Method for mix design of hot-mix asphalt mixture produced with intermittent mixer

A technology of mix ratio design and asphalt mixture, which is applied in the direction of roads, road repair, roads, etc., can solve the problems of unsatisfactory design effect of hot mix asphalt mixture and inability to achieve screening capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0144] Example: Mineral Material Proportion Design and Application in Production Proportion Design of the Present Invention

[0145] A certain project is the upper layer of the road surface of the expressway, the mixture type is AC-16, and the asphalt is modified with SBS.

[0146] The construction unit selected three kinds of basalt crushed stones, respectively 9.5-19mm (A material), 4.75-9.5mm (B material), 2.36-4.75mm (C material), and limestone machine-made sand 0-4.75mm (D material) , Mineral powder (F material).

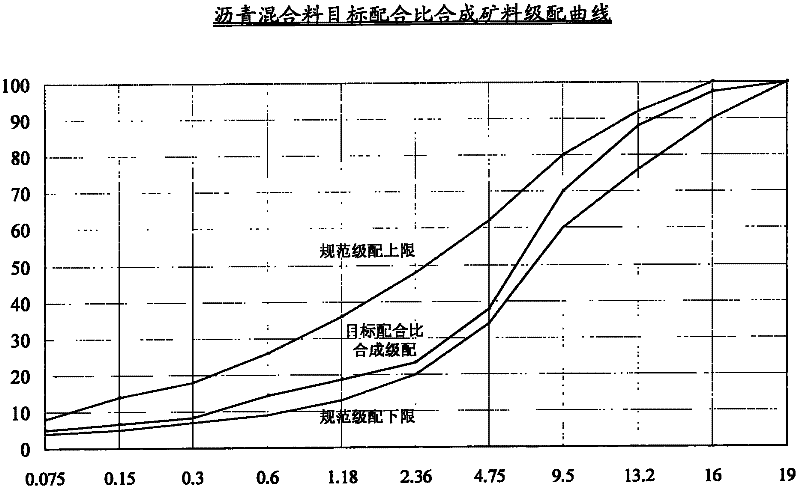

[0147] The design results of the target mix ratio are as follows: the ratio of cold material is A material: B material: C material: D material: F material = 33:34:6:24:3, and the synthetic gradation is shown in Table 1. figure 1 is a schematic diagram of the synthetic grading curve of the target mix ratio.

[0148] Table 1 Synthesis gradation of hot mix asphalt mixture target mix ratio

[0149]

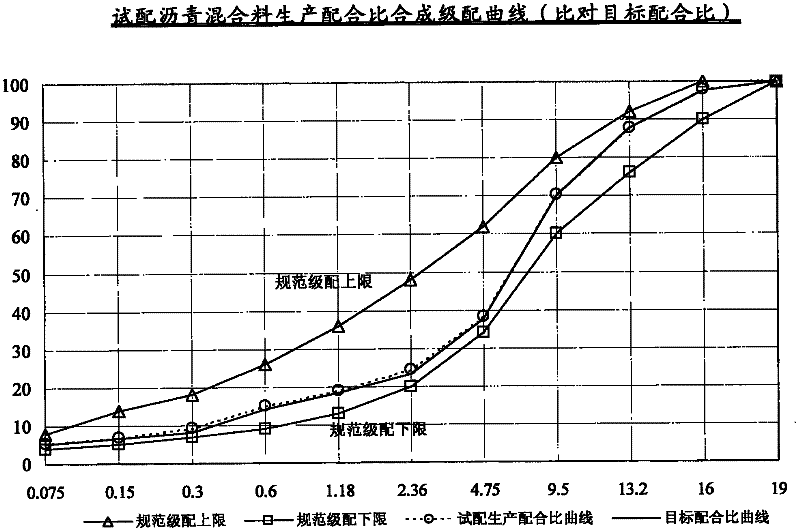

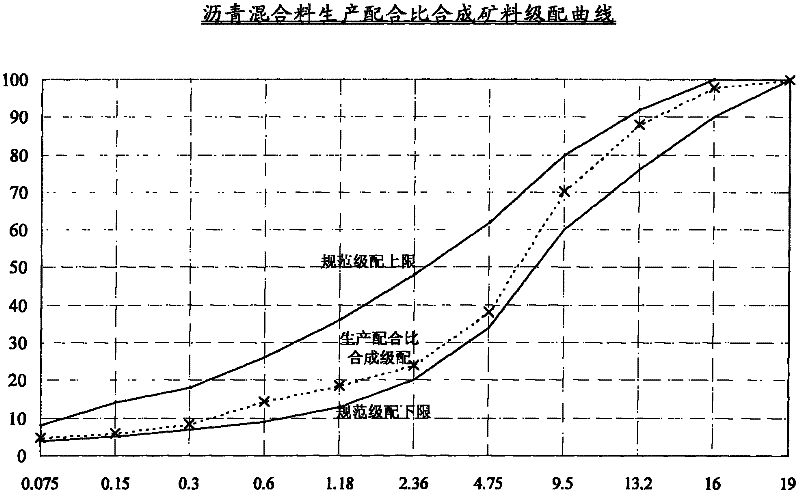

[0150] The four batch mixers that are planned to use the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com