High-activity ore slag powder and preparation technology thereof

A preparation process and technology of slag powder, which is applied in the field of concrete to achieve the effects of increasing specific surface area, improving activity index and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

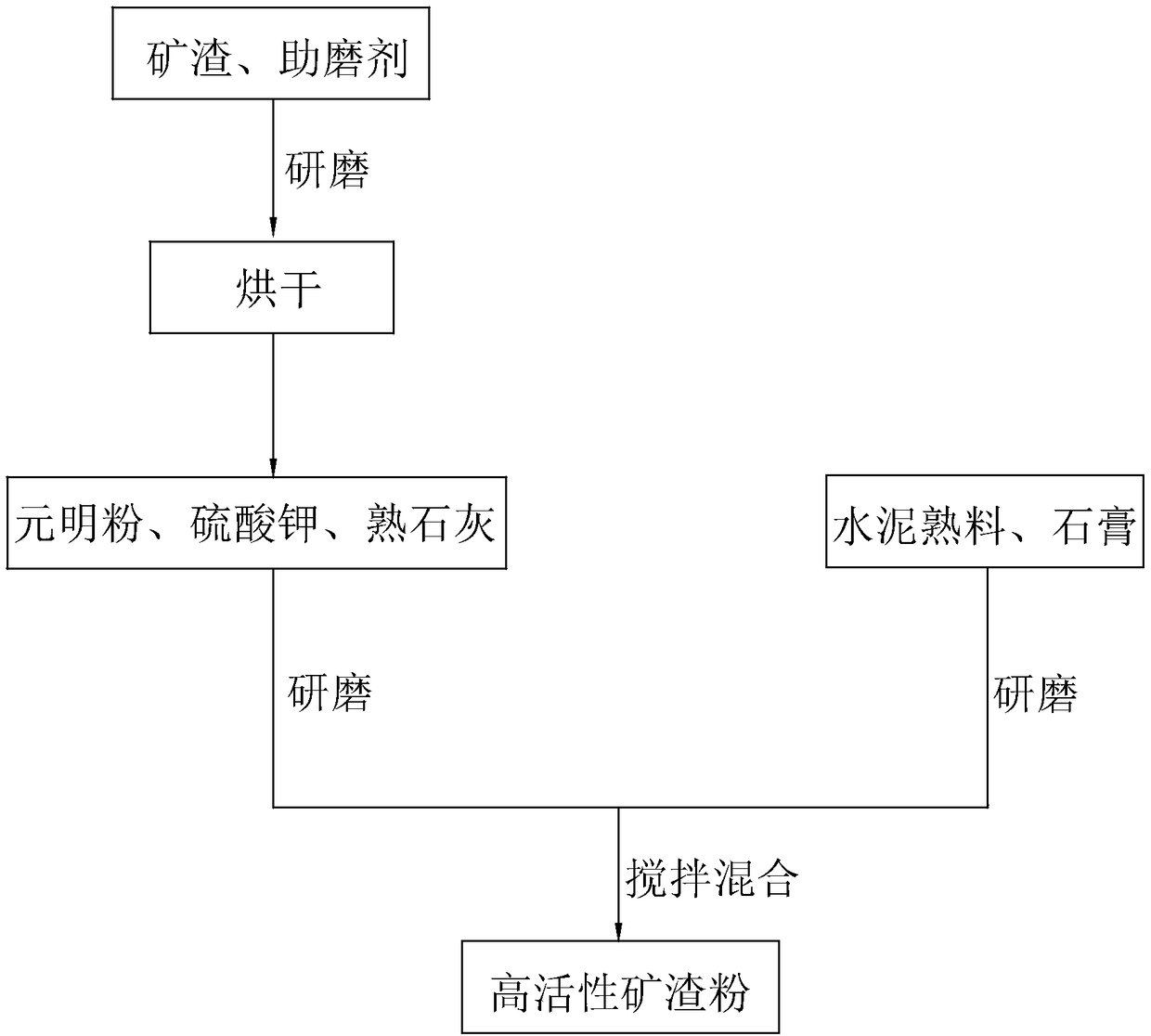

Method used

Image

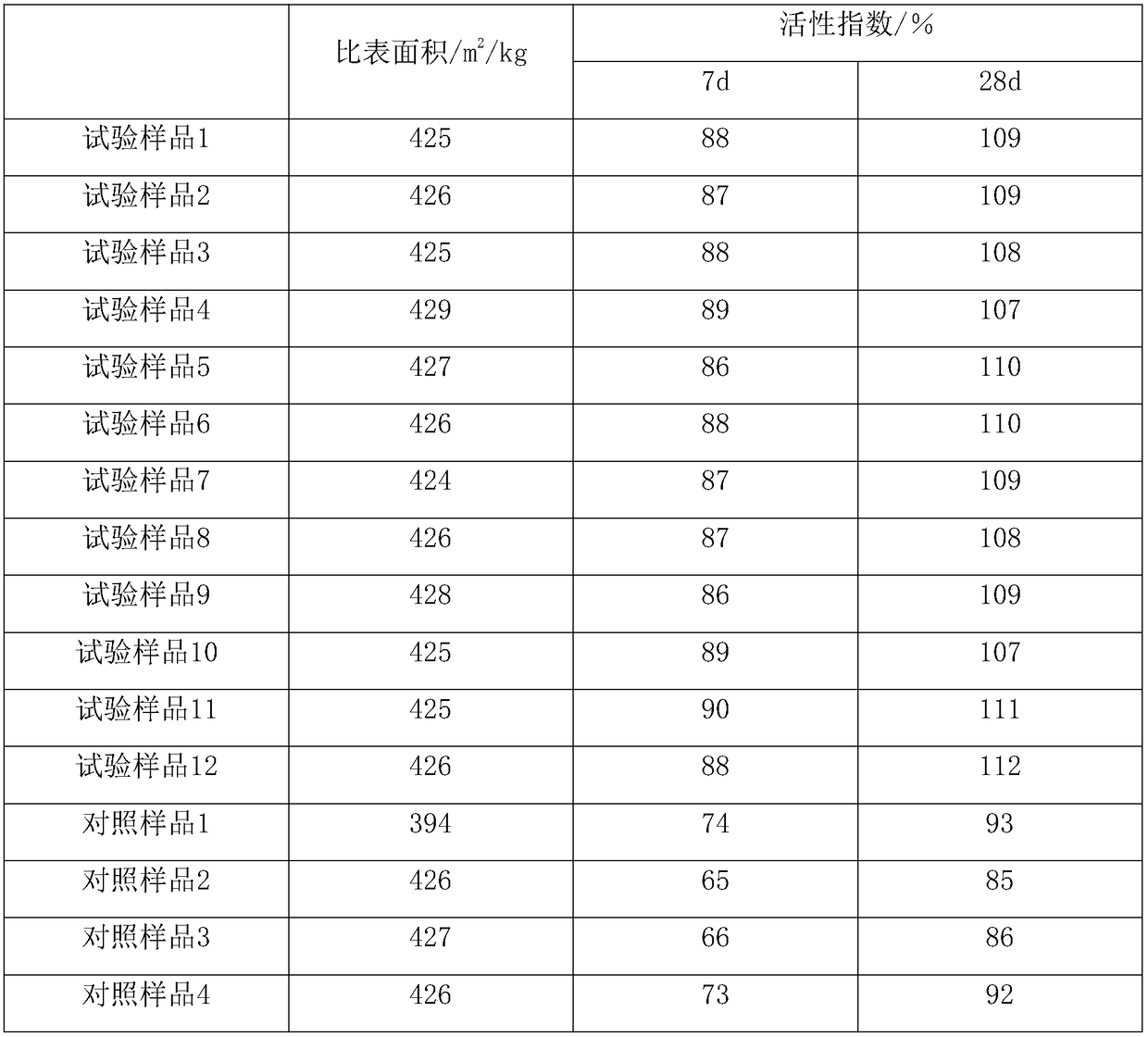

Examples

Embodiment 1

[0040] Embodiment 1: A kind of highly active slag powder, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0041] Step 1, select the alkaline slag with higher active components of Nangang, add triethanolamine in corresponding parts by weight, put it into a vertical mill for grinding, and the vertical mill speed is 120r / min;

[0042] Step 2, drying, passing hot air with a temperature of 105°C into the vertical mill for drying;

[0043] Step 3, putting sodium sulfate, potassium sulfate and slaked lime into a vertical mill for grinding to obtain a mixture;

[0044] Step 4: Grind cement clinker and gypsum together, and then stir and mix with the mixture in Step 3 to obtain high-activity slag powder.

Embodiment 2-10

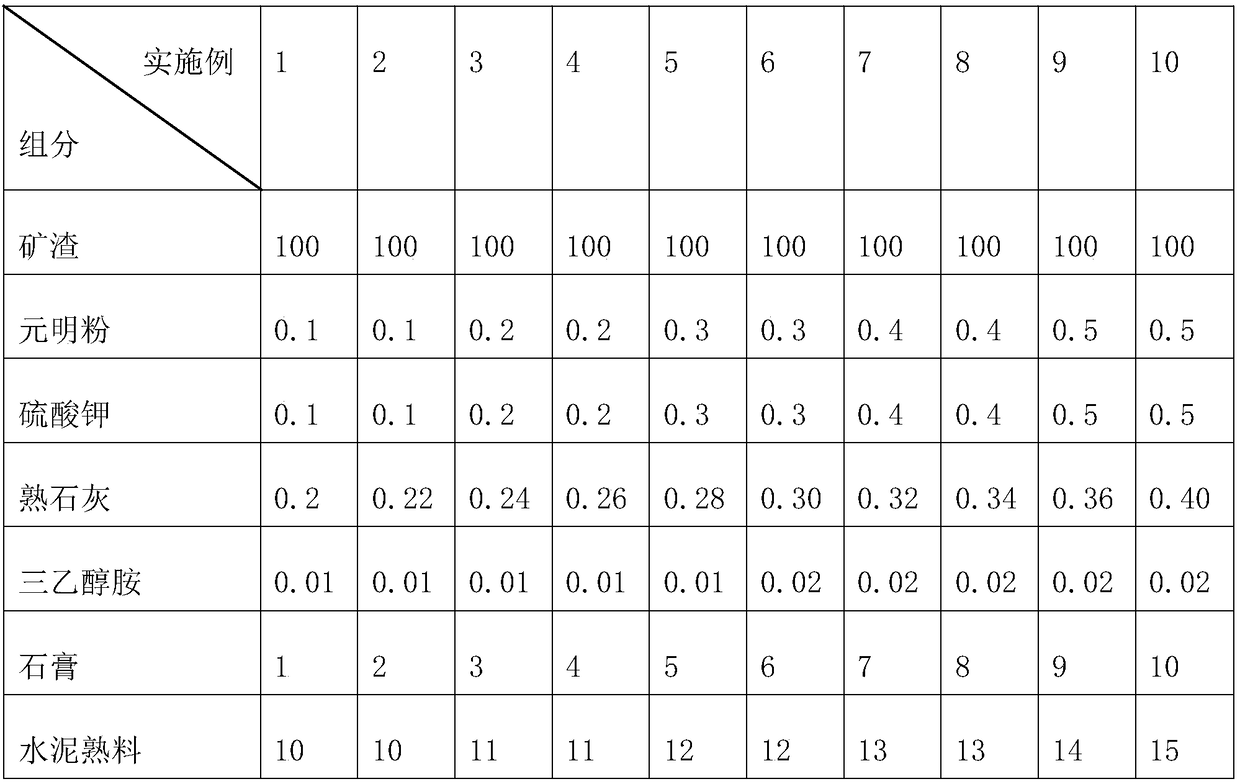

[0045] Example 2-10: a highly active slag powder, the difference from Example 1 is that the components and their corresponding parts by weight are shown in Table 1.

[0046] Each component and parts by weight thereof in table 1 embodiment 1-10

[0047]

Embodiment 11

[0048] Embodiment 11: a kind of highly active slag powder, the difference from embodiment 1 is that the grinding aid adopts glycerol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com