Self-repairing composite coating, application of self-repairing composite coating, anticorrosion material and preparation method of anticorrosion material

A composite coating and self-healing technology, applied in chemical materials and application fields, can solve the problems of corrosion inhibitors not being released quickly, not forming a protective film, not being able to inhibit corrosion, etc., achieving excellent biocompatibility, easy molding, and processing short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

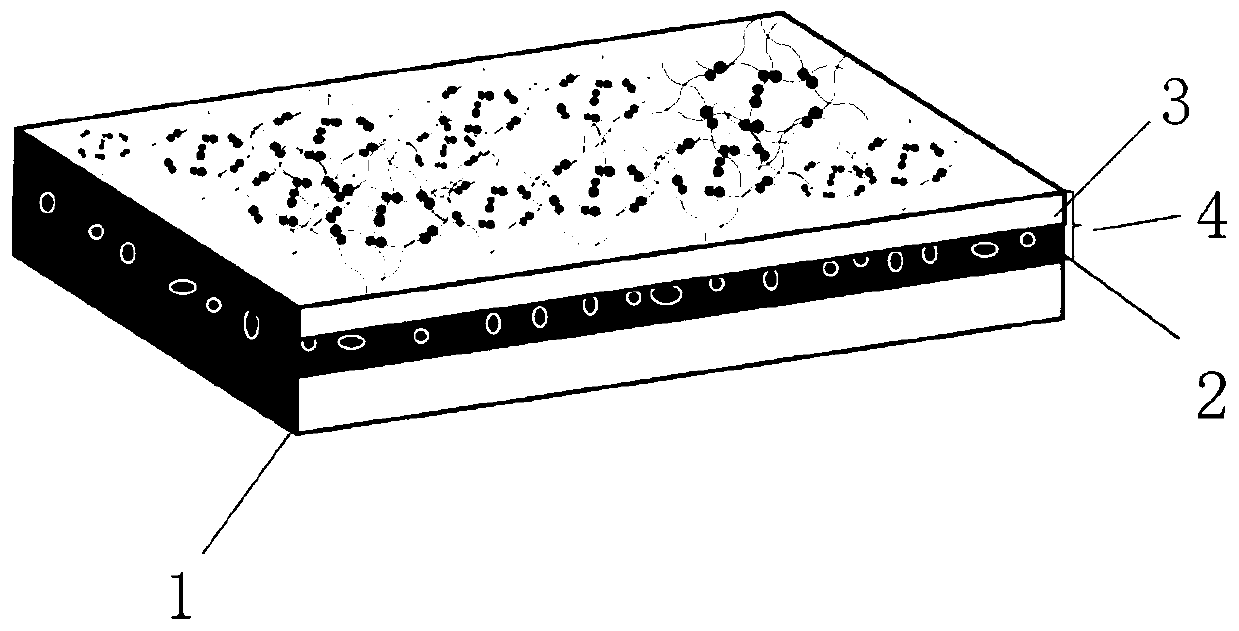

[0061] The first embodiment of the present invention provides a self-healing composite coating 4 and the application of the self-healing composite coating 4 in anti-corrosion. Such as figure 1 As shown, the self-healing composite coating 4 of the present invention includes: a hydrophobic layer 2 and a hydrophilic layer 3 in contact, wherein

[0062] The hydrophobic layer 2 comprises a hydrophobic substance;

[0063] The hydrophilic layer 3 includes a self-healing layer 31, and the self-healing layer 31 contains a hydrophilic substance A, and the hydrophilic substance A contains one or a combination of two or more dynamic covalent bonds.

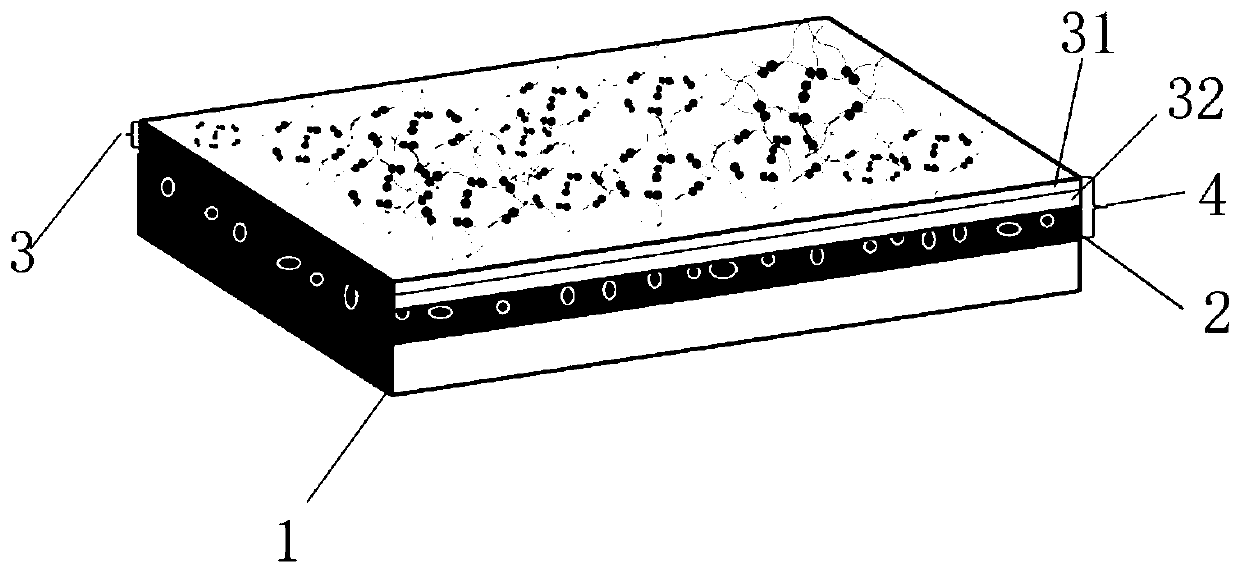

[0064] In a specific embodiment, such as figure 2 As shown, the hydrophilic layer 3 also includes a transition layer 32 in contact with the self-healing layer 31, wherein the transition layer 32 exists between the self-healing layer 31 and the hydrophobic layer 2, or The transition layer 32 exists on the side of the self-healing layer 31...

no. 2 approach

[0089] A second embodiment of the present invention provides an anti-corrosion material. The anti-corrosion material includes a substrate 1 and a self-repairing composite coating 4 formed on the surface of the substrate 1; the self-repairing composite coating 4 is the self-repairing composite coating 4 in the first embodiment.

[0090]Generally speaking, in the present invention, the self-repairing composite coating 4 can be directly formed on the surface of the substrate 1, thereby playing the role of corrosion protection and self-repairing; the present invention can also prepare the self-repairing composite coating 4 in advance, and then Then it is arranged on the surface of the base body 1 to play the role of anti-corrosion.

[0091]

[0092] In the present invention, the self-healing composite coating 4 can be formed on the surface of the substrate 1, wherein the substrate 1 includes one or a combination of two or more of metal, ceramics, plastics and glass, wherein the ...

no. 3 approach

[0098] The third embodiment of the present invention provides a method for preparing an anti-corrosion material, comprising the following steps:

[0099] Prepare the self-healing layer material by taking the hydrophilic substance A;

[0100] Prepare hydrophobic material by taking hydrophobic substance;

[0101] making the self-healing layer material and the hydrophobic material alternately form a hydrophilic layer 1 and a hydrophobic layer 2 on the surface of the substrate 1, the hydrophilic layer comprising a self-healing layer 31;

[0102] In the present invention, the hydrophobic layer 2 may be in contact with the surface of the substrate 1, and the hydrophilic layer 3 is formed on the opposite side of the hydrophobic layer 2 to the substrate 1; or the The hydrophilic layer 3 is in contact with the surface of the substrate 1 , and the hydrophobic layer 2 is formed on the side of the hydrophilic layer 3 opposite to the substrate 1 . Preferably, the hydrophobic layer 2 is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com