Cement production method

A production method and cement technology, applied in cement production, clinker production, etc., can solve the problems of unfavorable environmental protection, high production cost, and low efficiency, and achieve the effects of increasing the output of the machine, occupying a small area, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

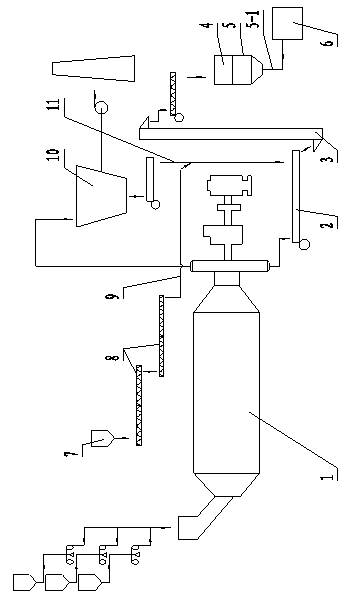

Image

Examples

Embodiment 1

[0025] The cement that present embodiment produces PⅡ42.5 comprises the preparation material of following percentage by weight: cement clinker 83.3%, gypsum 4.2%, limestone 4.5%, slag micropowder 8%, and its production method comprises the following steps:

[0026] A. Use high-fine grinding ball mill to pre-grind slag to form slag powder, and the specific surface area of slag powder is controlled at 440m 2 / kg, 45μm sieve ≤ 1.0%, send the slag fine powder to the silo for standby;

[0027] B. After weighing the cement clinker, gypsum and limestone calculated according to the above raw material ratio with a feeding scale, put them into a ball mill and mix and grind them until the specific surface area is 345 m 2 / kg, 80μm sieve ≤ 3.2%, 45μm sieve ≤ 17.0%;

[0028] C. Send the fine powder milled in step B into the air conveying chute placed at the end of the grinding process. At the same time, the slag fine powder calculated according to the above raw material ratio is passed th...

Embodiment 2

[0033] The cement that present embodiment produces P.O42.5 comprises the preparation material of following percentage by weight: cement clinker 72.2%, gypsum 4.8%, limestone 7%, slag micropowder 16%, and its production method comprises the following steps:

[0034] A. Use high-fine grinding ball mill to pre-grind slag to form slag powder, and the specific surface area of slag powder is controlled at 440m 2 / kg, 45μm sieve ≤ 1.0%, send the slag fine powder to the silo for standby;

[0035] B. After weighing the cement clinker, gypsum and limestone calculated according to the ratio of the above raw materials with a feeding scale, put them into the ball mill together and mix and grind until the sieve residue of 80 μm is ≤3.0%;

[0036] C. Send the fine powder milled in step B into the air conveying chute placed at the end of the grinding process. At the same time, the slag fine powder calculated according to the above raw material ratio is passed through the reamer conveyor fro...

Embodiment 3

[0041] The cement of present embodiment production P.O52.5 comprises the compounded material of following percentage by weight: cement clinker 87.2%, gypsum 4.3%, limestone 3.5%, slag micropowder 5%, and its production method comprises the following steps:

[0042] A. Use a high-fine grinding ball mill to pre-grind the slag to form slag powder. The fineness of the slag powder is controlled at 45 μm and the sieve ≤ 1.0%, and the slag powder is sent to the silo for standby;

[0043] B. After weighing the cement clinker, gypsum and limestone calculated according to the ratio of the above raw materials with a feeding scale, put them into the ball mill together for mixing and grinding until the specific surface area is 365m 2 / kg, 80μm sieve ≤ 3.0%, 45μm sieve ≤ 17.0%;

[0044] C. Send the fine powder milled in step B into the air conveying chute placed at the end of the grinding process. At the same time, the slag fine powder calculated according to the above raw material ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com