Method for increasing magnetic field intensity in magnetic field separation area and magnetic separation equipment

A magnetic separation equipment and magnetic field technology, applied in the method and magnetic separation equipment, to improve the field of magnetic field strength in the magnetic field separation area, can solve the problems of low removal efficiency of magnetic objects, no relative movement, and no display of disadvantages, etc., to reduce non-magnetic Effects of inclusion of magnetic substances, improvement of grinding grade, and reduction of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

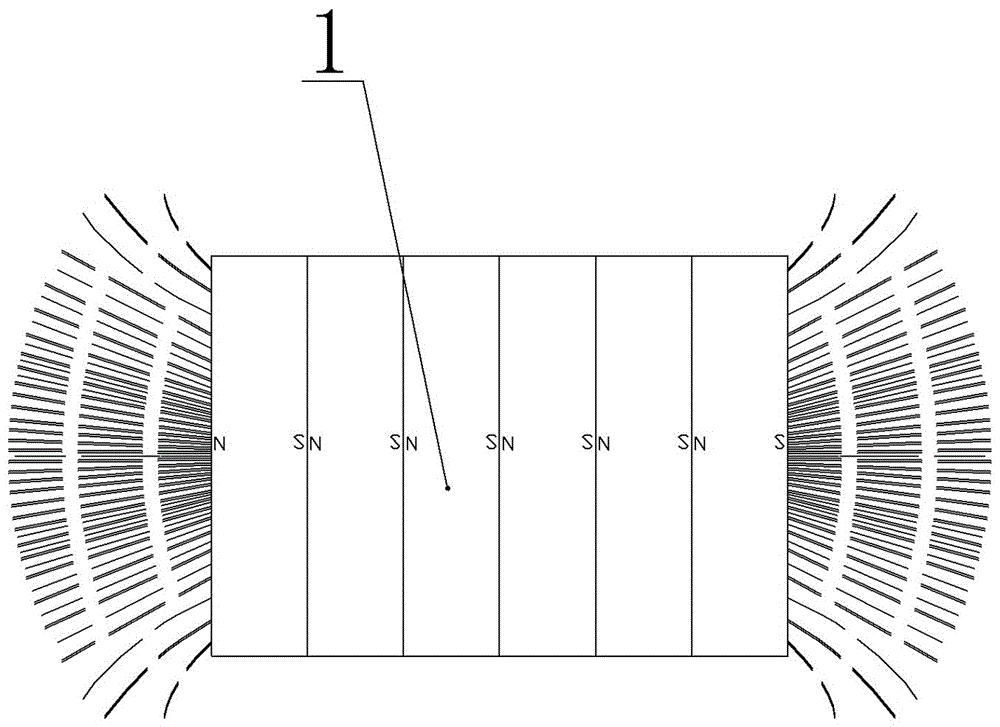

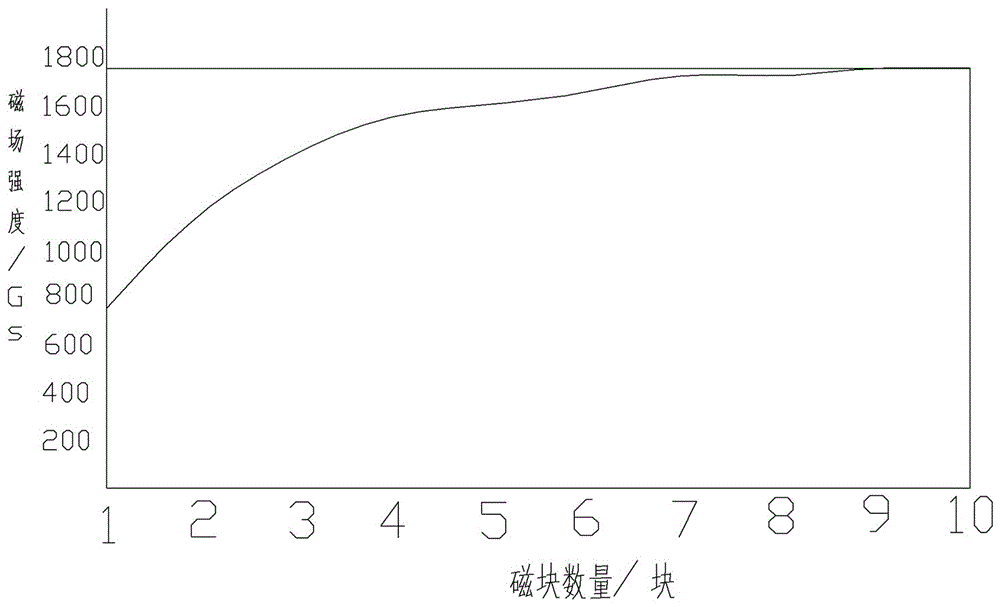

[0040] Embodiment one: see Figure 5-Figure 7 , a method for increasing the magnetic field intensity of the permanent magnet magnetic field sorting area, arrange the N poles and N poles, S poles and S poles of several square permanent magnet blocks 1 with relative gaps one by one, and press them tightly through a fixed frame such as a magnetic system fixing frame The permanent magnetic block group 10 is formed, thereby extruding the original square magnetic block N pole and S pole plane magnetic field into a high-field-strength strip with N poles and S poles alternately arranged along the magnetic block gap of the square magnetic block group magnetic field.

[0041] Several magnetic gathering media are arranged within the effective range of the high field strength strip magnetic field to convert the continuous strip magnetic field into discontinuously distributed magnetic gathering points, thereby further strengthening the field strength of the strip magnetic field.

[0042] ...

Embodiment 2

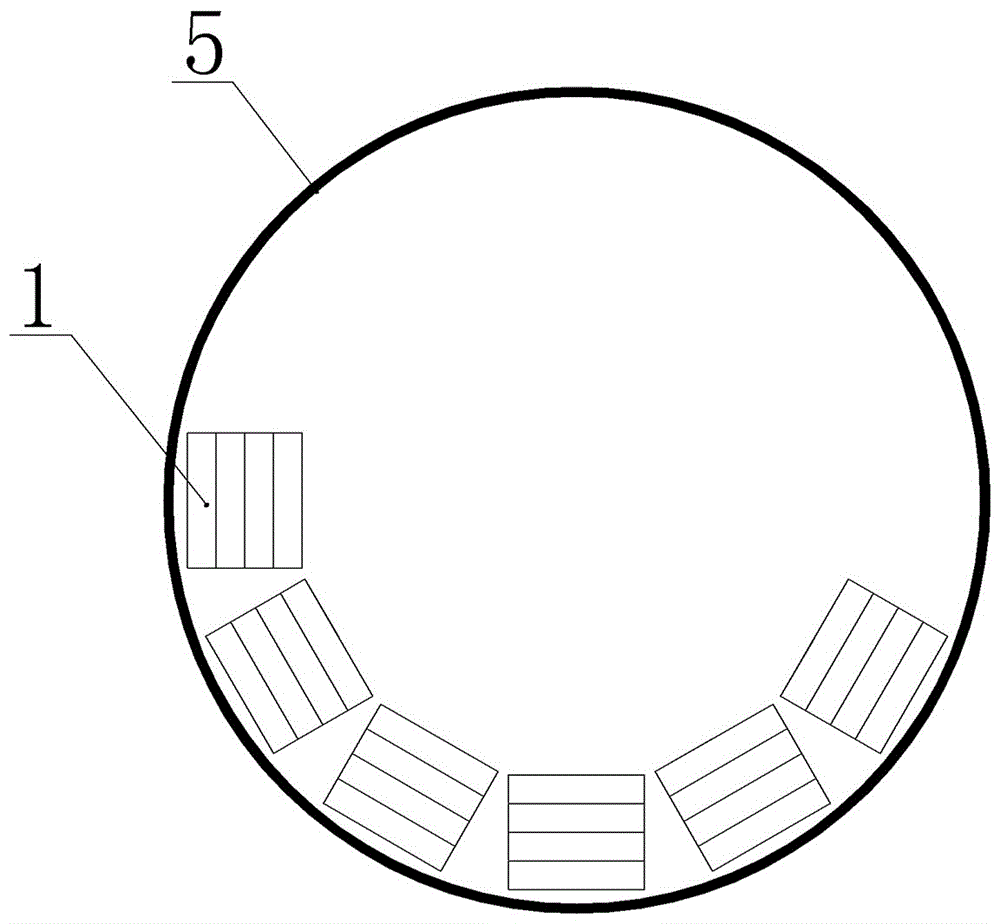

[0043] Embodiment two: see Figure 5-Figure 8 , this embodiment adopts the magnetic system arrangement method described in Embodiment 1 to further complete the magnetic system structure applied to the magnetic separation equipment, which is a strip-shaped strong magnetic field permanent magnetic field that improves the magnetic field intensity of the permanent magnetic field separation area. In the magnetic system, the permanent magnet blocks 10 are continuously arranged in m groups along the sides of a regular polygon with M sides to form N poles and S poles with the center of the regular polygon as the vertex and m×360° / M as the wrap angle The strip-shaped strong magnetic field permanent magnet system arranged densely and alternately, where m≤M, according to different magnetic separation equipment, the wrap angle of the magnetic system is selected according to actual requirements.

Embodiment 3

[0044] Embodiment three: see Figure 5-Figure 9 , a permanent magnetic separation equipment for non-metallic ore iron removal, which is a dry magnetic separation equipment, including a frame 2, a box 4 with a magnetic mineral discharge port 8 at the bottom of the top opening and a box body arranged horizontally 4, the cylindrical barrel 5 in the box body 4 is fixedly provided with a strip-shaped strong magnetic field permanent magnet magnetic system coaxial with the cylindrical barrel 5 by a magnetic system fixing frame 25 on the top of the box body 4, and the strip-shaped strong magnetic field The permanent magnet magnetic system includes m permanent magnet block groups that are continuously distributed along the sides of a regular polygon whose number of sides is M, wherein m<M, and the permanent magnet block groups are N poles and N poles, S poles, and S poles are arranged and compressed one by one to form a permanent magnet block group. The magnetic system wrap angle α of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com