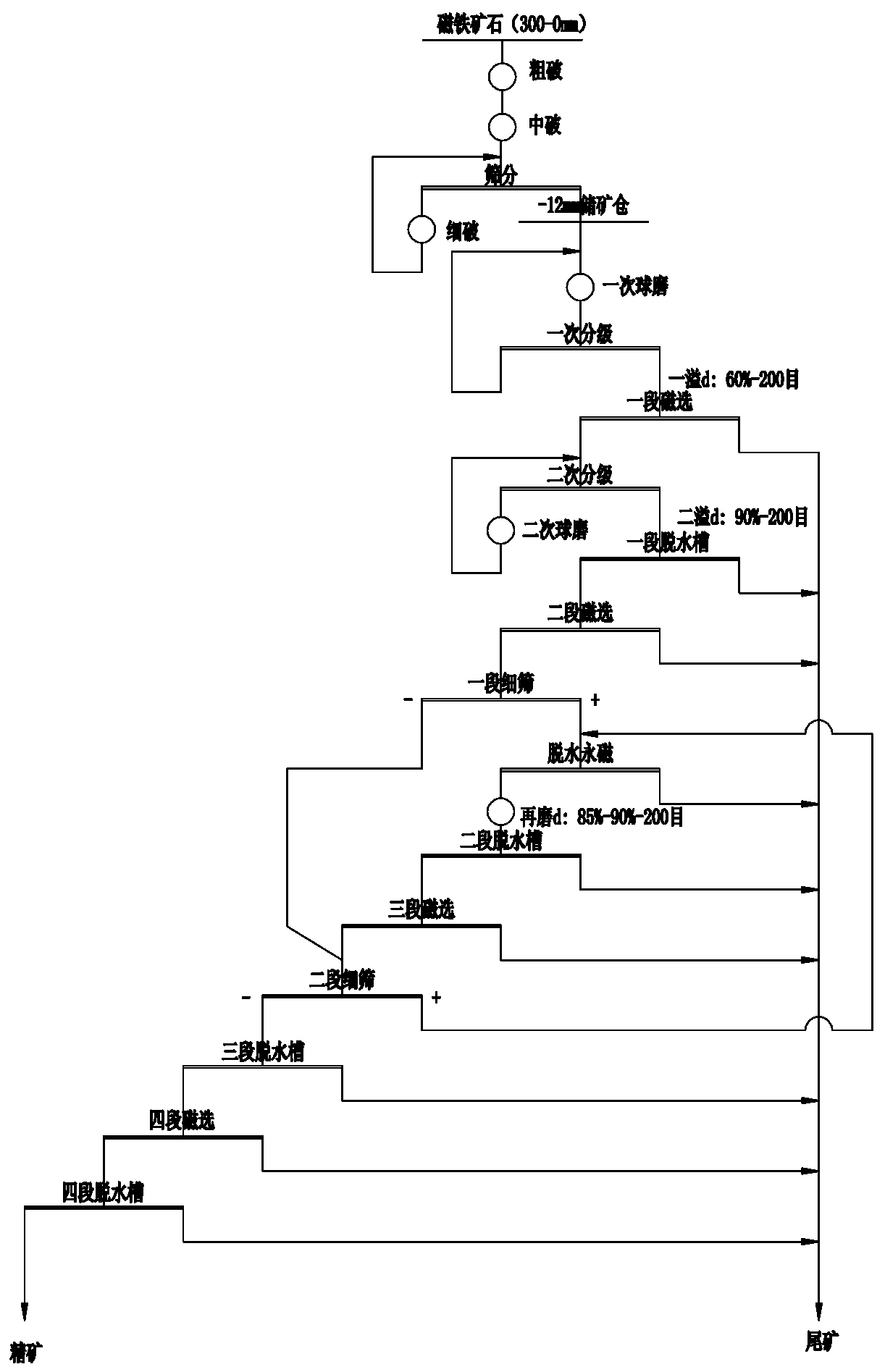

Magnetite high compression rolling wet pre-concentration-stage grinding-fine screen tower rolling magnetic separation process

A high-pressure roller mill and stage grinding technology, which is applied in the magnetite high-pressure roller mill wet field, can solve the problems of high beneficiation cost, unstable process, and large number of crushing sections, achieving significant economic benefits, improving grinding fineness, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

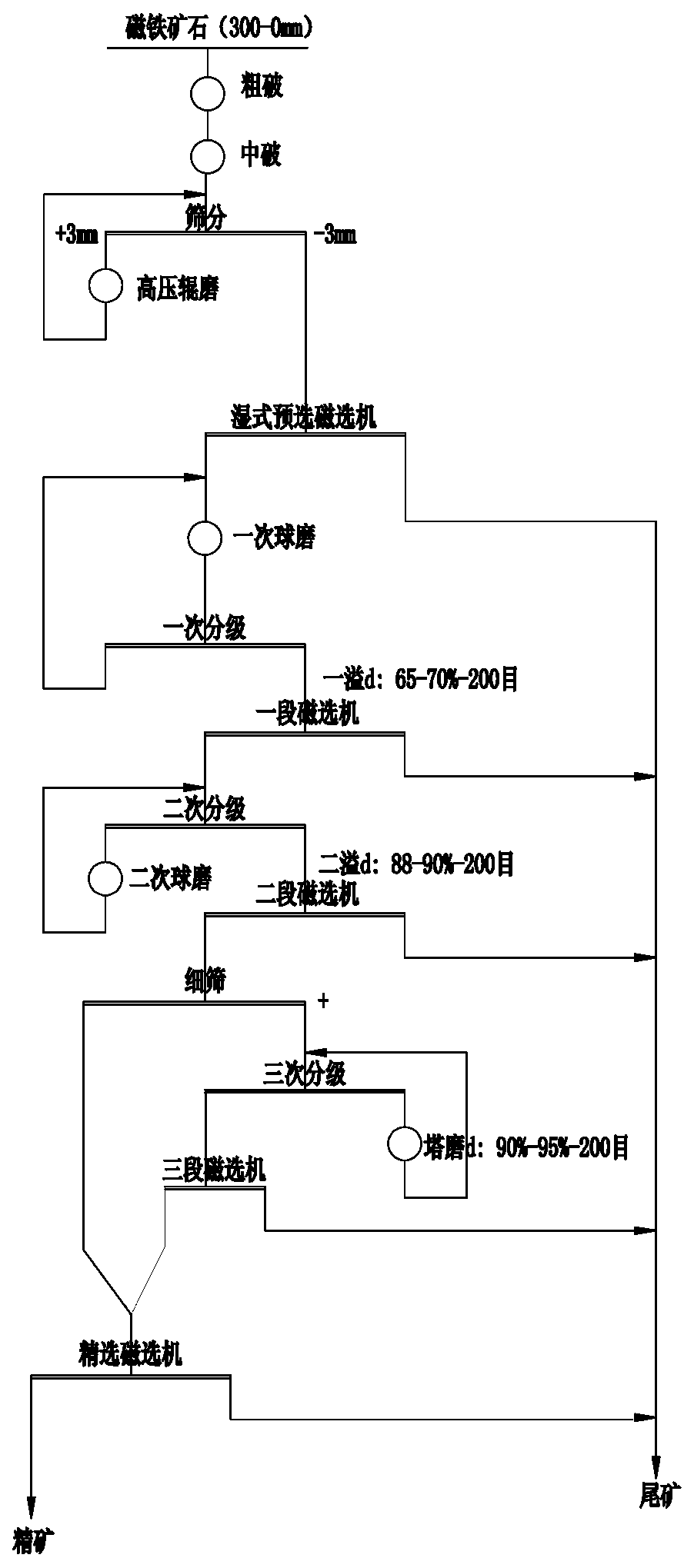

[0038] Such as figure 2 Shown: a kind of magnetite high-pressure roller mill wet type pre-selection-stage grinding-fine screen tower mill magnetic separation process of the present invention comprises rough breaking operation and medium breaking operation, is characterized in that also comprising the following steps:

[0039] 1) The secondary crushing product with a grade of 31.5% and a particle size of 25mm-0 mm is fed into a closed-circuit high-pressure roller mill-screening operation composed of a high-pressure roller mill and a screening device to obtain a high-pressure crushing product with a particle size of 3mm-0 mm. Roller mill-screening products, the high-pressure roller mill model is GLGY-06025H roller mill;

[0040] 2) Feed the high-pressure roller mill-screened product into the wet pre-separation magnetic separator to obtain the wet pre-separation magnetic separator concentrate with a grade of 36.5% and the wet pre-magnetic separator tailings with a grade of 7.95%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com