Cement grinding aid

A technology of cement grinding aids and waste liquid, which is applied in the field of cement grinding aids, can solve the problems of high purchase price of grinding aids, unsatisfactory water demand, and unclear components, so as to reduce over-grinding and optimize Cement particle gradation, effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

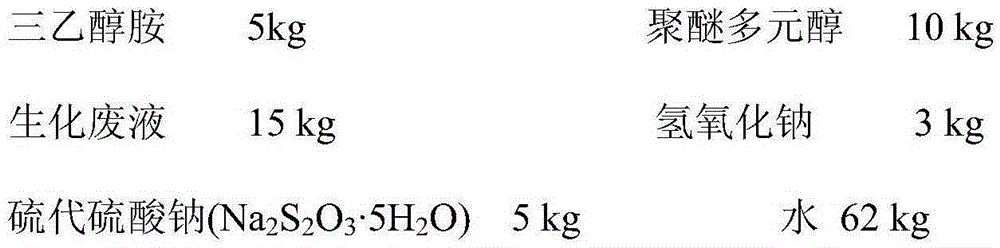

[0021] Embodiment 1. a kind of cement grinding aid, is made of the raw material of following weight:

[0022]

[0023] The biochemical waste liquid is the waste liquid produced by Jinan Huaming Biochemical Co., Ltd., which produces industrial sodium gluconate.

[0024] The preparation method is:

[0025] (1) First mix the biochemical waste liquid and sodium hydroxide evenly, and react at room temperature, and the reaction time is about 20 minutes.

[0026] (2) Add 20kg of water to sodium thiosulfate to prepare an aqueous solution of sodium thiosulfate, then add it to the mixture in step (1), and stir evenly at room temperature.

[0027] (3) Add triethanolamine, polyether polyol and the rest of water into the mixture in step (2), and stir evenly at room temperature.

Embodiment 2

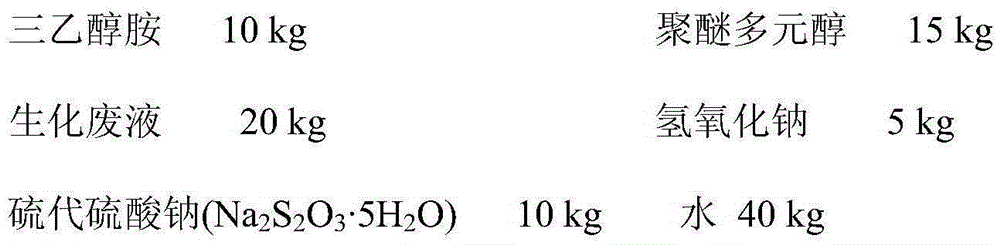

[0028] Embodiment 2 A kind of cement grinding aid, is made of the raw material of following weight:

[0029]

[0030] The biochemical waste liquid is the waste liquid from the production of industrial itaconic acid by Jinan Huaming Biochemical Co., Ltd.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0032] Embodiment 3 A kind of cement grinding aid, is made of the raw material of following weight:

[0033]

[0034] The biochemical waste liquid is a mixture of industrial sodium gluconate waste liquid and industrial itaconic acid waste liquid produced by Jinan Huaming Biochemical Co., Ltd., with a mixing ratio of 1:1.

[0035] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com