Method and device for continuously detecting compactness of asphalt concrete pavement

A technology of asphalt concrete and detection methods, applied in the direction of material inspection products, etc., can solve the problems of high construction complexity, achieve the effect of convenient system construction, low system construction cost, and project quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

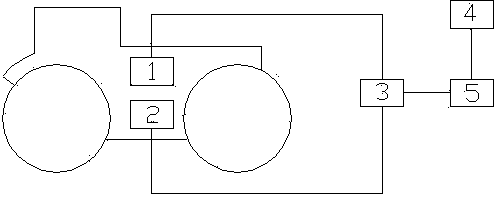

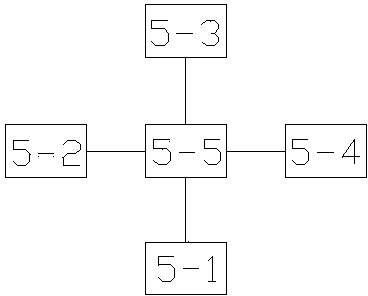

Image

Examples

Embodiment

[0072]Take the construction of a highway project in Jiangxi Province as an example. The compaction operation of AC-25 (gradation A) under a certain road surface mainly adopts two kinds of compaction machines, Hummer HD130 vibratory roller and Sany SPR300 tire roller. The HD130 road roller is a vibratory roller with double drums. During the operation, the front wheel mainly vibrates. The amplitude is 0.75mm, the vibration frequency is 42HZ, and the driving speed is roughly controlled at about 5km / h. The construction process of the compaction operation is a double-steel-wheel vibratory roller for static pressure once, followed by a double-steel-wheel vibratory roller for front wheel vibration compaction 2 to 4 times, and then two rubber-tired rollers for 1-2 times , the final double-drum roller static pressure until the road surface is flat and free of wheel marks.

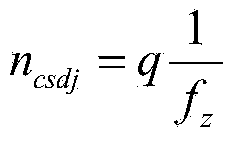

[0073] Through data processing, each 0.4 second is a detection unit, and an effective acceleration value A is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com