Manufacturing method of concrete head-forging pipe pile with tapered pile tip

A manufacturing method and technology of conical piles, applied in the direction of manufacturing tools, sheet pile walls, foundation structure engineering, etc., can solve the problems of conical pile tip voids, conical pile tip inconsistencies, difficult to form pointed parts, etc., to achieve Good integrity, guaranteed sealing, and strong penetrating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

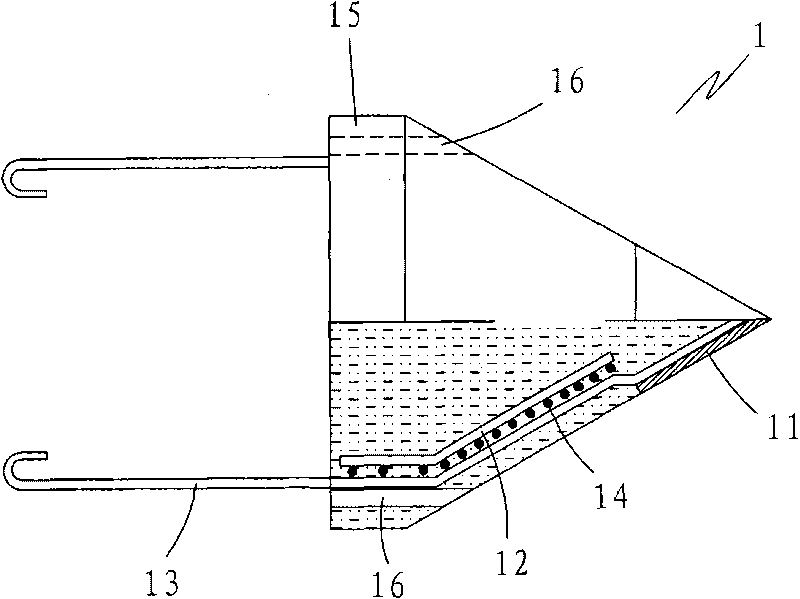

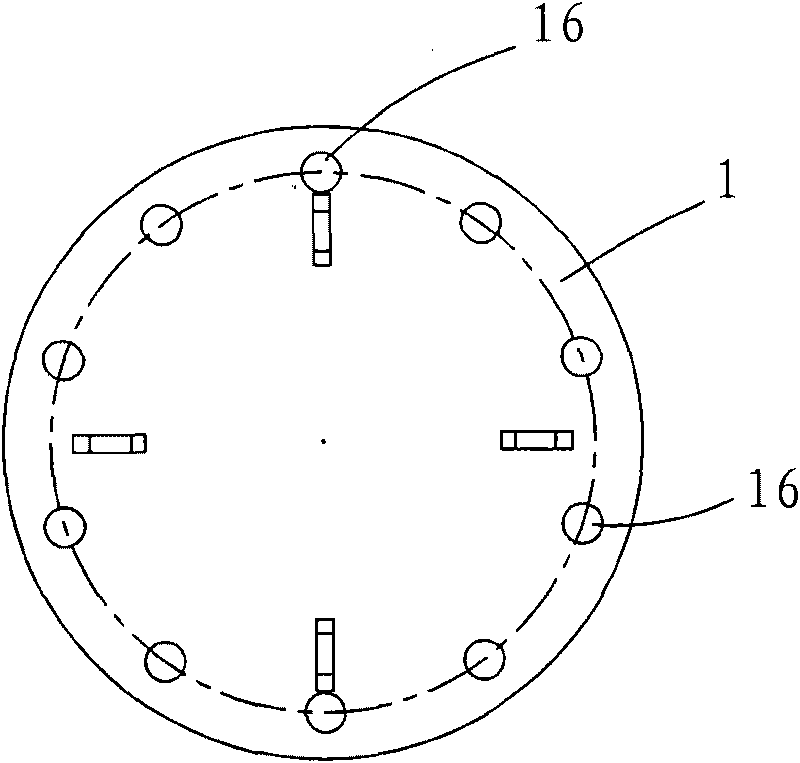

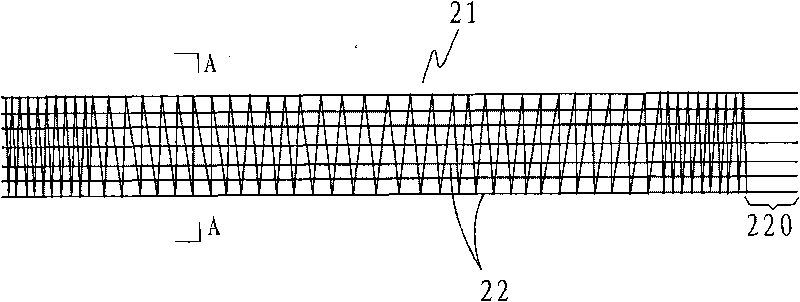

[0030] see figure 1 Shown, the manufacture method of the concrete headed pipe pile with tapered pile point of the present invention, it comprises:

[0031] Step 11, such as figure 1 As shown, make a pile point iron 11 and a tapered steel bar skeleton 12 of a tapered pile point 1, and the pile point iron 11 has a tapered pile point connecting steel bar 13, and this tapered pile point connecting steel bar 13 can be used on the one hand Connect the pile point iron 11 and the tapered steel bar skeleton 12, on the other hand, it can also be used to connect with the pile body 2 described later. Moreover, the tapered reinforcement skeleton 12 may also include a reinforcing steel bar 14 to increase the overall strength of the tapered pile tip 1 .

[0032] Step 12. Prefabricate the conical pile point 1 with the same label as the pipe pile, and make the cone slope angle of the conical pile point 1 be 45°-56°. The cone slope angle in this range has strong soil breaking ability and is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com