Sun-proof printing ink as well as preparation method and application thereof in sun-proof transfer film

A technology of light fastness and ink, which is applied in the direction of ink, application, household utensils, etc., can solve the problem of heavy pigment powder and difficult to print, and achieve the effect of reducing ink powder weight, good color retention, and bright and consistent colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

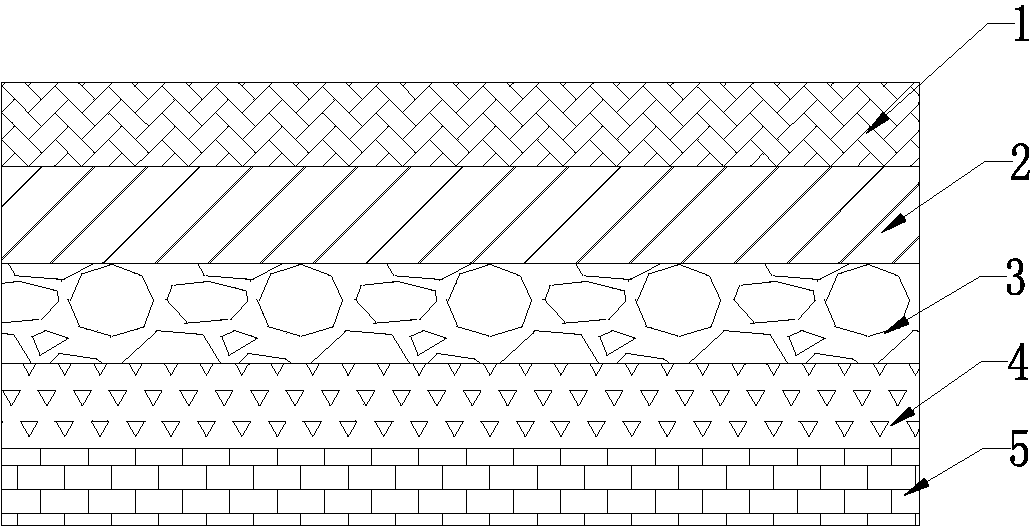

[0065] Such as figure 1 As shown, a light-resistant transfer film includes a base film layer 1, a release layer 2 and an adhesive layer 5 from top to bottom, and an ultraviolet absorber is arranged between the base film layer 1 and the release layer 2. The material coating 3 is provided with a light-resistant ink coating between the ultraviolet absorbing material coating 3 and the adhesive layer 5 .

[0066] The ultraviolet absorbing material coating 3 is coated with an ultraviolet absorbing material, and the formula of the ultraviolet absorbing material is:

[0067] Ultraviolet absorber UV-P 5 parts

[0068] Ultraviolet absorber UV-9 6 parts

[0069] UV absorber UV-327 5 parts

[0070] Acrylic resin liquid 45 parts

[0071] Acetate butyl cellulose resin liquid 12 parts

[0072] 6 parts isopropyl alcohol

[0073] 20 parts of n-propyl acetate.

[0074] A light-resistant ink coated on the above-mentioned light-resistant ink coating 4, prepared from the following component...

Embodiment 2

[0090] Such as figure 1 As shown, a light-resistant transfer film includes a base film layer 1, a release layer 2 and an adhesive layer 5 from top to bottom, and an ultraviolet absorber is arranged between the base film layer 1 and the release layer 2. The material coating 3, the light-resistant ink coating 4 is arranged between the ultraviolet absorbing material coating 3 and the adhesive layer 5.

[0091] The ultraviolet absorbing material coating 3 is coated with an ultraviolet absorbing material, and the formula of the ultraviolet absorbing material is:

[0092] Ultraviolet absorber UV-P 6 parts

[0093] Ultraviolet absorber UV-9 5 parts

[0094] UV absorber UV-327 6 parts

[0095] Acrylic resin liquid 48 parts

[0096] Acetate butyl cellulose resin liquid 14 parts

[0097] 5 parts isopropyl alcohol

[0098] 18 parts of n-propyl acetate.

[0099] A light-resistant ink coated on the above-mentioned light-resistant ink coating 4, prepared from the following components...

Embodiment 3

[0115] Such as figure 1 As shown, a light-resistant transfer film includes a base film layer 1, a release layer 2 and an adhesive layer 5 from top to bottom, and an ultraviolet absorber is arranged between the base film layer 1 and the release layer 2. The material coating 3, the light-resistant ink coating 4 is arranged between the ultraviolet absorbing material coating 3 and the adhesive layer 5.

[0116] The ultraviolet absorbing material coating 3 is coated with an ultraviolet absorbing material, and the formula of the ultraviolet absorbing material is:

[0117] Ultraviolet absorber UV-P 6 parts

[0118] Ultraviolet absorber UV-9 5 parts

[0119] UV absorber UV-327 6 parts

[0120] Acrylic resin liquid 50 parts

[0121] Acetate butyl cellulose resin liquid 18 parts

[0122] 6 parts isopropyl alcohol

[0123] 15 parts of n-propyl acetate.

[0124] A light-resistant ink coated on the above-mentioned light-resistant ink coating 4, prepared from the following components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com