Suspension type counter weight clinometer and measurement method

A heavy hammer inclinometer and measurement method technology, which is applied in construction and other directions, can solve the problems that the measurement range and accuracy cannot meet the requirements, the measurement efficiency is low, and the construction period is affected, so as to improve operation efficiency, simplify operation and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

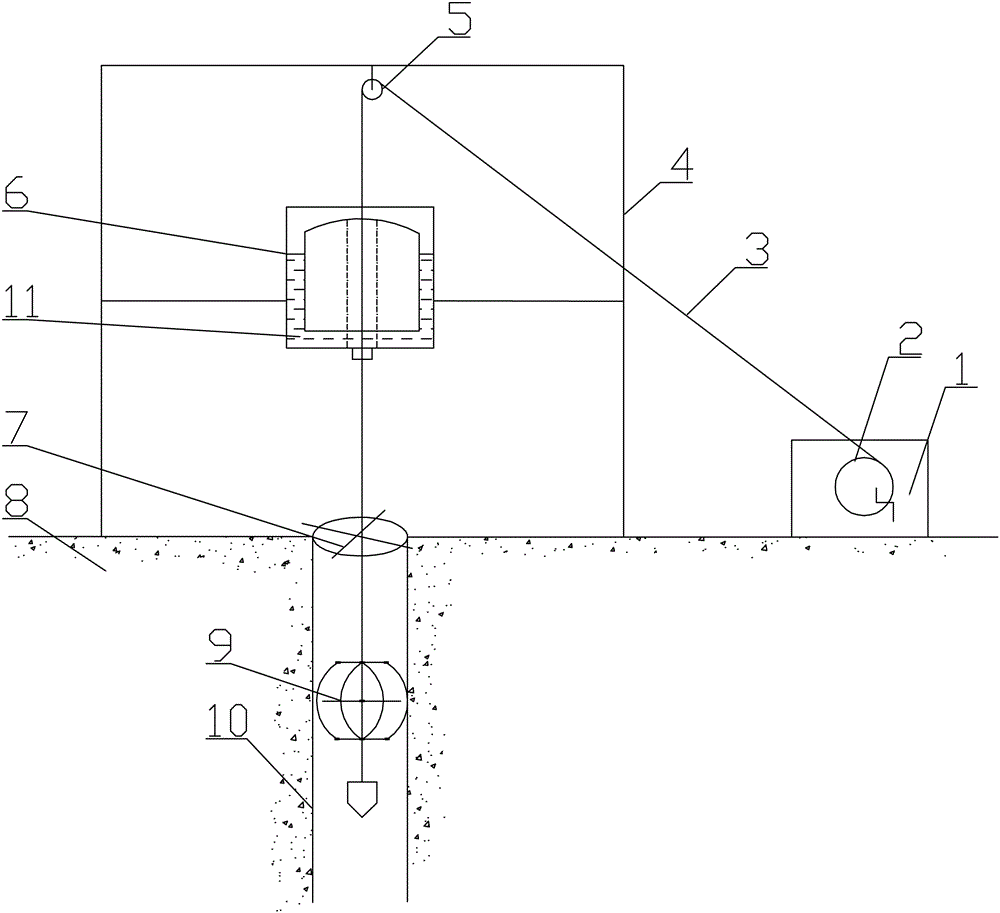

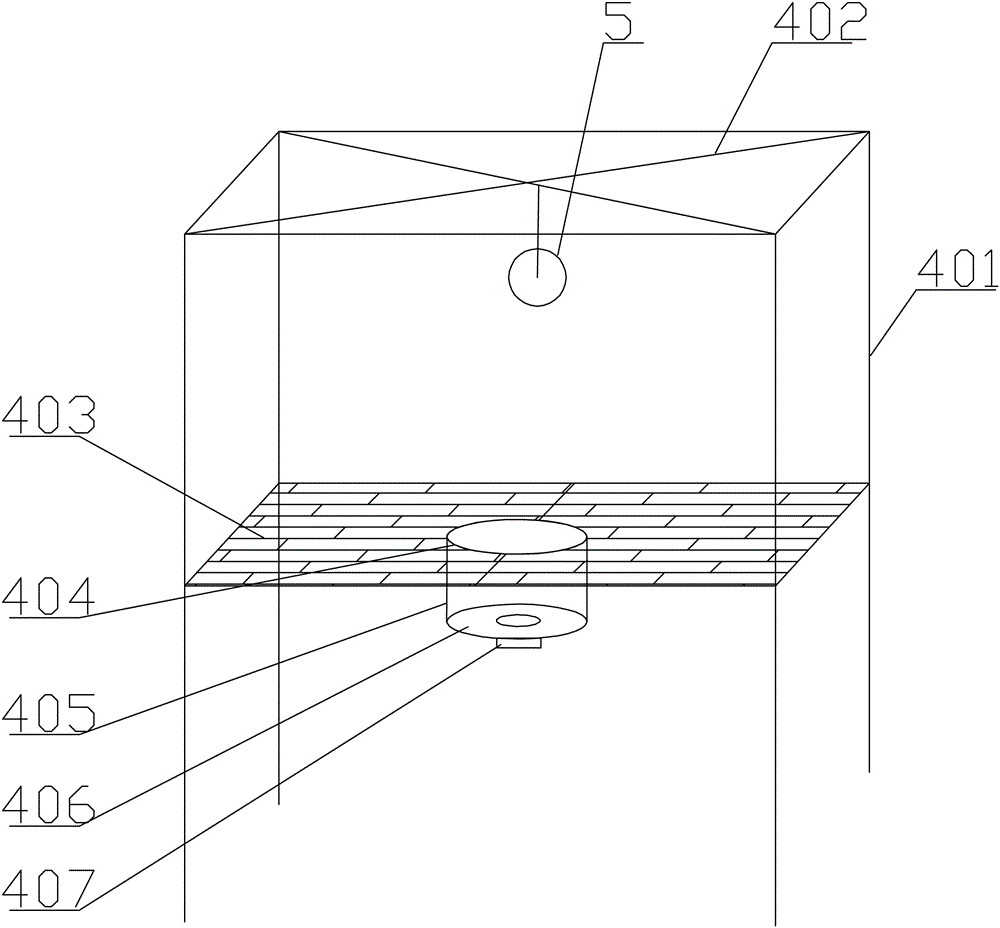

[0051] see Figure 1-6 , a suspension weight inclinometer, which includes a hoisting motor 1, a hoisting tube 2 of the hoisting motor 1 is wound with a steel wire rope 3, and the steel wire rope 3 passes through a fixed pulley 5 fixed on the top of the support platform 4, the The middle part of the support platform 4 is equipped with a buoyant device 6, and the steel wire rope 3 passes through the buoyant device 6, and the end of the steel wire rope 3 is connected with a wire hanging device 9, and the wire hanging device 9 is located in the inside of the hole to be measured 10, and the hole to be measured 10 The inlet position is provided with a measuring device 7 . Through the above-mentioned structure, the lower part of the line hanging device 9 can be smoothly inserted into the inside of the hole 10 to be measured, and at the same time, the diameter of the steel tape ruler spring 905 on the line hanging device 9 can be adjusted so that it can adapt to holes to be measured w...

Embodiment 2

[0058] The method for measuring the inclination of the aperture using a suspended weight inclinometer comprises the following steps:

[0059] 1) Install the support platform 4, build the measurement platform, and build the measurement platform directly above the hole to be measured 10 after the drilling, wherein the height of the support platform 4 from the hole to be measured 10 is 2m;

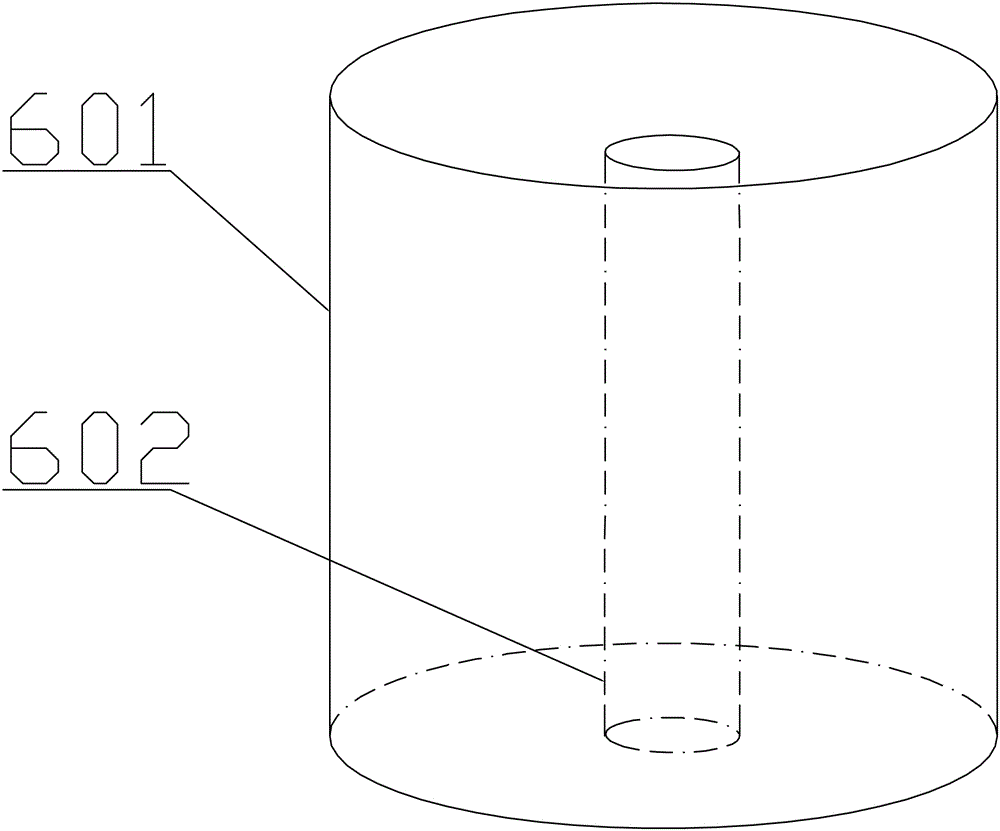

[0060] 2) Install the buoy device 6, place the outer cylinder 601 in the steel hoop 405 of the support platform 4, keep the center of the outer cylinder 601 consistent with the axis line of the steel hoop 405, and fill the inside of the outer cylinder 601 with water 11, and make the inner cylinder 604 float on the water 11;

[0061] 3) adjust the diameter of the line hanging device 9 to match the aperture of the hole 10 to be measured, and ensure that it can pass through the aperture 10 to be measured smoothly,

[0062] 4) Hang the steel wire rope 3, pass the stainless steel wire rope 3 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com