Connection device for mounting and dismounting wheel hub cover

A connecting device and hub cover technology, which is applied in the direction of wheel cover discs, wheels, transportation and packaging, etc., can solve the problems of easy-to-damage hubs, bolts, removal tools that are not easy to use, and affect driving safety, etc., to achieve compact structure, easy assembly and disassembly Convenience and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

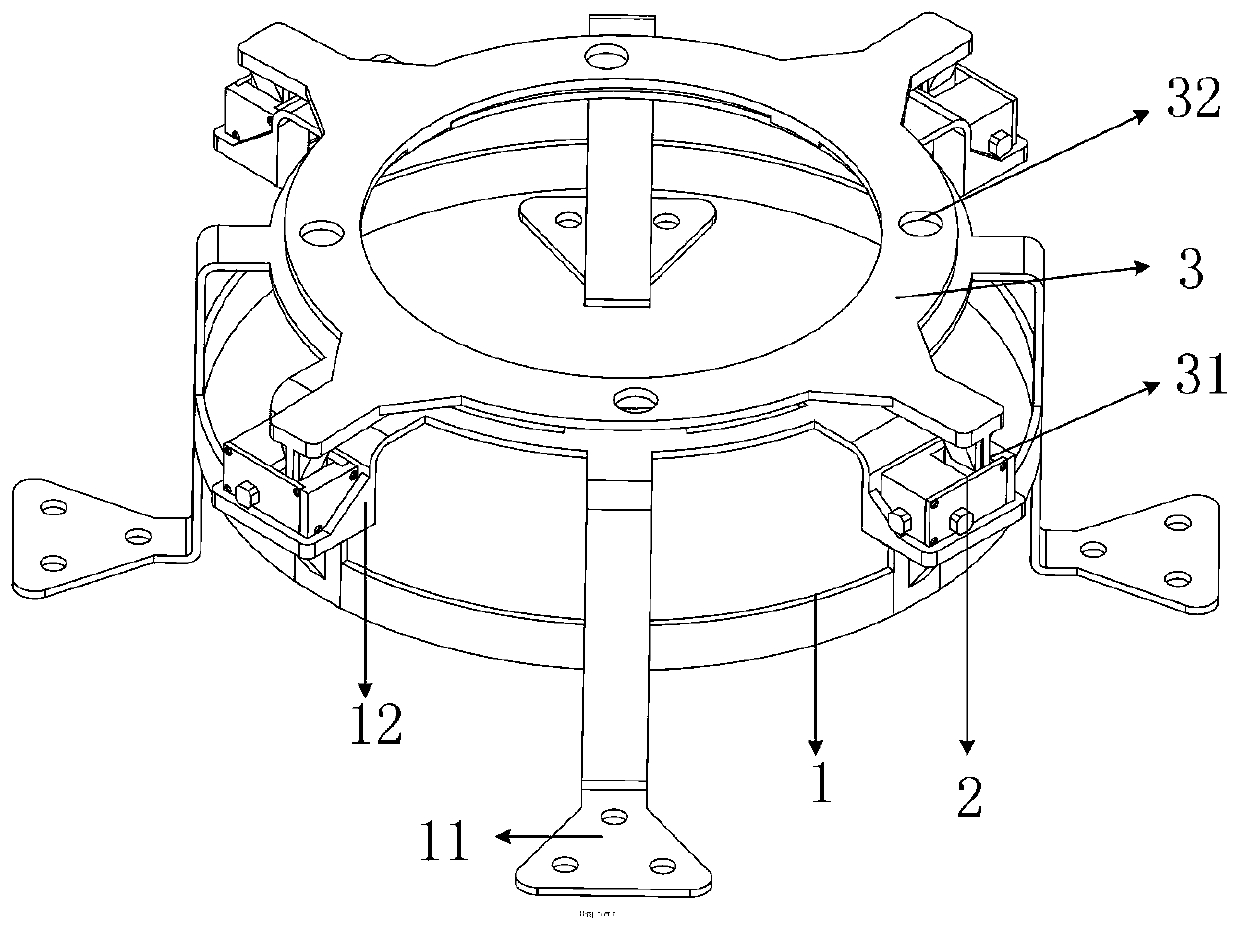

Embodiment 1

[0041] The automobile wheel hub quick connecting device of this embodiment includes a bracket 1 , a connecting device 2 and a transition tooling device 3 . One side of the bracket 1 is connected to the hub through four bolt seats 11, and four bases 12 are arranged around the other side to install and fix the connecting device 2. One end of the connecting device 2 is connected to the base 12 on the side of the bracket. For fixing, the other end cooperates with the hook 31 of the transitional tooling device to realize quick connection. The transitional tooling device 1 is fixed with the hubcap by bolts 32, and the hook 31 and the connecting device 2 can realize quick connection and disassembly.

[0042] The bracket 1 is a hollow cylindrical frame, the axis of the cylinder is in line with the axis of rotation of the wheel, one end of the cylindrical frame is connected to the hub through four bolt seats 11, and four bases 12 are arranged on the side of the other end. , the base is...

Embodiment 2

[0050] The automobile hub quick connecting device of the present embodiment comprises a bracket 1, a connecting device 2 and a transitional tooling device 3, the bracket 1 and the transitional tooling device 3 have the same structure and function as that of the embodiment 1, and the external structure of the connecting device 2 is similar to that of the embodiment 1. The internal structure and layout are different.

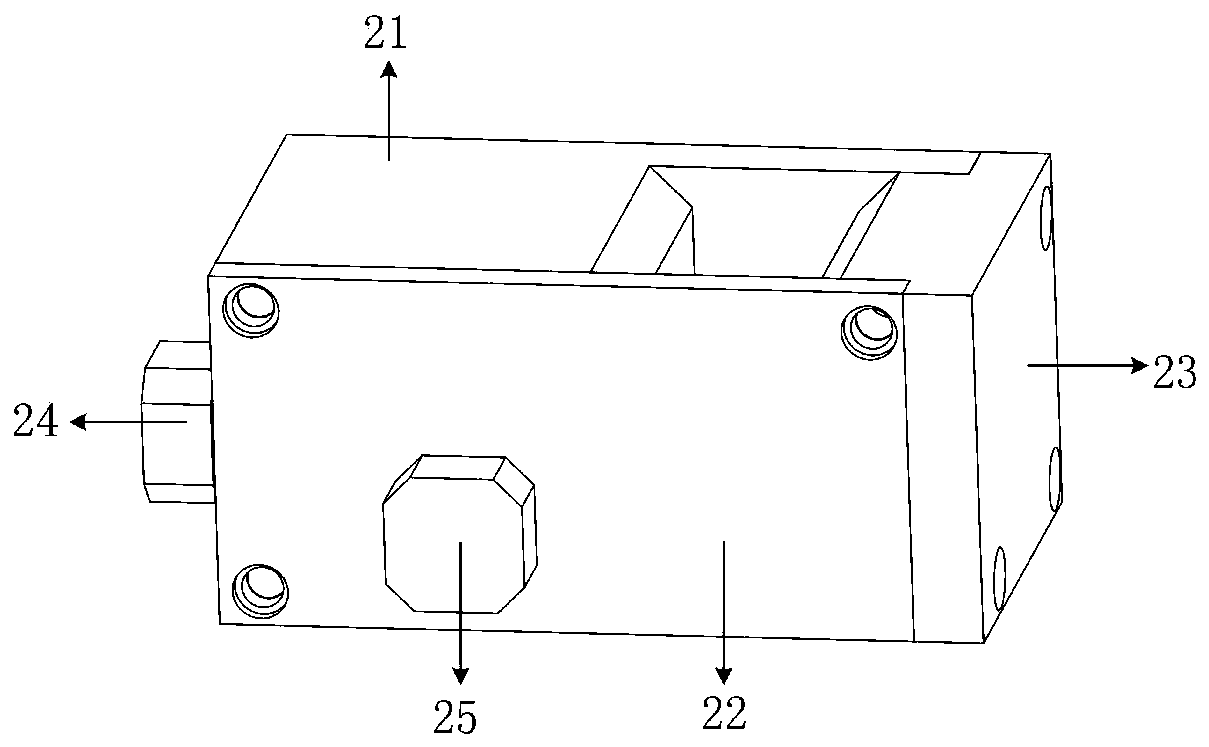

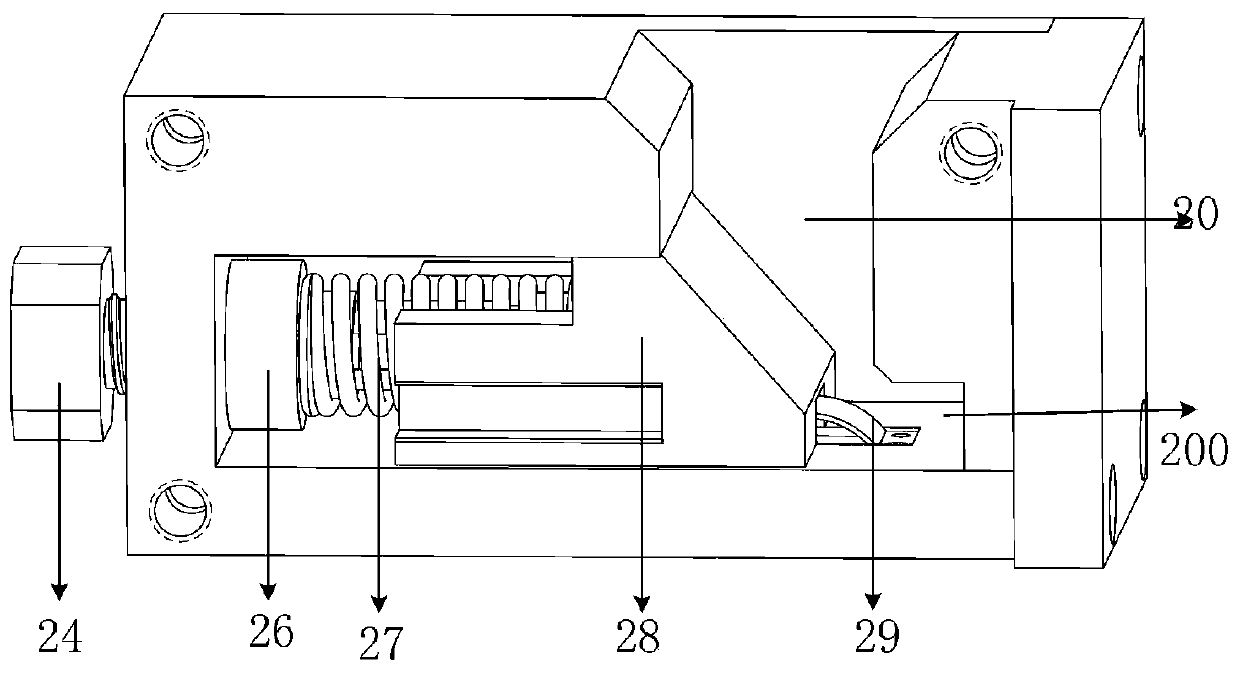

[0051] The external structure of the connecting device 2 is as Figure 5 As shown, the connection device 2 is a box body with an inlet slot and a limit slot, which is composed of a first frame 201, a second frame 202 and a third frame 203 arranged in a staggered manner, and the limit block 204 is placed inside the box body for use. In order to support the rest of the internal structure and perform constrained positioning, an entrance slot is formed between the limiting block 204 and the third frame 203 for the L-shaped hook 31 to enter the interior of the device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com