Installation platform of reinforcement cage and using method thereof

A technology for installing platforms and steel cages, applied in construction, sheet pile walls, infrastructure projects, etc., can solve problems such as difficult construction, affecting construction period and installation quality, and increasing additional costs, so as to improve installation quality and save costs. and resources, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

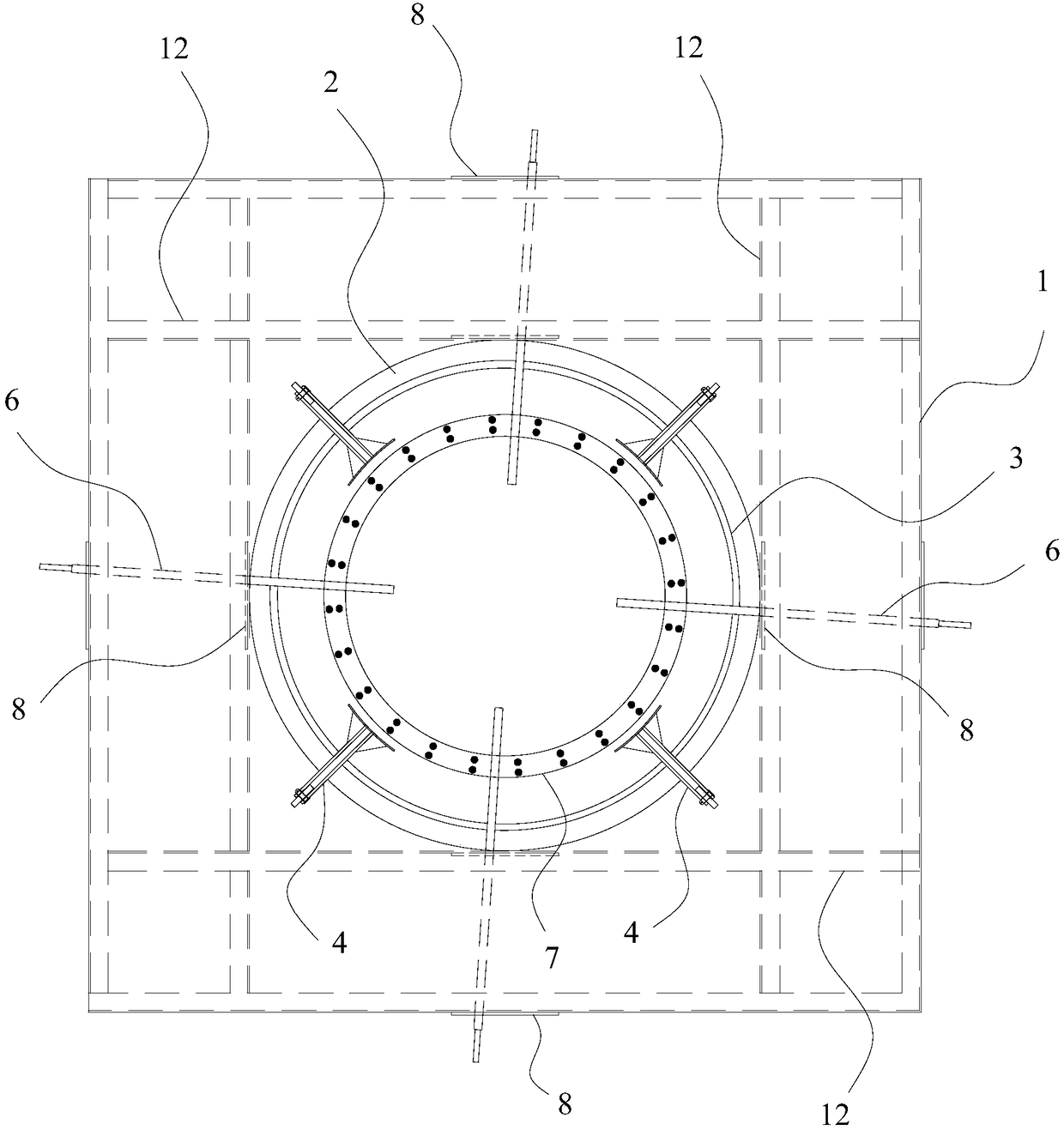

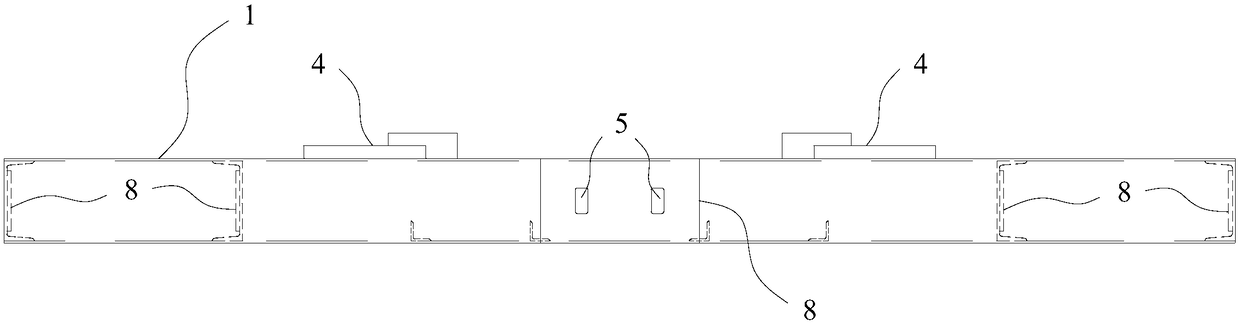

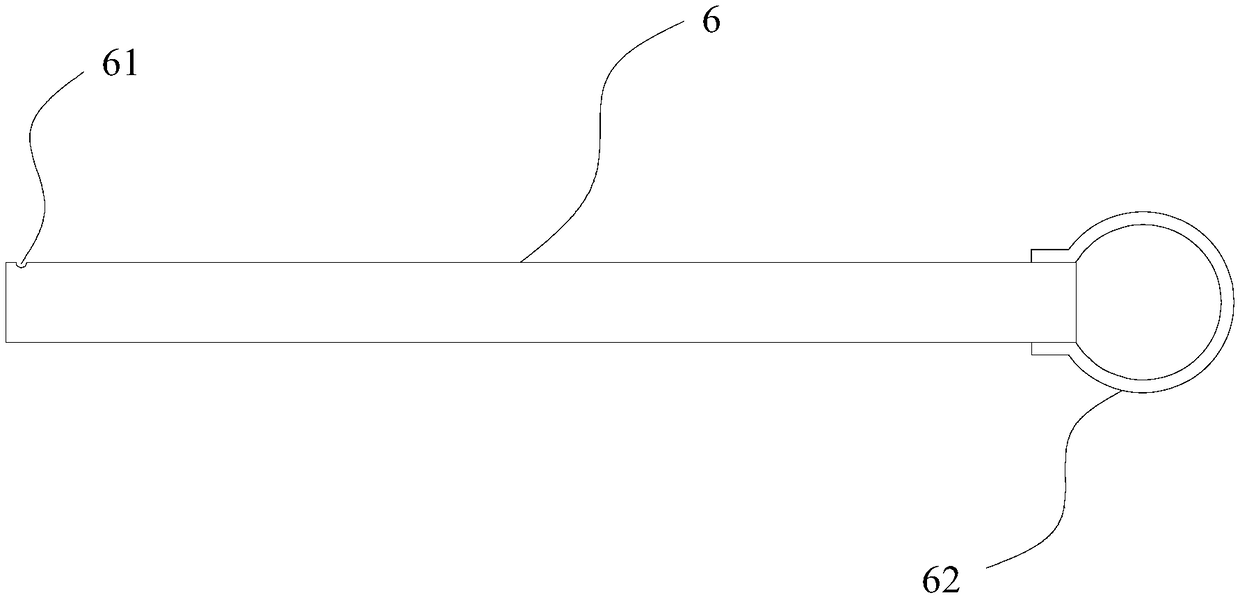

[0041] A kind of reinforcement cage installation platform of the present invention, as Figure 1-3 As shown, a body 1 comprising a cuboid, the cross section of the body 1 is a square, preferably, the body 1 comprises a frame 12 and a panel, the panel is used to form the frame 12 into a box, the body 1 A through hole 2 is provided in the middle of the body, and the diameter of the through hole 2 is adapted to the diameter of the casing 3. Preferably, the diameter of the through hole 2 is 5-15 cm larger than the diameter of the casing 3. The body 1 The height of the lower surface is higher than the height of the top surface of the casing 3, and the upper surface of the body 1 is provided with at least two stoppers 4, preferably, there are four stoppers 4, and the body Each corner of 1 is provided with a said limiting part 4, and each said limiting part 4 is hingedly connected to said body 1, and the distance between two adjacent said limiting parts 4 is equal, and each said limi...

Embodiment 2

[0043] The using method of a kind of reinforcing cage installation platform of the present invention adopts a kind of reinforcing cage installing platform as in embodiment 1, and its using method comprises the following steps:

[0044] a. After the main body 1 is installed in place, hoist the reinforcement cage 7 in sections, and insert the bolt 6 into the tunnel 5 on the top of the current reinforcement cage 7 for temporary fixation;

[0045] B, then correct the central position of the current reinforcement cage 7 by the limiting part 4;

[0046] c. Hoist the next section of reinforcement cage 7, and dock the next section of reinforcement cage 7 with the current reinforcement cage 7;

[0047] d, take out all described bolts 6 of fixing current reinforcement cage 7, insert in the tunnel 5 of next section reinforcement cage 7 and carry out temporary fixation;

[0048] e. Repeat steps c and d until all reinforcement cages 7 are connected and installed.

[0049] Adopt this meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com