Electrode bit for coiled tubing high-voltage electrical pulse/mechanical composite drilling

A high-voltage electric pulse and coiled tubing technology, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc., to achieve the effects of good technology inheritance, good liquid conditions, and improved drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, the present invention can also be implemented in other ways than those described here. Therefore, the protection scope of the present invention is not limited by the specific embodiments disclosed below.

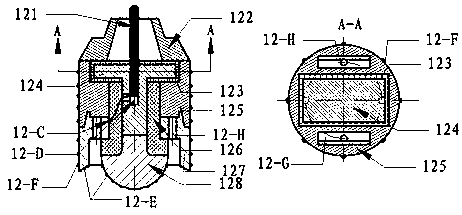

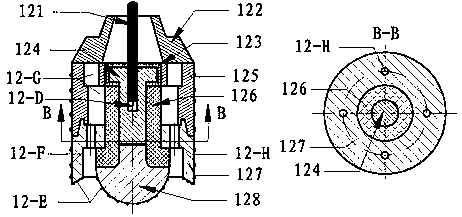

[0025] Electrode bits for coiled tubing high-voltage electric pulse-mechanical composite drilling according to some embodiments of the present invention will be described below with reference to the accompanying drawings.

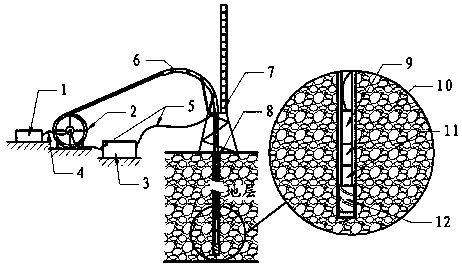

[0026] figure 1 It is a schematic diagram of a vertical well drilled by the coiled tubing high-voltage electric pulse-mechanical composite rock-breaking drilling method. The entire dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com