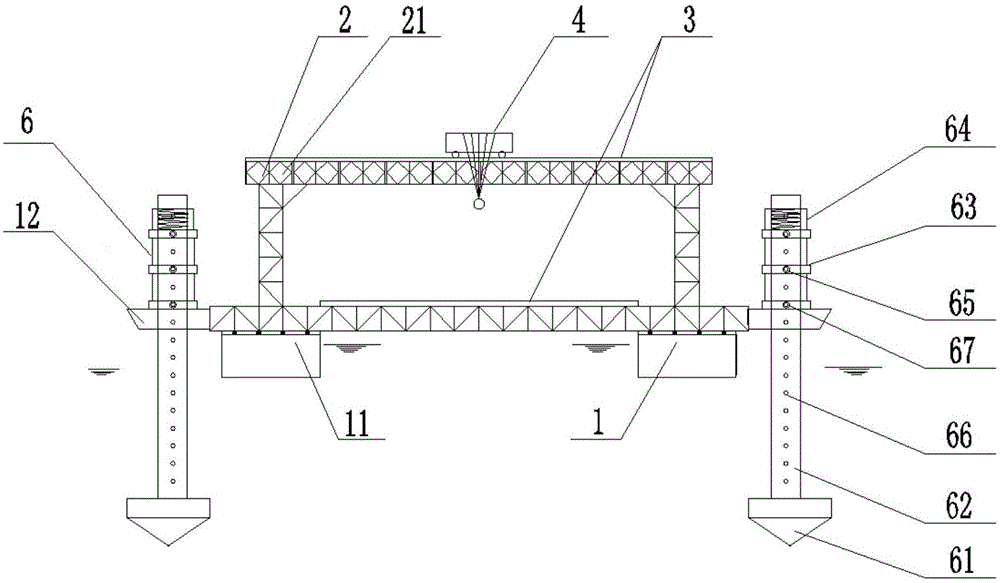

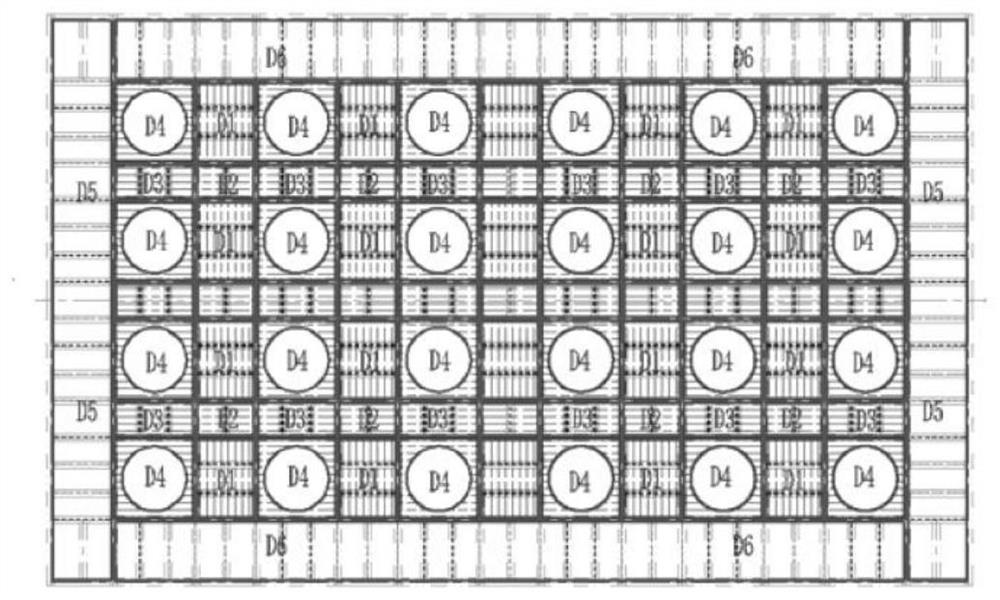

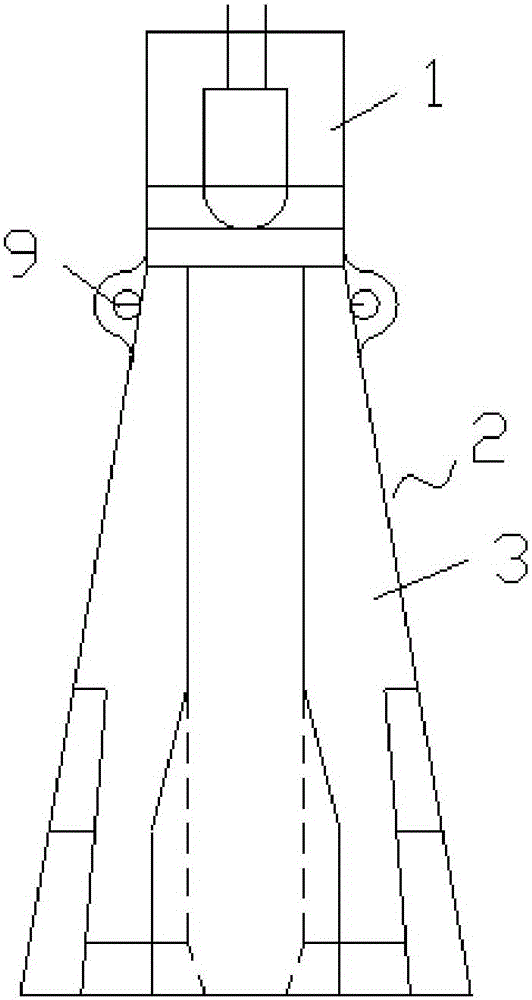

Movable construction platform for bridge foundation building

InactiveCN105088964AEasy to moveAdjustable shiftBridge erection/assemblyBulkheads/pilesBraced frameBody system

The invention provides a movable construction platform for bridge foundation building. The movable construction platform for bridge foundation building comprises floating bodies, horizontal support frameworks, horizontal backing plates, a lifting system, temporary fixing devices and support body systems; the horizontal support frameworks are laid on the upper surfaces of the floating bodies, the horizontal backing plates are laid on the upper surfaces of the horizontal support frameworks, filling pile holes formed according to bridge foundation building are formed in the horizontal backing plates, the lifting system is erected on the horizontal backing plates, and the support body systems are arranged on the peripheries of the floating bodies; each support body system comprises an anchor head, a support leg, support seats, hydraulic lifting equipment and bolt pins, wherein bolt pin holes longitudinally extending in a separated mode are formed in the support leg, through holes correspondingly communicated with the bolt pin holes are formed in the support seats, and the bolt pins are correspondingly inserted into the bolt pin holes and the through holes which are communicated with each other. The movable construction platform for bridge foundation building has the advantages that the platform can be steadily and firmly fixed on the construction water surface, cannot be shaken under the influences of tides or waves when construction is performed and is suitable for arrangement of various filling piles in bridge building; in addition, the size of the platform can be regulated, and construction is easy.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

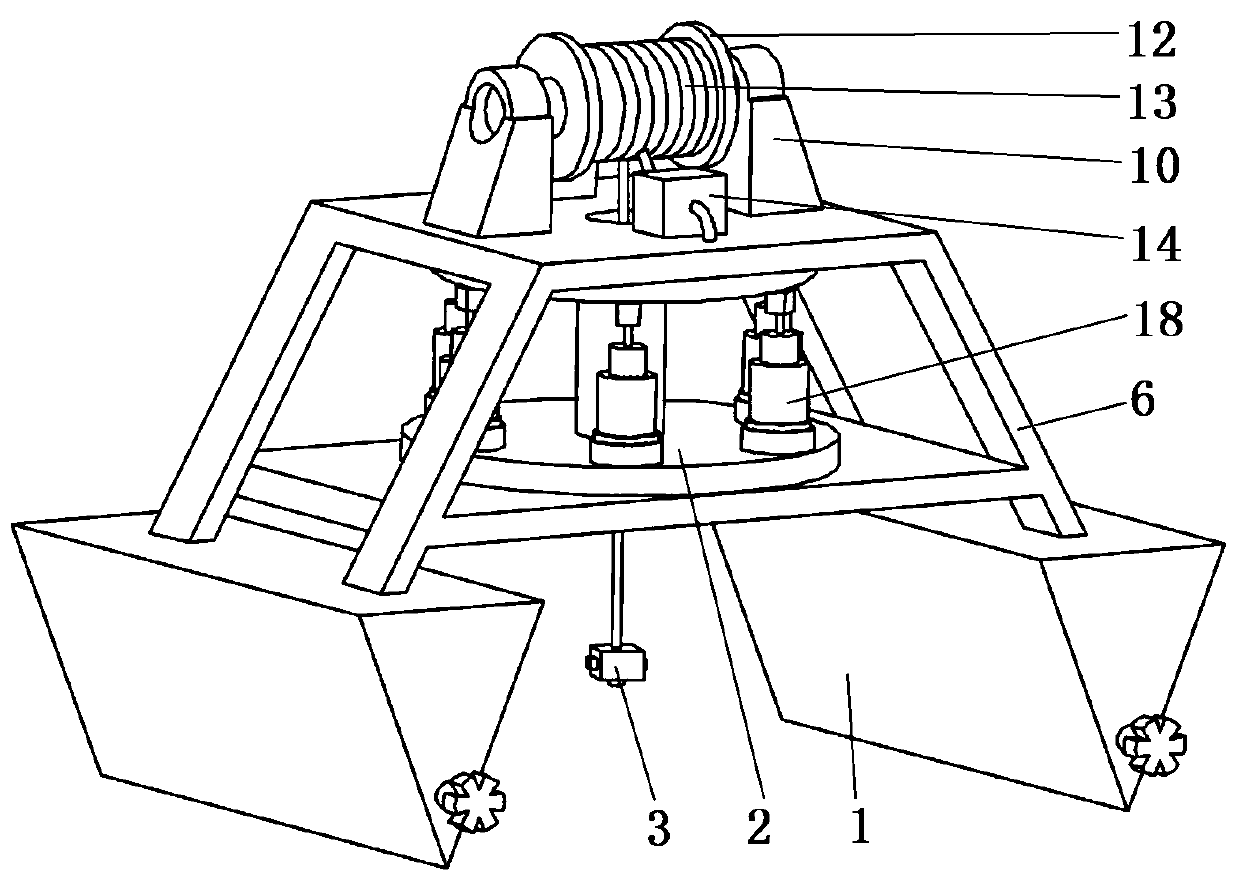

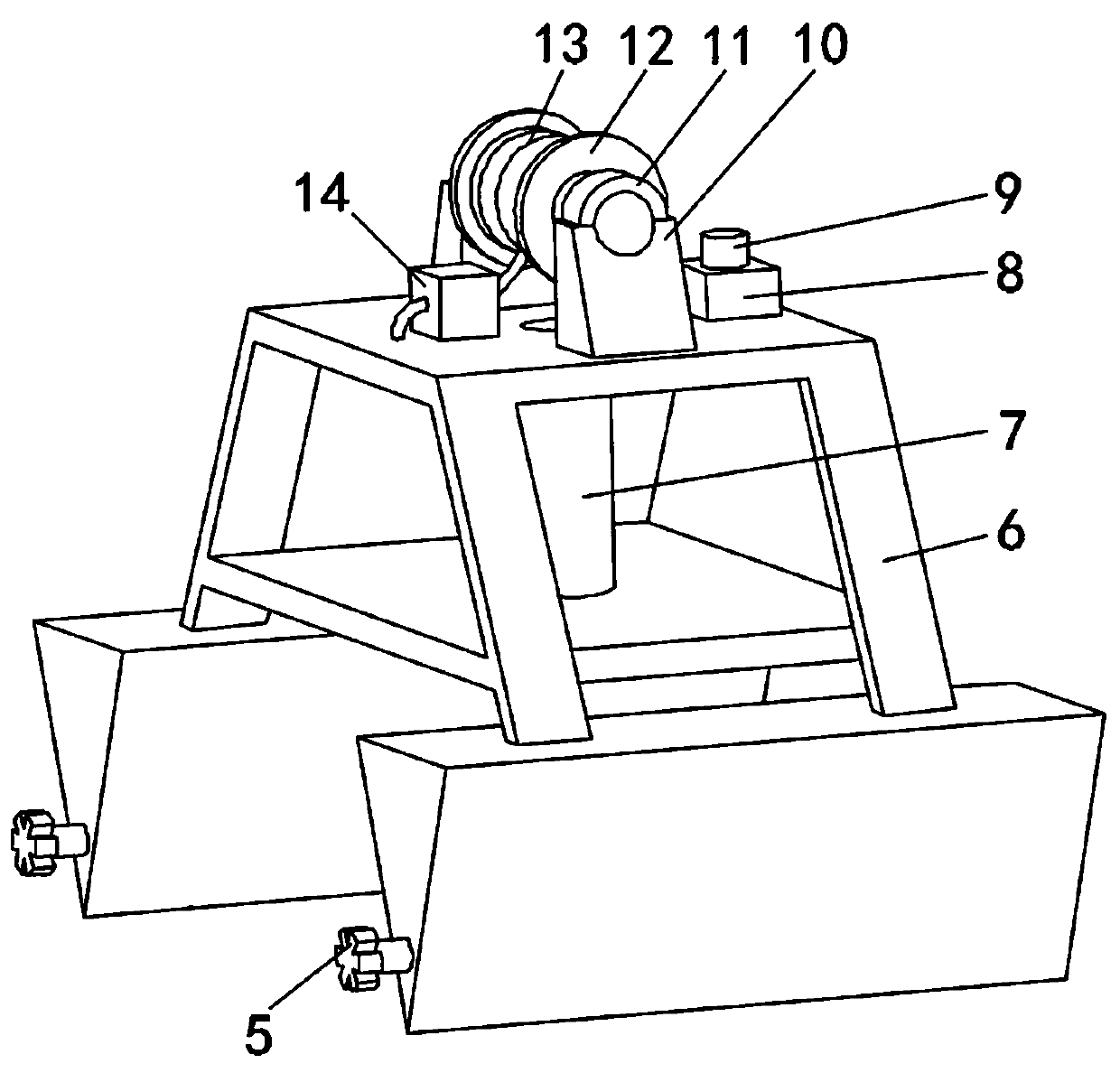

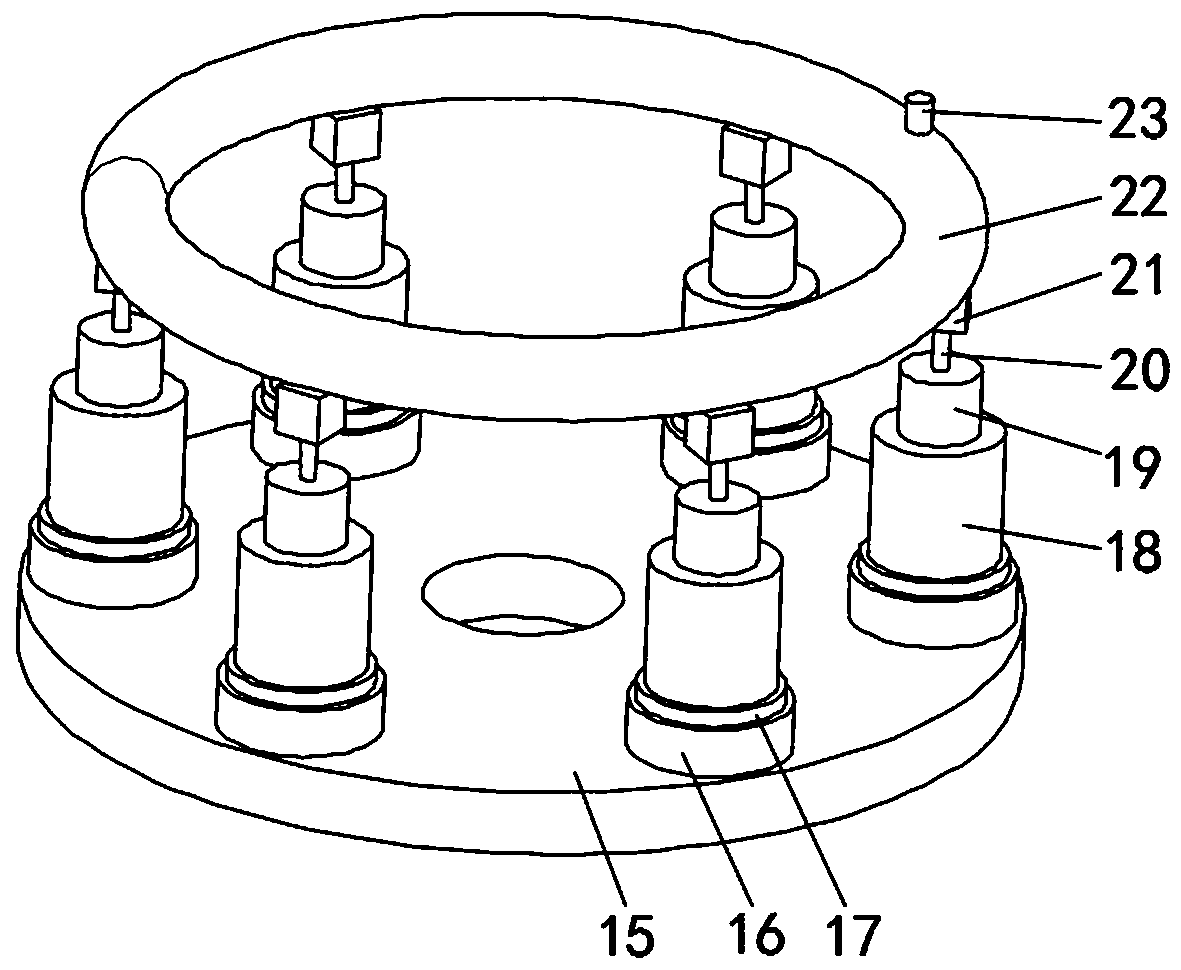

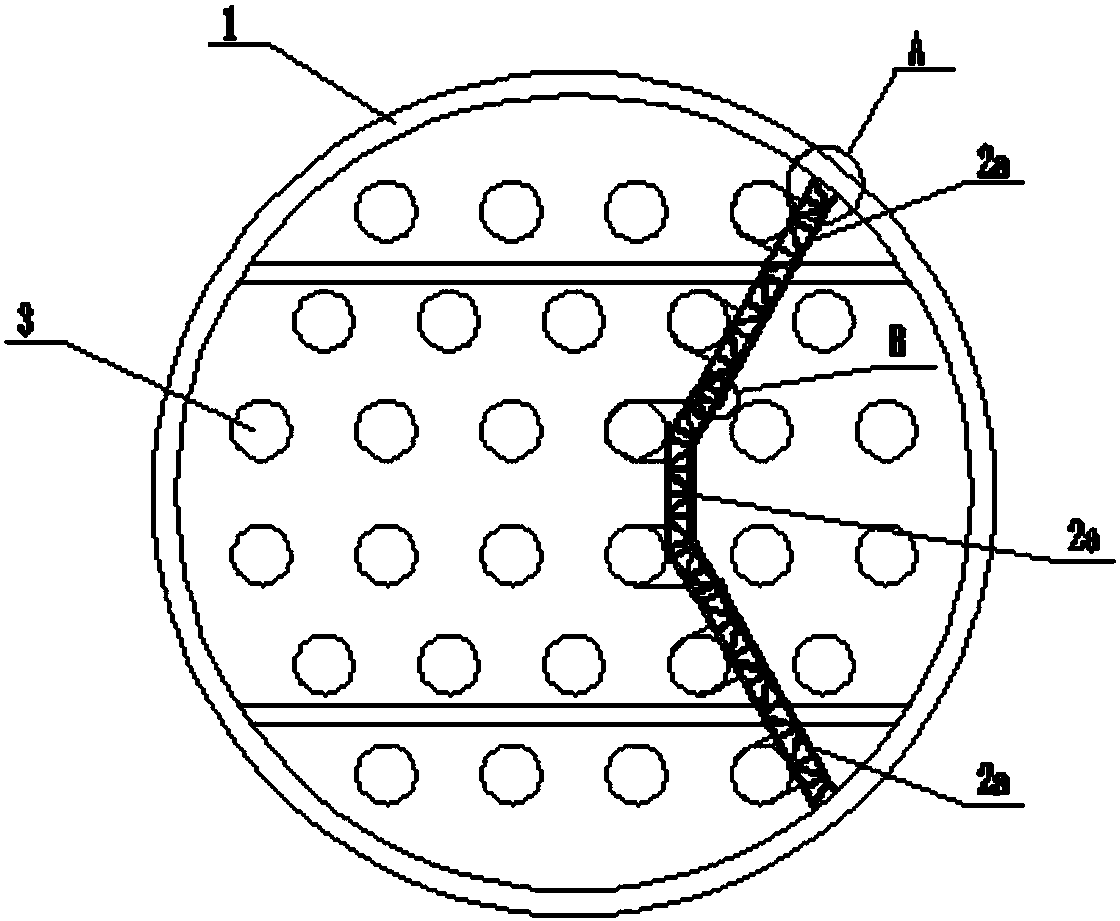

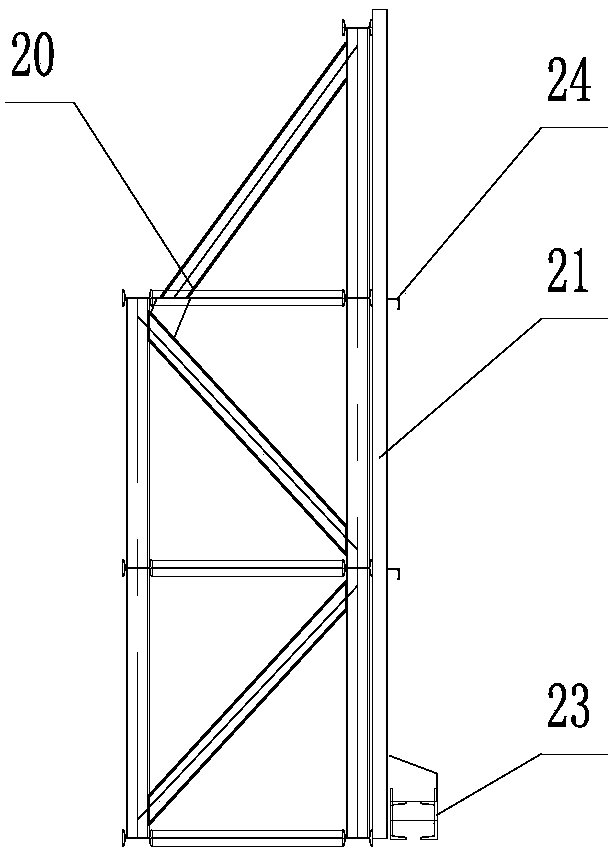

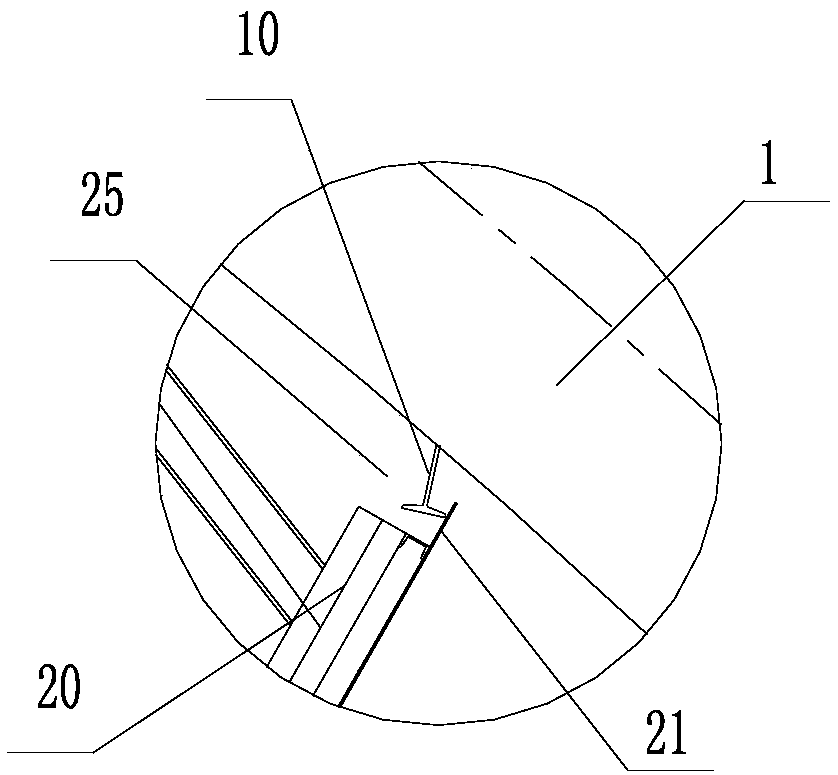

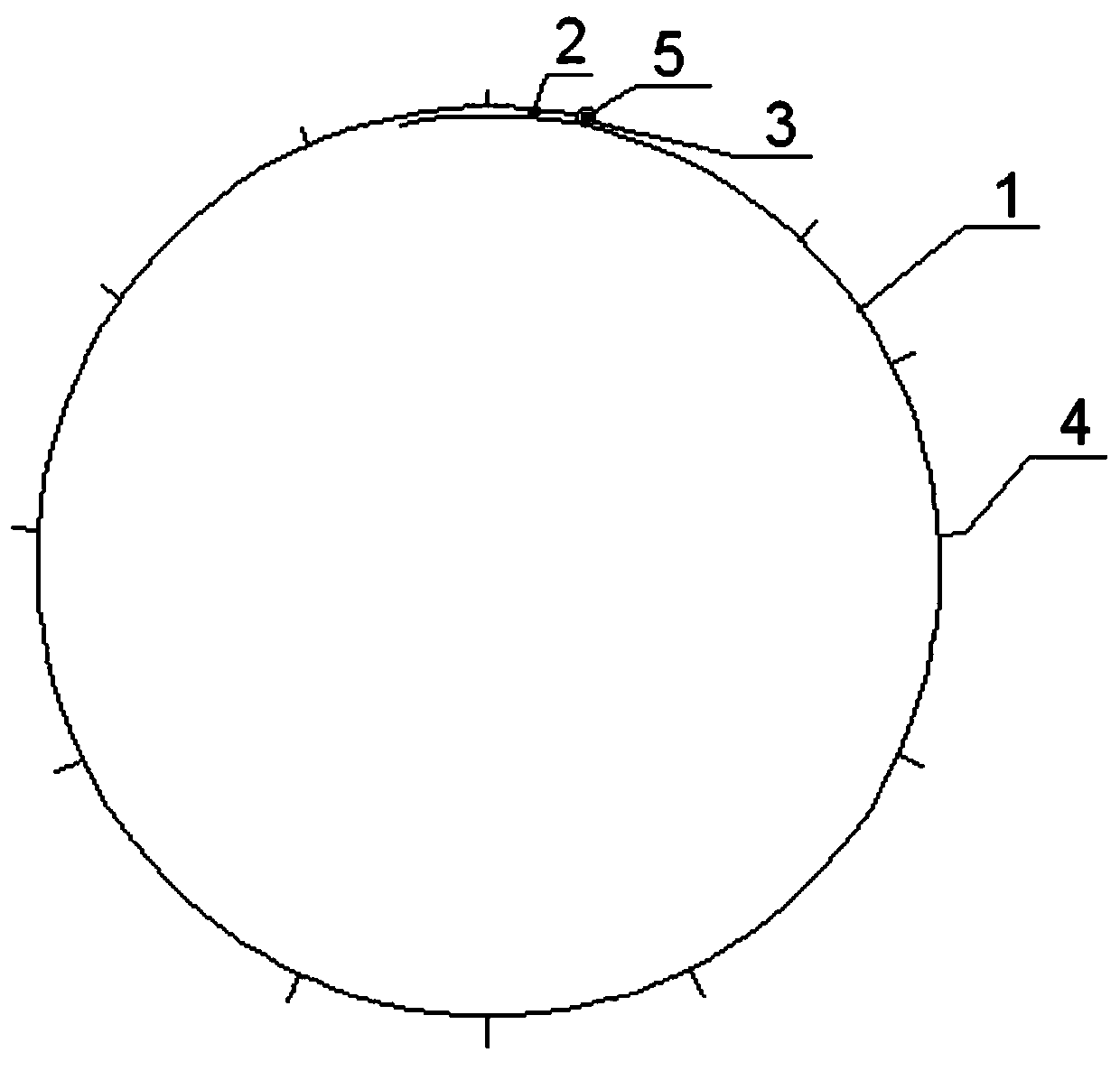

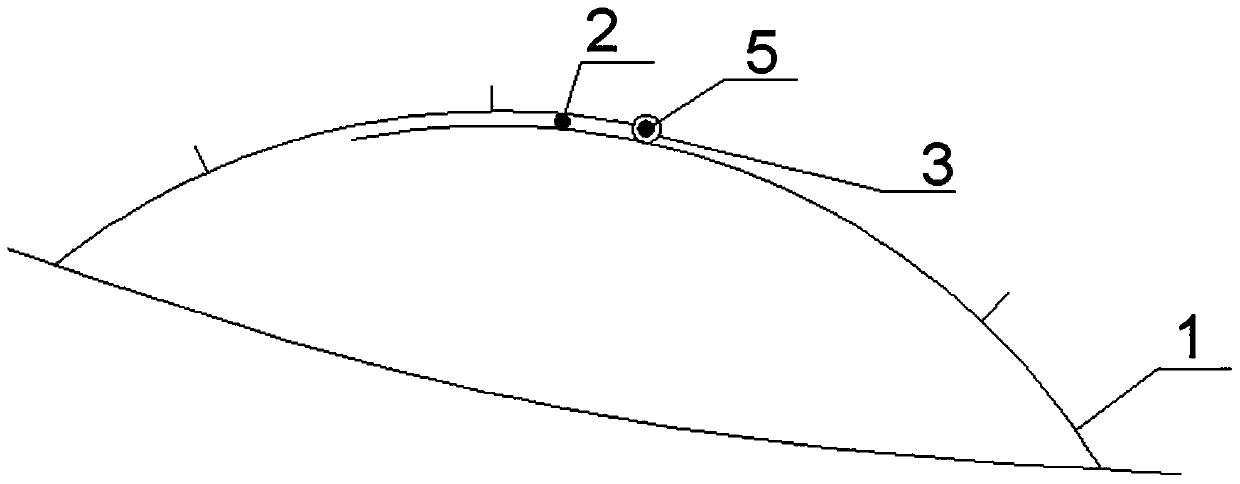

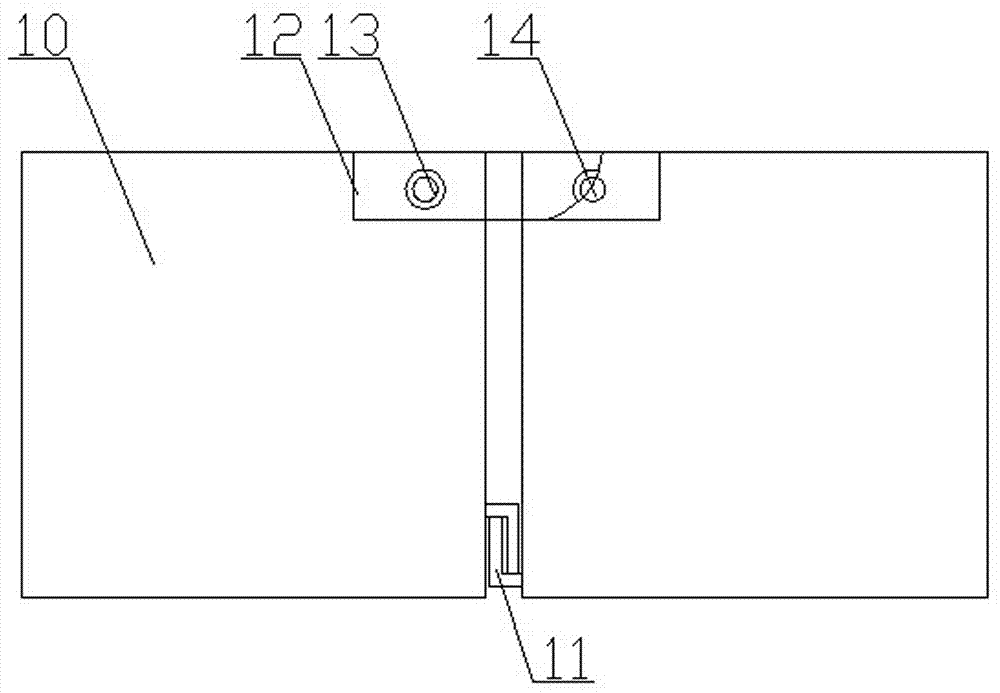

Water quality sampling unmanned catamaran and sampling method thereof

InactiveCN109632384AImprove stabilityConducive to decentralizationWithdrawing sample devicesHydrodynamic/hydrostatic featuresPeristaltic pumpMarine engineering

The invention discloses a water quality sampling unmanned catamaran and a sampling method thereof, and belongs to the technical field of environment monitoring. The water quality sampling unmanned catamaran comprises two catamaran bodies arranged in parallel, wherein the two catamaran bodies are in rigid connection through a fixed trapezoidal frame above the catamaran bodies; an upper platform anda lower platform are arranged on the trapezoidal frame; a cylindrical tube penetrating through the upper platform and the lower platform is arranged in the middle of the trapezoidal frame in a penetrating way; a windlass corresponding to the cylindrical tube is arranged on the upper platform; a bearing support frame matched with the windlass is also arranged on the upper platform; a water collecting pipe is wound on the windlass; one end, passing through the cylindrical tube, of the water collecting pipe is connected with a water sample collector; the other end of the water collecting pipe isconnected with a peristaltic pump fixed on the upper platform; and a water sample distributor is arranged on the lower platform, and is connected with the peristaltic pump. Through the arrangement ofa water sample collection device on the unmanned catamaran in parallel arrangement, the stability of the water sample collection device in the unmanned catamaran moving process is improved.

Owner:SHANGHAI UNIV

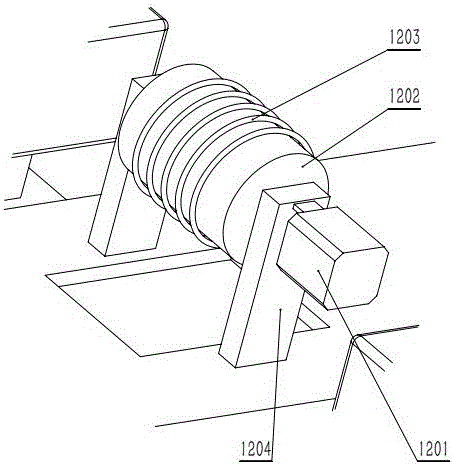

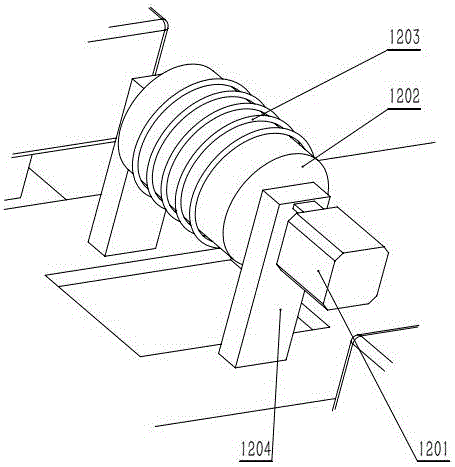

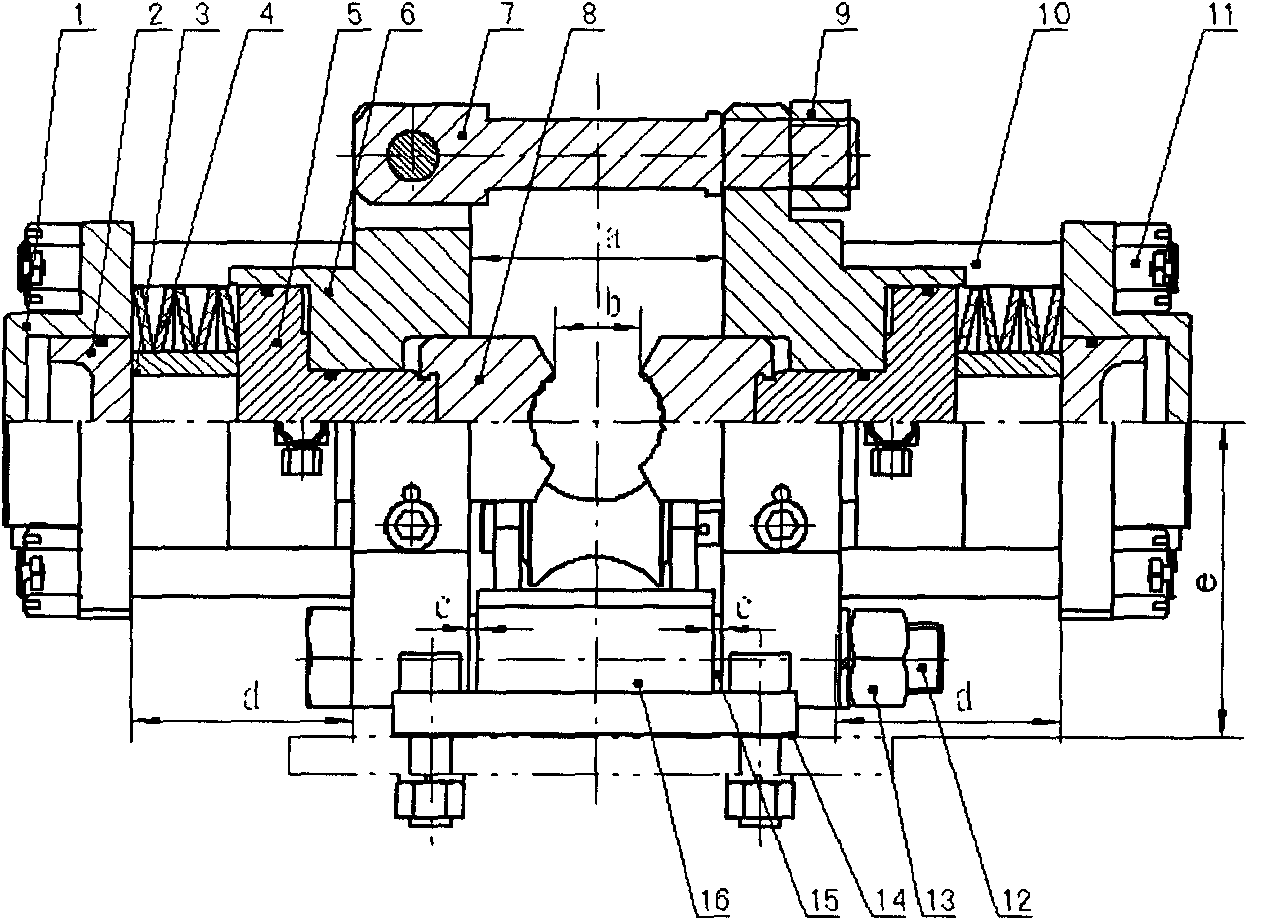

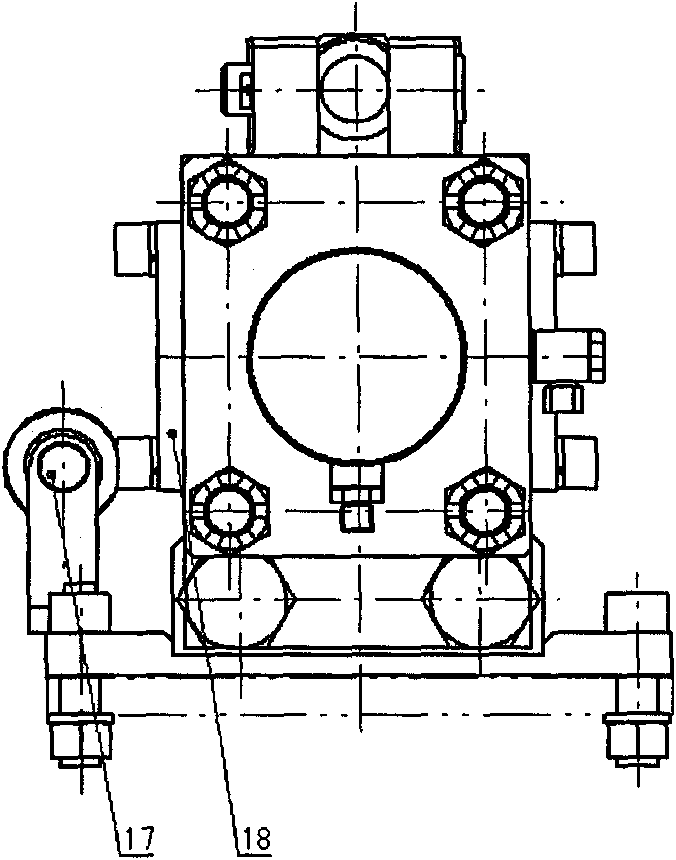

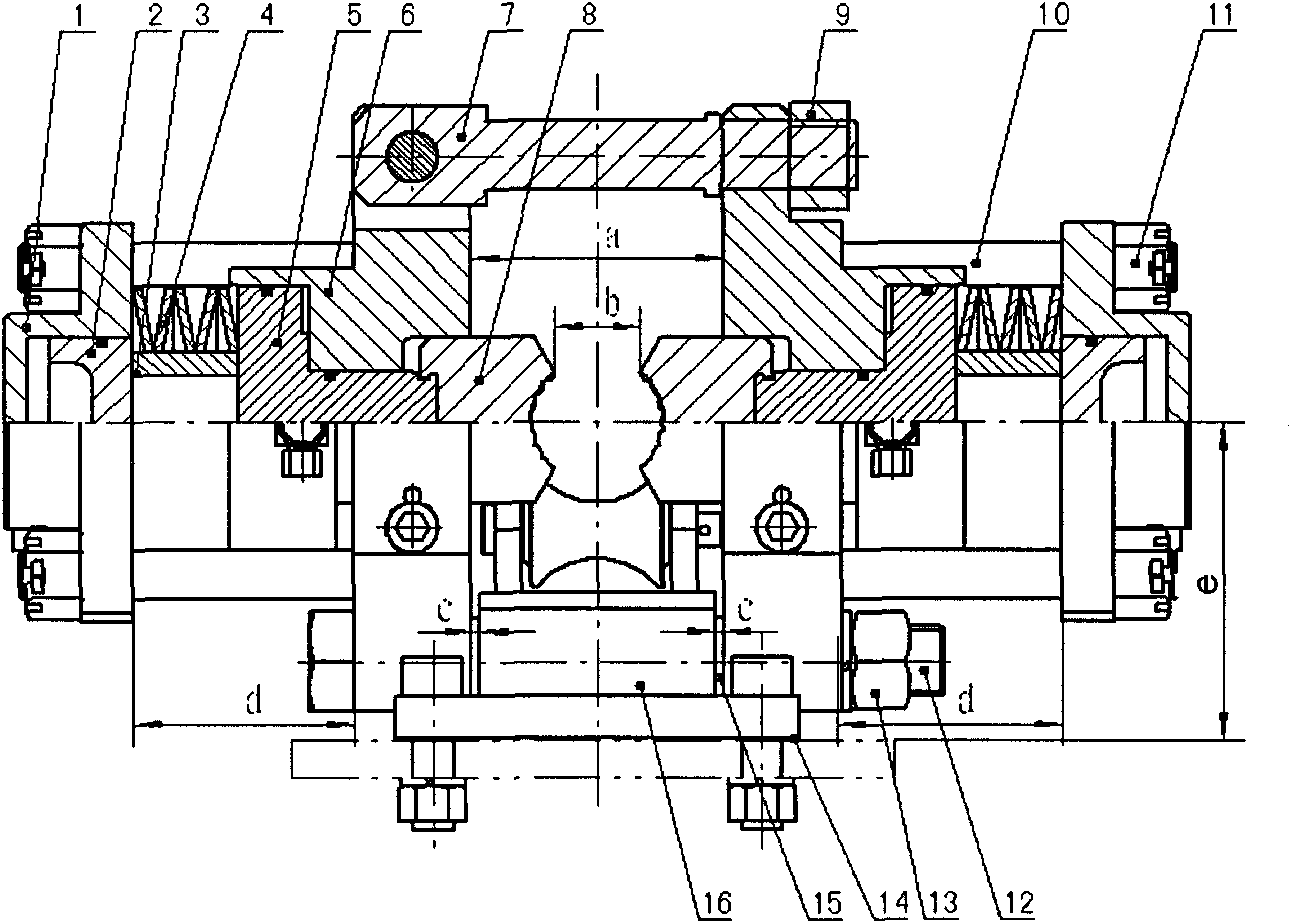

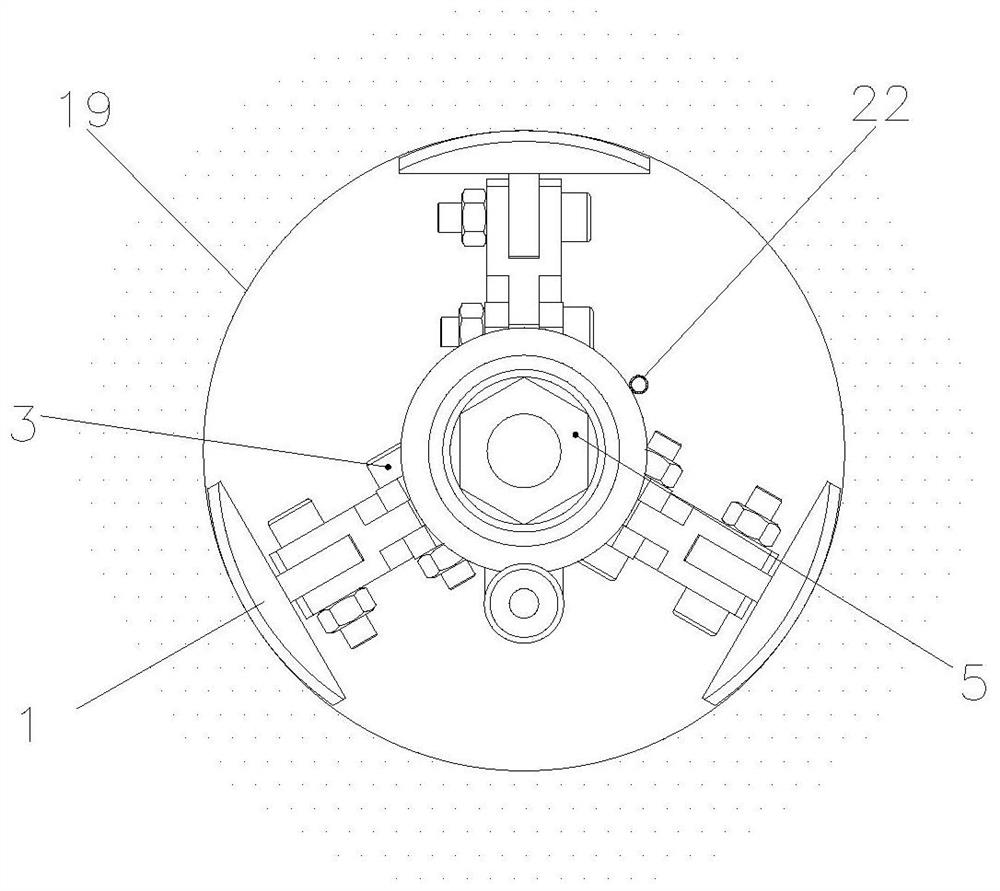

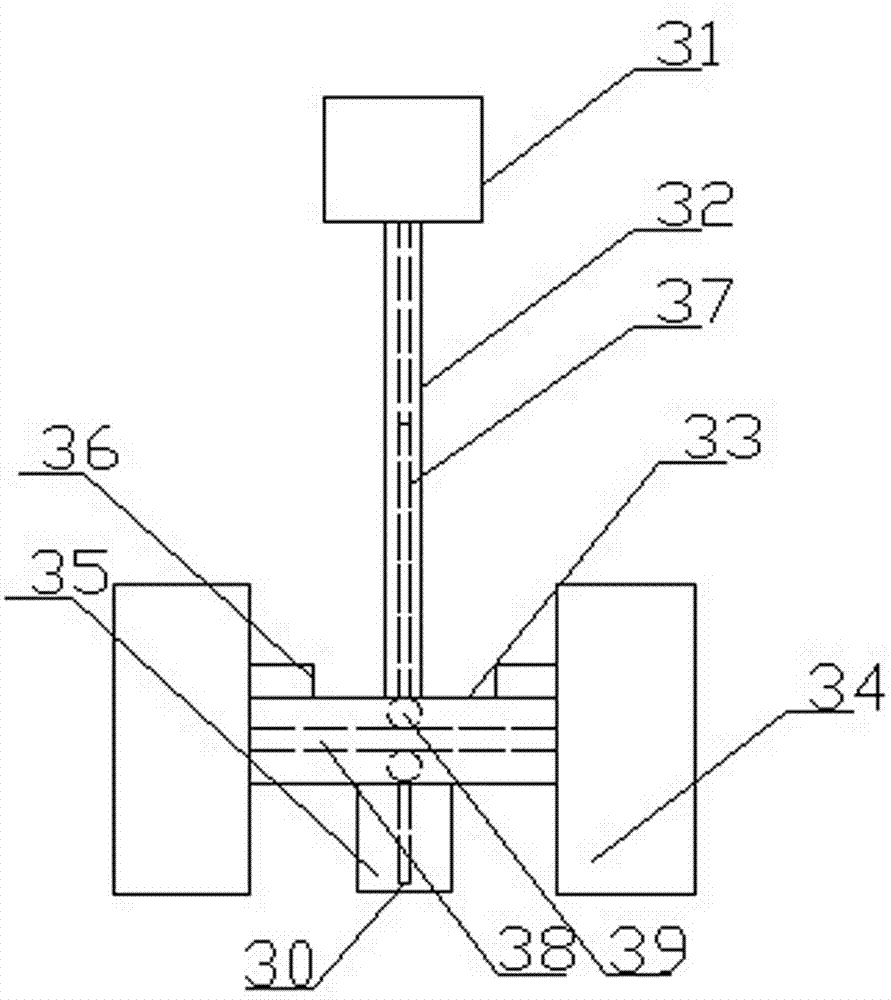

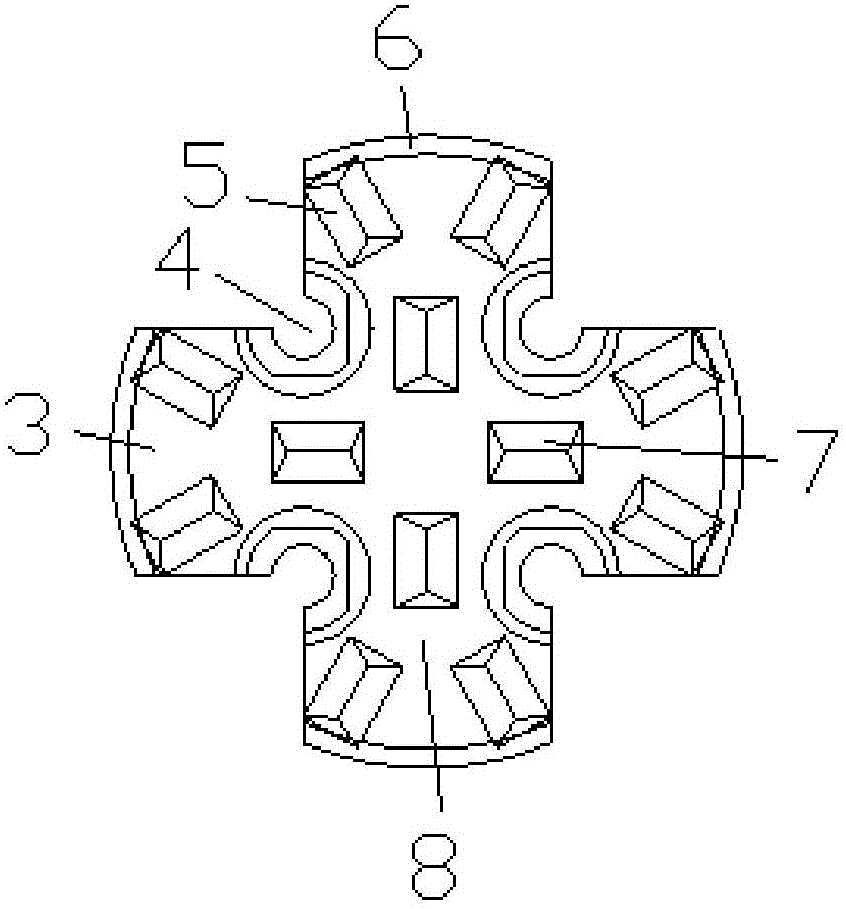

Open-top composite clamp holder

ActiveCN101775965AConducive to decentralizationLarge openingEarth drilling toolsDrilling rodsMaster cylinderEngineering

The invention discloses an open-top composite clamp holder. An all-hydraulic power head type drilling machine is usually provided with a clamp holder which is mainly used for clamping drilling rigs in holes and preventing the drilling rigs in holes from sliding and can be matched with a power head to automatically disassemble a drill pipe. The invention adopts open-top both-side symmetric arrangement, and two master cylinders are symmetrically arranged on two ends of the center of the clamp holder; a master cylinder piston is arranged in each master cylinder, and a slave cylinder piston is arranged in a slave cylinder; a slip is arranged in the master cylinder; a disc spring is connected with the master cylinder piston which is connected with the slip; a shore is arranged between the slave cylinder piston and the master cylinder piston; the lower ends of two master cylinders are connected with the sleeve, and the upper ends are provided with upper draw bars; the sleeve is arranged on a base and is connected by a base draw bar and a nut. The invention has big opening amount, low starting pressure and simple structure, can automatically center, is conveniently to let pass a thick-diameter drill rig and can clamp the drill rigs during sudden power cut.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

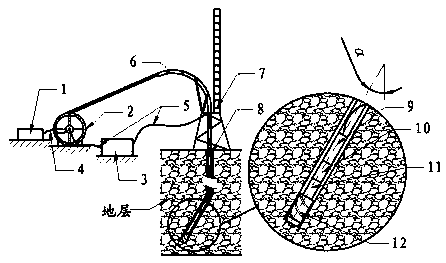

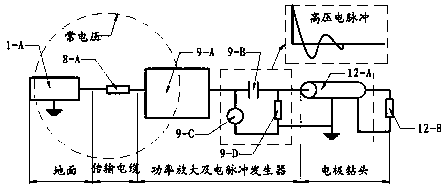

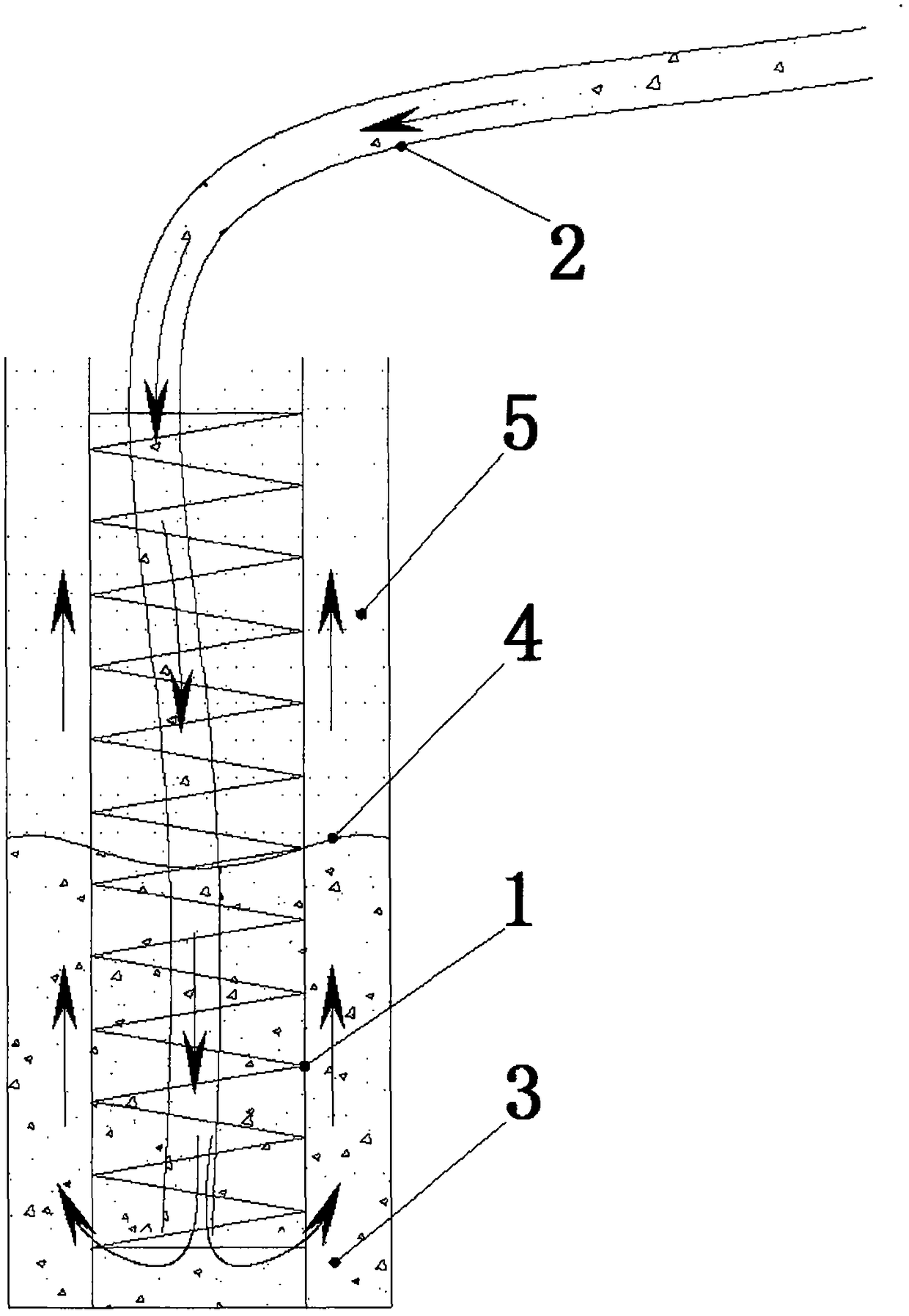

Drilling method for coiled tubing high-voltage electrical pulse/mechanical composite rock breaking

ActiveCN109577859APlay the role of pre-shreddingIncrease contactDrill bitsDirectional drillingHorizontal wellsSlurry

The invention relates to a drilling method for cabled coiled tubing high-voltage electrical pulse / mechanical composite rock breaking. A system for the drilling method includes a ground surface and control apparatus, a coiled tubing drum, a deionizing pump and its slurry purifying system, a cable, a hydraulic line, a coiled tubing injection head, a derrick, a cabled coiled tubing, a power amplification and electrical pulse generator, a coiled tubing connector, an underground power drill and electrode bit and the like. The traditional coiled tubing drilling method and the high-voltage electricalpulse drilling rock-breaking method (including electrical pulse rock breaking and hydroelectric rock breaking) are combined herein; the drilling method is suitable for both straight wells and oriented wells (including horizontal wells); a high-voltage electrical pulse generator is arranged in a lower drill combination, so that energy conversion efficiency is improved. The drilling method also hasthe advantages that, for instance, cable lowering is convenient, rock breaking efficiency is high, well wall quality is good, and deep well drilling cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

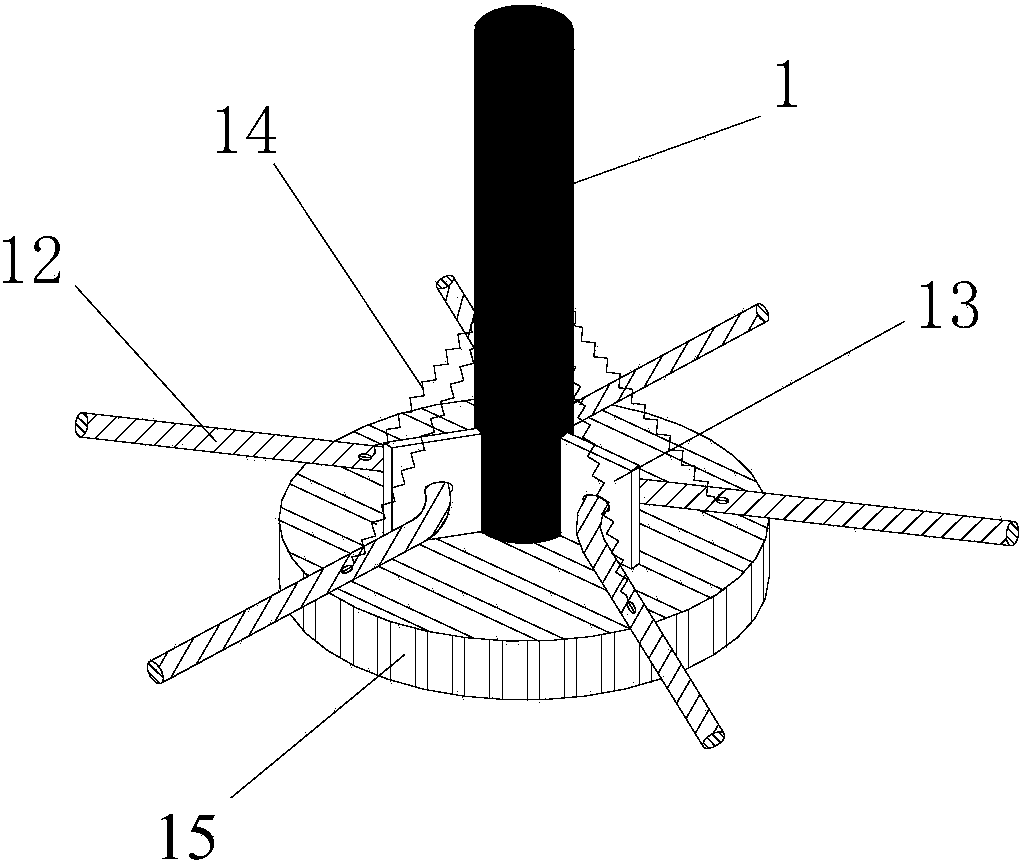

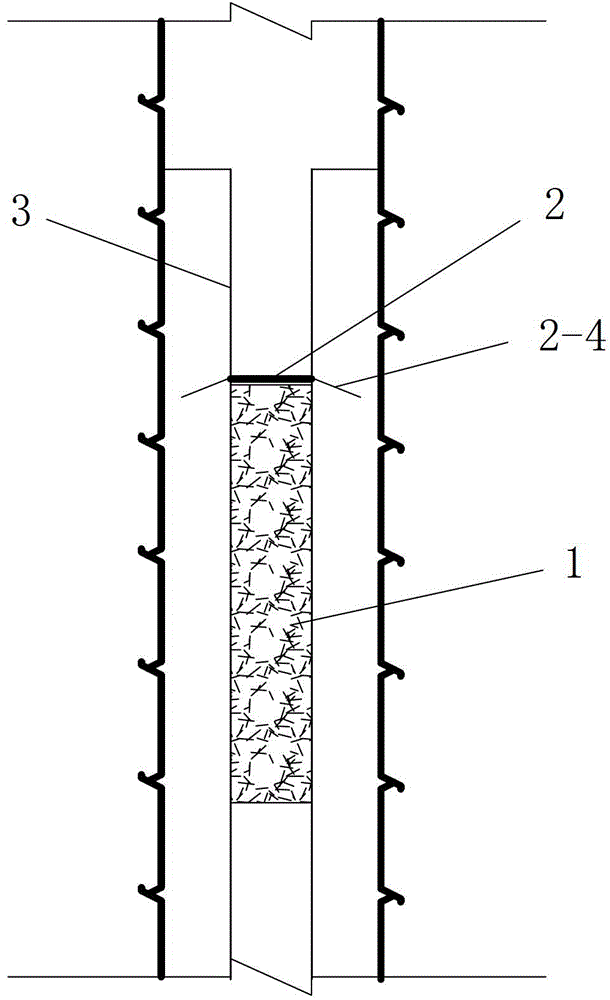

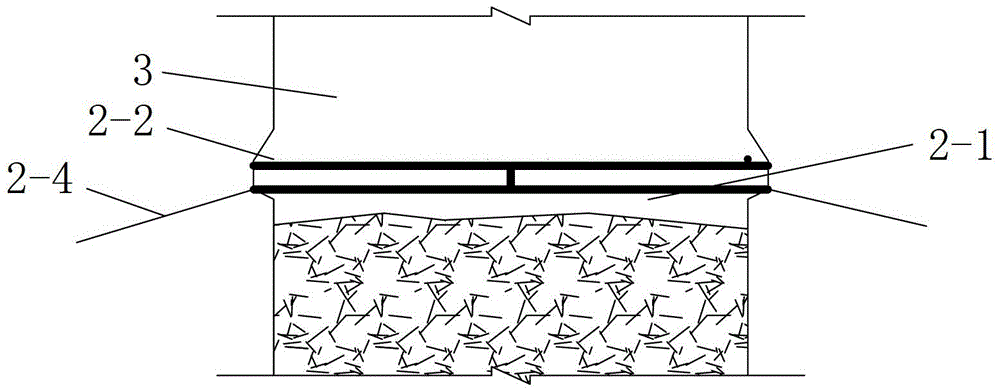

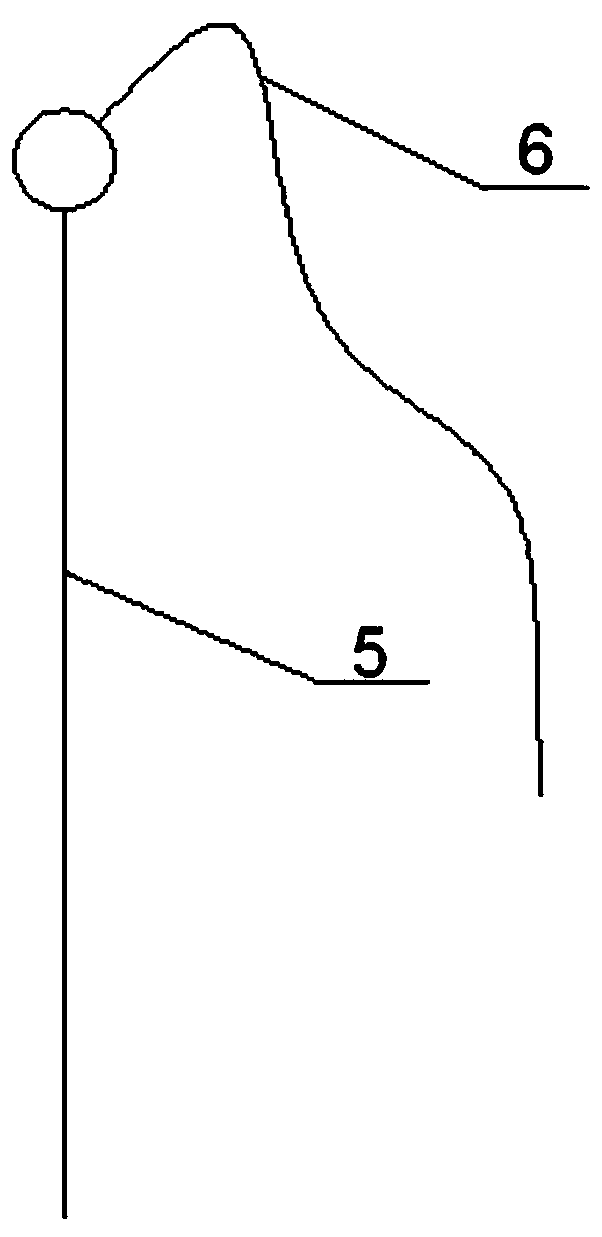

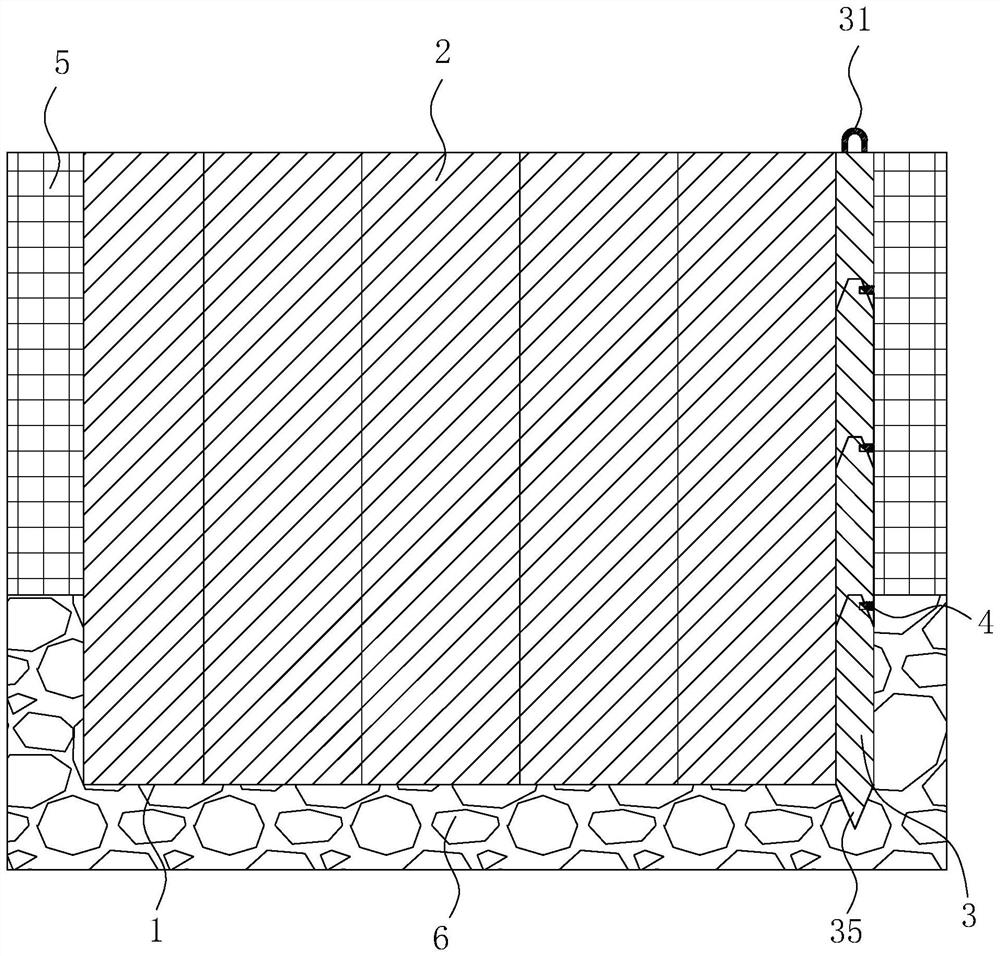

Lead hole implanted anti-floating rock anchor rod with supporting trays and construction method thereof

ActiveCN104234050AHigh bonding strengthImprove molding qualityProtective foundationBulkheads/pilesRebarRock bolt

The invention relates to a lead hole implanted anti-floating rock anchor rod with supporting trays. The lead hole implanted anti-floating rock anchor rod is characterized by mainly consisting of an anchor rod, supporting tray steel bar frameworks, a chassis, a backing plate and an anchor head, wherein an anchoring section of the anchor rod is arranged in a rock stratum pore passage with the supporting trays; the rock stratum pore passage is filled with a steel bar anchoring agent; the steel bar anchoring agent is wrapped with a geotextile bag; a free section of the anchor rod is arranged in a foundation bottom plate, is wrapped with a drivepipe and is isolated from concretes of the bottom plate; the supporting tray steel bar frameworks are fixed to the anchor rod in a manner of corresponding to the heights of the supporting trays in the rock stratum pore passage. The reaming supporting trays are arranged in the rock stratum pore passage, and the expandibility and adhesiveness of the steel bar anchoring agent are utilized, so that the anchoring force in unit length of the anchor rod is improved, the anti-floating capability of the anchor rod can be increased, the length of the anchor rod and the drilling depth of a rock stratum can be relatively shortened, and the lead hole implanted anti-floating rock anchor rod has favorable technical and economical benefits. The invention also discloses a construction method of the anti-floating rock anchor rod.

Owner:德达交通建设发展集团有限公司

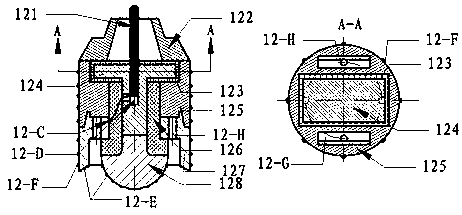

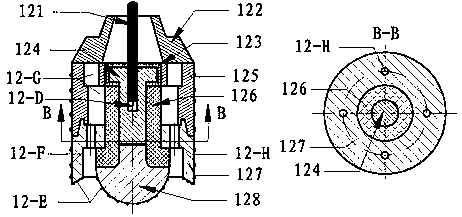

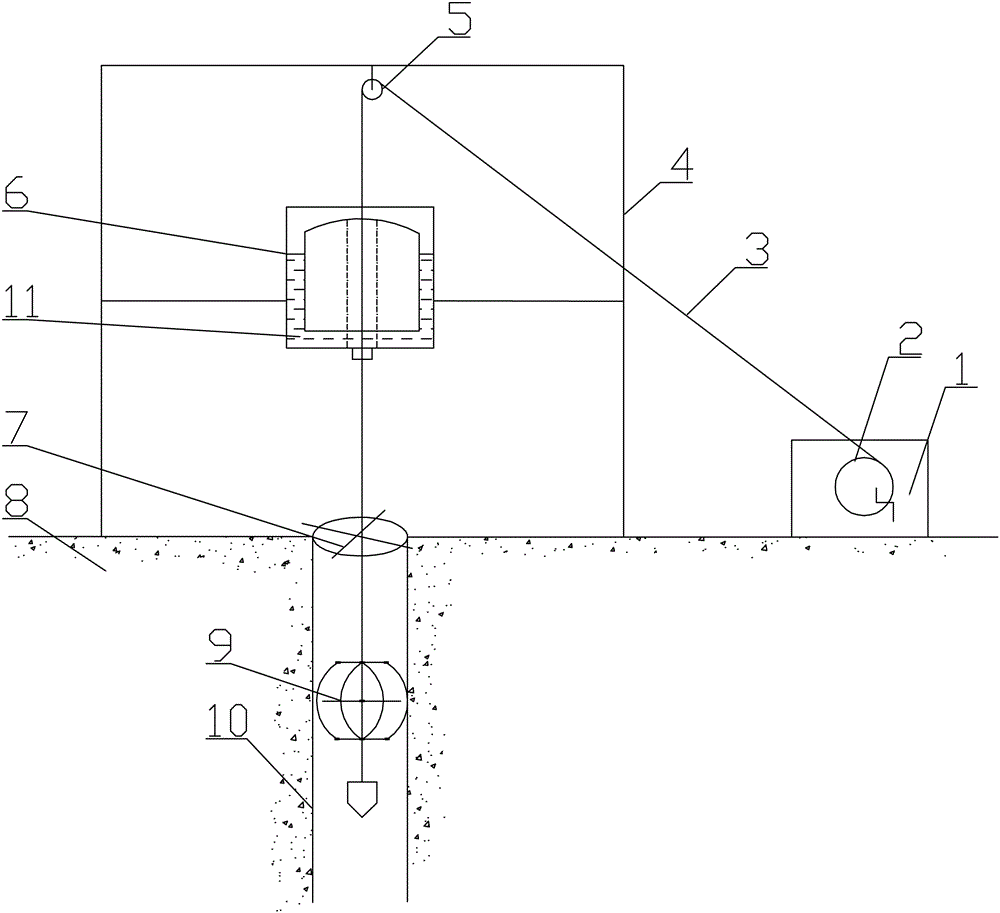

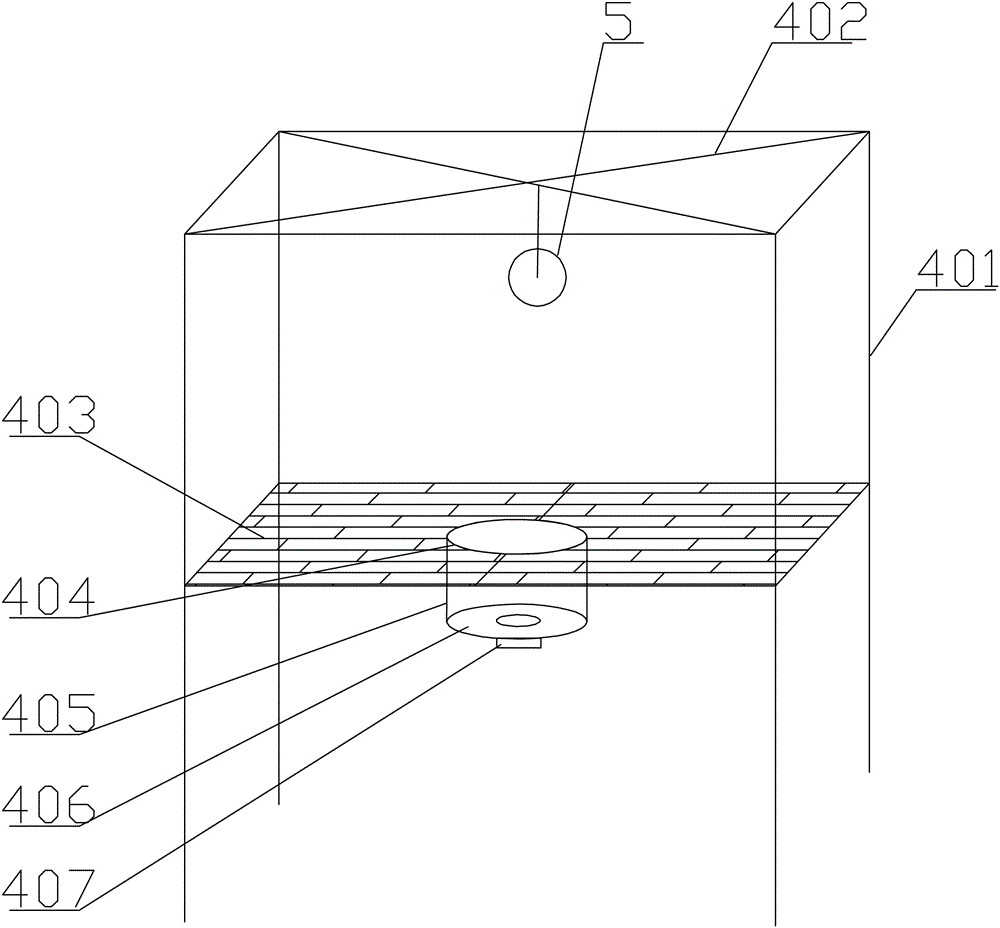

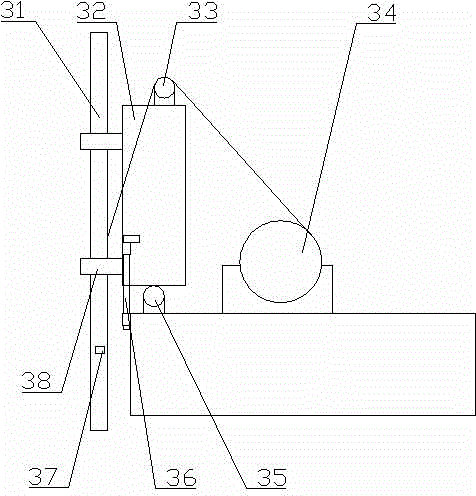

Suspension type counter weight clinometer and measurement method

The invention relates to a suspension type counter weight clinometer and a measurement method. The suspension type counter weight clinometer comprises a winch motor, wherein a steel wire rope winds a winch barrel of the winch motor and penetrates through a fixed pulley fixed at the top of a supporting platform; a floating barrel device is mounted in the middle of the supporting platform; the steel wire rope passes through the floating barrel device; a linear vertical suspension device is connected with the tail end of the steel wire rope and is located in a hole to be detected; and a measuring device is located at an inlet position of the hole to be detected. The clinometer provided by the invention can be used for carrying out high-frequency and high-precision detection in drilling construction with very high perpendicularity requirements; and an efficient and high-precision perpendicularity detection device, which is convenient to mount, has accurate and reliable data and can meet real-time detection requirements, can be provided for a drilling construction site through the clinometer.

Owner:CHINA GEZHOUBA GRP SURVEY DESIGN CO LTD

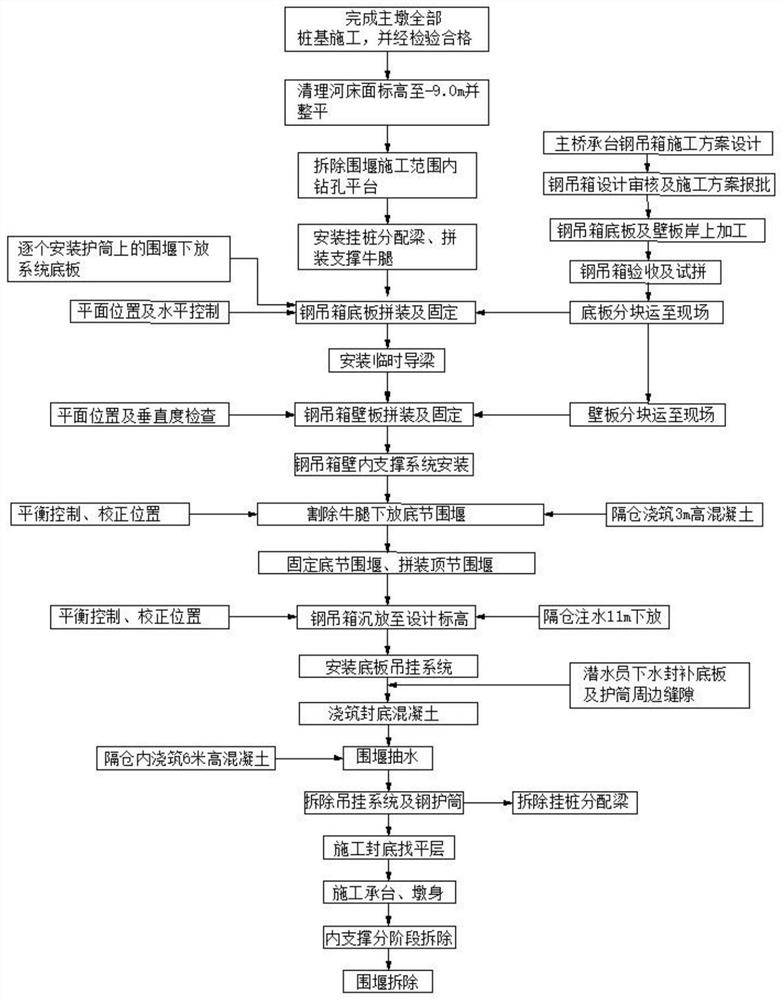

Construction method for double-wall steel suspension cofferdam of main bridge bearing platform of super-large bridge

PendingCN111980020AGood effectEasy to makeBridge structural detailsBridge erection/assemblyArchitectural engineeringCofferdam

The invention provides a construction method for a double-wall steel suspension cofferdam of a main bridge bearing platform of a super-large bridge. The construction method comprises the following steps that S1, steel casings are built on a river bed, and the cofferdam is assembled on the portions, above the surface of water, of the steel casings; S2, the cofferdam is laid down, and internal supports are installed in the cofferdam; S3, top-sealing concrete is poured in the cofferdam, and accumulated water in the cofferdam is drained; S4, the portions from pier bodies to the lower side of the middle internal support are built, and connecting supports are arranged between the pier bodies and the inner wall of the cofferdam and between the pier bodies; S5, the portions from the pier bodies tothe top internal support are built, and connecting supports are arranged between the pier bodies and the inner wall of the cofferdam and between the pier bodies; S6, the pier bodies are built to be above the surface of water, building of the pier bodies is completed, and building of a large bridge main pier foundation is completed. Embedded parts are arranged on the pier bodies, supporting piecesare arranged between the pier bodies and the cofferdam and between the pier bodies, the supporting pieces are connected with the embedded parts, the support of the interior of the cofferdam is enhanced, and the structural strength of the cofferdam is ensured.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

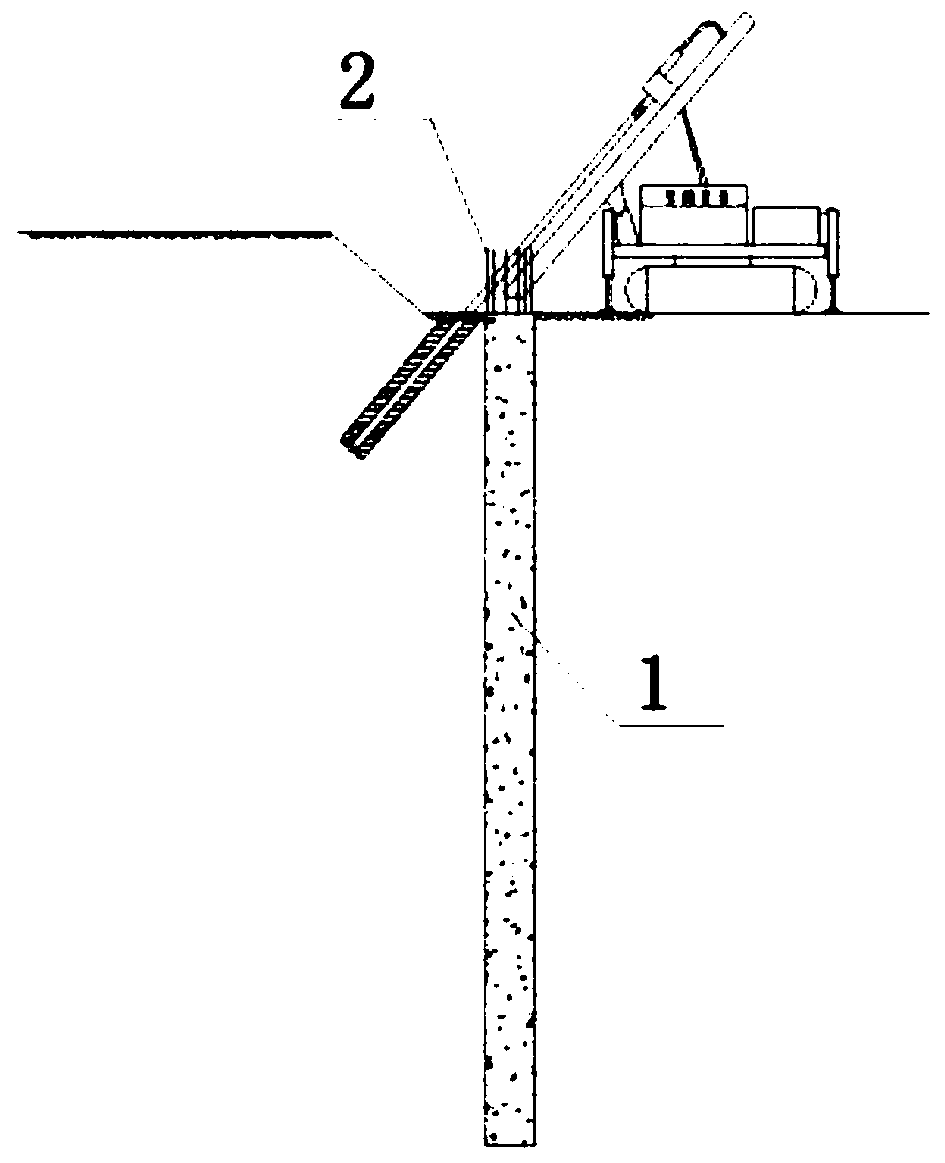

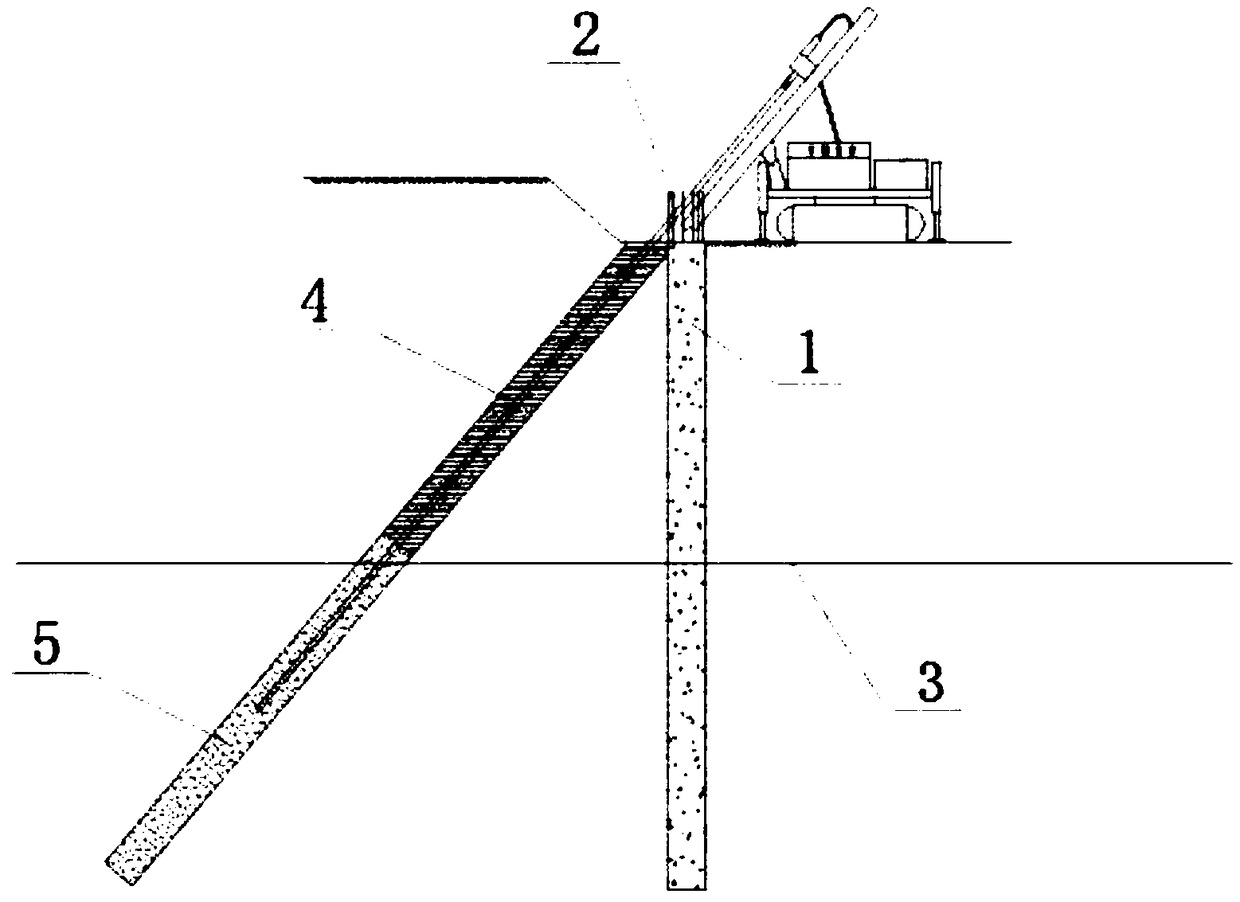

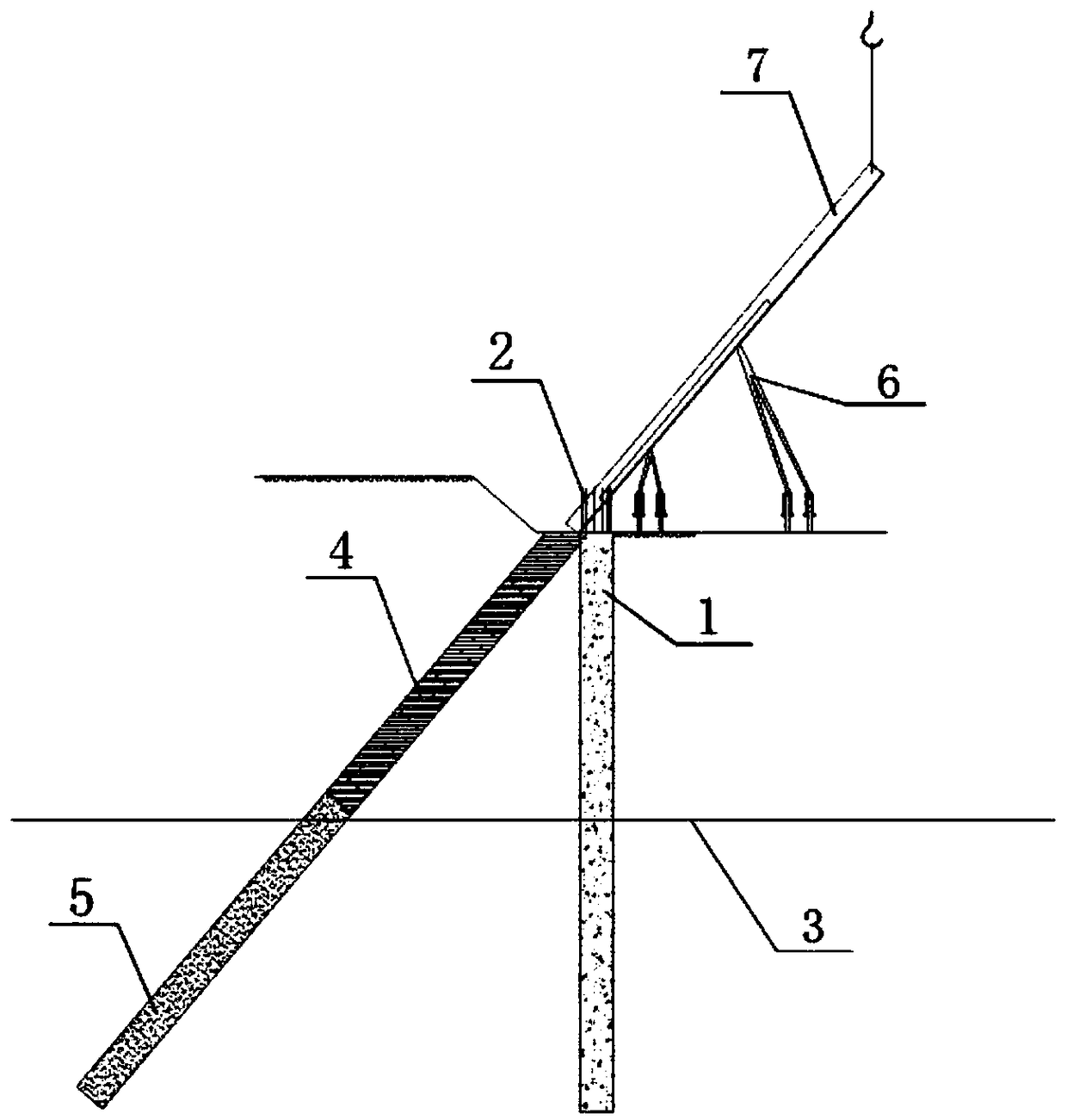

Construction method of foundation pit inclined support pile and auxiliary tool thereof

InactiveCN108625377AConducive to decentralizationSimple and fast operationExcavationsCement pasteRebar

The invention discloses a construction method of a foundation pit inclined support pile and an auxiliary tool thereof, and relates to the technical field of building foundation pit support construction. After foundation pit support piles are constructed, pile heads are broken down, so that rebars of anchorage sections are exposed, holes are drilled in the direction of holes of inclined support piles, the holes are divided by the foundation pit bottom elevation, hollow holes are formed in the upper parts, bearing holes are formed in the lower parts, and cement paste is injected into the bearingholes. Steel pipe piles or prefabricated pipe piles are used as the inclined support piles to be put on the support surface of the auxiliary device, the angle and position of the auxiliary device areadjusted, and the inclined support piles are put downwards until the bottoms of the inclined support piles are put in the bottoms of the bearing holes; the tops of the inclined support piles are anchored into crown beams, concrete is poured, and foundation pits can be dug after the design strength is reached. The operation of the prefabricated pipe piles is simpler and more convenient than that of concrete pouring, so that the construction period is short; the inclined support piles are put downwards by using the auxiliary device, so that the construction efficiency is high; and the inclinedsupport piles and a main body are combined into a whole, the soil pressure of the inclined support piles is transferred to soil at the bottom of the foundation pits, and the inclined support parts andthe middle parts of the foundation pits are dug at the same time, so that the total construction period of the foundation pit engineering is greatly shortened.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD +1

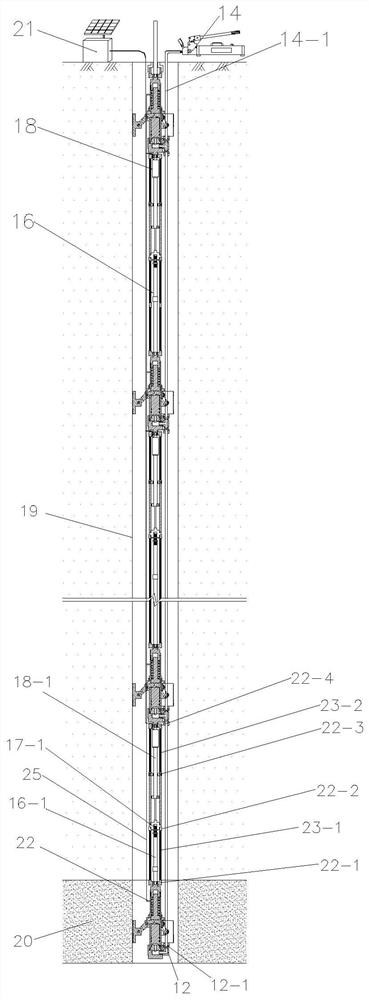

Soil body layered settlement monitoring device and method

ActiveCN112411513ASimple structureReasonable designIn situ soil foundationSoil scienceHydraulic pump

The invention discloses a soil body layered settlement monitoring device and a method. The device comprises a plurality of settlement monitoring mechanisms; each settlement monitoring mechanism comprises an anchoring mechanism, a displacement sensor and a displacement transmission rod; each anchoring mechanism comprises a sleeve, a piston, a compression spring reset mechanism and an anchoring part; a sealing cover and a bottom cover are arranged at the lower end of each sleeve; a top cover is arranged at the upper end of each sleeve; a hydraulic pipe component for providing hydraulic oil for the pistons is arranged on the bottom covers; and a hydraulic pump is arranged outside the top of a embedding hole. The method includes the steps of step one, drilling the embedding hole; step two, temporarily assembling the settlement monitoring mechanisms on the ground; step three, lifting the settlement monitoring mechanisms and installing the displacement sensors; step four, continuously lifting the settlement monitoring mechanisms and anchoring the anchoring mechanisms; step five, backfilling the embedding hole; and step six, acquiring layered settlement monitoring data. The soil body layered settlement monitoring device is reasonable in design, the settlement deformation monitoring of soil at different depths is achieved, the monitoring precision is high, and the automation degree ishigh.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

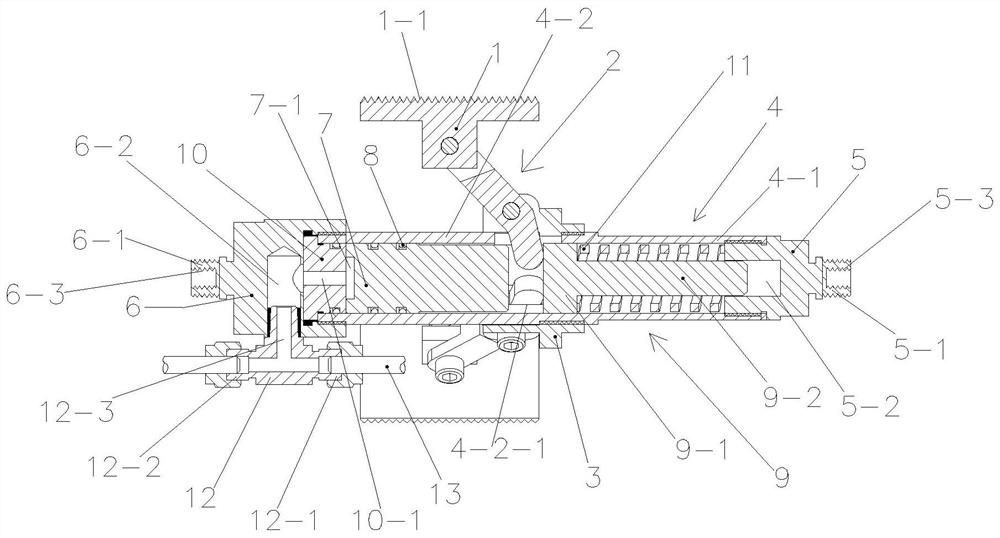

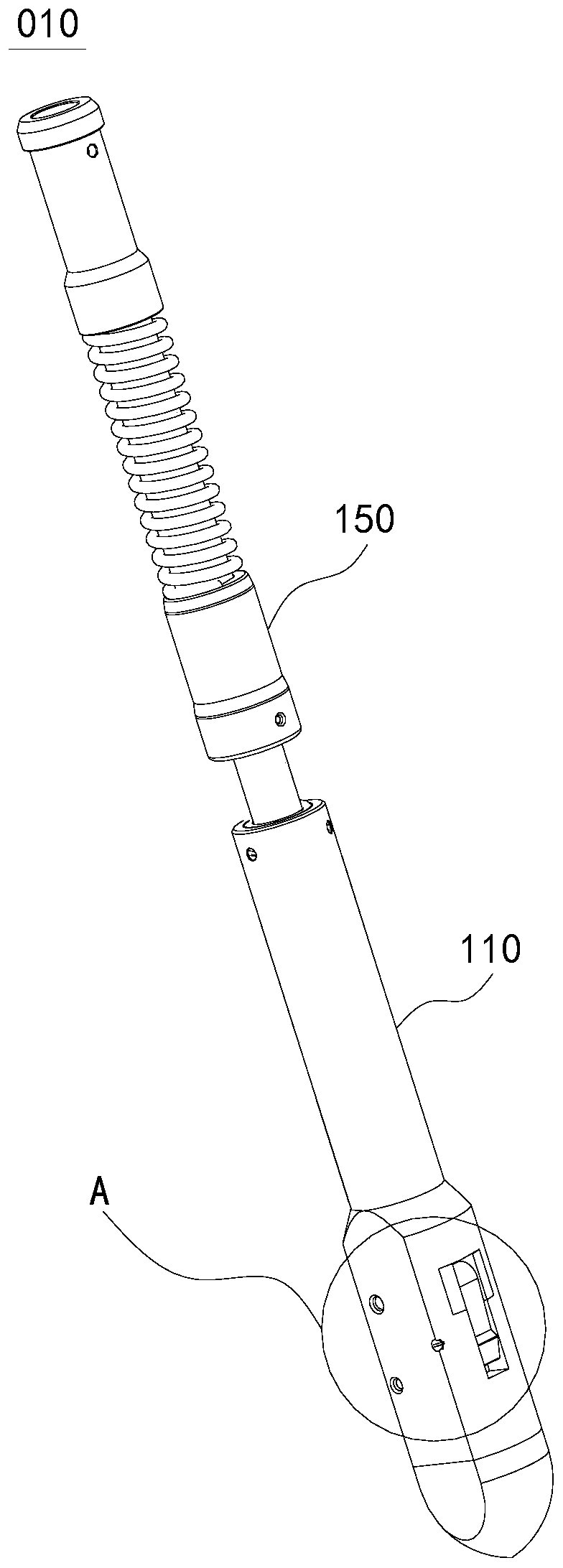

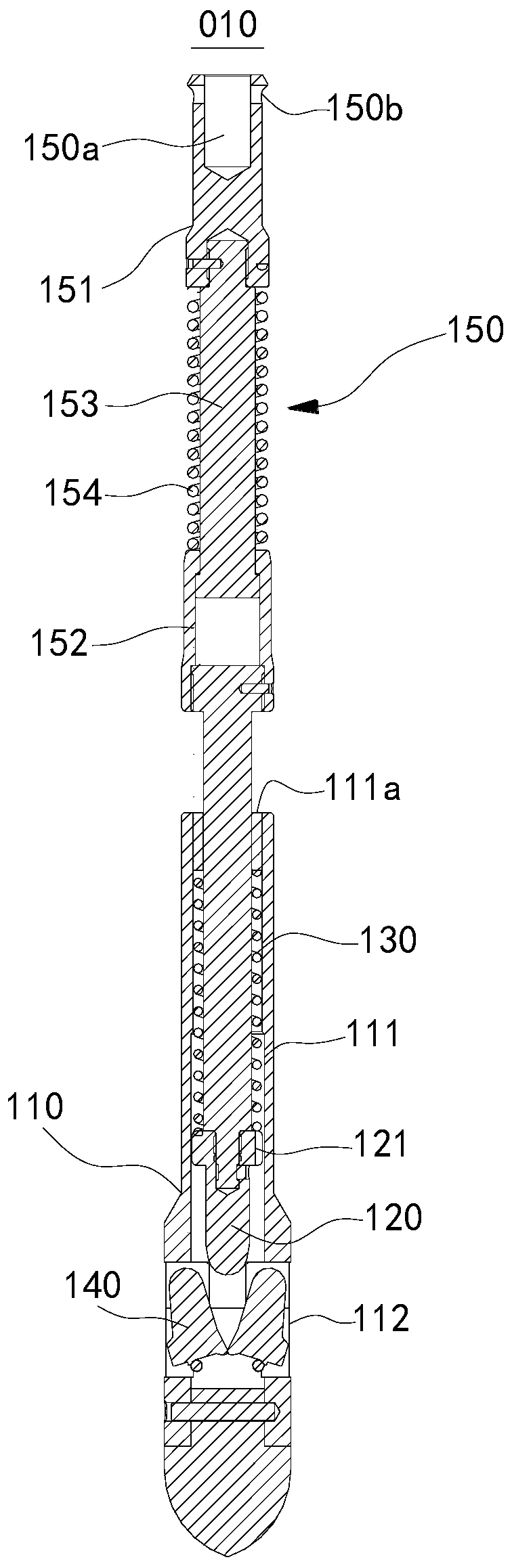

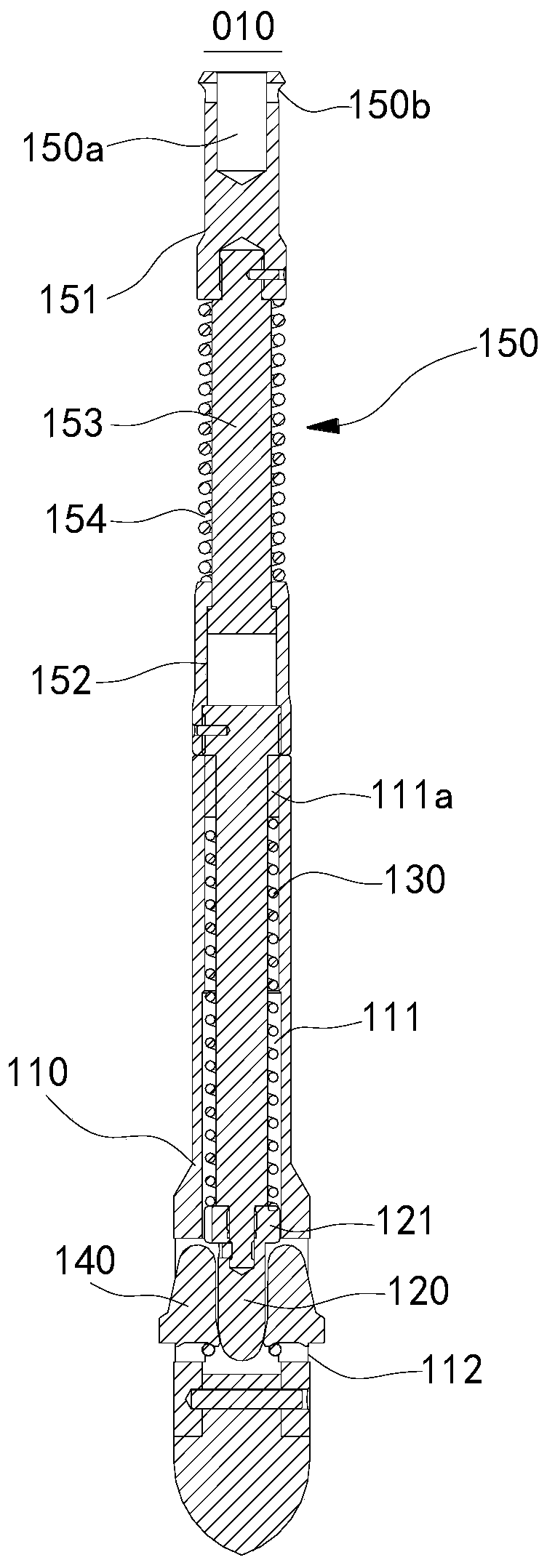

Clamping device, downhole tool and downhole release structure

The application relates to the technical fields of natural gas and oil exploitation, and discloses a clamping device, a downhole tool and a downhole release structure. When the clamping device provided by the embodiments of the application is put down into an oil-gas well, an extrusion part is positioned at the abdication position, so that the clamping device can be smoothly put down to the presetposition in the oil-gas well. When the clamping device reaches the preset position in the oil-gas well, a power mechanism drives extrusion part to move towards an extrusion position, the extrusion part extrudes a clamping piece radially outwards so as to enable the clamping piece to move to the outside of a radial channel, and the clamping piece can be embedded into a gap at a coupling part of the oil-gas well at the moment, so that the clamping device is fixed in the oil-gas well. When the clamping device needs to be removed from the oil-gas well, the extrusion part moves to the abdication position under the action of the external force or the power mechanism, the clamping device is lifted upwards by means of a fishing device at the moment, and the clamping piece moves radially inwards under the action of the external force so as to get away from the gap at the coupling part, so that the clamping device is enabled to be fished to the outside of the oil-gas well.

Owner:成都百胜野牛科技有限公司

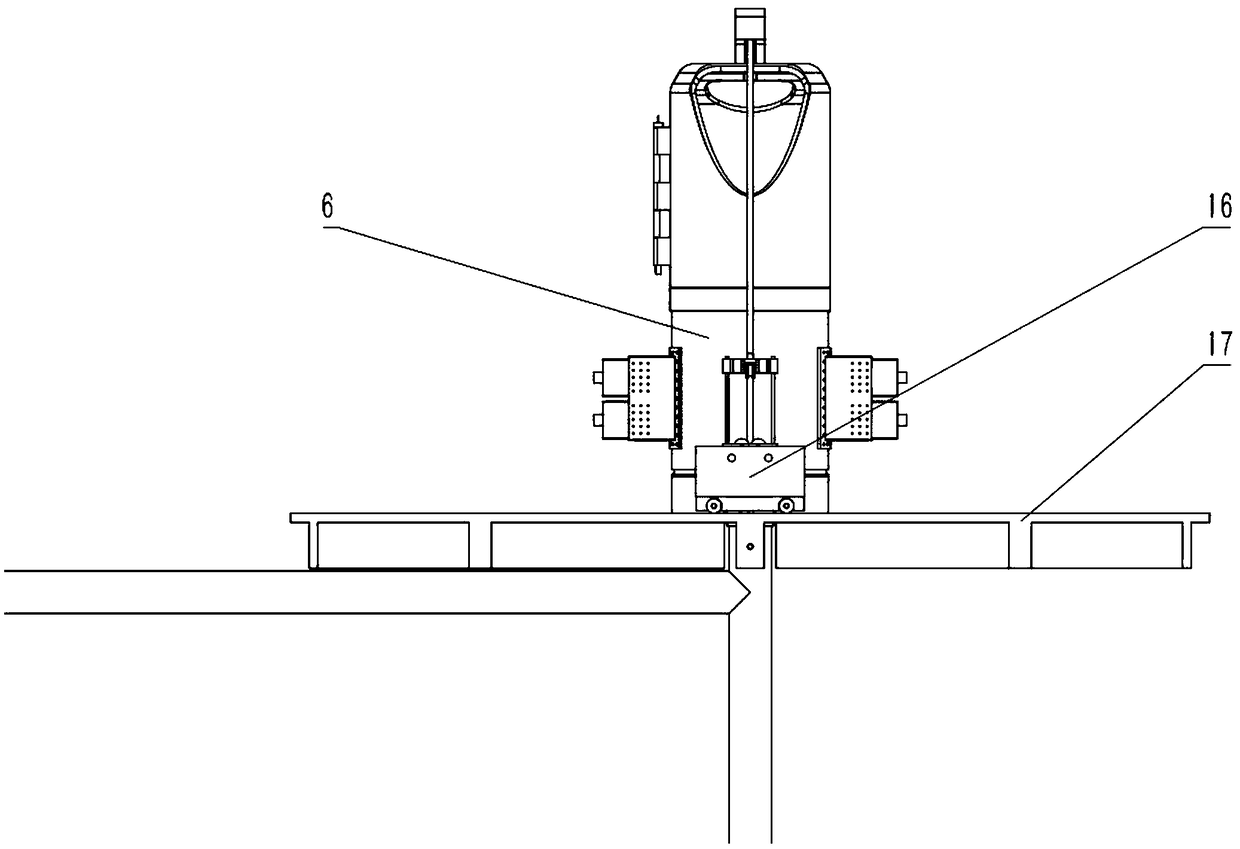

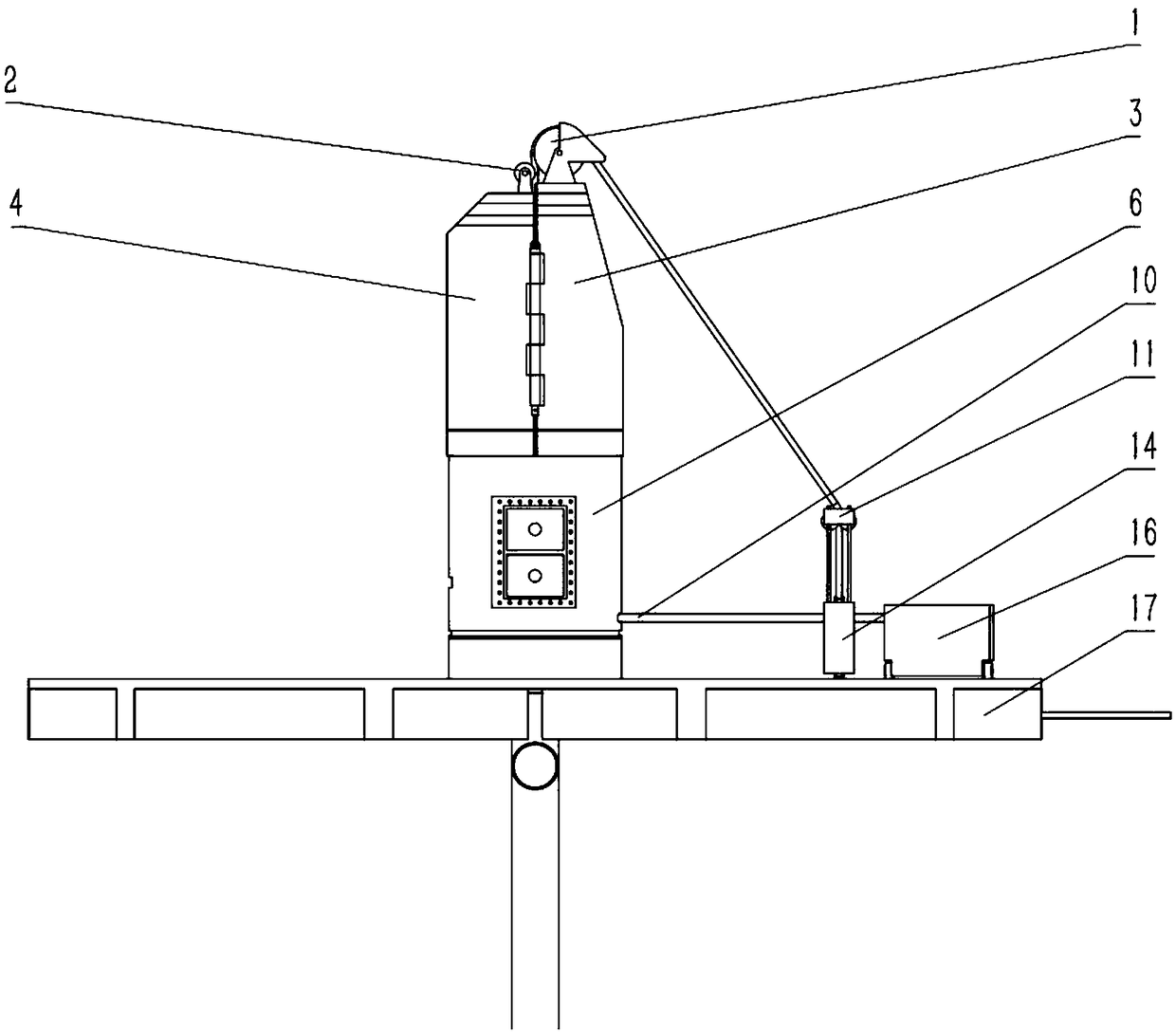

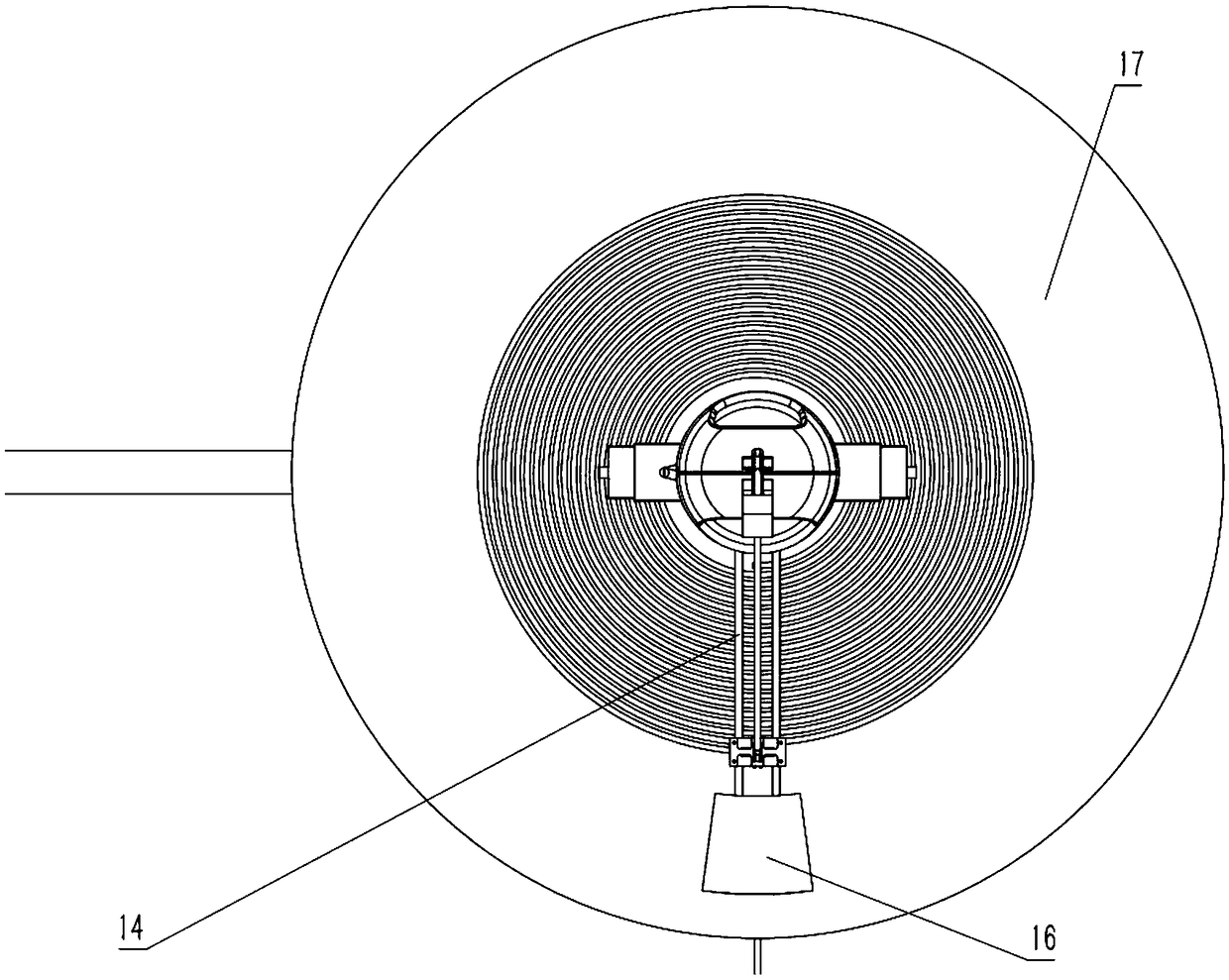

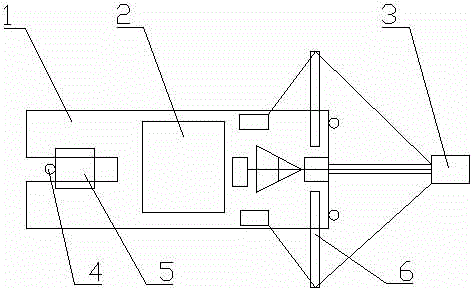

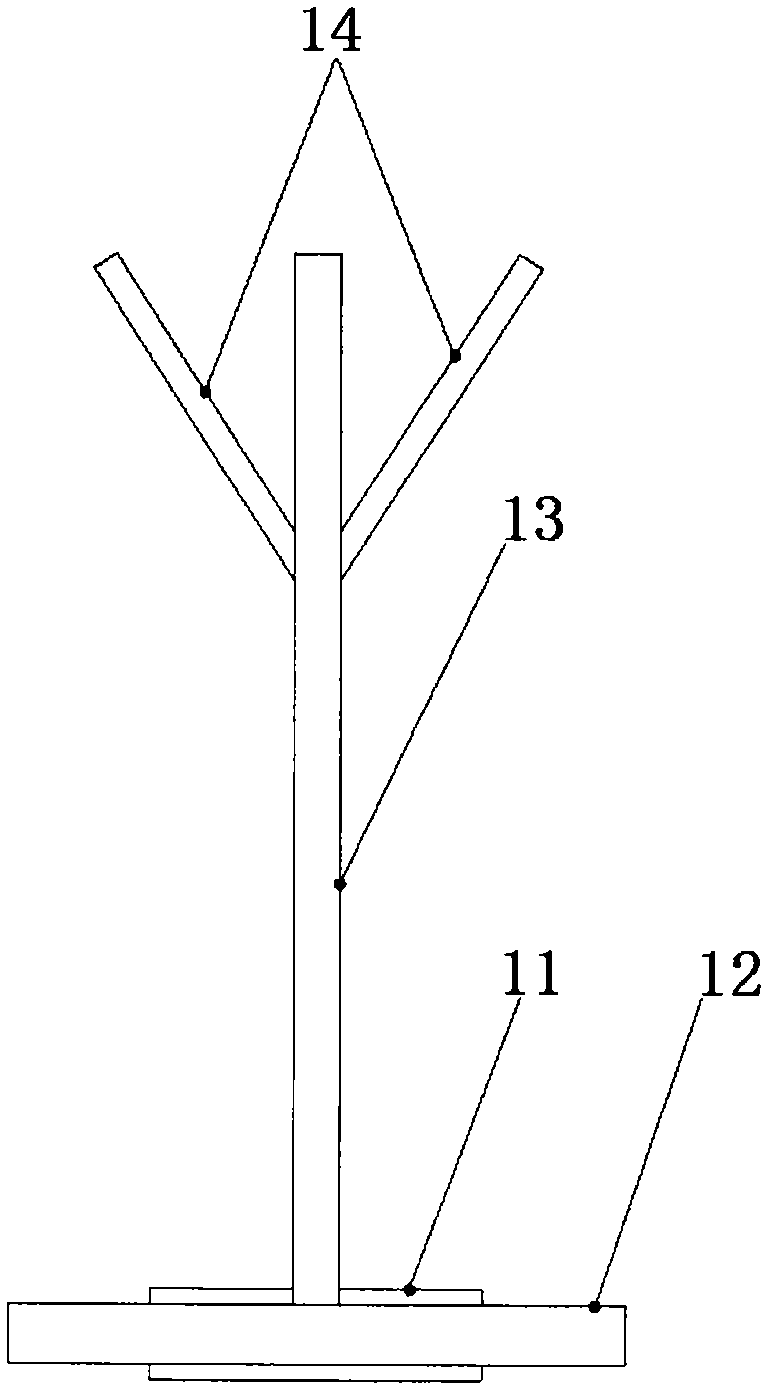

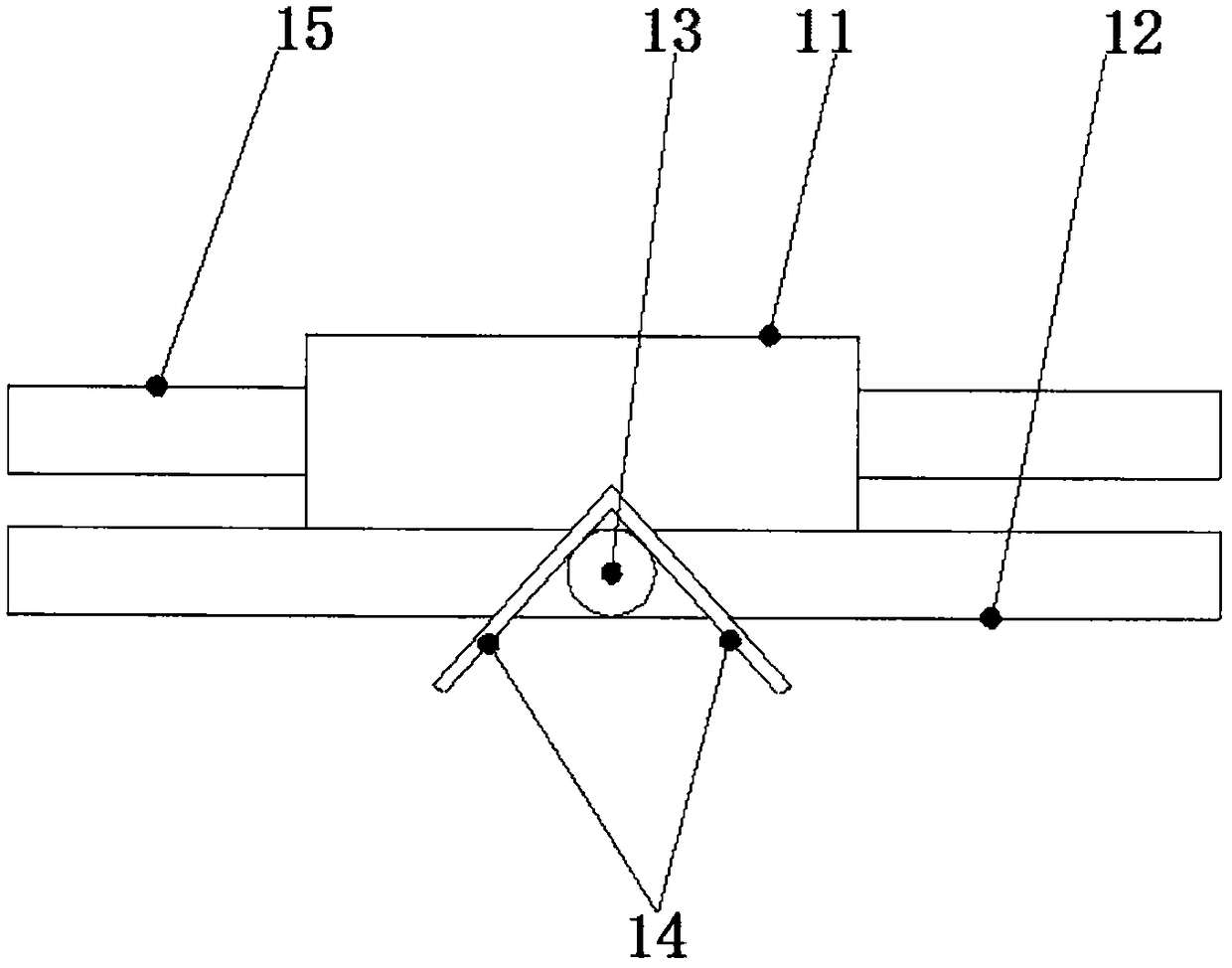

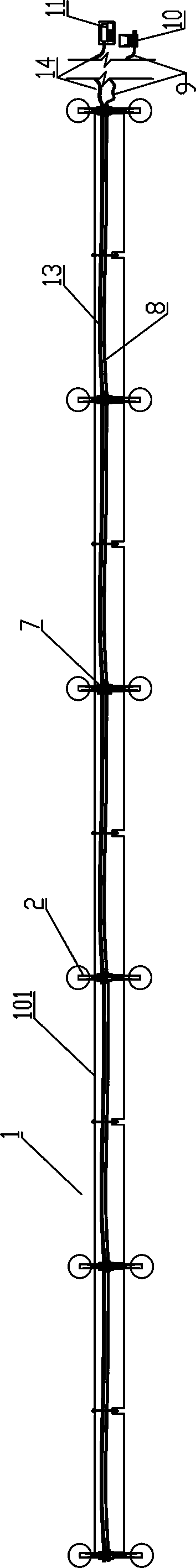

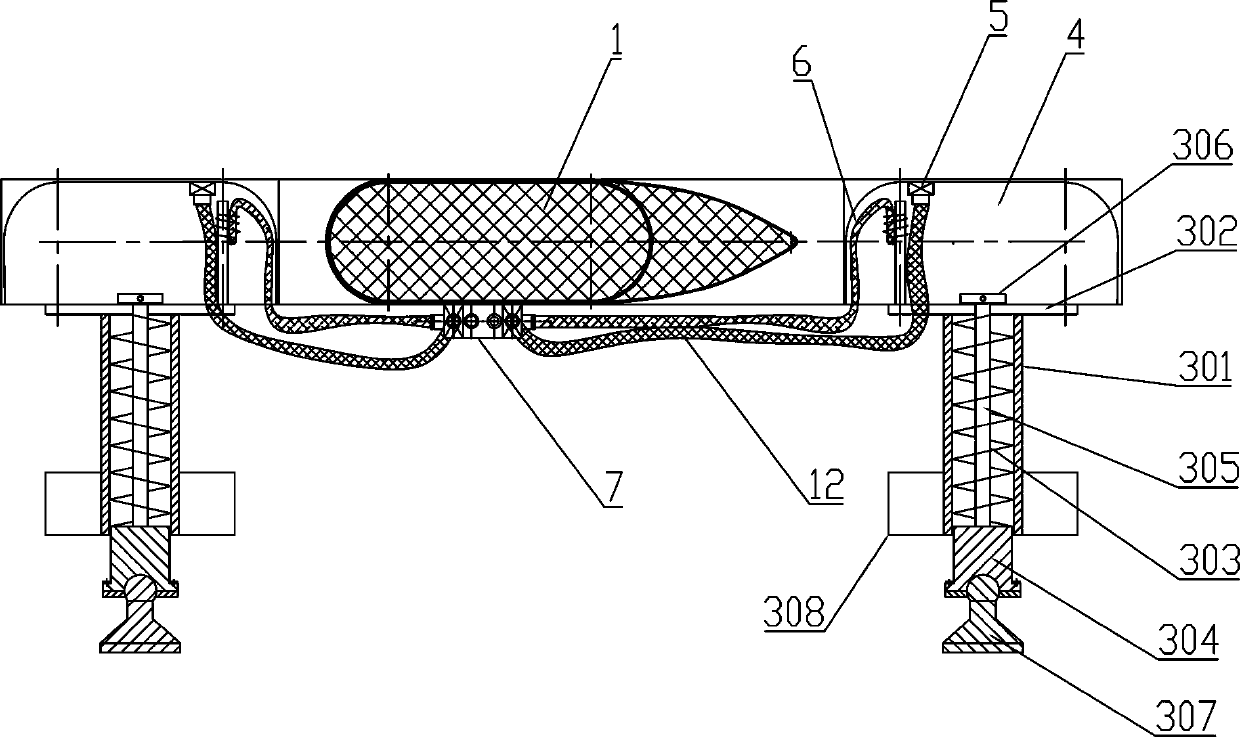

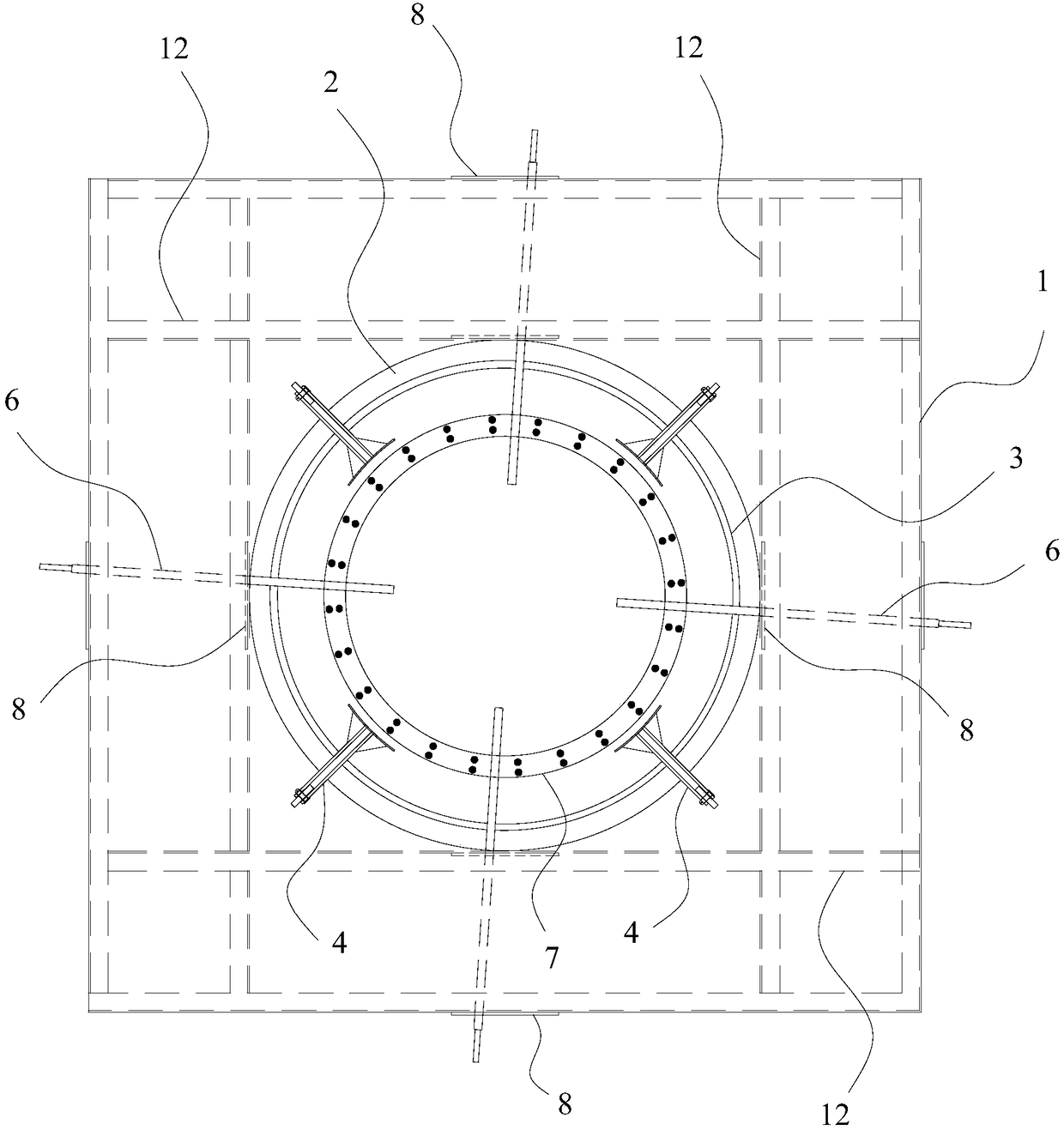

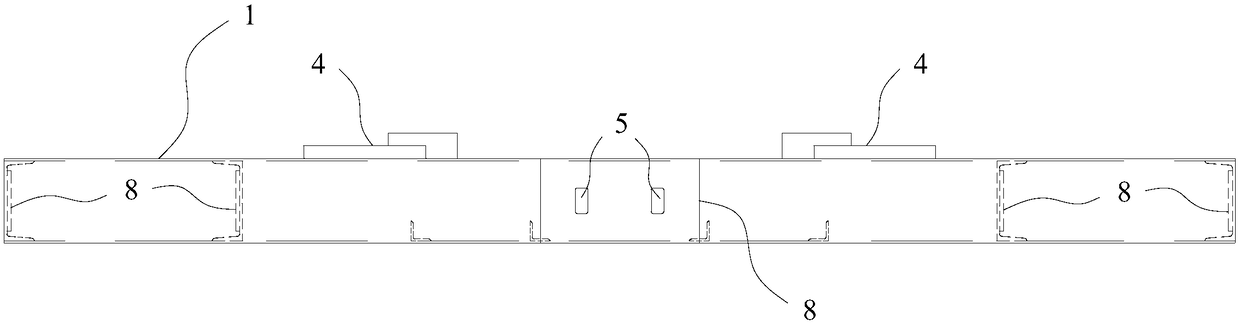

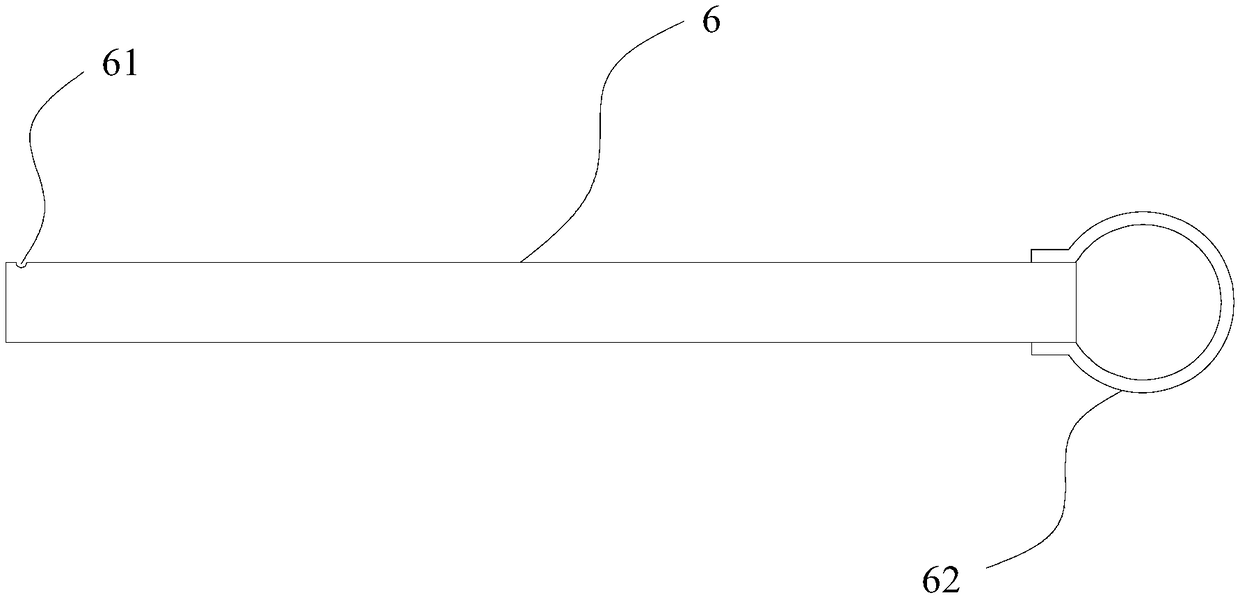

Bionic cable conduit ground storage system for self-balancing drilling tool system

PendingCN109209258AAvoid elevationImprove scalabilityDrilling rodsConstructionsTechnological systemElectro hydraulic

The invention discloses a bionic cable conduit ground storage system for a self-balancing drilling tool system, and relates to the technical fields of boring and drilling. The storage system is composed of a snake coiling imitated cable conduit storage mechanism, a cable conduit storage introducing mechanism and a cable conduct conveying and injection mechanism. The problem that a cable conduit tends to offset on a roller in a lifting drilling tool of a present winch is solved, and the difficulty in electro-hydraulic isolation technology in dynamic-static sealing and dynamic-static states of acable conduit fixing end and a ground stationary part of a rotating roller on the winch is overcome; the cable conduit ground storage requirement of a down-hole torsion self-balancing cabled drillingtool system is satisfied, the storage space is saved, the storage efficiency is improved, the technical bottleneck in lifting and placing down the cable conduit is overcome, and a technical system ofthe down-hole torsion self-balancing cabled drilling tool system is filled and completed.

Owner:JILIN UNIV

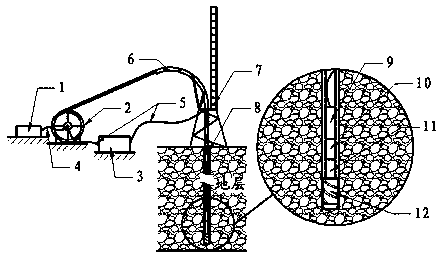

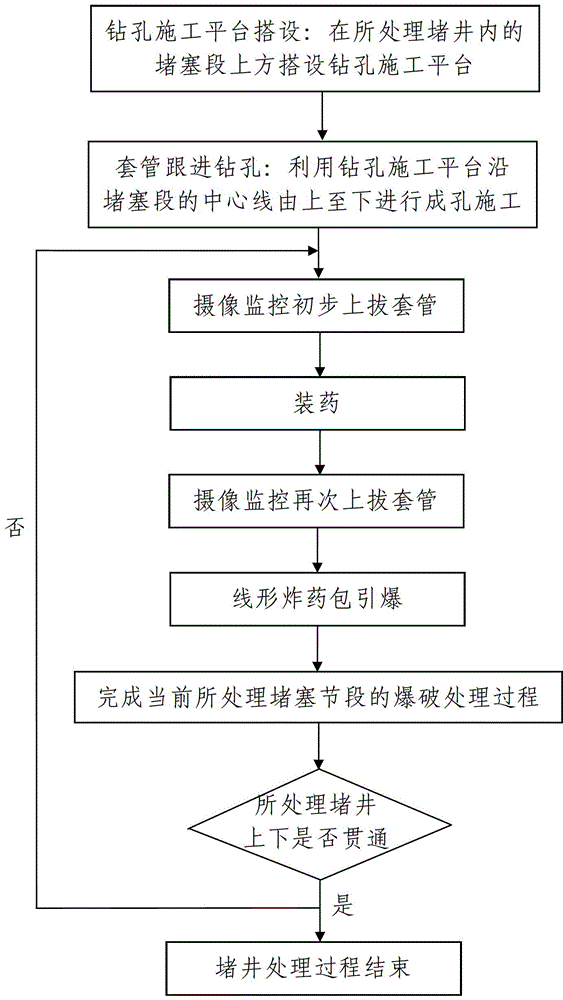

Method for treating well blockage through camera positioning and sectioning blasting

ActiveCN102877808AEasy to operateAccurately find out the blockageBorehole/well accessoriesOperabilityEnvironmental geology

The invention discloses a method for treating well blockage through camera positioning and sectioning blasting. The method comprises the following steps of: (1) building a drilling construction platform: building the drilling construction platform above a blockage section in a blocked well to be treated; (2) utilizing a sleeve pipe to follow up drilling: utilizing the drilling construction platform for pore-forming from top to bottom along a central line of the blockage section; (3) treating the blocked well through sectioning blasting as follows: 301, blasting a blockage segment on the bottom: primarily upwards pulling the sleeve pipe and filling through camera monitoring, secondarily upwards pulling the sleeve pipe, blasting explosives, and judging whether the blocked well to be treated is through up and down or not through camera monitoring; 302, blasting a last blockage segment; and 303, judging whether the blocked well to be treated is through up and down or not; and (4) finishing the whole blocked well treatment process. The method has simple steps, is convenient to realize, and has strong operability, good use effect and small construction condition limitation, so that the construction progress of blocked well treatment is greatly accelerated, the cost is saved, and the safety of blocked well treatment construction can be ensured.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

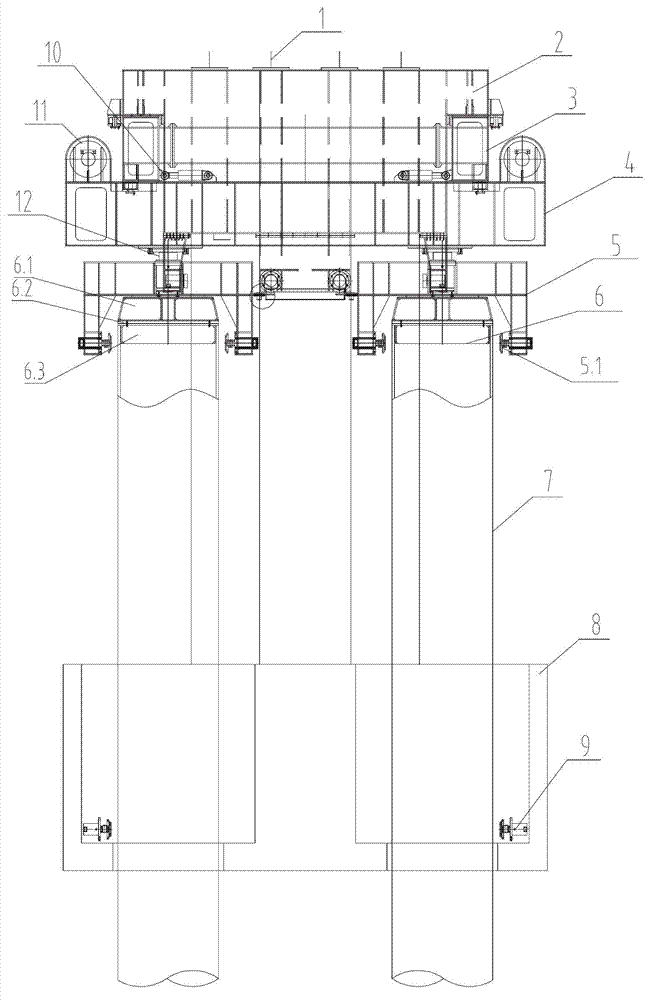

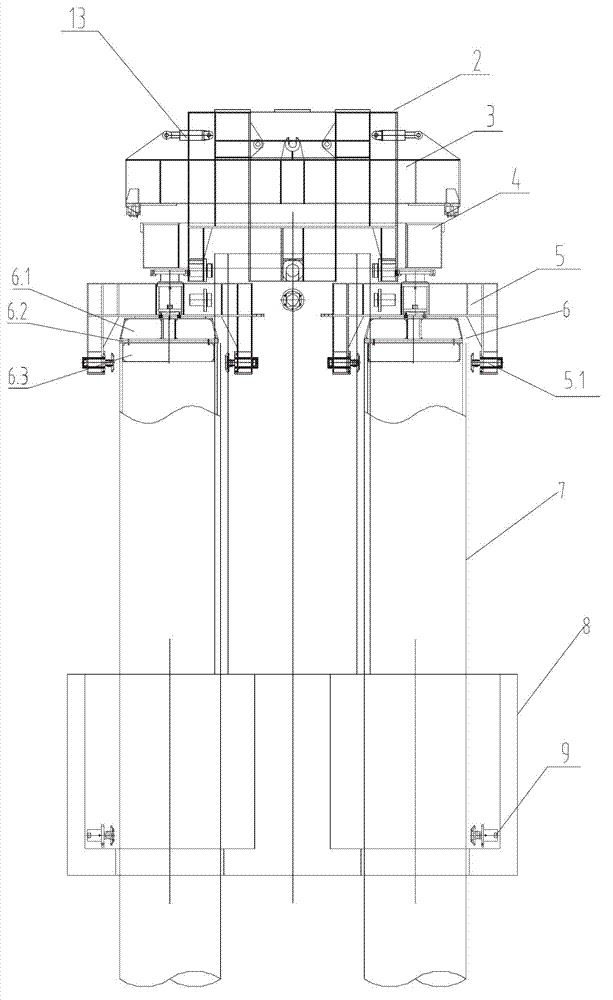

Multifunctional hydraulic hanger for bridge prefabricated foundation construction and construction steps thereof

ActiveCN102926397AWith precise positioning functionReduce construction difficultyFoundation engineeringBridge erection/assemblyPre stressAbutment

The invention discloses a multifunctional hydraulic hanger for bridge prefabricated foundation construction and construction steps thereof. The multifunctional hydraulic hanger comprises a combined girder system structure and a prefabricated abutment, wherein a lifting lug for lifting a whole suspension system is arranged on the combined girder system; a preformed hole allowing a steel pipe pile to pass though is formed in the prefabricated abutment in the vertical direction; a through hole is formed in the combined girder system structure; the girder system structure is integrally linked with the prefabricated abutment through a tensioned prestressed steel reinforcement sleeved in the through hole; a horizontal position regulating mechanism is arranged on the combined girder system structure; and a vertical position regulating oil cylinder and a steel pipe pile guiding mechanism for regulating the verticality and overall elevation of an abutment body are arranged between the lower end surface of the combined girder system structure and the steel pipe pile. The multifunctional hydraulic hanger for the bridge prefabricated foundation construction further has the function of accurately positioning the prefabricated abutment in addition to the functions that the conventional hanger only possesses; and therefore, the construction difficulty caused by system transformation that the conventional hanger is adopted for hanging, then accurate positioning is realized and the like is reduced; and the construction efficiency is improved.

Owner:CCCC SECOND HARBOR ENG +2

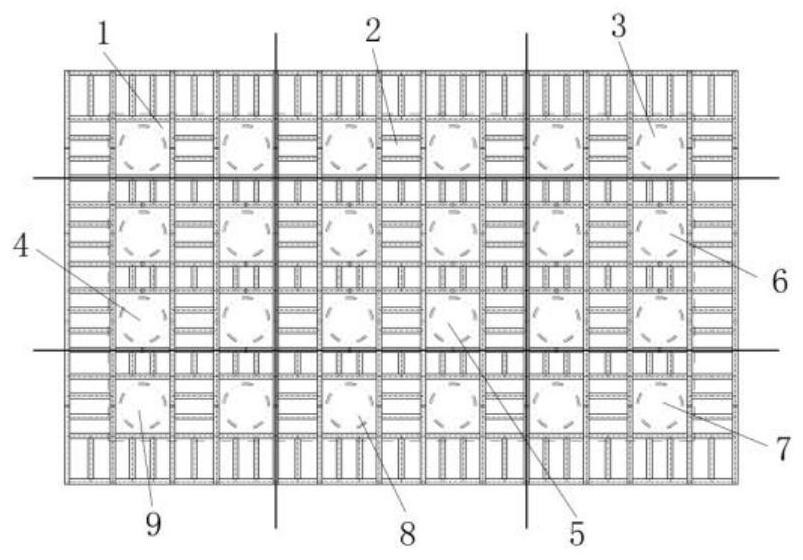

Bottom Compartment for Bottom Sealing of Underwater Sub-cabin of Large Cofferdam and Construction Method of Sub-cabin Bottom Cover

The invention discloses a bottom compartment for bottom sealing of an underwater sub-cabin of a large cofferdam, which relates to the technical field of bridge construction, it is used to separate thecofferdam and seal the bottom, it is characterized that the bottom compartment is composed of at least two compartments, the bulkhead section comprises a truss, at least one side of the truss is provided with a panel, the two panels are sealed and connected, and all the panels can enclose a sealed dividing surface. The bottom compartment for the bottom sealing of the underwater sub-cabin of the large cofferdam provided by the invention is provided with a plurality of bay sections, the structure is simple, the dead weight of each bay section is small, the lowering is convenient, and the cofferdam can be applied to the bottom sealing of the underwater sub-cabin of the large cofferdam and has better construction quality.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

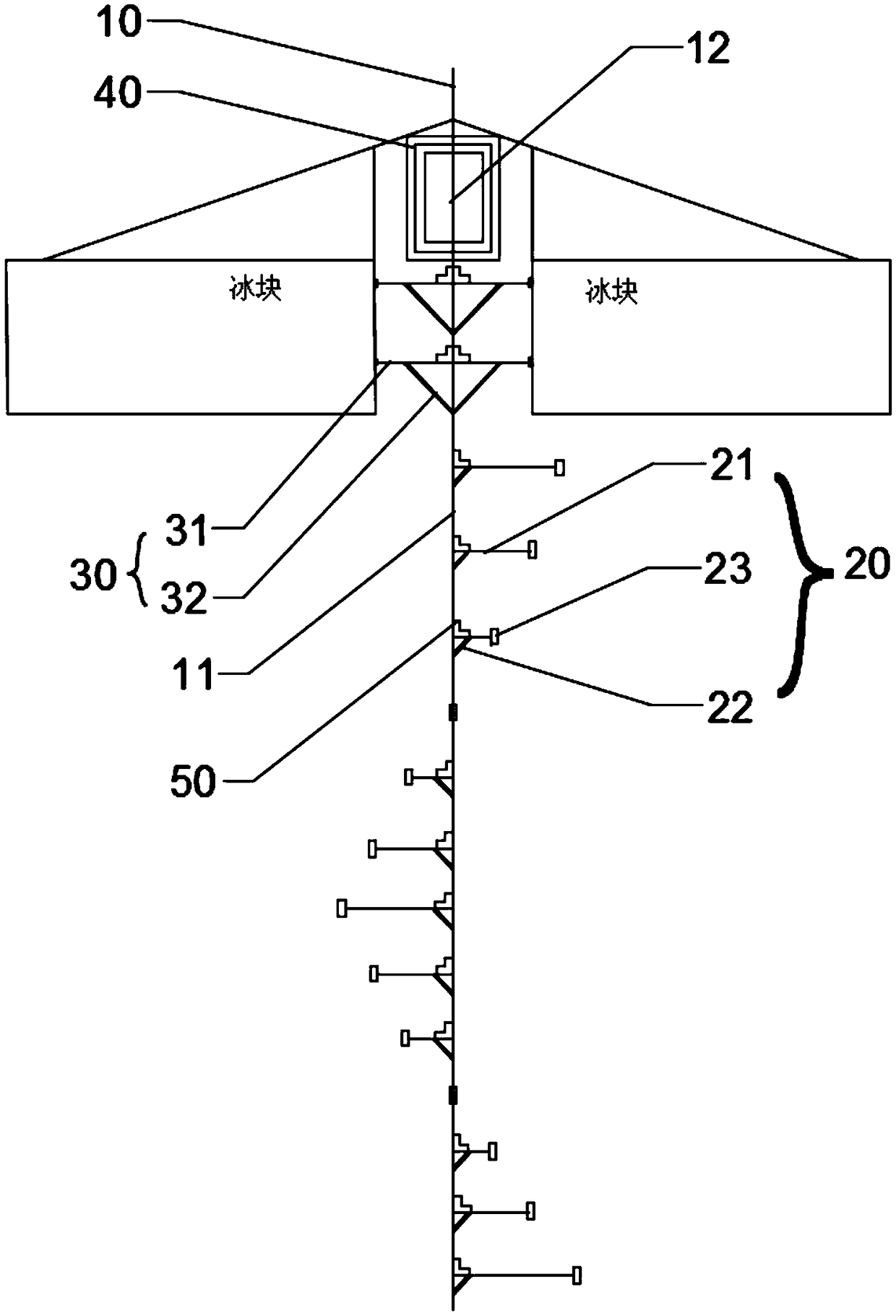

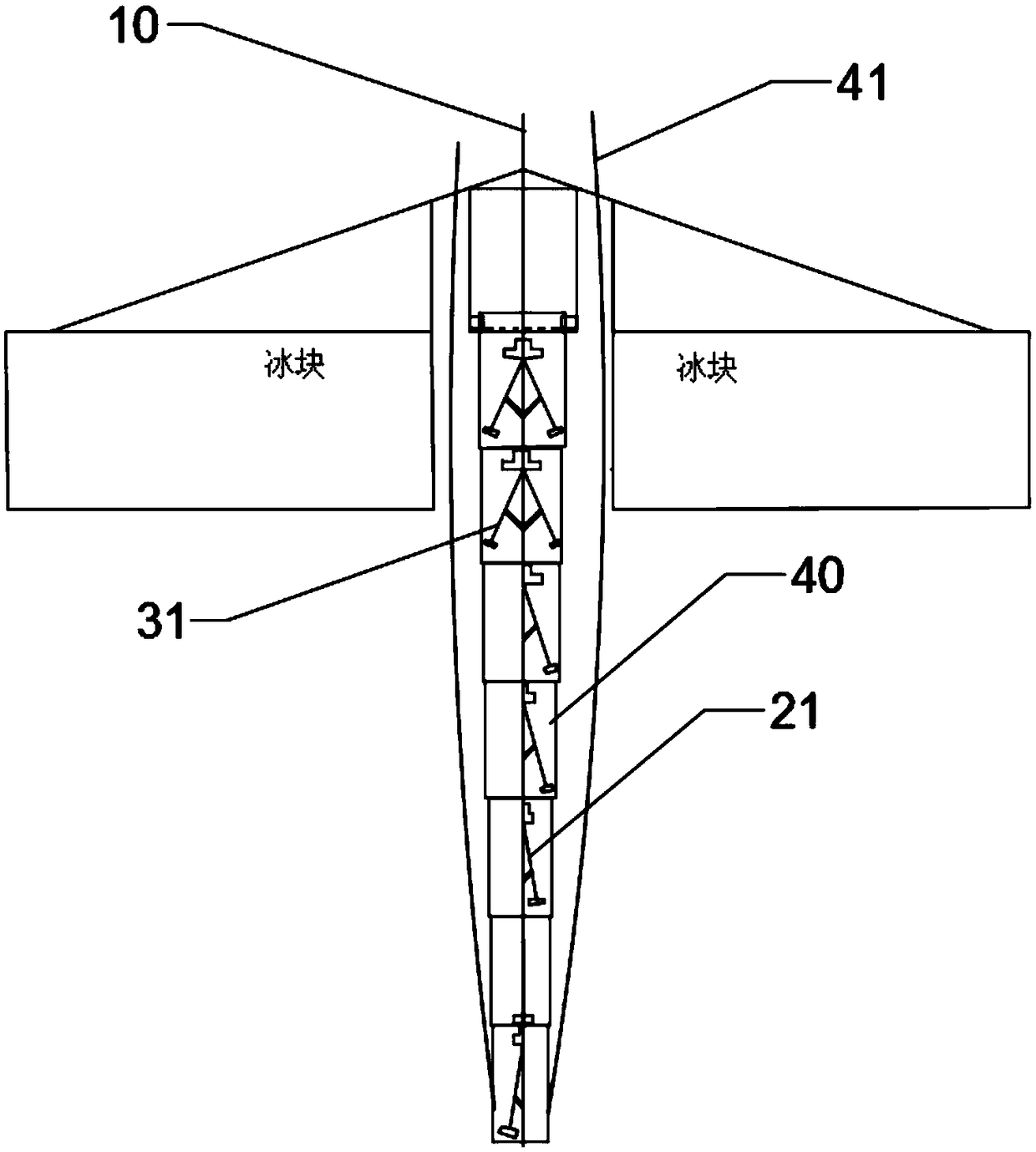

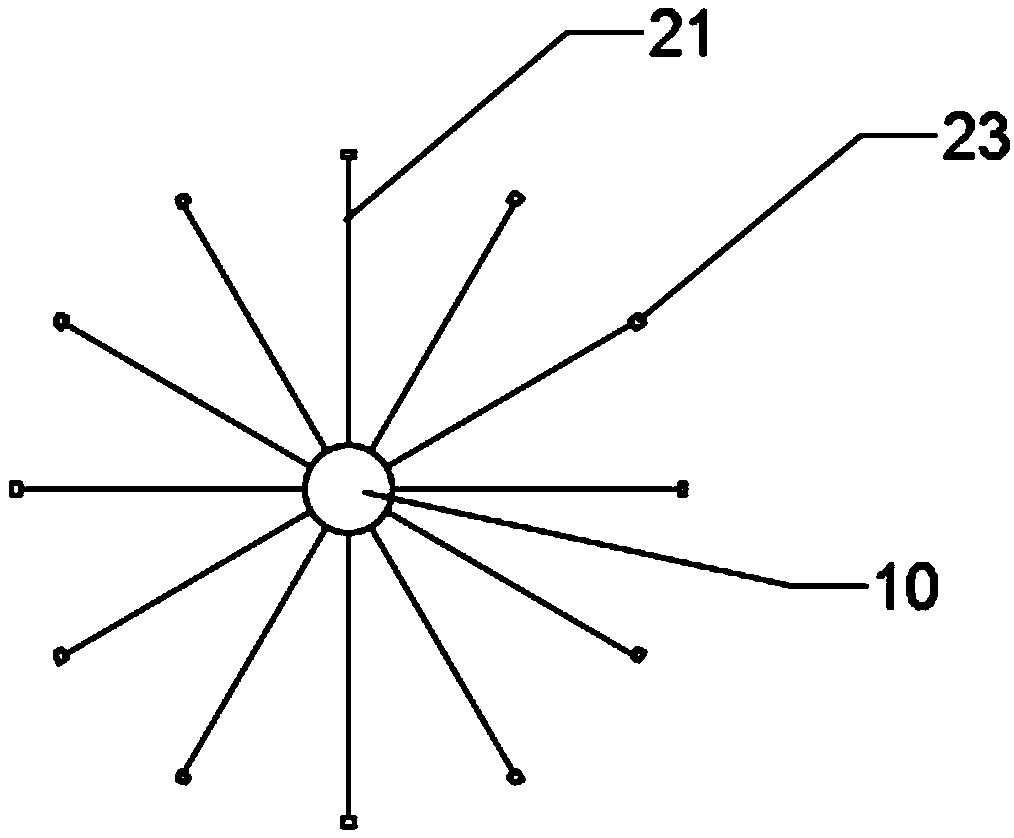

Subglacial marine optical observation equipment

The invention provides subglacial marine optical observation equipment, which comprises a vertical bar, a plurality of measuring units, at least two symmetrically arranged support units and a telescopic sleeve sleeved on the vertical bar. The vertical bar comprises an observation end and a fixed end; the plurality of measuring units are arranged at the observation end of the vertical bar at an equal interval; each measuring unit includes a measuring support, a first spring and a probe; the support units are disposed at the fixed end of the vertical bar; each support unit includes a support rodand a second spring, and one end of the telescopic sleeve is fixed at one side of the fixed end far from the observation end; when the telescopic sleeve contracts, the measuring supports and the support rods are all in an open state; and when the telescopic sleeve extends along the observation end, the support units and the measuring units can be accommodated in the telescopic sleeve. According to the invention, the equipment is not affected by the flow of subglacial seawater, has small error of measured data and improved accuracy, and the protection of the telescopic sleeve also makes the equipment convenient to use and reduces damage.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION +1

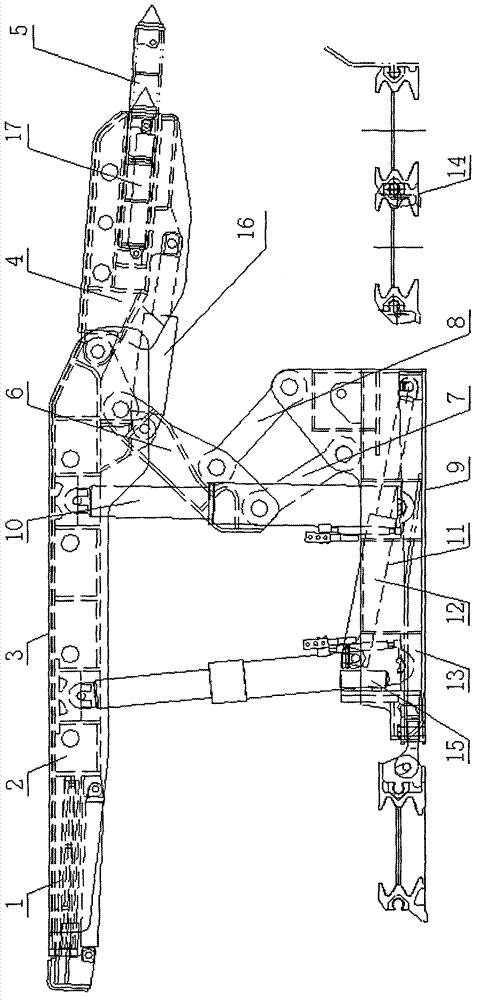

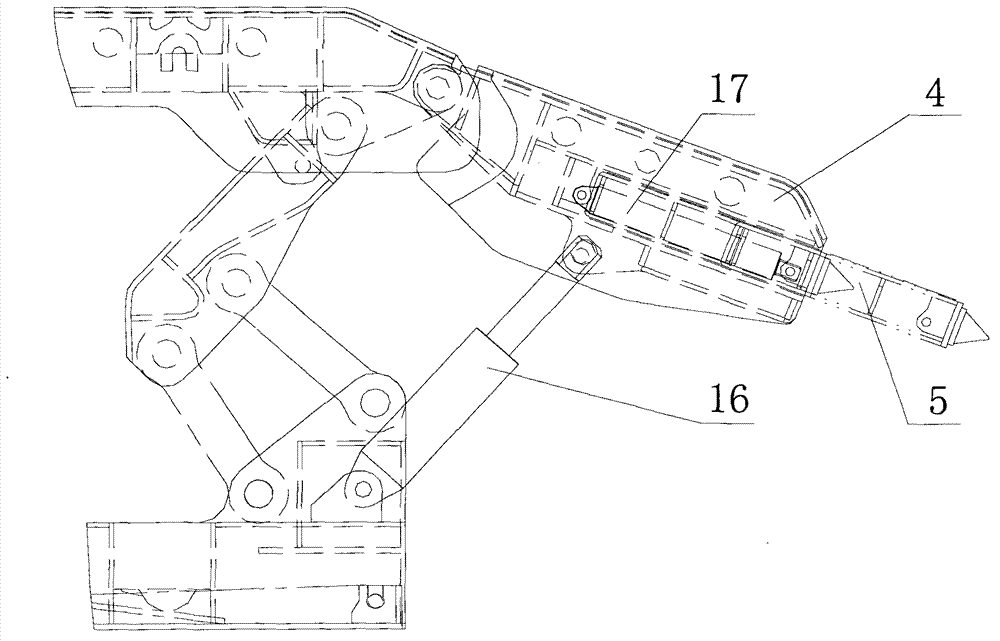

Caving coal hydraulic support with large swing beam structure

InactiveCN102900450ACoal discharge window is largeHigh coal pointMine roof supportsCarrying capacityStructural engineering

The invention discloses a caving coal hydraulic support with a large swing beam structure and is improvement of an existing caving coal hydraulic support. The caving coal hydraulic support with the large swing beam structure is mainly composed of a top beam, a telescopic beam, a shield beam, a side protecting plate, a connecting rod, a base, a thrust mechanism, a column, jacks and an operating valve. The caving coal hydraulic support with the large swing beam structure further comprises a large swing beam, the lower side of the large swing beam is hinged to a swing beam jack, the front end of the large swing beam is hinged to a hinged hole above the rear portion of the top beam, and an oil cylinder of the swing beam jack is hinged to a hinged base below the rear portion of the top beam or the base so as to form a reverse four-linkage structure. Furthermore, an inserting plate and an inserting plate jack are arranged in the large swing beam. The caving coal hydraulic support with the large swing beam structure has the advantages of being large in coal placing window and high in coal placing point, facilitating discharge of large top coal, and facilitating improvement of top coal recovery rate. When the swing beam jack is supported on the base, carrying capacity of the large swing beam can be increased, and lowering of an adjacent coal layer of the nearest coal layer can be performed conveniently.

Owner:SHANDONG UNIV OF SCI & TECH

Underwater sludge suction dredging machine and dredging method

InactiveCN104060639AEasy to liftConducive to decentralizationMechanical machines/dredgersBarges/lightersSludgeMarine engineering

The invention relates to an underwater sludge suction dredging machine and a dredging method. The underwater sludge suction dredging machine comprises a boat body, an operating chamber, a truss, a dredging head, positioning devices, a stepping device, left and right translating devices and sludge discharging devices, wherein the operating chamber is formed on the middle part of the boat body; the dredging head is connected to the head of the boat body through the truss; the positioning devices are arranged on the head and the tail of the boat body; the stepping device is arranged on the tail of the boat body; the left and right translating devices are arranged on the head of the boat body; the dredging head is a dual-bucket wheeled dredging head; one sludge discharging device is arranged in each bucket wheel.

Owner:卜建余

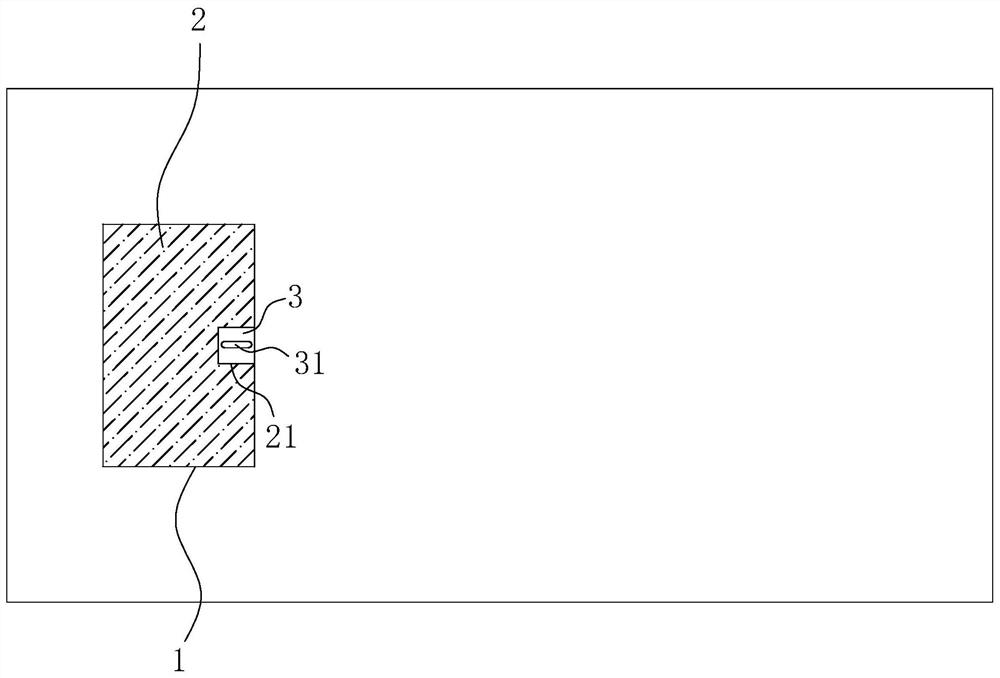

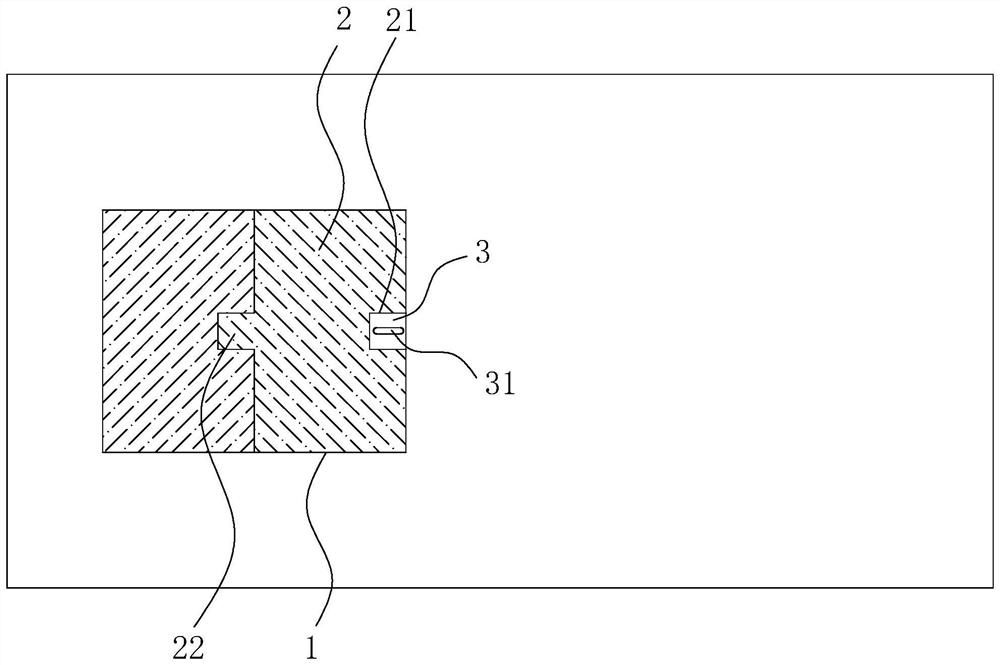

Cast-in-place concrete pile reinforcement cage barbed floating prevention device and application method thereof

The invention provides a cast-in-place concrete pile reinforcement cage barbed floating prevention device. The floating prevention device comprises a base, barbs, springs and limiting stop dogs, wherein the base is fixed to the outer sidewall of a reinforcement cage; one end of each barb is rotatably connected to one end of the base; the springs are used for forming pretightening force between thebarbs and the base; the limiting stop dogs are fixed to the upper surface of the base; one end of each limiting stop dog abuts against the upper surface of the corresponding barb and is used for limiting the extreme position of the barb in the rotating process. According to the floating prevention device, the barbs and the base are connected through hinges and the springs to enable the barbs andthe base to be closed and opened; when the barbs and the base are in an opened state, the reinforcement cage can be dropped and lifted up conveniently; when the barbs and the base are in a closed state, the tip ends of the barbs can firmly grasp the hole wall, and the floating prevention effect is good; during pouring of concrete, the cast-in-place concrete pile reinforcement cage barbed floatingprevention device can prevent the reinforcement cage from floating without additional staff and devices.

Owner:SHANXI CONSTR ENG CO LTD

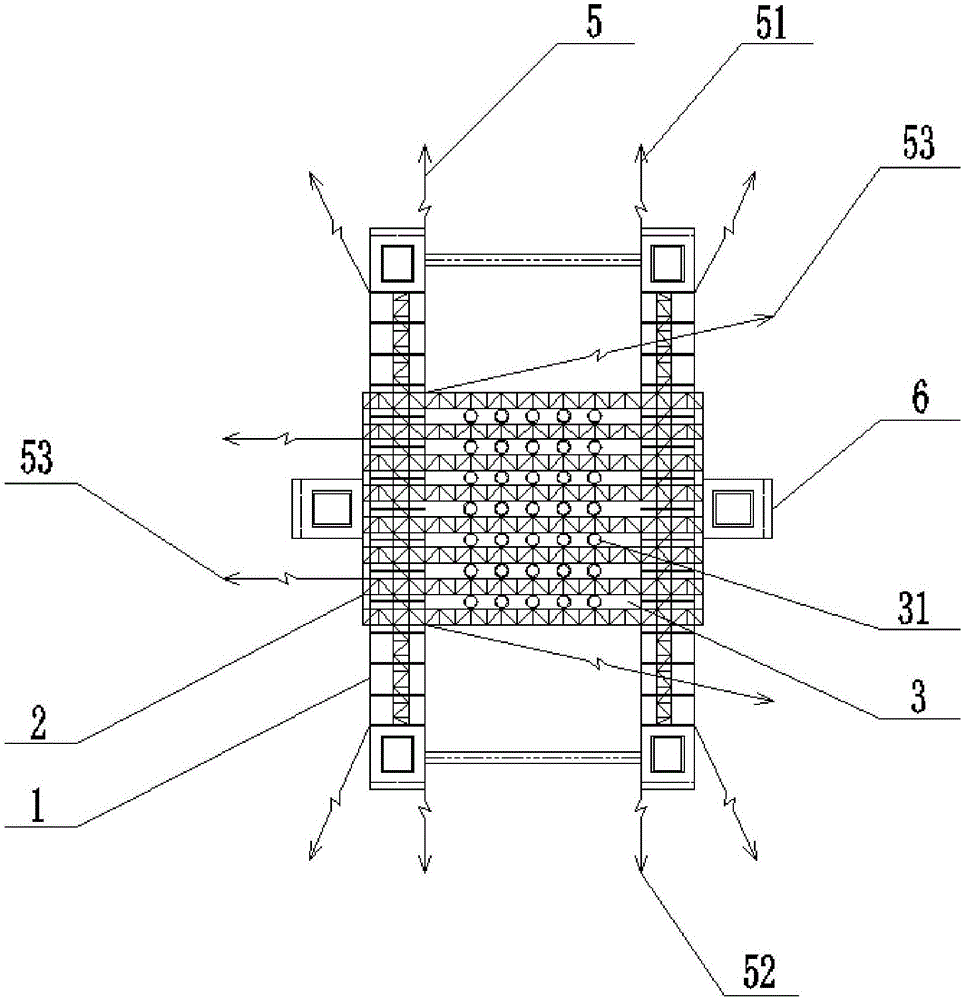

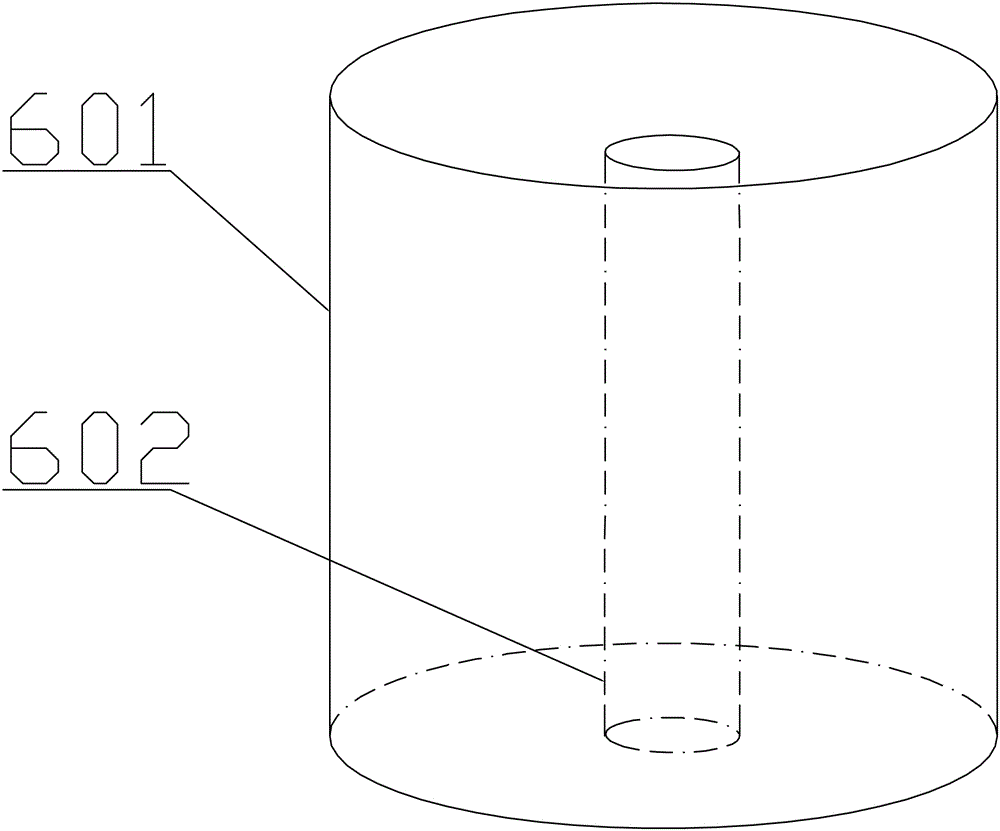

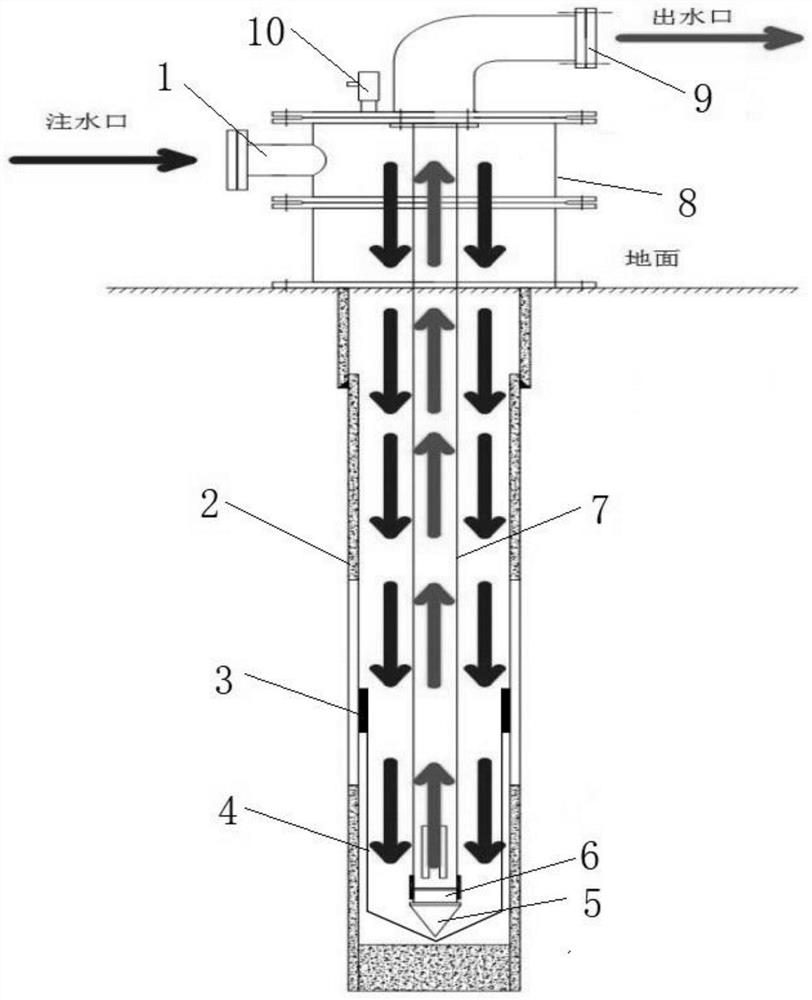

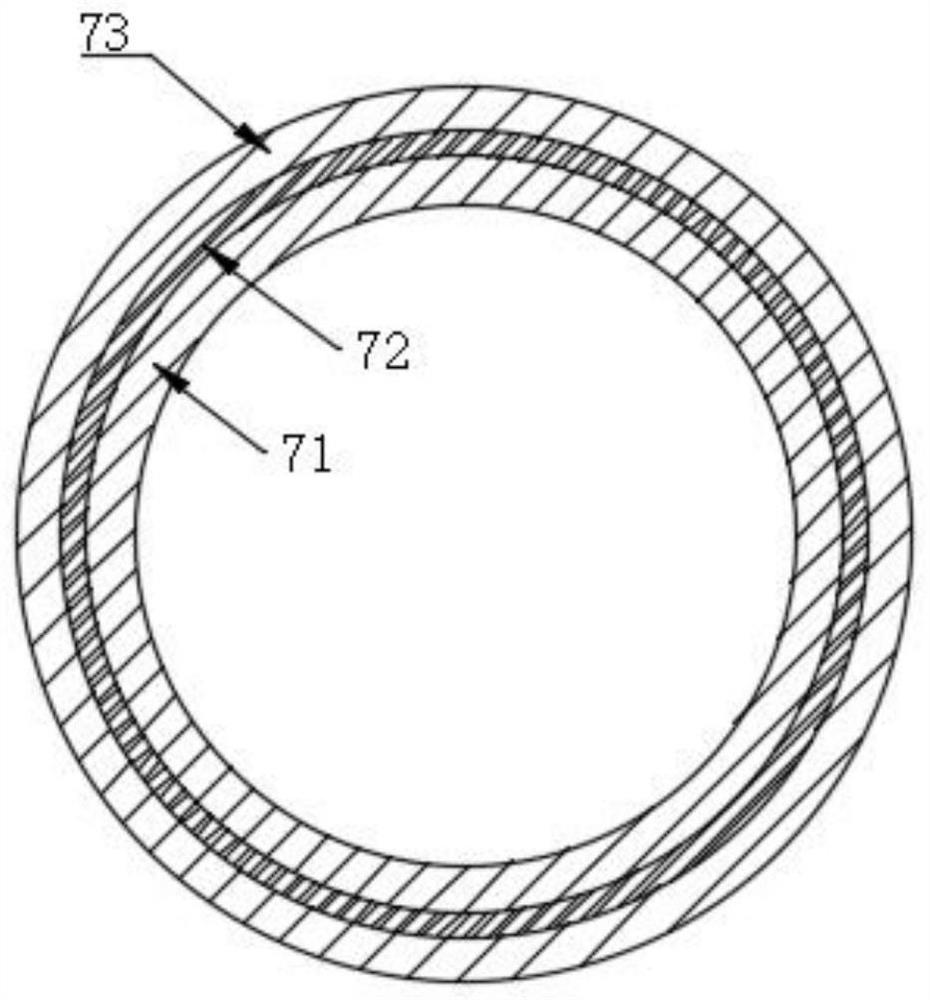

Closed middle-deep geothermal energy underground heat exchange device

PendingCN113587465AAffect the service lifeConducive to decentralizationCollector components/accessoriesLighting and heating apparatusEnvironmental geologyMechanical engineering

The invention relates to a closed middle-deep geothermal energy underground heat exchange device. The device comprises a heat removal inner pipe, a heat exchange sleeve and a support device, wherein the support device is arranged on the ground of a geothermal well; the upper end of the heat removal inner pipe is connected with the support device, and the lower end of the heat removal inner pipe extends into the bottom of the geothermal well; the heat exchange sleeve is arranged at the lower part of the heat removal inner pipe in a sleeving manner; a packer is arranged between the heat exchange sleeve and the geothermal well; a water injection pipe is arranged on the side surface of the support device; a water outlet pipe connected with the heat removal inner pipe is arranged at the top of the support device; and the lower end of the heat removal inner pipe is connected with a screen pipe and a balance weight pipe. The screen pipe is connected to the lower end of the heat removal inner pipe, water flow flowing through the heat removal inner pipe can be filtered by the screen pipe and then enters the heat removal inner pipe, and impurities in the water flow can be blocked outside the heat removal inner pipe by the screen pipe, so that the situation that the inner wall of the heat removal inner pipe is abraded by the impurities and the service life of the heat removal inner pipe is affected is avoided.

Owner:天津鑫新源节能科技有限公司

Method for preventing hole collapse of drilling pile by automatic ejecting steel protection cylinder

The invention discloses a method for preventing hole collapse of a drilling pile by automatic ejecting a steel protection cylinder. The method is characterized in that the steel protection cylinder which can be automatically ejected after being rolled is lowered into a to-be-supported position in the drilling pile, so that the steel protection cylinder is ejected, and the outer wall of the steel protection cylinder and the hole wall of the drilling pile are bonded and fixed to form a support. According to the method, a steel protection cylinder device capable of being automatically ejected anda steel protection cylinder lifting and placing device are used for construction, the steel protection cylinder device capable of being automatically ejected comprises the cylindrical steel protection cylinder formed by rolling a steel plate, the two ends of the steel plate are in lap joint to form handers, a steel bar is welded to the inner side face of the hander, located on the outer side, ofthe steel protection cylinder in the height direction of the steel protection cylinder to form a retraction clamping groove, a plurality of nuts are arranged at the handers position of the steel protection cylinder, the handers of the steel protection cylinder are connected through bolts inserted in the nuts, the top ends of the bolts are connected with connecting ropes, a plurality of steel bar heads are fixedly connected to the outer side surface of the steel protection cylinder, and the steel protection cylinder can be sleeved on the steel protection cylinder lifting device.

Owner:CHINA RAILWAY NO 10 ENG GRP NO 1 ENG CO LTD

Cutter suction underwater silt remover with double bucket-wheels and three cutters

ActiveCN104264735AEasy to installEasy to transportMechanical machines/dredgersUnderwaterMarine engineering

The invention relates to a cutter suction underwater silt remover with double bucket-wheels and three cutters. The cutter suction underwater silt remover comprises a floating body, an operating cab and a silt removing device, wherein the operating cab is arranged in the middle part of the floating body and the silt removing device is connected to the head of the floating body; the cutter suction underwater silt remover further comprises positioning devices, a stepping device, a left-and-right transverse shifting device and a silt inflow device, wherein the positioning devices are arranged on the head and the tail of the floating body, the stepping device is arranged on the tail of the floating body, the left-and-right transverse shifting device is arranged on the head of the floating body; a silt removing head is a silt removing with double bucket-wheels and the silt inflow device is arranged in the silt removing head. The cutter suction underwater silt remover with double bucket-wheels and three cutters has the advantages of stable positioning, accurate stepping, adjustable left-and-right range of silt removing swing width, and thorough silt removal.

Owner:卜建余

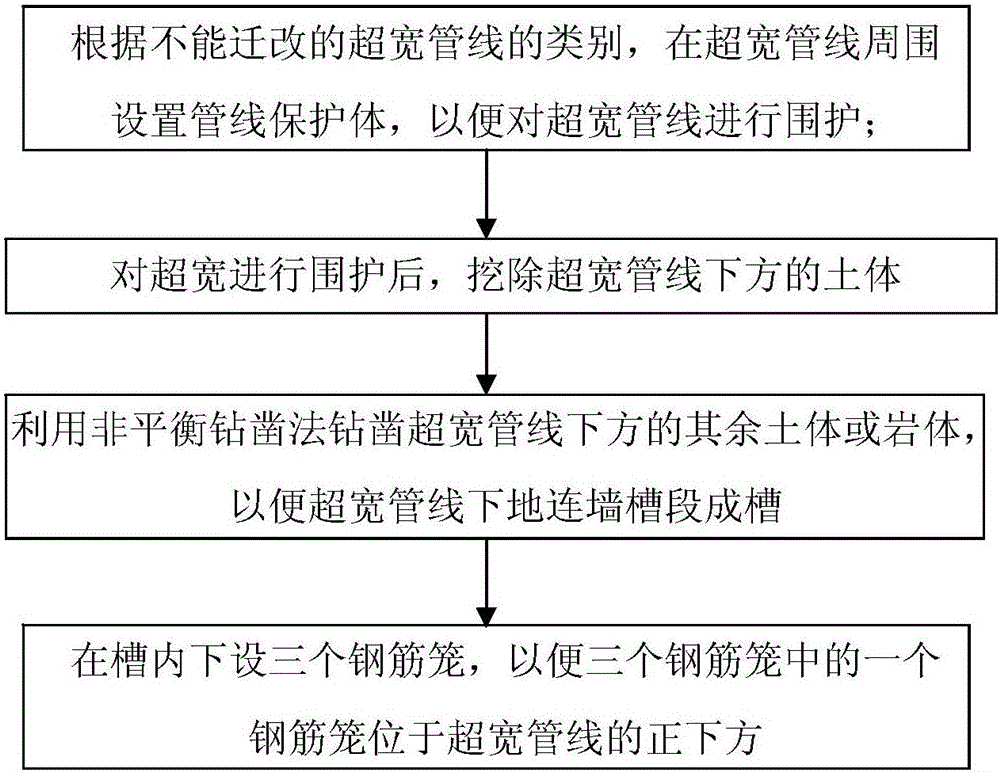

Construction method for underground continuous wall below ultra-wide pipeline

ActiveCN105926584AGuarantee the quality of the projectSpeed up the progress of the projectBulkheads/pilesRebarExcavator

The invention discloses a construction method for an underground continuous wall below an ultra-wide pipeline. The construction method includes the steps that according to the category of the ultra-wide pipeline incapable of being moved and modified, a pipeline protecting body is arranged around the ultra-wide pipeline so that the ultra-wide pipeline can be conveniently enveloped and protected; after the ultra-wide pipeline is enveloped and protected, the soil mass below the ultra-wide pipeline is excavated through a long-arm excavator; after the soil mass below the ultra-wide pipeline is excavated, the rest of soil mass or rock mass below the ultra-wide pipeline is drilled through a non-balanced drilling method so that an underground continuous wall groove segment below the ultra-wide pipeline can conveniently form a groove; and after the underground continuous wall groove segment below the ultra-wide pipeline forms the groove, three reinforcement cages are downwards arranged in the groove so that one of the three reinforcement cages can be conveniently located under the ultra-wide pipeline. According to the method, the groove is formed through the non-balanced drilling method, the reinforcement cages are downwards arranged in the manner that one groove is provided with the three cages, the engineering quality is guaranteed, the engineering progress is accelerated, and the moving and modifying cost is saved.

Owner:SINOHYDRO FOUND ENG

Concrete diaphragm wall construction method

InactiveCN112554217AFirmly connectedConducive to decentralizationBulkheads/pilesArchitectural engineeringMarking out

The invention relates to a concrete diaphragm wall construction method. The concrete diaphragm wall construction method comprises the following steps that S1, site leveling mechanical equipment is used for conducting site leveling operation on an area where holes are to be excavated and formed; S2, surveying and setting out are conducted, specifically, surveying and marking out are conducted on the construction ground according to a design drawing of a concrete diaphragm wall; S3, groove-shaped holes are excavated in the construction ground through large excavating mechanical equipment; S4, before concrete is poured into the groove-shaped holes, groove-forming columns are downwards put into the groove-shaped holes, the concrete is poured after the groove-forming columns are put down, and after the concrete is firmly formed, the groove-forming columns are taken out of formed concrete wall sections; S5, the step S3 and the step S4 are continuously and sequentially repeated, holes are formed beside the formed concrete wall sections, concrete is poured, and a concrete continuous wall is finally formed by each concrete wall section; S6, maintenance is conducted; and S7, quality inspection is conducted. The concrete diaphragm wall construction method has the effect of improving the connecting firmness of the two adjacent concrete wall sections.

Owner:浙江河海建设有限公司

Building engineering manual lifting device

InactiveCN111547639AEasy to operate and controlReduce energy consumptionPortable liftingWinding mechanismsRatchetArchitectural engineering

The invention discloses a building engineering manual lifting device. The device comprises a box, two direction-changing fixed pulleys symmetrically fixed to the top of a wall and two pulley blocks, wherein two triangular suspenders are symmetrically mounted on the upper surface of the box, a fixed wheel is mounted on each triangular suspender, the two fixed wheels are connected with the two pulley blocks respectively in a hanging mode, and an adjustment rope is wound around each direction-changing fixed pulley and the corresponding pulley block at the same side. According to the device, the box can be easily lifted by manpower through the pulley blocks, the box can be lifted to be suspended at a fixed point through cooperation of an inner ratchet and a spring pawl in a control box, and safety is enhanced; a special-shaped rotary shaft is in linkage with the spring pawl through a connecting rope, and the control box can conveniently place the box down; and through a reset spring in cooperation with the special-shaped rotary shaft, danger caused by hand slip is avoided, and the safety of the device is further enhanced.

Owner:天长市千盛建设有限公司

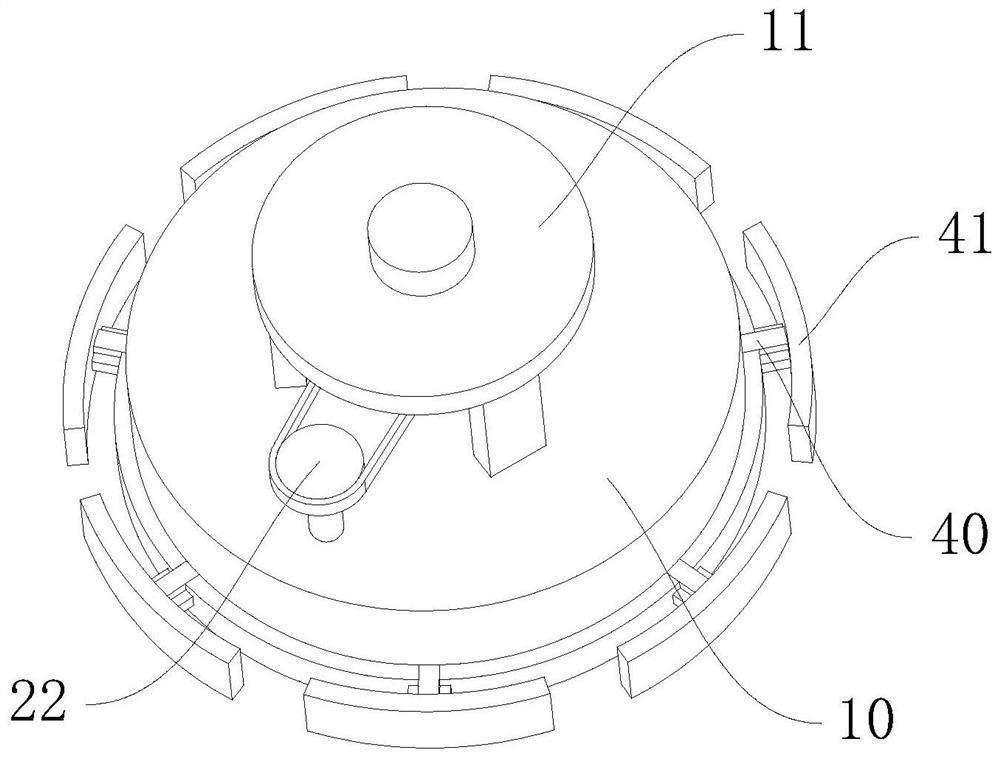

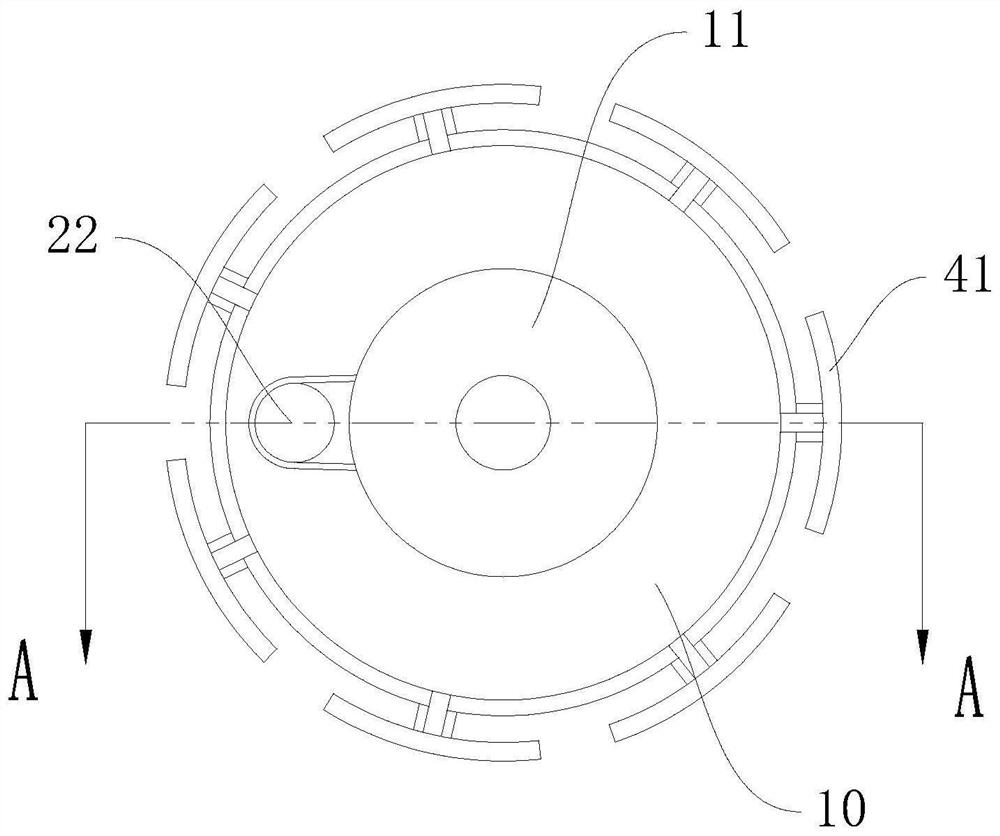

Mechanical hand

InactiveCN111889609ANot easy to grabConducive to decentralizationGripping headsForging/hammering/pressing machinesRobot handEngineering

The invention discloses a mechanical hand, and belongs to the field of automation. The device comprises a support, multiple grabbing devices and a drive device. The support comprises a round bottom disc, a cover body and a hanging bracket, and the cover body is fixedly arranged on the bottom disc. The hanging bracket is fixedly arranged on the cover body and used for providing hanging fulcrums. The grabbing devices comprise sliding rods and supporting plates corresponding to the sliding rods one to one. The sliding rods are slidingly arranged on the bottom disc, the multiple sliding rods are evenly arranged along the circumference of the center of the bottom disc, the supporting plates are of arc-shaped structures bent towards the center of the bottom disc, and the supporting plates are fixedly arranged at the ends, away from the bottom disc, of the sliding rods. The drive device is used for driving the sliding rods to be away from or close to the bottom disc. The inner rings of annular workpieces are grabbed, the external space is not occupied, the inner rings of the annular workpieces are jacked through the supporting plates, the annular workpieces are clamped through friction force, when the annular workpieces are released, it is only needed to draw the sliding rods in inwards, and the annular workpieces are easy to release and grab.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Bottom-sitting-type underwater platform adapting to uneven water bottoms and storing and expanding method of bottom-sitting-type underwater platform

ActiveCN109850101AImprove rigidityConducive to decentralizationUnderwater equipmentMarine engineeringSystem building

The invention provides a bottom-sitting-type underwater platform adapting to uneven water bottoms and a storing and expanding method of the bottom-sitting-type underwater platform. The bottom-sitting-type underwater platform comprises an underwater platform main body, a rigid support set, elastic supports and salvage barrel type auxiliary storing and expanding systems; the rigid support set comprises a plurality of rigid supports which are arranged on the underwater platform main body at intervals; the elastic supports are arranged at the bottoms of the two ends of the rigid supports; and thesalvage barrel type auxiliary storing and expanding systems are mounted in the rigid supports. The bottom-sitting-type underwater platform can provide multi-point elastic supporting and can adapt to mooring of the uneven water bottoms, and the system building cost is lowered.

Owner:CHINA THREE GORGES UNIV

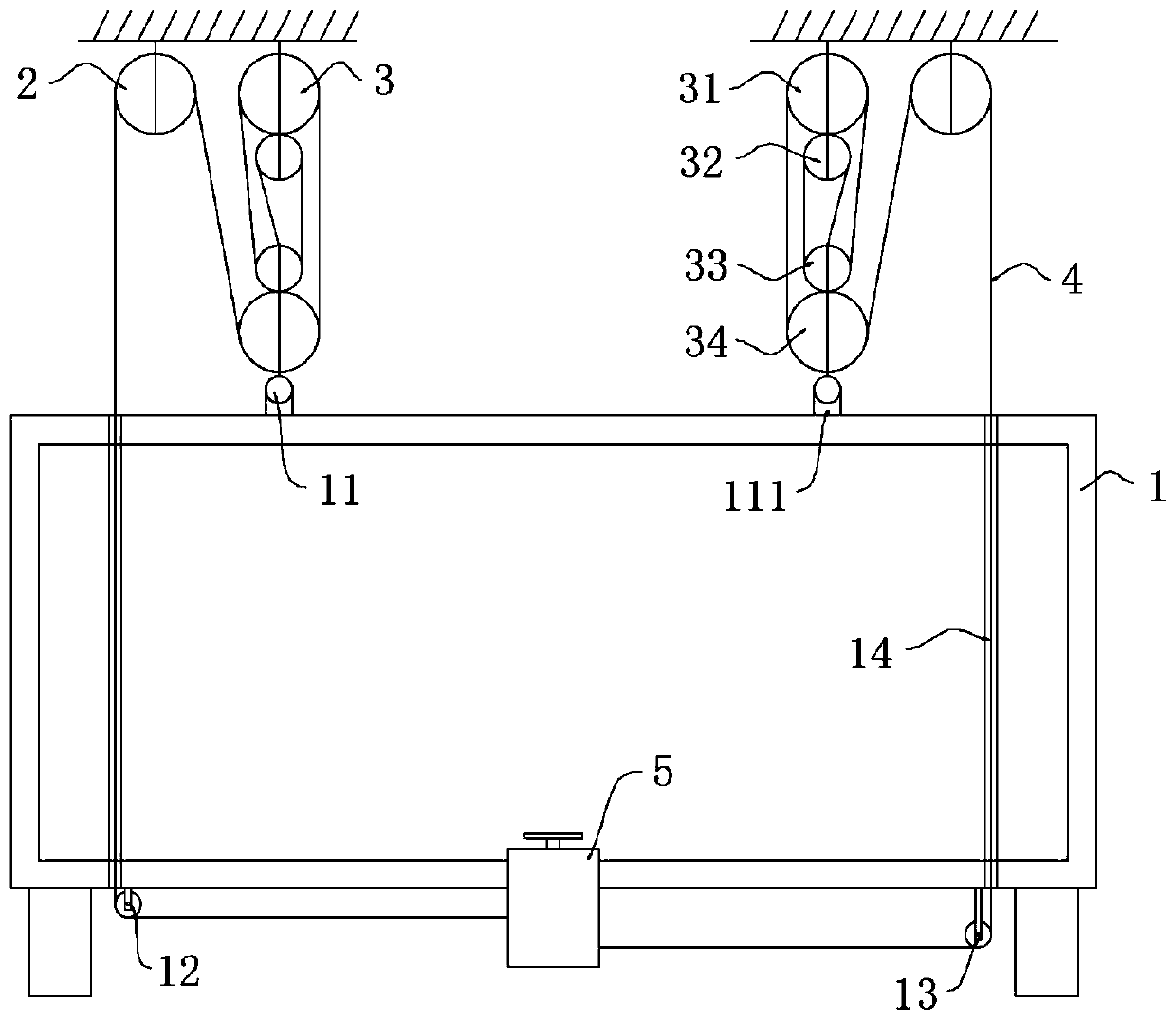

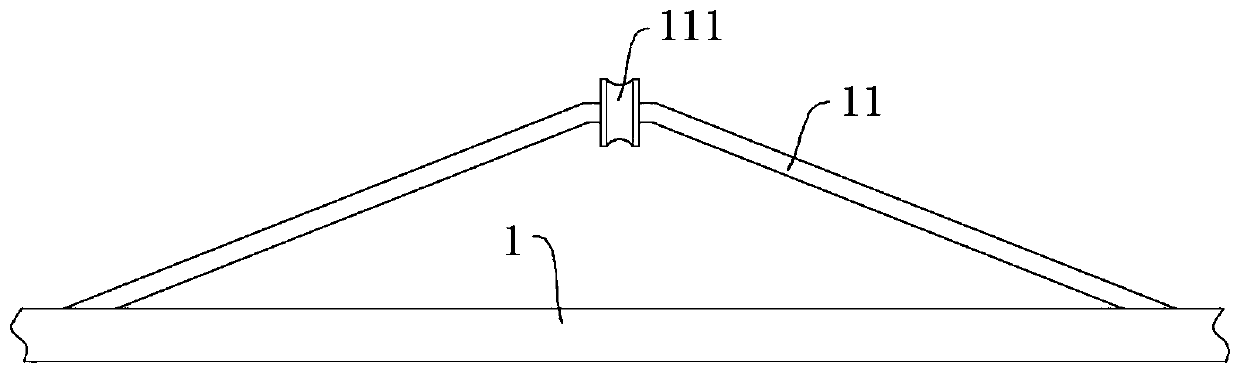

Installation platform of reinforcement cage and using method thereof

The invention discloses an installation platform of a reinforcement cage and a using method thereof. The installation platform comprises a body which contains a cuboid, the body is provided with a through hole, the diameter of the through hole is matched with the diameter of a protective cylinder, the height of the lower surface of the body is larger than the height of the top face of the protective cylinder, at least two limiting parts are arranged on the upper surface of the body, and the front ends of all the limiting parts extend into the through hole; the front ends of all the limiting parts are concentric, all the front ends are concentric with the protection cylinder, and at least one communicating hole channel is formed in each side face of the body; and the sizes of the hole channels are adaptive in the sizes of bolts, and all the bolts are used for being connected with the body and the reinforcement cage. By the adoption of the device, the operation platform can be provided when the reinforcement cage is installed and concrete is poured, so that the installation stability of the reinforcement cage is ensured, the construction difficulty of workers is lowered, the construction efficiency is improved, the operation progress is accelerated, the positioning of the reinforcement cage is effectively realized, and the installation quality of the reinforcement cage is improved.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

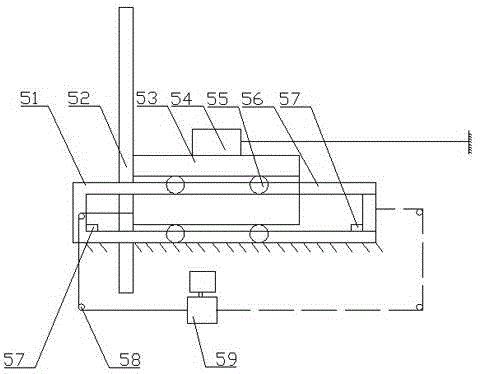

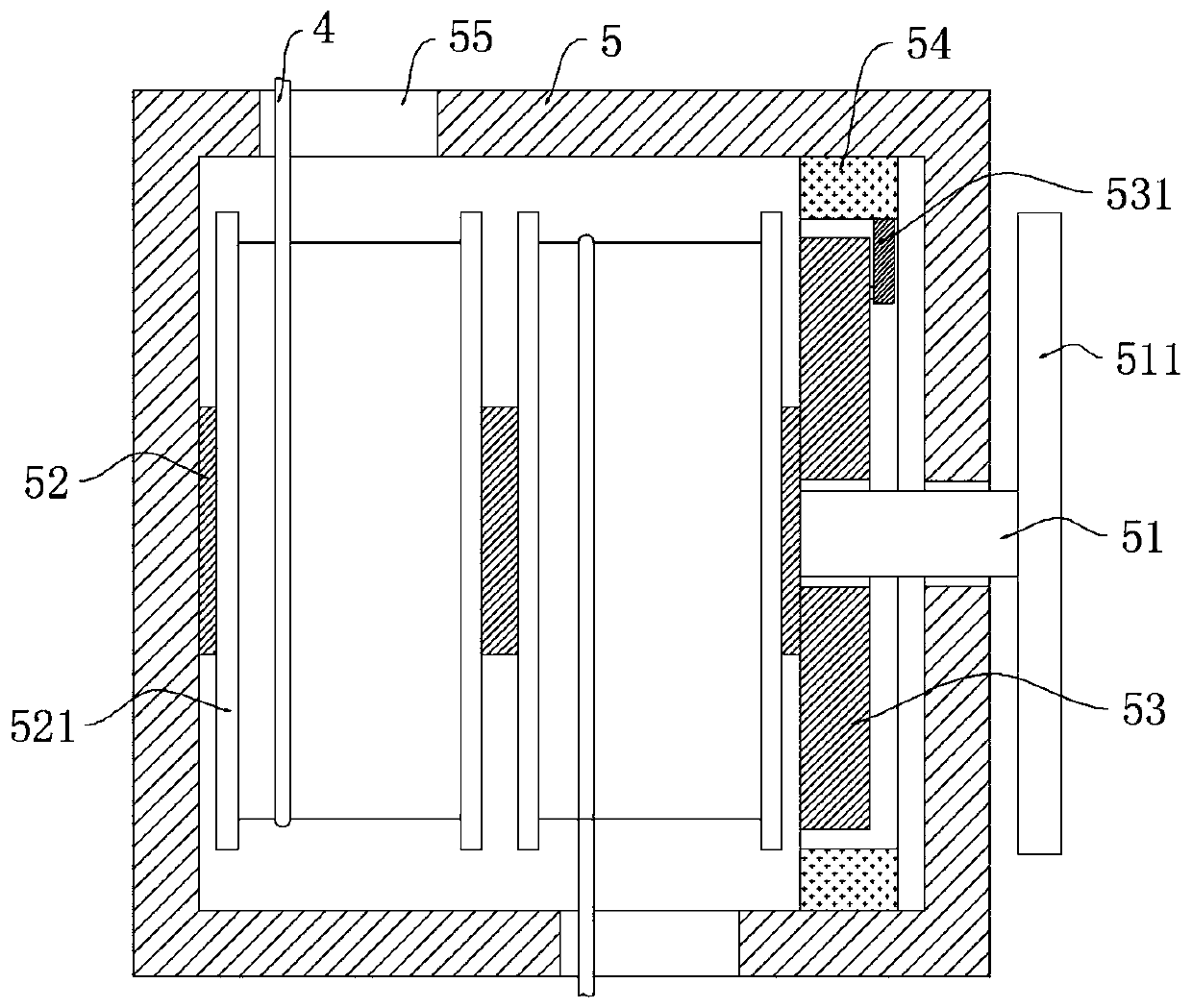

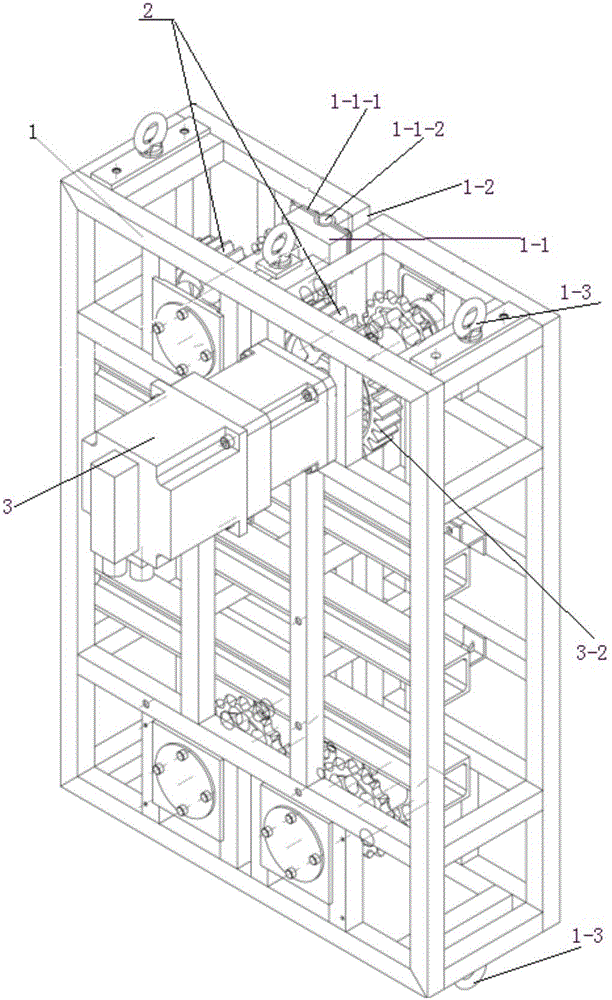

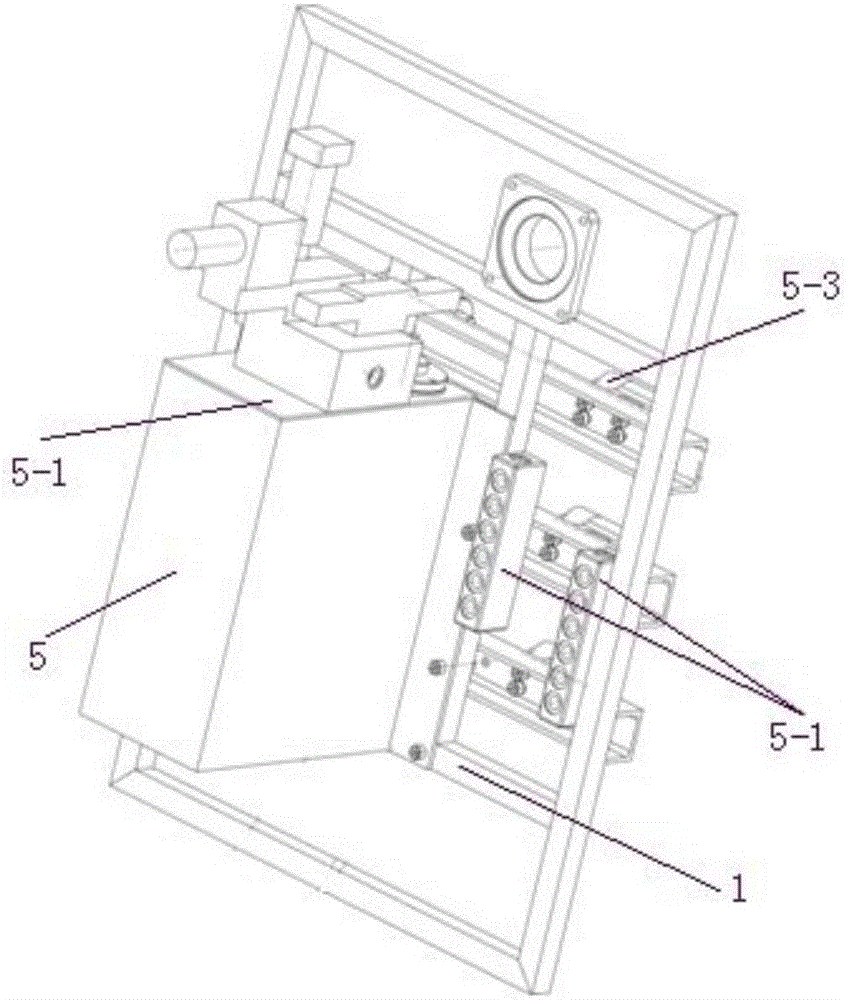

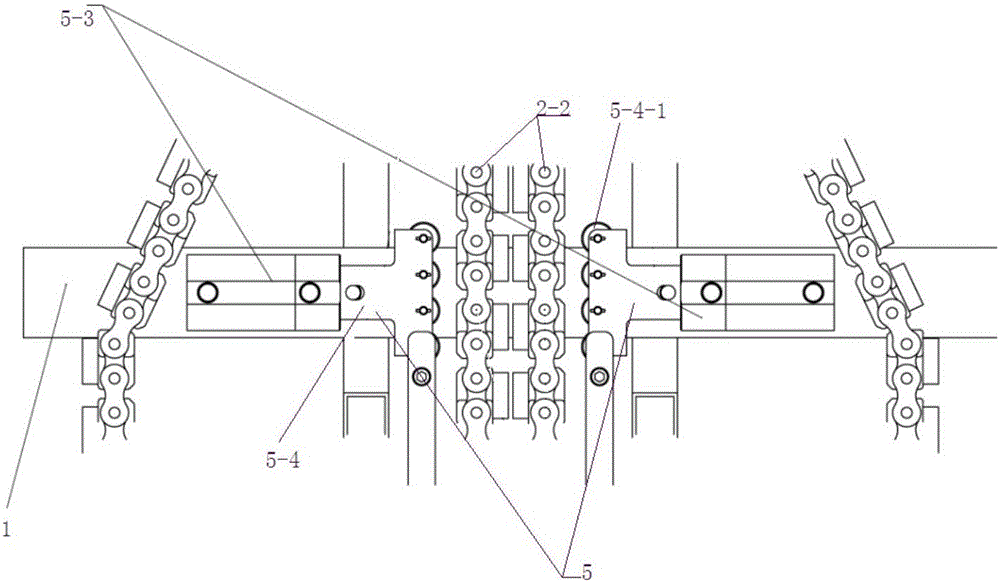

Hard cable injection system

ActiveCN106058742AChange the drop force valueImprove applicabilityMechanical energy handlingApparatus for laying cablesRack unitEngineering

The invention relates to the technical field of oil well logging, and specifically relates to a hard cable injection system. The hard cable injection system comprises an electric control box for controlling work of the whole hard cable injection system and a rack unit. The rack unit is equipped with a mechanical transmission unit and a mechanical drive unit which are connected. The mechanical transmission unit is used for clamping a cable and placing the cable down. The mechanical drive unit is used for driving the mechanical transmission unit. The rack unit is further equipped with a hydraulic clamping unit which is used for applying a clamping force for cable clamping to the mechanical transmission unit. The mechanical drive unit and the hydraulic clamping unit are connected with the electric control box. The system can overcome down-hole pressure to place a cable down in a well. In the process of cable placing, the tension of a logging cable can be observed in real time, and whether an instrument connected to the cable or the cable is blocked or whether the cable is still wound on an oil pipe can be judged according to the change in tension of the cable.

Owner:XIAN CARNATION ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com