Seawater resistant cement

An anti-seawater and cement technology, applied in the field of cement, can solve the problems of anti-seawater erosion, seawater erosion resistance and poor freeze-thaw resistance, and achieve the effects of improving erosion resistance, improving erosion resistance and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention has the following two embodiments.

[0048] One. the percentage by mass of each component of the formula of the first embodiment is as follows:

[0049] Portland cement clinker: 50%;

[0050] Gypsum: 4%;

[0051] Manganese slag: 12%;

[0052] Fly ash: 12%;

[0053] Slag: 12%;

[0054] Active SiO 2 : 4%;

[0055] Silicon-aluminum active composite material: 4%;

[0056] Bulking agent: 2%.

[0057] Two. the percentages by mass of each component of the formula of the second embodiment are as follows:

[0058] Portland cement clinker: 45%;

[0059] Gypsum: 5%;

[0060] Manganese slag: 14%;

[0061] Fly ash: 14%;

[0062] Slag: 14%;

[0063] Active SiO 2 : 4%;

[0064] Shangyu porcelain stone: 2%;

[0065] Expanding agent> 2%.

[0066] The characteristic mechanism of anti-seawater of the present invention is as follows:

[0067] 1. Corrosion resistance

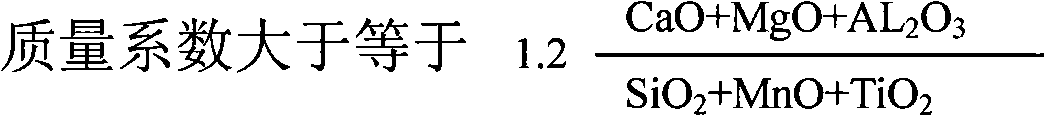

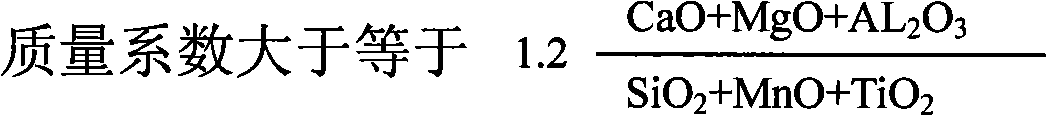

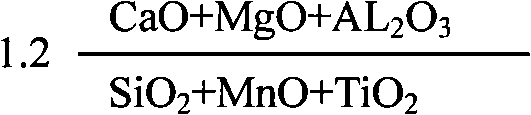

[0068] The performance of cement against sulfate, chloride and other salts is rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com