Stokehole coal pulverization device

A pulverizing device, coal furnace technology, applied in the direction of grain processing, etc., can solve the problems that the grinding effect is difficult to guarantee, hinder the operation of coal pulverization, etc., and achieve the effect of improving the grinding efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

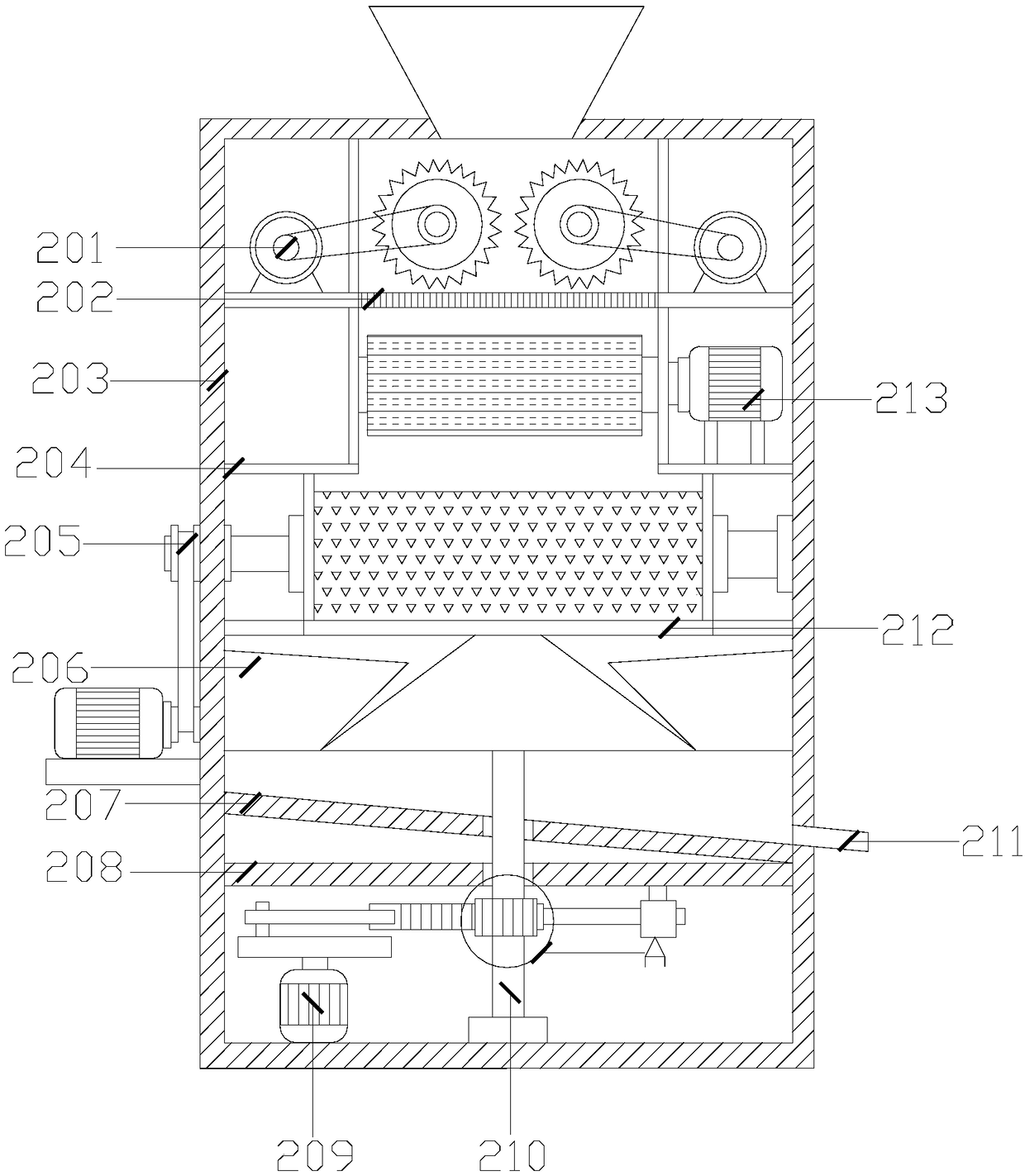

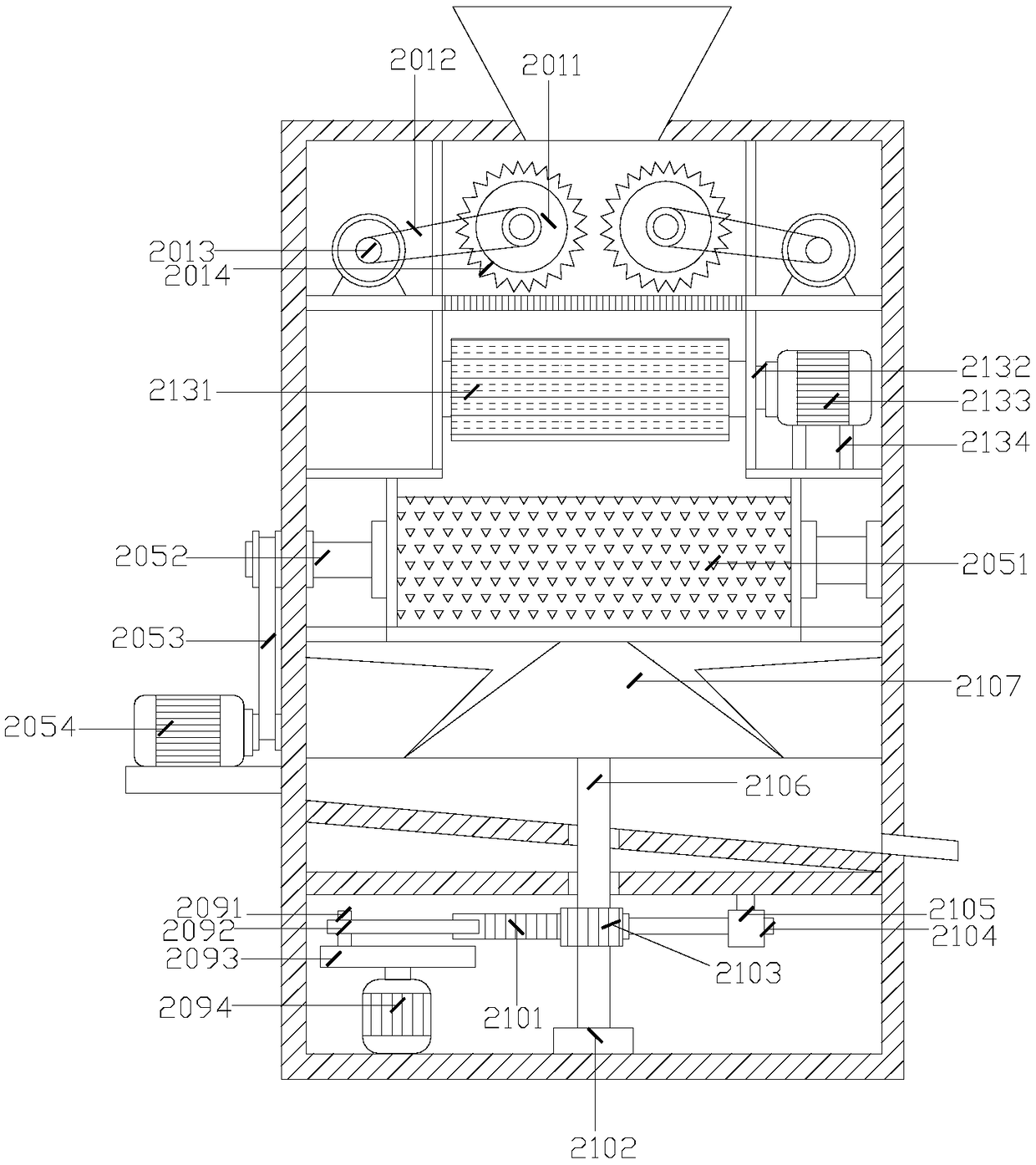

[0021] like Figure 1-Figure 5 As shown, the present invention provides a coal pulverizing device in front of a furnace, the structure of which includes a powder outlet 1, a rolling and grinding pulverizing mechanism 2, a control host 3, a regulator 4, a hopper 5, and an iron taking door 6. The front end of the rolling, grinding and pulverizing mechanism 2 is fixedly provided with a groove for movable installation of the powder outlet 1, and the two are integrally formed structures. And the two are fitted together, the rear end of the iron-receiving material door 6 is fixedly buckled to the top of the front end of the rolling, grinding and pulverizing mechanism 2 and is reinforced and connected by connecting parts, and the regulator 4 is transversely welded to the rolling and grinding system. The top of the powder mechanism 2 is fixedly connected by a positioning pin. The bottom of the hopper 5 is fixedly welded to the upper end of the regulator 4 and communicates with the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com