Magnetite dry-separation tailing-discarding pre-separation technology

A magnetite and dry separation technology, applied in the directions of magnetic separation, solid separation, sieving, etc., can solve the problems of restricting the grade of iron ore concentrate, low recovery rate, increase of beneficiation cost, etc., to increase raw ore processing capacity and iron The effect of concentrate production, effective mineral resources, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

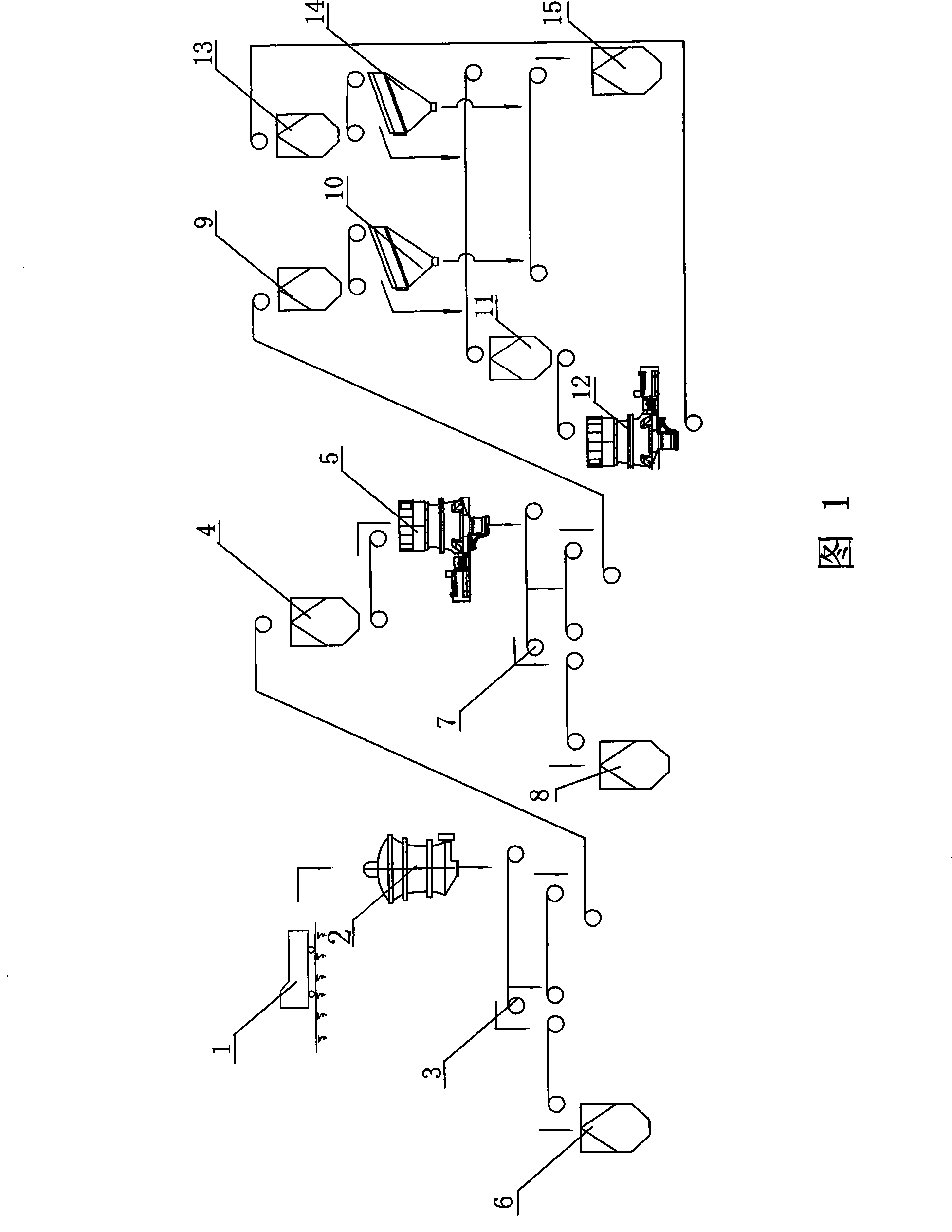

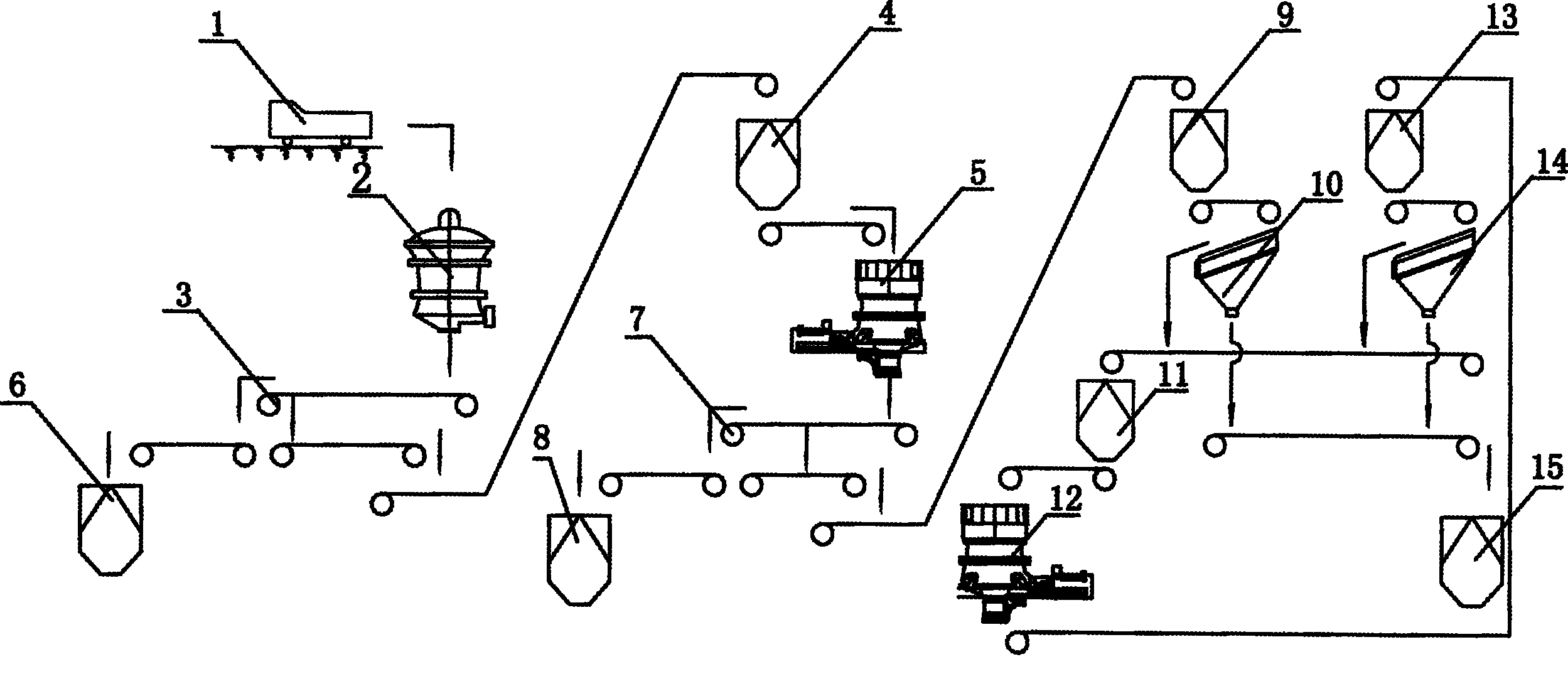

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 Shown, magnetite dry selection of the present invention throws tailings pre-selection process flow as follows:

[0020] (1) The magnetite ore is sent to the coarse crusher 2 by the mine car 1 for crushing, and the coarse crusher 2 discharges the material through the coarse crushing belt conveyor into a section of dry magnetic pulley 3, and separates a section of concentrate product and a section of waste rock.

[0021] (2) A section of concentrate product enters the middle crusher 5 through the middle crusher ore bin 4 from the first section of the concentrate belt machine, and a section of waste rock enters the first section of waste rock bin 6 through the third belt conveyor.

[0022] (3) The discharge of the intermediate crusher 5 enters the second-stage dry magnetic pulley 7 through the intermediate cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com