Construction method for underground continuous wall below ultra-wide pipeline

A technology of ultra-wide pipelines and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inability to guarantee the continuity of the ground connection wall under the ultra-wide pipeline, affect construction safety, prolong the construction period, etc., and achieve avoidance The risk of unsafe accidents, the effect of ensuring the quality of the project and accelerating the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

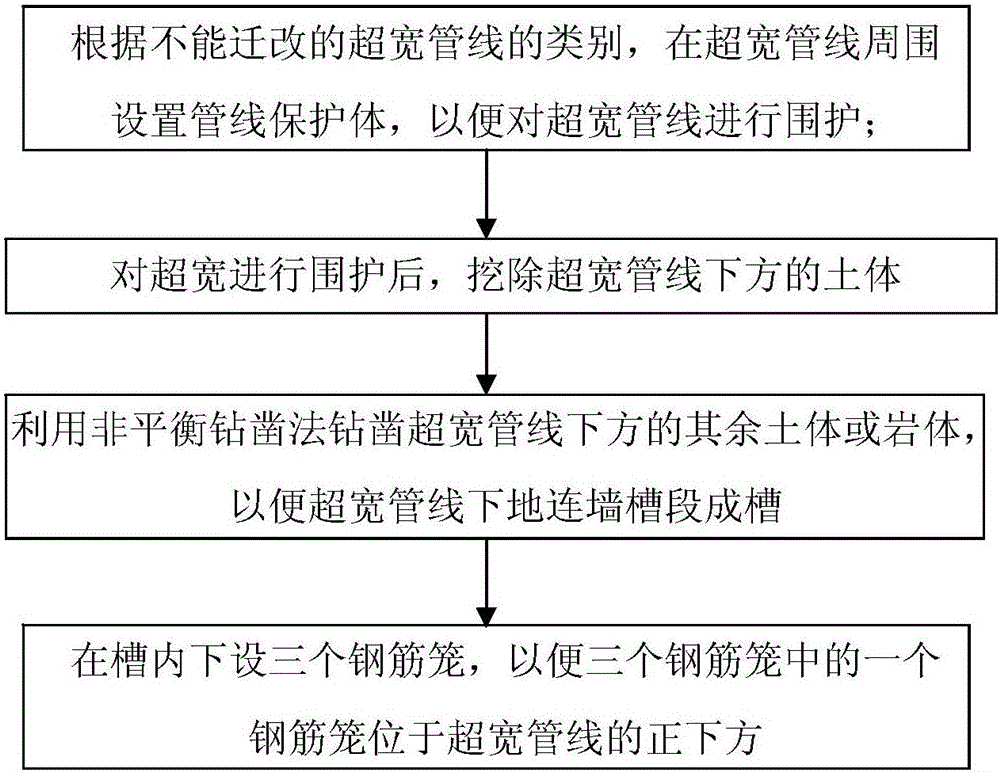

[0048] like image 3 As shown, it is a flow chart of the construction method of the ultra-wide pipeline under the ground connection wall provided by the present invention. As can be seen from the figure, the method includes:

[0049] According to the category of ultra-wide pipelines that cannot be relocated, a pipeline protection body is set around the ultra-wide pipeline to protect the ultra-wide pipeline;

[0050] After enclosing the ultra-wide pipeline, use the long-arm excavator to excavate the soil under the ultra-wide pipeline;

[0051] After the soil below the ultra-wide pipeline is excavated, use the unbalanced drilling method to drill the remaining soil or rock mass below the ultra-wide pipeline, so that the groove section of the ground connection wall under the ultra-wide pipeline can be grooved;

[0052] After the groove section of the ground connection wall under the ultra-wide pipeline is grooved, three reinforcement cages are installed in the groove so that one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com