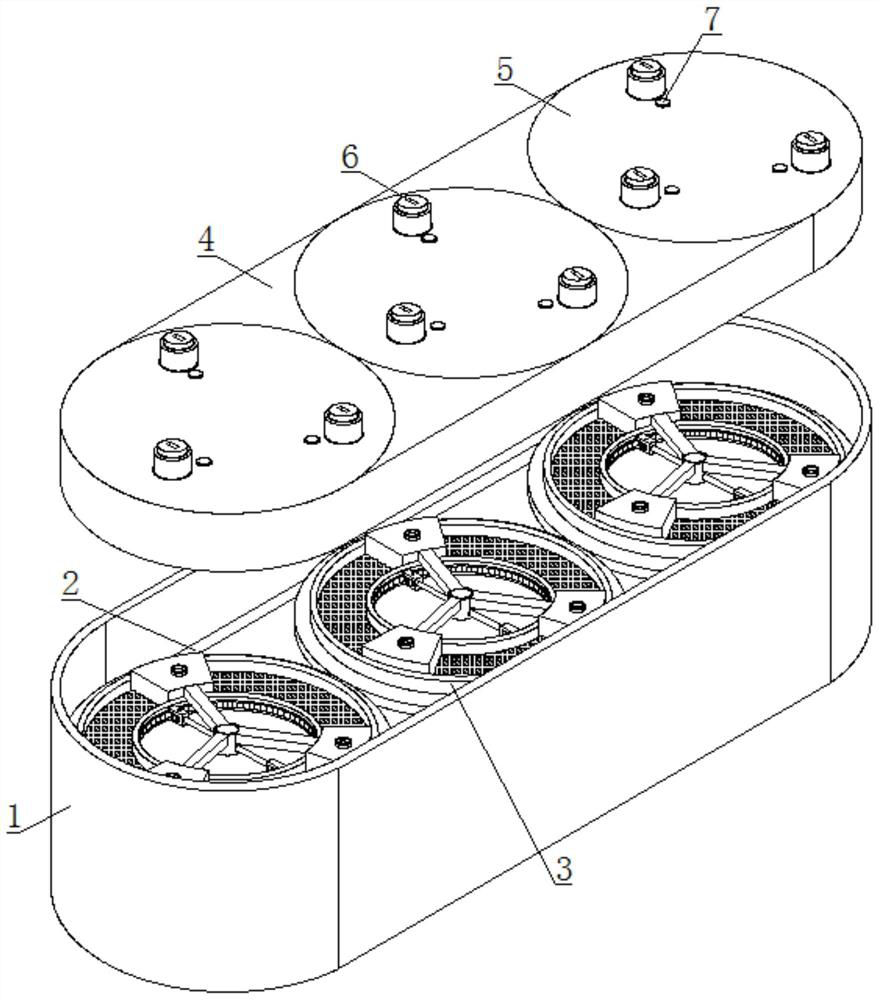

Water-based ink grinding and mixing device with proportion regulation and control function and implementation mode of water-based ink grinding and mixing device

A water-based ink and mixing device technology, which is applied in grain processing and other fields, can solve the problems of waste of resources, cumbersome operation, and low utilization rate of grinding machines, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

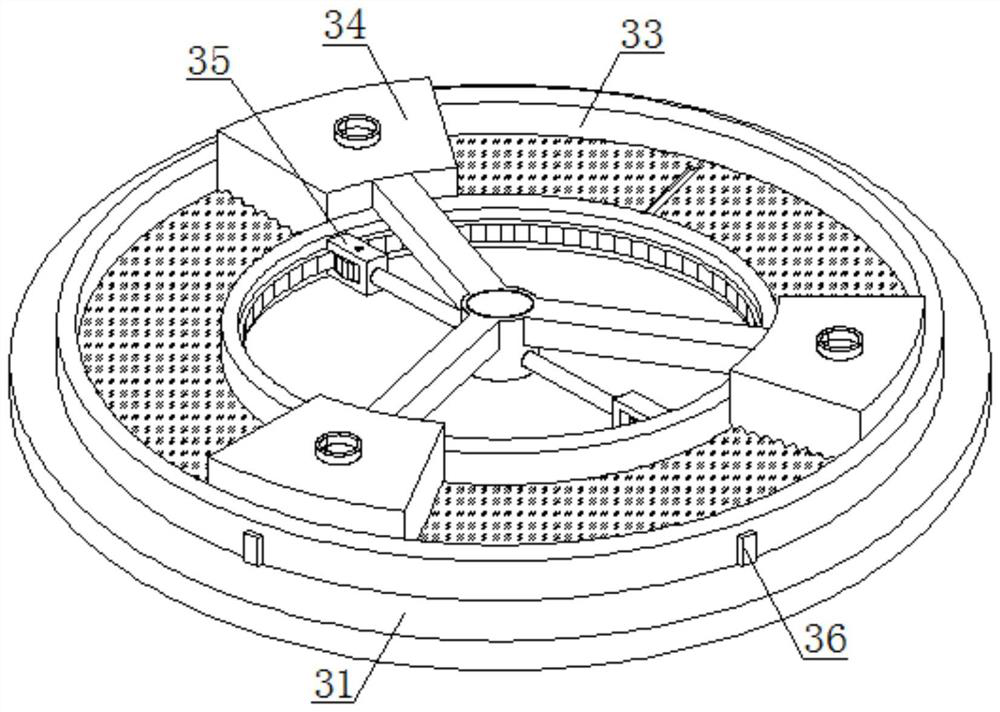

Method used

Image

Examples

Embodiment approach , 1 proportion Embodiment approach

[0052] In order to further better explain the above-mentioned embodiment, the present invention also provides a kind of embodiment, a kind of embodiment that possesses the water-based ink grinding and mixing device of regulating ratio, comprises the following steps:

[0053] Step 1: Pass several kinds of raw materials required for the deployment of water-based ink into the barrel cavity 65 from the feeding tray 71 along the reserved long hose 722 and the material guide vertical tube 72 for storage, and start the third driving rotary rod 678 , the extrusion block 677 pushes the push ring 672 along the extrusion groove 673, the piston disk 66 discharges the material stored in the cylinder chamber 65 along the liquid outlet groove 643, and the pressing height of the piston disk 66 is determined by the circumference of the extrusion block 677 Determined by the diameter of the movement path, when the extruding block 677 is close to the center of the rotating disk 671, the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com