Cutter suction underwater silt remover with double bucket-wheels and three cutters

An underwater dredging machine and double bucket wheel technology are applied in the direction of earthmoving machine/shovel, mechanically driven excavator/dredging machine, construction, etc., which can solve the problem of incomplete dredging, low mud concentration and inconvenience in use. and other problems, to achieve the effect of easy installation and transportation, convenient lifting and lowering, and avoiding long shaft transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

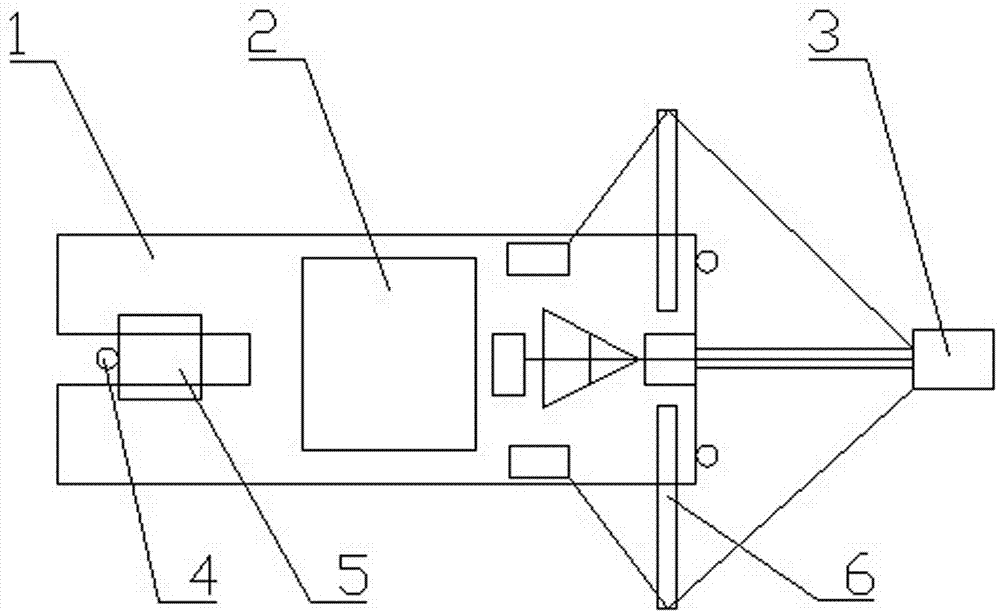

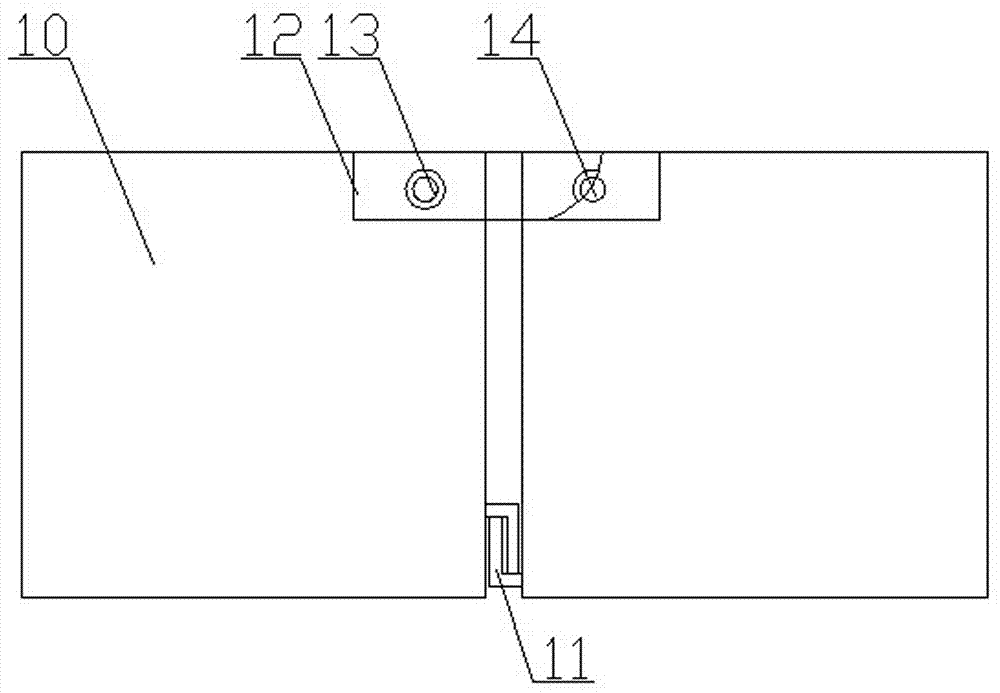

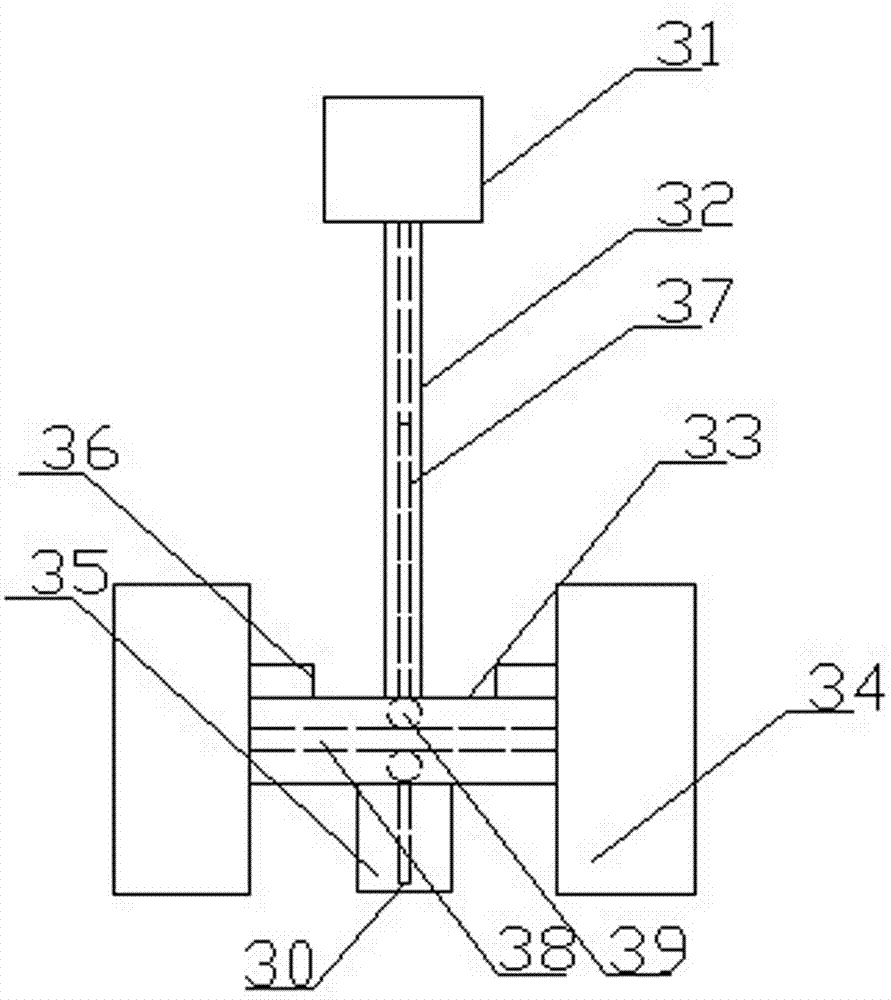

[0036] figure 1 As shown, a double-bucket-wheel-three-reamer-type cutter-suction underwater dredger includes a floating body 1, an operating room 2, a dredging device 3, a positioning device 4, a stepping device 5, and a left and right traverse device 6. The operating room 2 is arranged in the middle of the floating body 1, and the dredging device 3 is connected to the head of the floating body 1. The positioning device 4 includes three sets of spud units 52, wherein one set of spud units is installed at the tail of the floating body, and the other two sets The positioning pile unit is installed on the head of the floating body; the stepping device 5 is set at the tail of the floating body 1, the left and right traverse device 6 is set at the head of the floating body 1, and the dredging head 3 is a double bucket wheel type dredging The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com