Patents

Literature

79results about "Iron carbonyls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

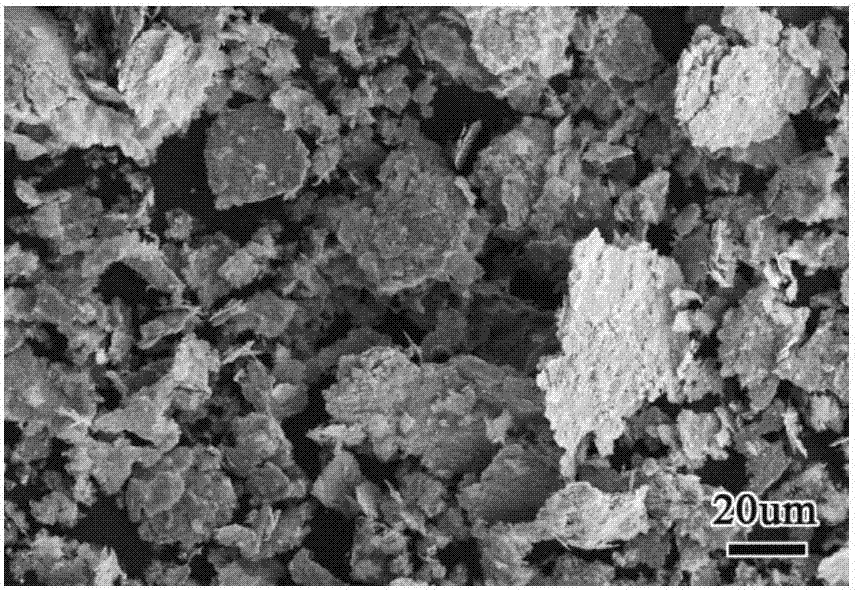

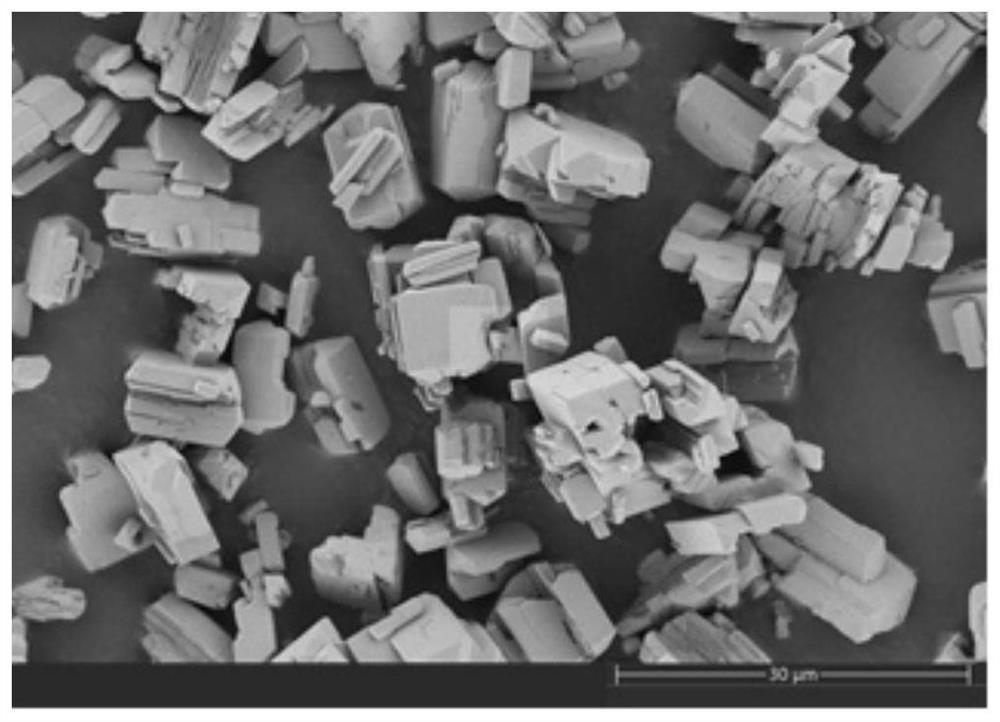

Preparation method for flaky carbonyl iron powder with high magnetic permeability

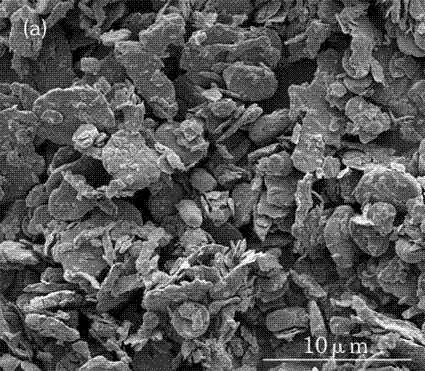

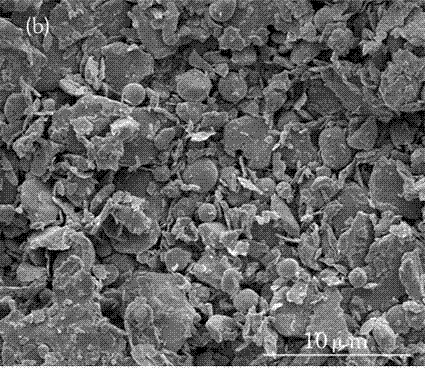

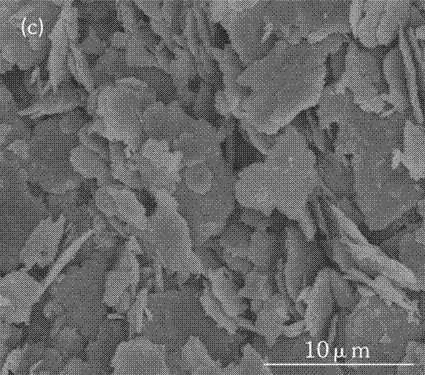

InactiveCN102815754ASimple materialEasy to operateMaterial nanotechnologyIron carbonylsIron powderActive agent

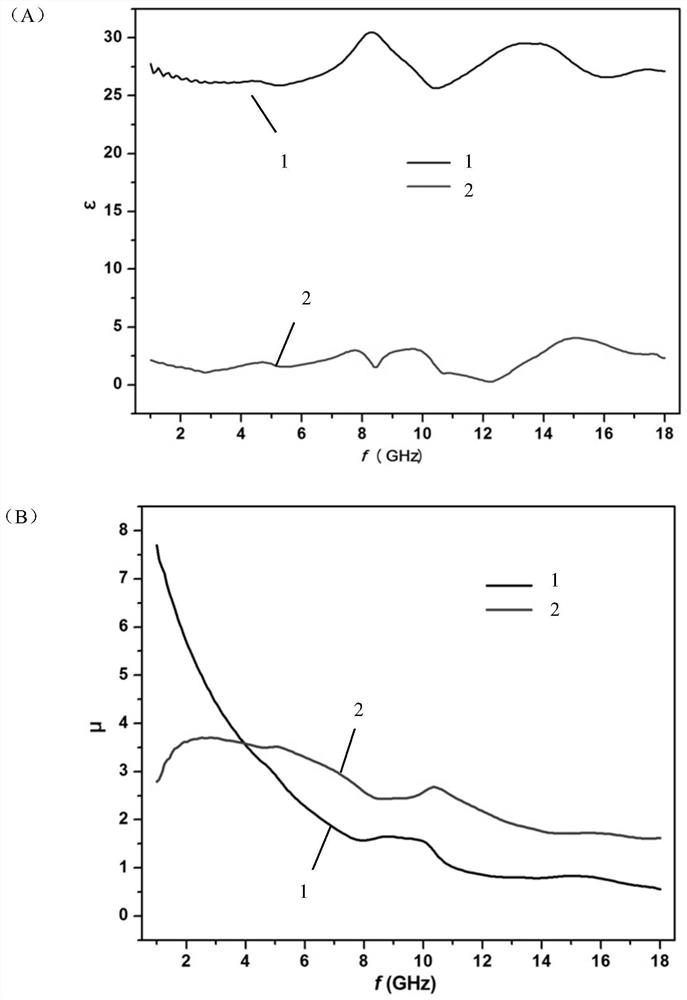

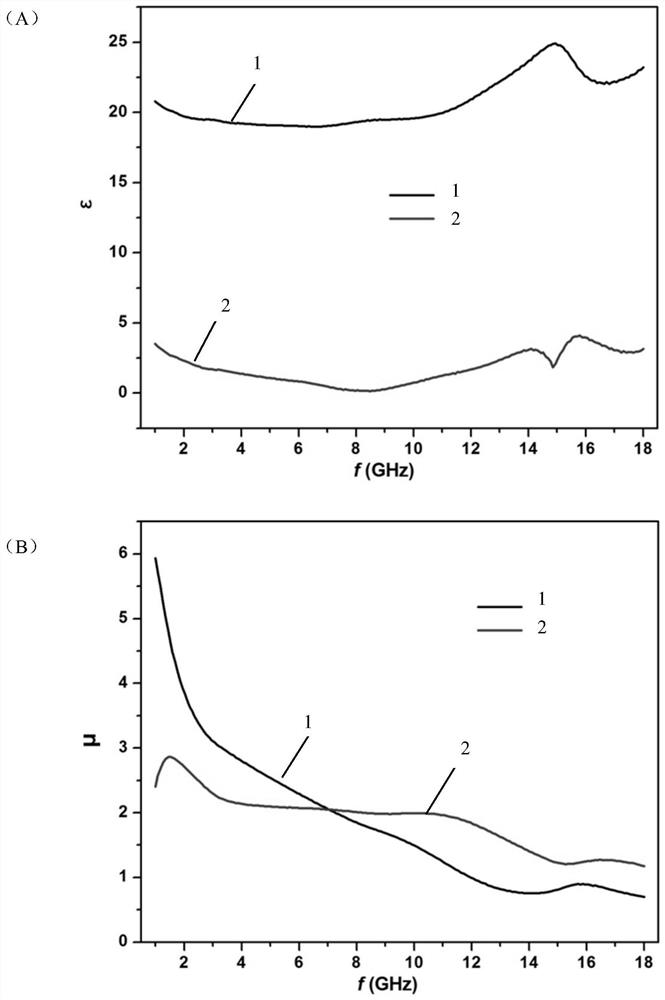

The invention relates to a preparation method for flaky carbonyl iron powder with high magnetic permeability, and belongs to the field of magnetic wave absorbing materials. The method comprises the following steps: 1, carrying out a primary ball milling process: at a room temperature, weighing 100-150 g of steel balls with a diameter of 3-6 mm, 5-10 g of carbonyl iron powder, and 0.01-0.1 g of a surfactant calcium stearate, measuring 30-50 ml of an organic solution, adding the materials and the solution to a 100 ml ball mill tank, and carrying out ball milling in a planetary type ball mill; 2, washing the carbonyl iron powder with the primary ball milling three times by using ethanol, and carrying out blow-drying at a room temperature or carrying out rapid drying at a temperature of 50-70 DEG C; 3, carrying out a secondary ball milling process: mixing the dried carbonyl iron powder and steel balls with a diameter of 3-6 mm according to the ratio of the primary ball milling process described in the step 1, and then carrying out ball milling for 2-10 minutes at a speed of 400-600 rotation / min; and 4, cooling the ball milling tank, and then separating the iron powder and the steel balls to obtain the flaky carbonyl iron powder sample. The process of the preparation method of the present invention is simple. With the preparation method of the present invention, a dielectric property is not changed while high magnetic permeability is provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

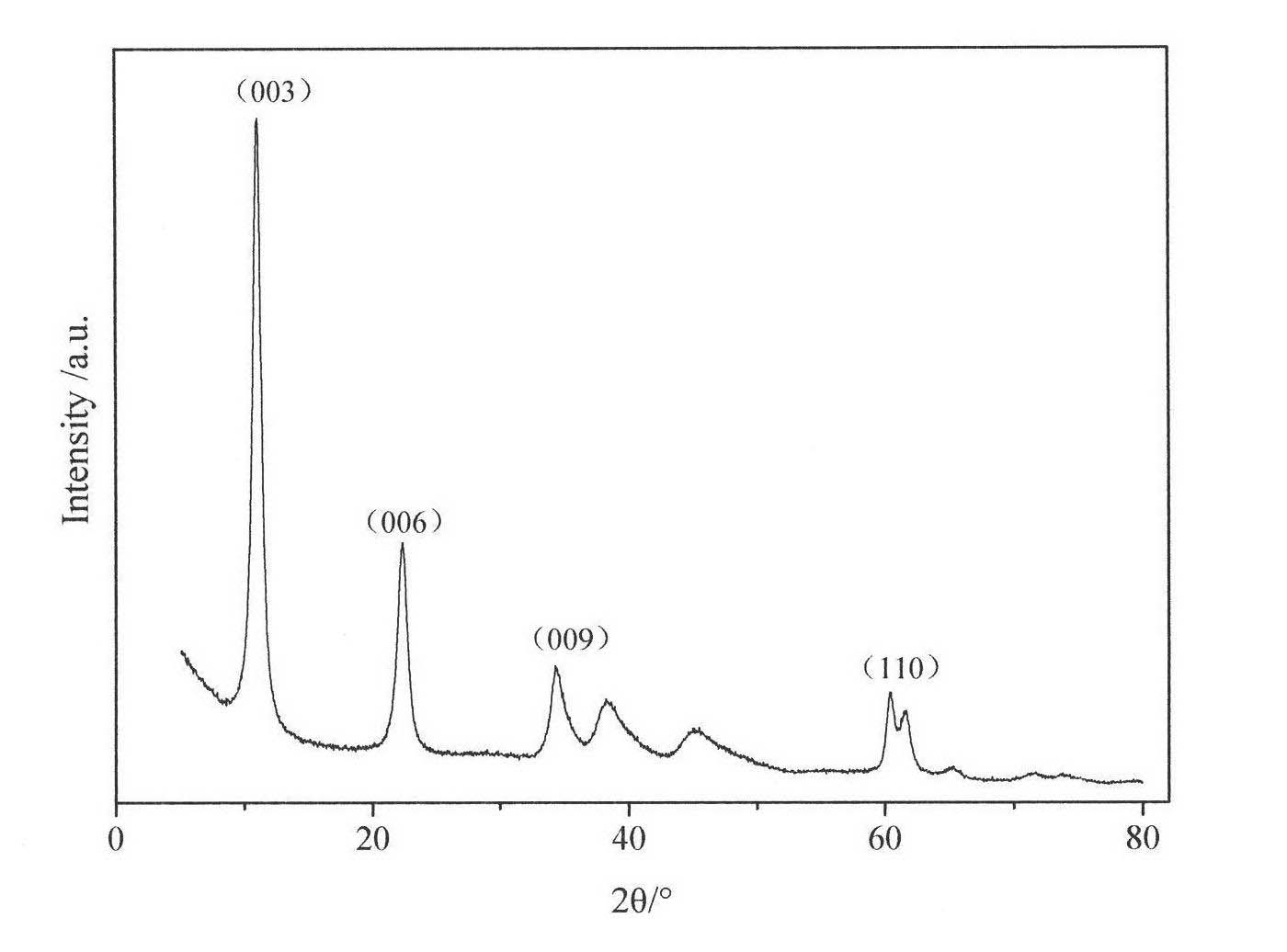

Method for preparing hydrotalcite

InactiveCN101817510AGuaranteed grain size uniformityReduce pH fluctuationsOxide/hydroxide preparationIron oxides/hydroxidesHydrotalciteBuffer solution

The invention relates to a method for preparing hydrotalcite, which comprises the following steps of: (1) preparation of buffer solution, namely preparing the buffer solution with a pH value of 9 to 10 by using aqueous ammonia and ammonium chloride or aqueous ammonia and ammonium bicarbonate; (2) dripping of metal salt solution, namely dripping the metal salt solution into the stirred buffer solution, and continuously stirring the solution for 1 to 1.5 hours after the dripping is finished; (3) crystallization and washing, namely crystallizing the stirred mixed solution for 6 to 24 hours at the temperature of between 55 and 95 DEG C, and filtering and washing the crystallized solution to obtain filter solution and filter cakes; and (4) drying and grinding, namely drying the filter cakes at the temperature of between 55 and 95 DEG C and grinding the filter cakes into powder. The method provides a stable solution environment with a pH value of 9 to 10 for the formation of the hydrotalcite by using the buffer solution used as a precipitating agent, ensures complete crystal phase structure and uniform grain size of a hydrotalcite product, and solves the problems of difficult pH value control, wide grain size distribution and the like during preparing the hydrotalcite by using a traditional co-precipitation method in the industry.

Owner:HUZHOU TEACHERS COLLEGE

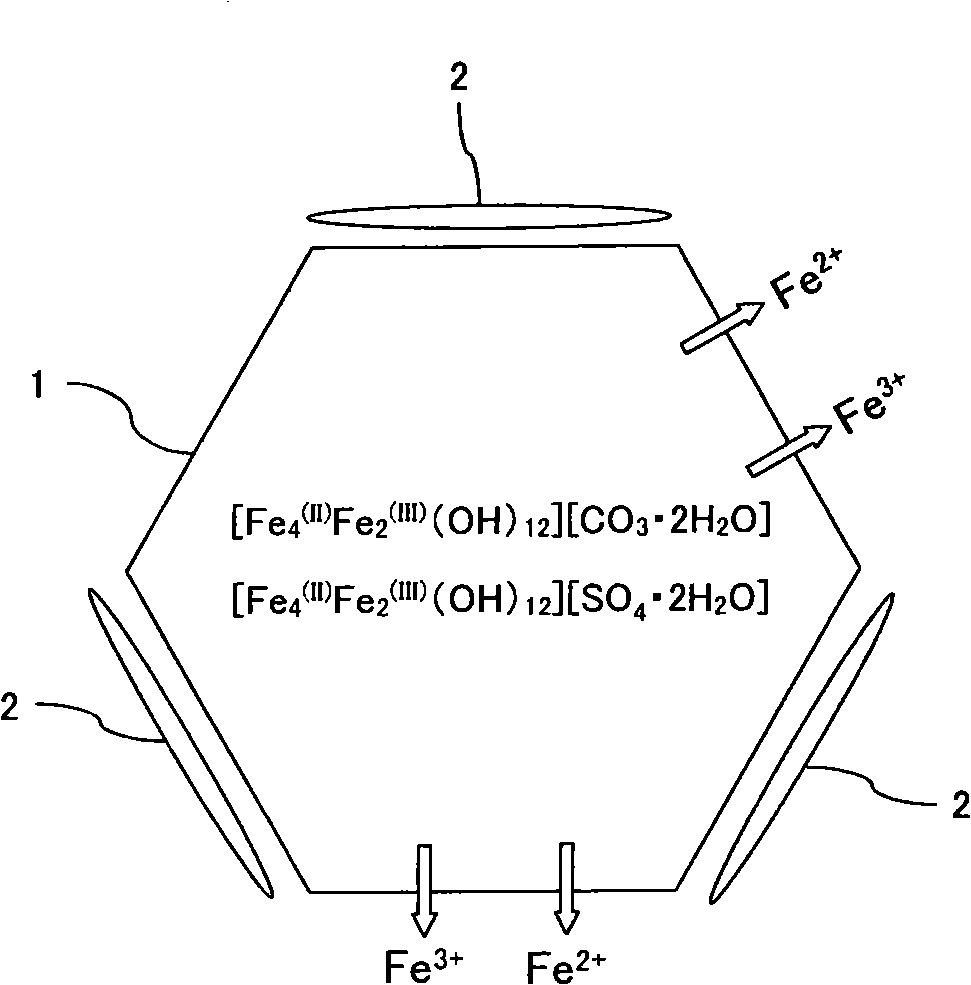

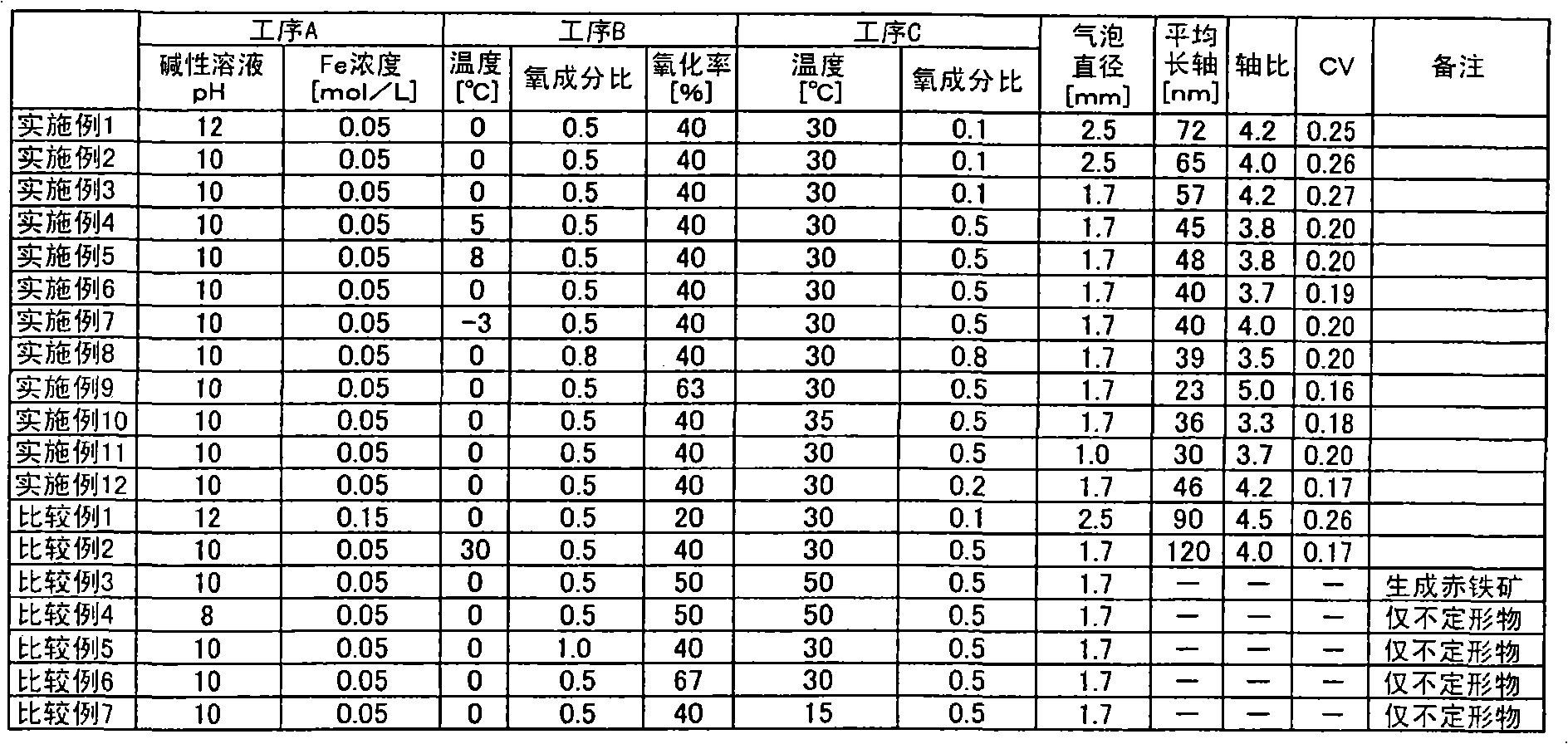

Method for producing iron oxyhydroxide particle

Owner:TDK CORPARATION

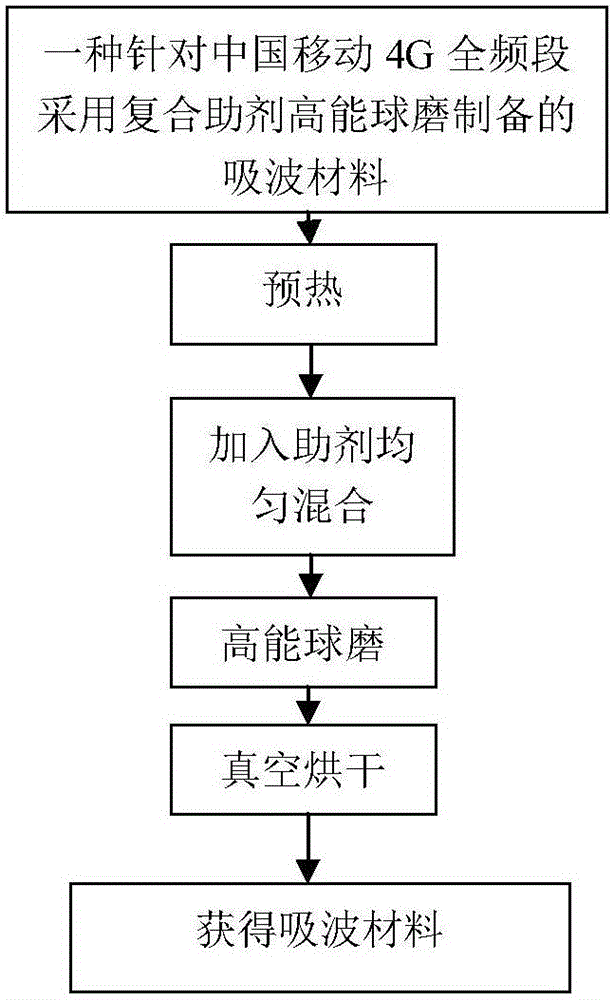

China Mobile 4G full band absorbing material, and preparation method and application thereof

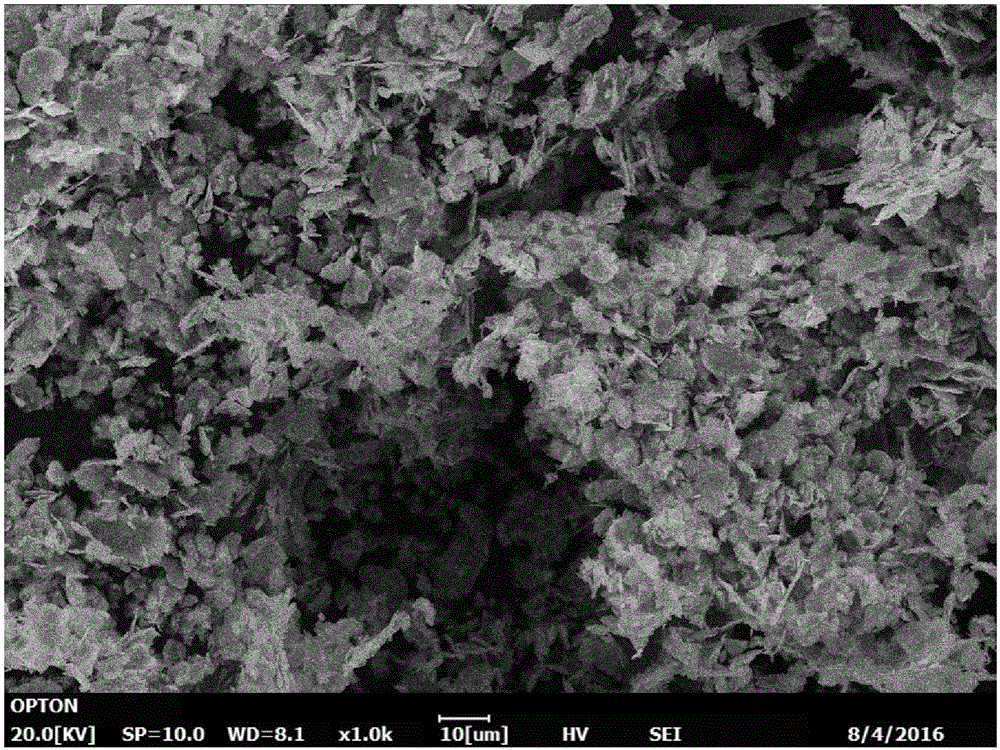

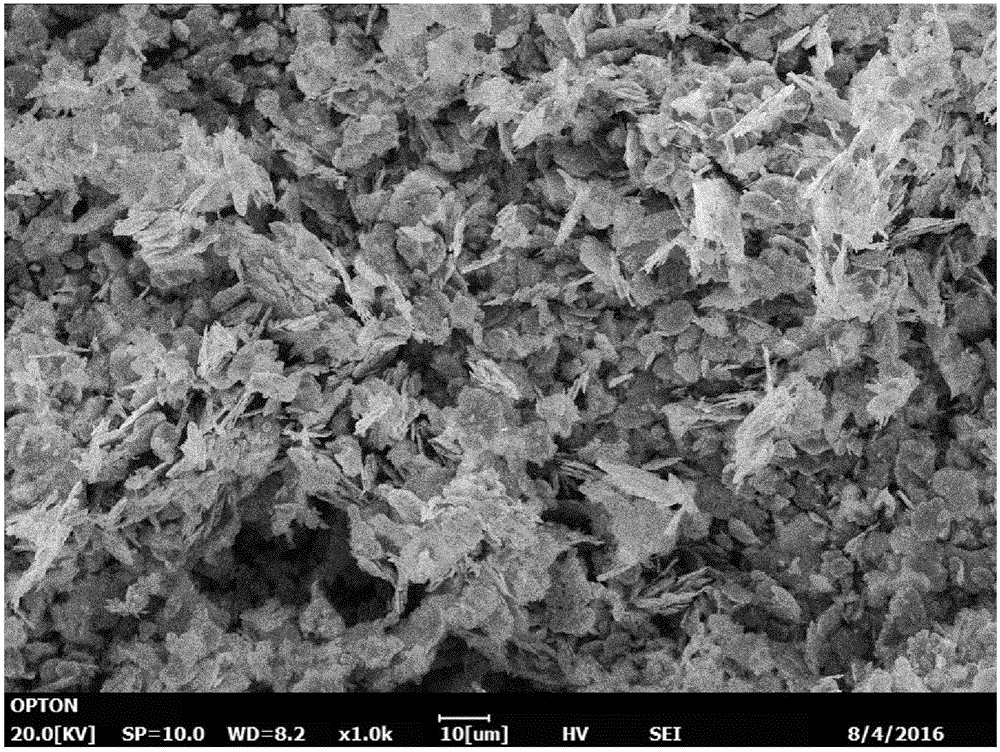

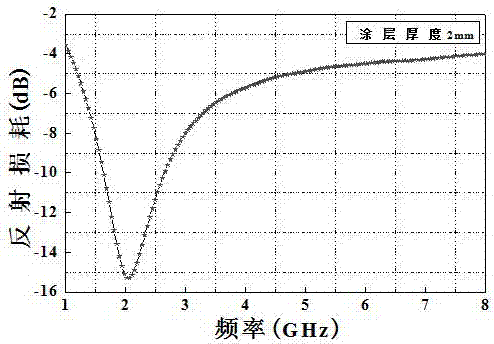

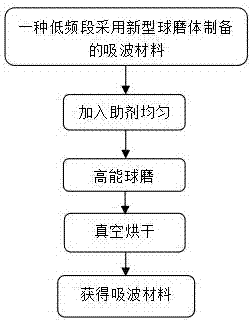

ActiveCN106064837AImproved signal-to-noise ratio performanceImprove communication qualityOther chemical processesIron carbonylsHigh energyImpedance matching

The invention discloses a China Mobile 4G full band absorbing material, and a preparation method and application thereof. A composite auxiliary agent of a silane coupling agent and a stearate surfactant is added to a carbonyl iron powder, and a high-energy ball milling process is carried out to prepare a sheet-shape carbonyl iron powder absorbing material with excellent impedance matching performance. The material can meet the following requirements: in the frequency range from 1 to 18 GHz, an absorbing coating has thickness of less than or equal to 2mm; the absorbing material has -8dB absorption bandwidth reaching 1.5GHz (1.3-2.8GHz), which completely covers the whole band of China Mobile 4G (1.8GHz-2.8GHz); the proportion of the silane coupling agent and stearate can be adjusted to obtain proper sheet structure and size, thus changing the relationship between the complex permittivity and complex permeability to reach impedance matching, and then adjusting the absorption peak position. The material achieves the purpose of selecting absorption interference noise at three arbitrary main frequencies of China Mobile 4G and improving the signal-to-noise ratio of the base station and mobile terminal.

Owner:南京威勒信息技术科技有限公司

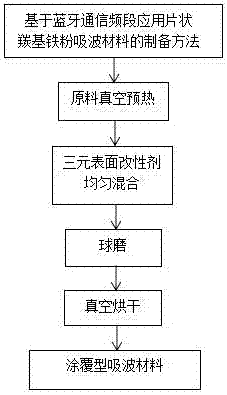

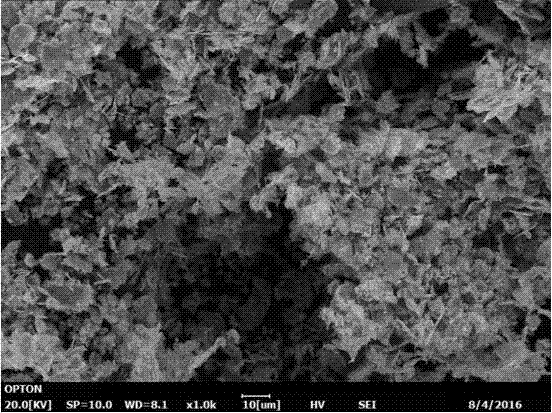

Preparation method of flaky carbonyl iron powder wave-absorbing material based on application of Bluetooth communication frequency band

ActiveCN107043134AEasy to manufactureImproving Impedance MatchingOther chemical processesIron carbonylsReflection lossPeak value

The invention discloses a preparation method of a flaky carbonyl iron powder wave-absorbing material based on application of a Bluetooth communication frequency band. The preparation method comprises the following steps: preheating carbonyl iron powder in vacuum, charging the preheated carbonyl iron powder and a ternary surface modifier together into a ball milling tank, using absolute ethyl alcohol as a ball milling medium, conducting uniform stirring and ball milling treatment, and finally conducting charging into a vacuum drying chamber for conducting drying to obtain the wave-absorbing material. The flaky carbonyl iron powder wave-absorbing material prepared by the method has the advantages of thin wave-absorbing coating, light surface density, wide absorption band, strong absorbability, good mechanical properties, simple preparation and the like. The flaky carbonyl iron powder wave-absorbing material can meet the following requirements: the reflection loss (RL) of the wave-absorbing material is computed according to the transmission line theory, and when the coating thickness is 2mm, the peak value of reflection loss reaches -15dB around 2GHz, and the real absorption frequency width is 1GHz (1.6-2.6GHz) when RL is less than -10 dB, thereby completely covering the all band (2.4-2.485 GHz) of Bluetooth.

Owner:安徽璜峪电磁技术有限公司

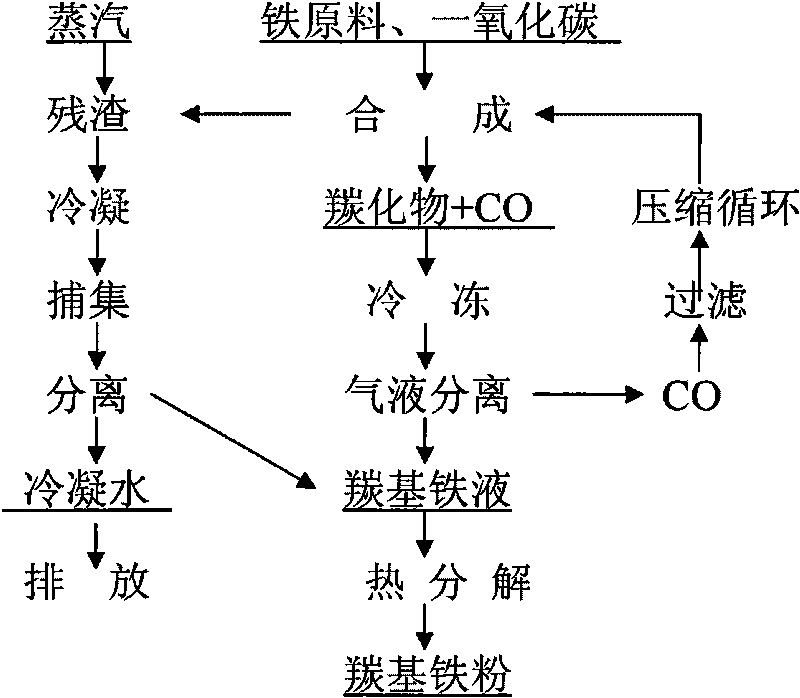

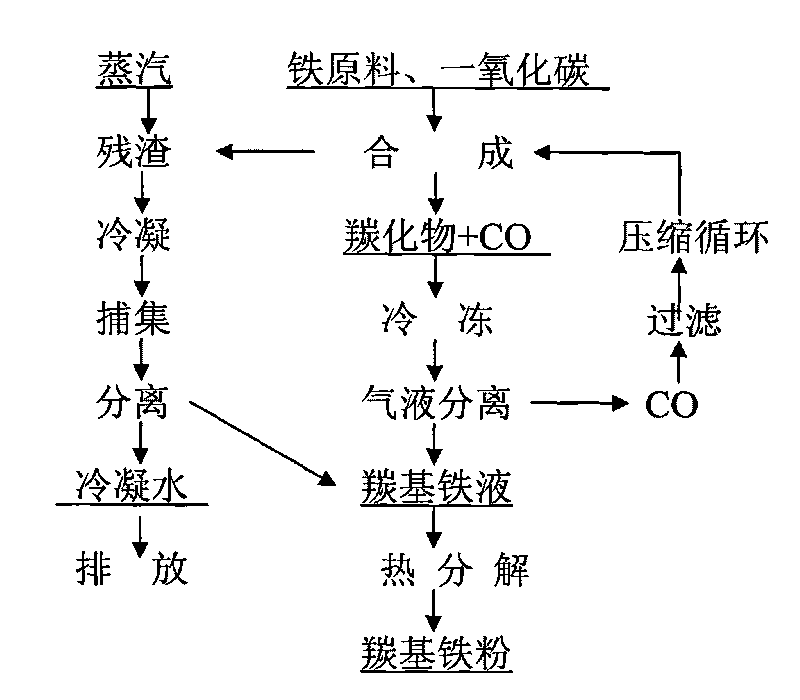

Method for preparing carbonyl iron powder in high-pressure circulating way

The invention relates to a method for preparing carbonyl iron powder in a high-pressure circulating way, comprising the following steps of: carrying out synthetic reaction between a porous sponge iron material and carbon monoxide to generate pentacarbonyl iron and synthesized residue, enabling the synthesized residue to enter a recycling flow, freezing the pentacarbonyl iron, freezing and fine-filtering the separated reaction gas by a water freezing machine, conveying into a synthesis kettle by a circulation compressor and circulating, filtering and purifying the pentacarbonyl iron, and decomposing the pentacarbonyl iron into micrometer-grade carbonyl iron powder by vaporization and thermal decomposition. Compared with the general process, the high-pressure air circulation and synthesis technology improves the carbonylation ratio, greatly reduces the carbon monoxide consumption per ton of the carbonyl iron powder, shortens the synthesis period to 3 days, improves the productivity by 55 percent, improves the working environment and the labor intensity of personnel simultaneously and reduces the environment pollution.

Owner:JIANGXI YUEAN SUPERFINE METAL

Preparation method of coated carbonyl iron powder

InactiveCN103046033AImprove high temperature resistanceImprove the problem that the heat treatment temperature is too lowIron carbonylsSolid/suspension decomposition chemical coatingIron powderPhosphate

A preparation method of coated carbonyl iron powder belongs to the technical field of magnetic functional materials prepared by powder metallurgy. The process steps are as follows: firstly, placing carbonyl iron powder into an acidic conditioning fluid, stirring for 5-60 min at the temperature of 20-70 DEG C, filtering, washing and drying; then placing the mixture in a magnesium ethoxide conditioning fluid, stirring for 30-120 min at the temperature of 50-120 DEG C by adopting the sol-gel method, filtering and washing; and finally drying the newly obtained mixture at 50-120 DEG C to obtain composite carbonyl iron powder coated by a phosphate layer and a magnesium oxide layer. The preparation method has the advantages that the prepared phosphate and magnesium oxide films can improve the material resistivity, play an insulating role and greatly lower the magnetic loss of soft magnetic powder cores; and the insulating films have better high-temperature resistance and can bear heat treatment at the temperature of 550 DEG C without damage.

Owner:CHINA IRON & STEEL RES INST GRP +1

Method for preparing carbonyl iron

InactiveCN101209862ARealize medium-pressure carbonylation scale productionCarbonylation reaction pressure dropIron carbonylsHydrogenIngot

The invention discloses a method to prepare carbonyl iron, which relates to a method to synthesize carbonyl iron with sponge iron as raw material. The invention is characterized in that preparation process is that: the sponge iron to be synthesized and reacted to generate carbonyl iron is made into sponge iron spherical particles and carbonylation synthesis is carried out after the sponge iron spherical particles are reduced and activated by hydrogen. The sponge iron is subject to a series of activation process such as compression, prereduction by hydrogen during the synthesis process of carbonyl iron in the method of the invention, thereby greatly reducing carbonylation pressure of sponge iron, maintaining the synthesis process of carbonyl iron to be carried out in middle pressure, decreasing production cost of carbonyl iron synthesis, lowering control requirement of carbonyl iron production technology for equipment and valves and improving the reaction speed and production efficiency of carbonyl iron industrial production.

Owner:JINCHUAN GROUP LIMITED

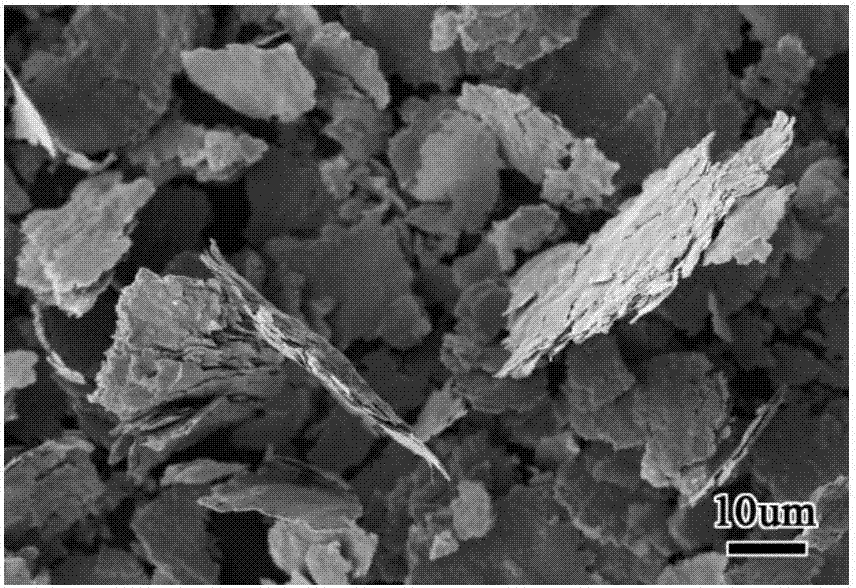

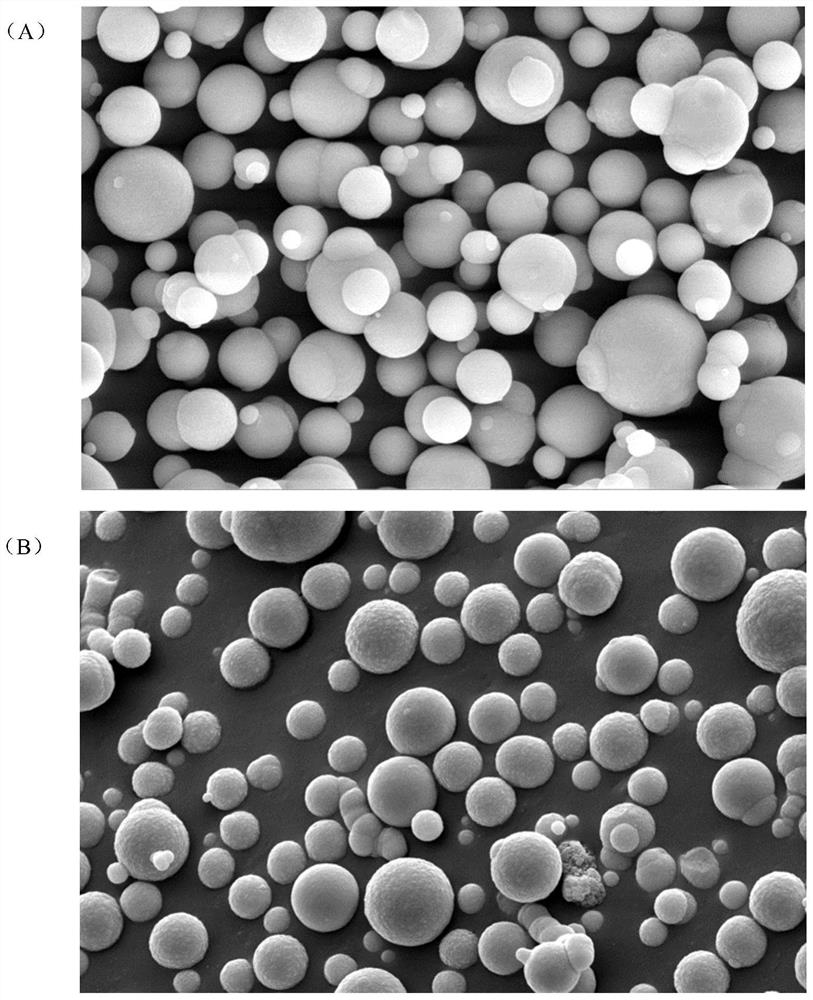

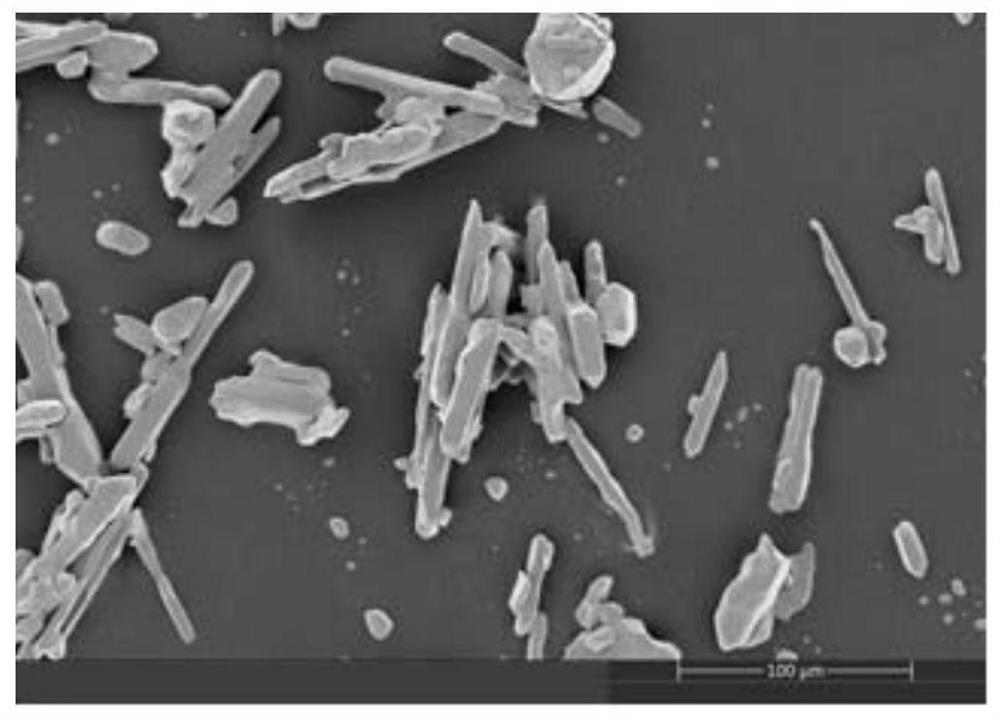

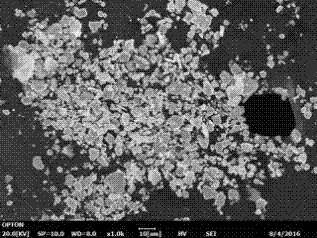

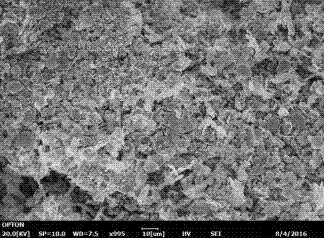

Method of preparing sheet-like carbonyl iron powder with plasma assisted ball milling

ActiveCN106946295AEasy to operateEase of industrial productionIron carbonylsIron powderControllability

The invention discloses a method of preparing sheet-like carbonyl iron powder with plasma assisted ball milling. The method includes the steps of: (1) under protection with inert gas, dry-milling carbonyl iron powder with average particle size being 5-200 [mu]m by a plasma assisted ball milling machine to produce multilayer sheet-like carbonyl iron powder being less than 100 [mu]m in particle size; and 2) dry-milling the multilayer sheet-like carbonyl iron powder through planetary ball milling to obtain secondary sheet-like carbonyl iron powder with average particle size being 2-50 [mu]m. The method is high in purity and activity of the product, has advantages in industrial promotion, achieves effective controllability of sheet size and has important significance in preparation of high-performance magnetic wave-absorbing materials.

Owner:SOUTH CHINA UNIV OF TECH

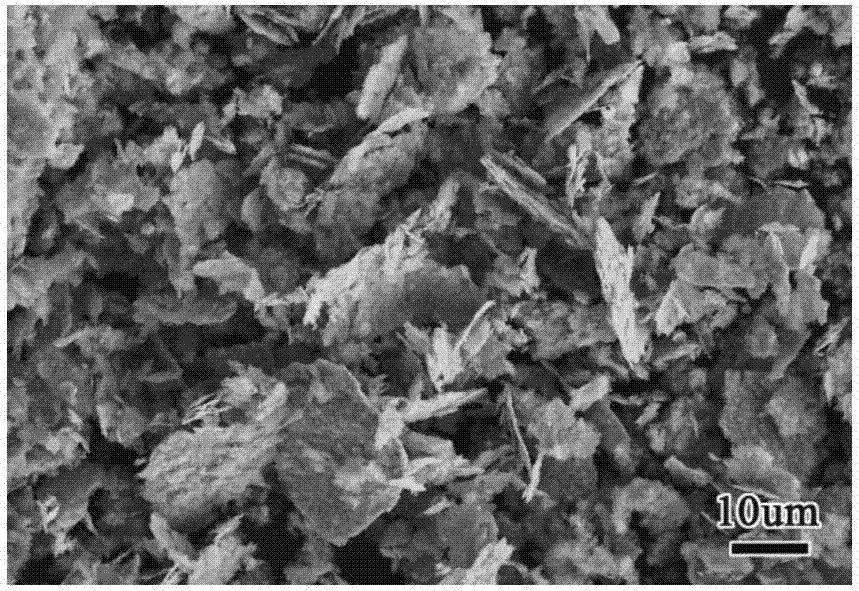

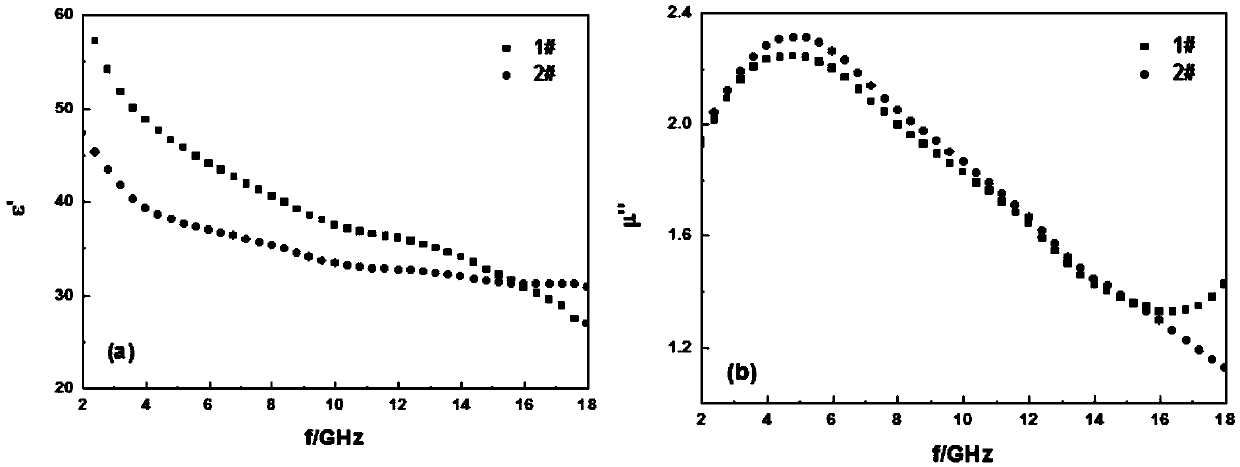

Method for preparing carbonyl iron powder absorbent for low-frequency electromagnetic wave absorption material

ActiveCN105271437AImprove permeabilityLow dielectric constantIron carbonylsIron powderHydrogen atmosphere

The invention relates to a method for preparing a carbonyl iron powder absorbent for a low-frequency electromagnetic wave absorption material. The method comprises the following steps: firstly, reducing spherical carbonyl iron powder in a hydrogen atmosphere at a high temperature to reduce the carbon oxygen content of the carbonyl iron powder and decrease the hardness of the carbonyl iron powder; secondly, adding a process control agent to perform wet-method ball milling in a vibrating ball mill to prepare sheet-like carbonyl iron powder; finally, treating the sheet-like carbonyl iron powder from which the process control agent is removed in a wet hydrogen atmosphere to obtain high-permeability sheet-like carbonyl iron powder, wherein a weak oxidation layer is arranged on the surface of the high-permeability sheet-like carbonyl iron powder. According to the method, the carbonyl iron powder can be efficiently transformed from a spherical shape into a sheet shape, the magnetic conductivity of the carbonyl iron powder can be obviously improved, a dielectric constant is reduced, and the absorption performance of the carbonyl iron powder at a low-frequency electromagnetic wave is improved.

Owner:南京南大波平电子信息有限公司

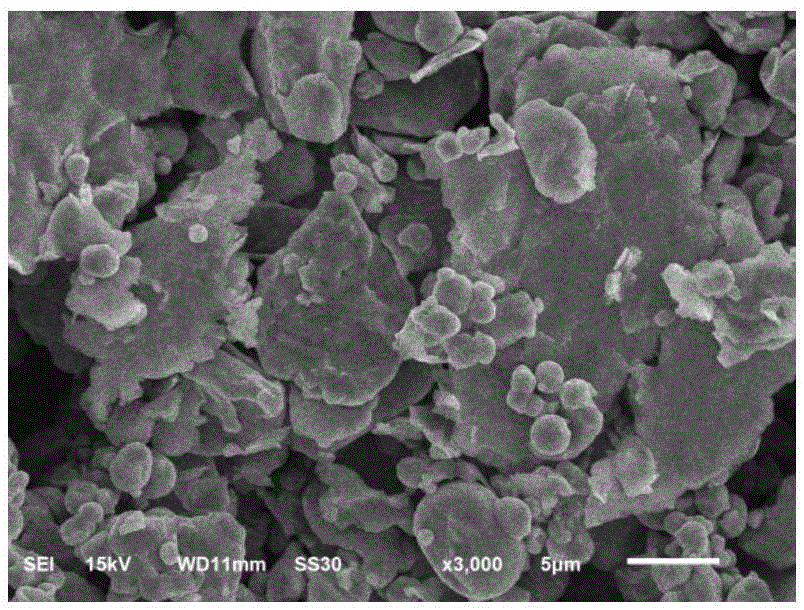

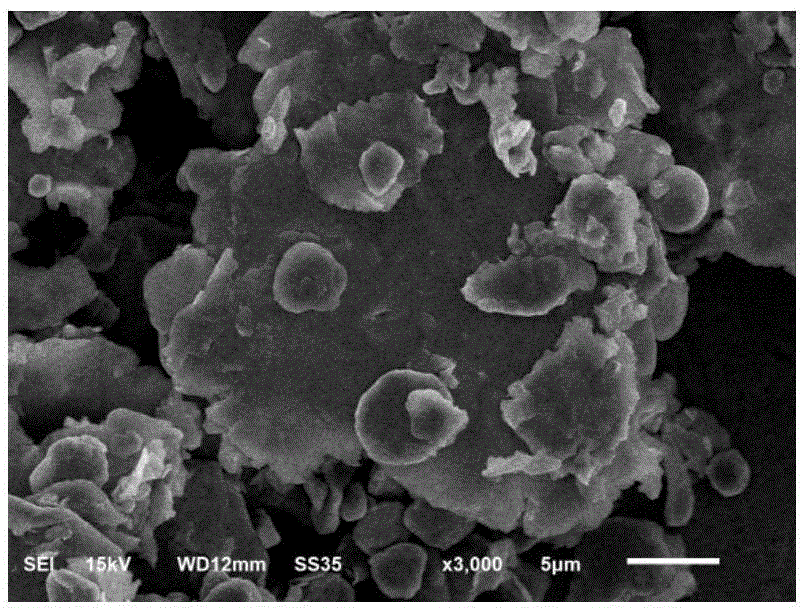

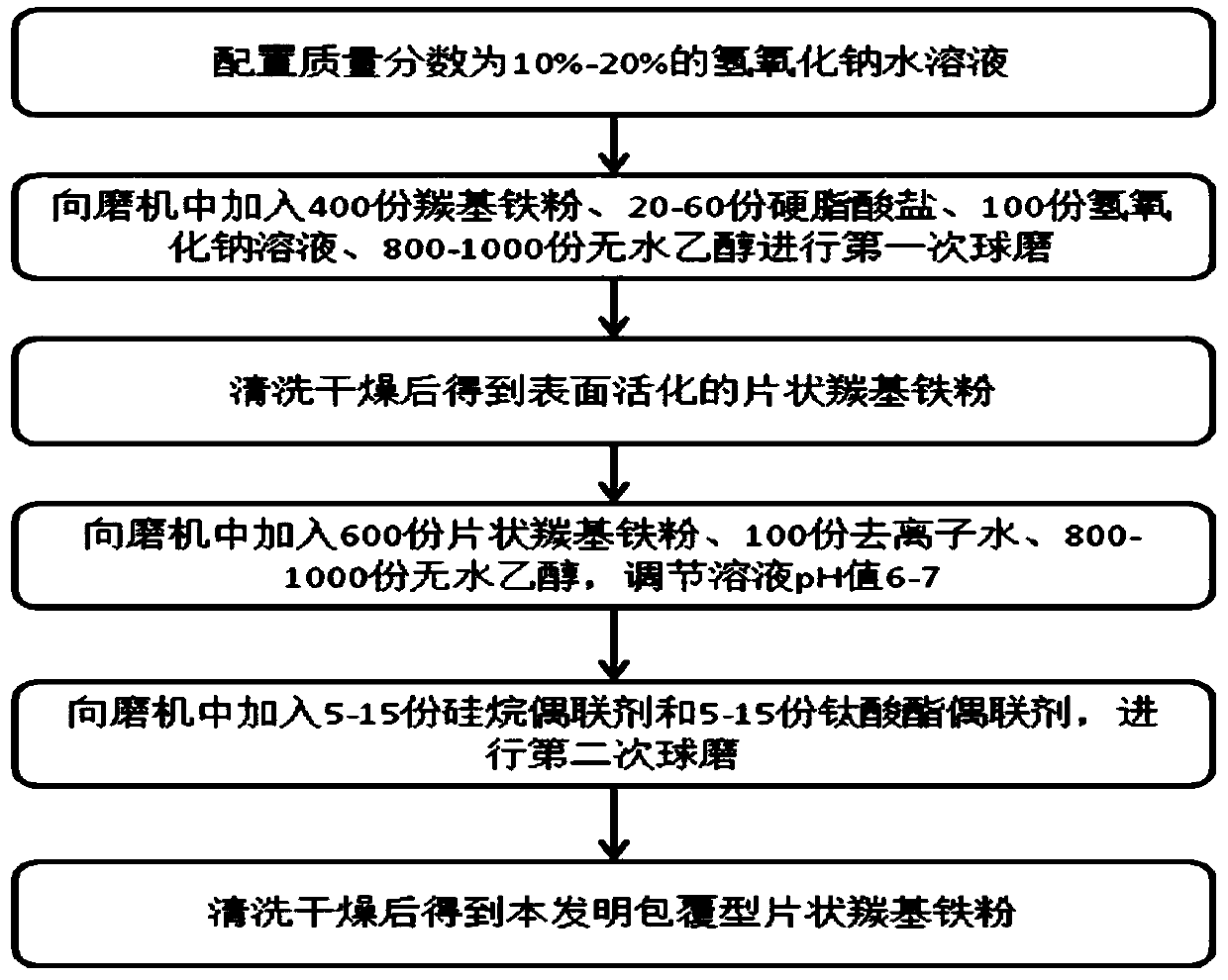

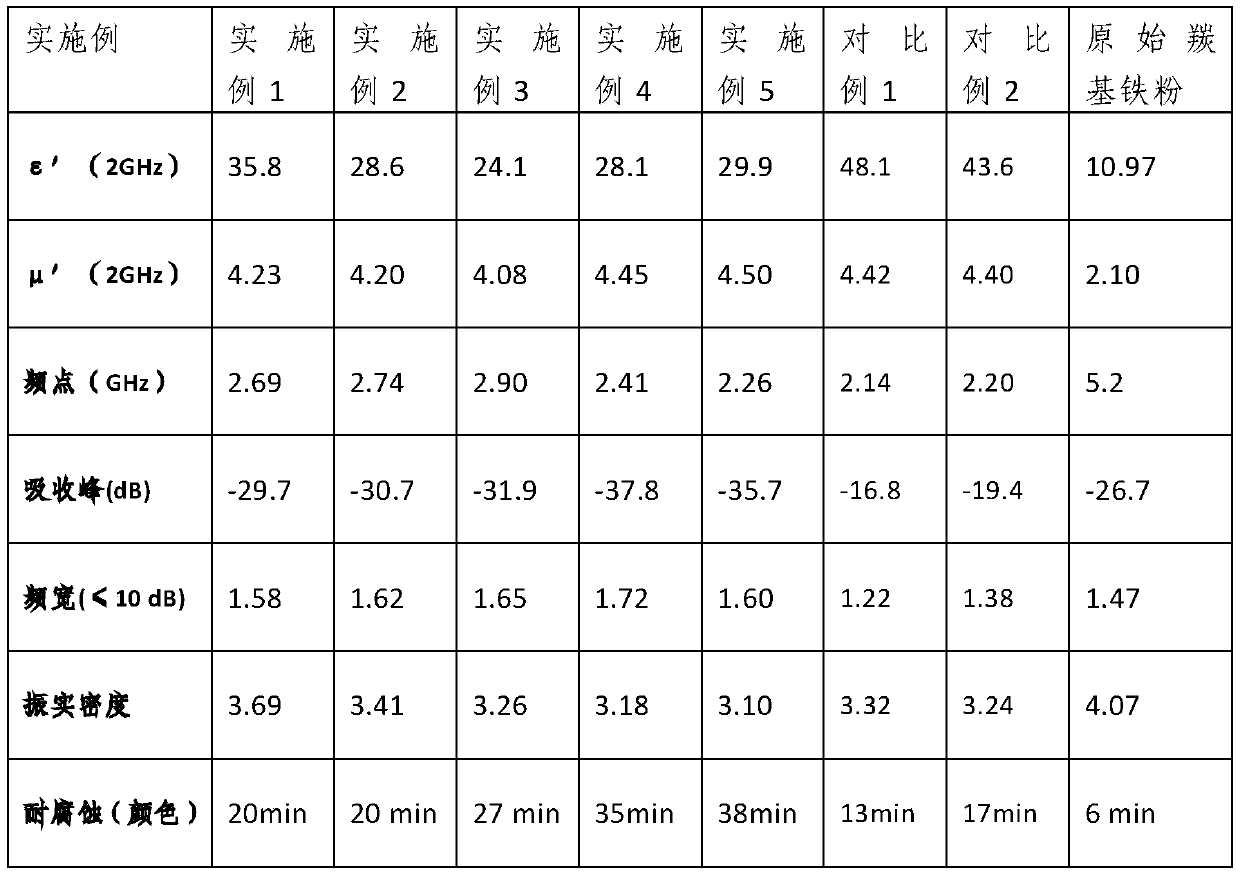

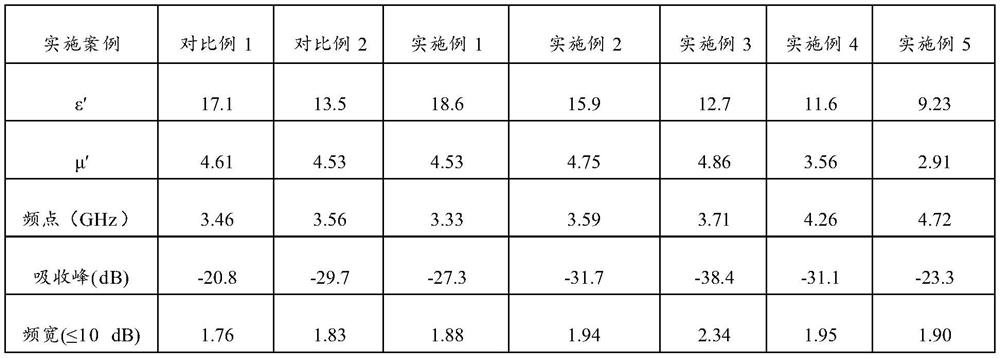

Preparation method of coated flaky carbonyl iron powder

ActiveCN111377485ALow densityImproving Impedance Matching PerformanceMagnetic/electric field screeningIron carbonylsOrganic filmStearic acid

The invention discloses a preparation method of coated flaky carbonyl iron powder. The preparation method comprises the following steps of: (1) preparing an aqueous solution of sodium hydroxide; (2) mixing and ball-milling the aqueous solution of sodium hydroxide, stearate, carbonyl iron powder and absolute ethyl alcohol; (3) cleaning the ball-milled slurry, and carrying out vacuum drying to obtain flaky carbonyl iron powder containing hydroxyl functional groups; (4) mixing the flaky carbonyl iron powder, deionized water and absolute ethyl alcohol, adjusting the pH value of the solution to 6-7with weak acid, and then adding a silane coupling agent and a titanate coupling agent for secondary ball milling; and (5) cleaning the slurry subjected to secondary ball milling, and carrying out vacuum drying to obtain the coated flaky carbonyl iron powder. According to the invention, two ball milling processes are adopted to prepare the flaky carbonyl iron powder which is low in density and good in impedance matching performance and is coated with an organic thin film layer on the surface, the absorption peak value of the carbonyl iron powder is lower than -29.7 dB within the frequency bandrange of 2.2 GHz to 2.9 GHz, the bandwidth of -10 dB reaches 1.72 GHz, and the carbonyl iron powder has the broadband efficient electromagnetic wave absorption characteristic.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

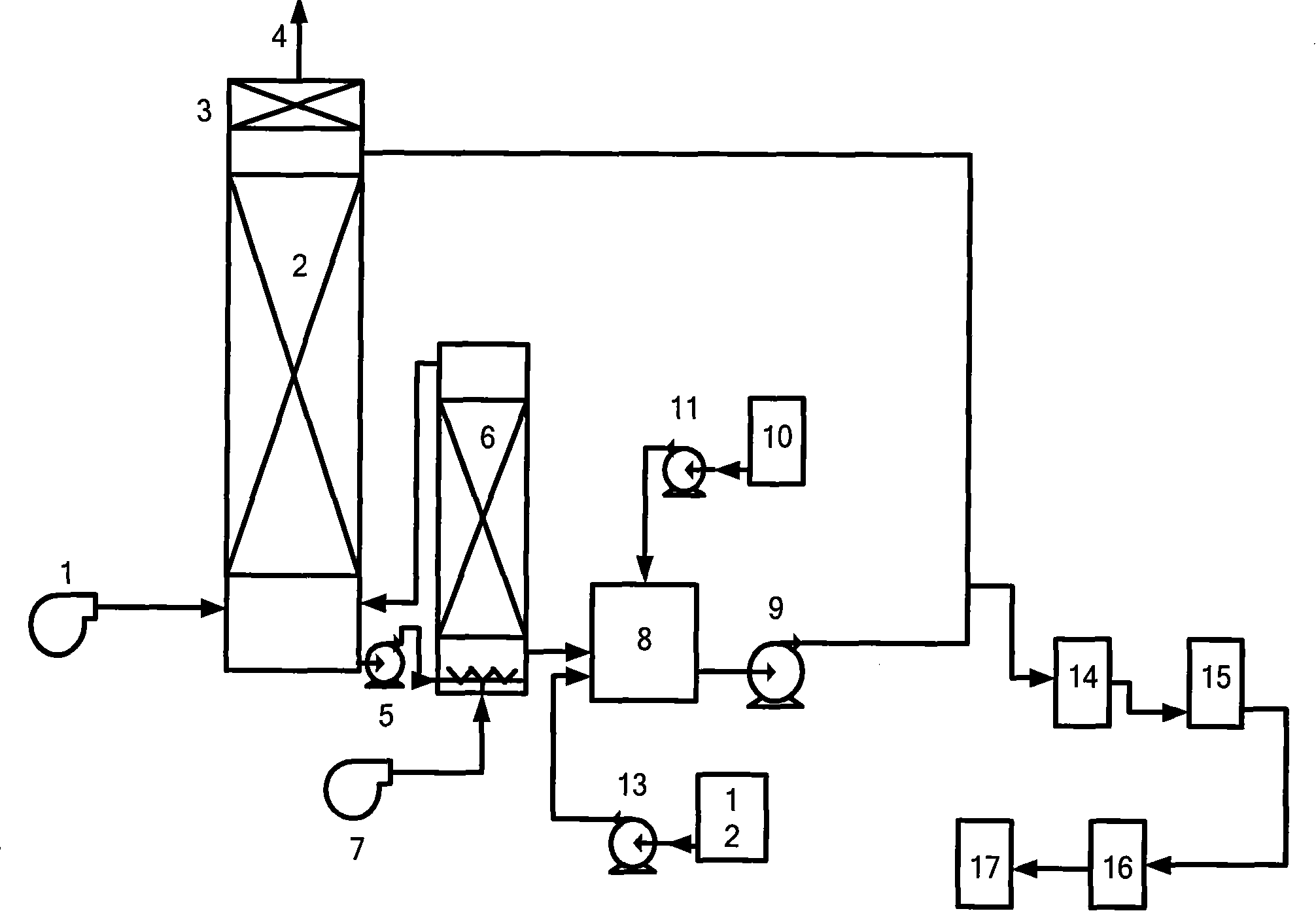

Technique of catalytic oxidation flue gas desulfurization and hydrocarbonylation by-product polymerization iron sulfate

InactiveCN101134154ALow costReduce usageDispersed particle separationIron carbonylsIron sulfateCatalytic oxidation

The catalytically oxidizing process for desulfurizing fume and co-producing polyferric sulfate includes: absorbing and dissolving SO2 from fume in a desulfurizing tower with ferrous sulfate solution as desulfurizing absorbent, catalytically oxidizing sulfite radical into sulfuric acid in the presence of O2 and iron ion as catalyst, reacting sulfuric acid and ferrous sulfate to co-produce liquid polyferric sulfate, and drying to obtain solid polyferric sulfate. The process has cheap desulfurizer, no waste discharge and obvious economic benefit, and is suitable for desulfurizing fume in boilers and other advantages.

Owner:DALIAN UNIV OF TECH

Process for producing carbonyl iron

The present invention is process of producing carbonyl iron. Pig iron and CO as material are reacted at pressure of 15-25MPa and temperature of 100-250deg.c to produce gaseous carbonyl iron; and gaseous carbonyl iron is then condensed to obtain the liquid carbonyl iron product. The present invention prepares liquid carbonyl iron through the carbonyl process, and the production process has high safety, short process, simple operation, no í‹three-wasteíŒ exhaust and high metal recovering rate and is suitable for industrial production.

Owner:JINCHUAN GROUP LIMITED

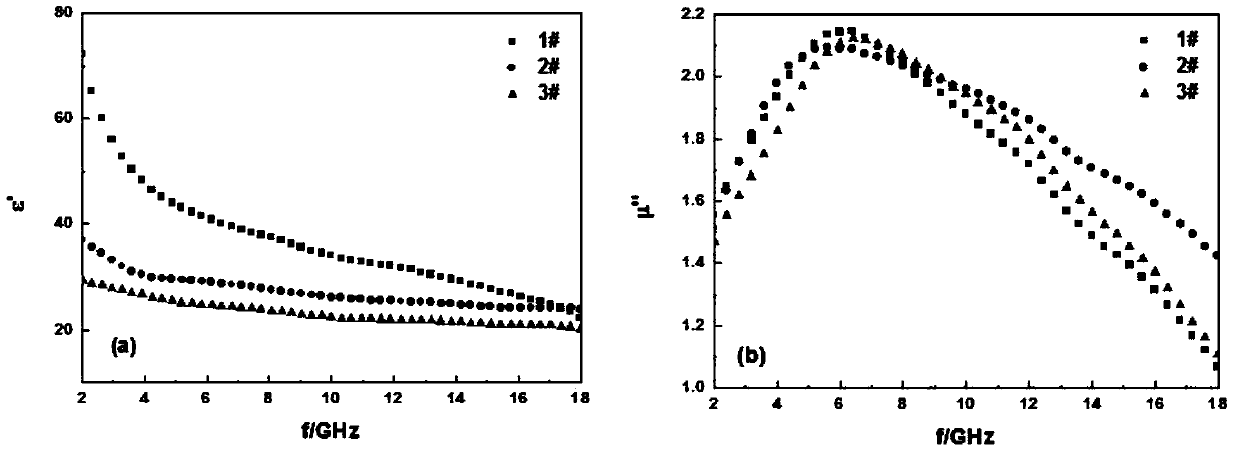

Modification method for electromagnetic parameters of carbonyl iron powder

InactiveCN105502517AHigh dielectric constantLow dielectric constantIron carbonylsDielectricNon destructive

The invention relates to a modification method for electromagnetic parameters of carbonyl iron powder and belongs to the field of absorbent preparation. The technical problem that the dielectric constant and the magnetic parameter of a carbonyl iron powder absorbent prepared through an existing preparation method are mismatched at a high mixing amount is solved. The preparation method includes the steps that firstly, the untreated carbonyl iron powder is treated according to a ball milling method through metal pots and ball milling balls so that the purposes of increasing the specific surface area, changing the micro-shape and then adjusting the electromagnetic parameters can be achieved; then, a passive film is generated on the surface of the carbonyl iron powder through a metal passivation chemical technology so that the dielectric constant of the carbonyl iron powder can be effectively reduced; finally, relatively-uniform phosphatized micron-size carbonyl iron powder particles are obtained by grinding the dried carbonyl iron powder in a non-destructive mode. By testing the electromagnetic parameters of the carbonyl iron powder, it is found that the real part of the dielectric constant of the treated carbonyl iron powder is significantly reduced, and the magnetic loss is kept unchanged basically, so that the purposes of parameter matching and parameter modification are achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of carbonyl iron

InactiveCN102718269AImprove surface activityIncrease carbonylation rateIron carbonylsHydrogenCarbonylation

The invention discloses a preparation method of carbonyl iron, and relates to an improvement of a method for preparing carbonyl iron by carbonylation reaction to sponge iron. The carbonyl iron preparation process is as follows: the sponge iron is taken as raw material; and the sponge iron is placed in a reaction kettle to perform reaction with carbon monoxide gas introduced in the reaction kettle. The preparation method is characterized in that the carbon monoxide introduced in the reaction kettle is added with hydrogen. The preparation method of carbonyl iron has the advantages of simple operation, significant effect and easy achievement. Through detection, the reaction speed ratio in the reverse carbonylation synthesis process is obviously changed, and at last the sponge iron carbonylation rate is improved.

Owner:JINCHUAN GROUP LIMITED

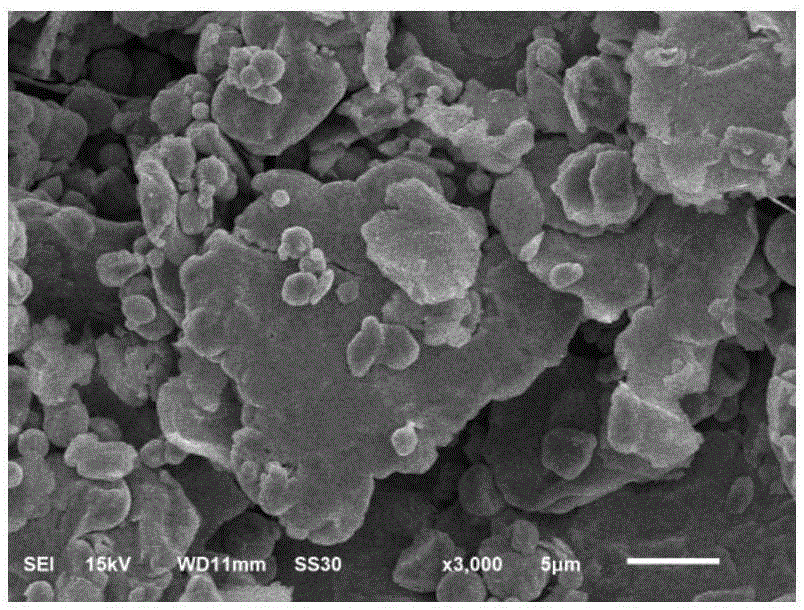

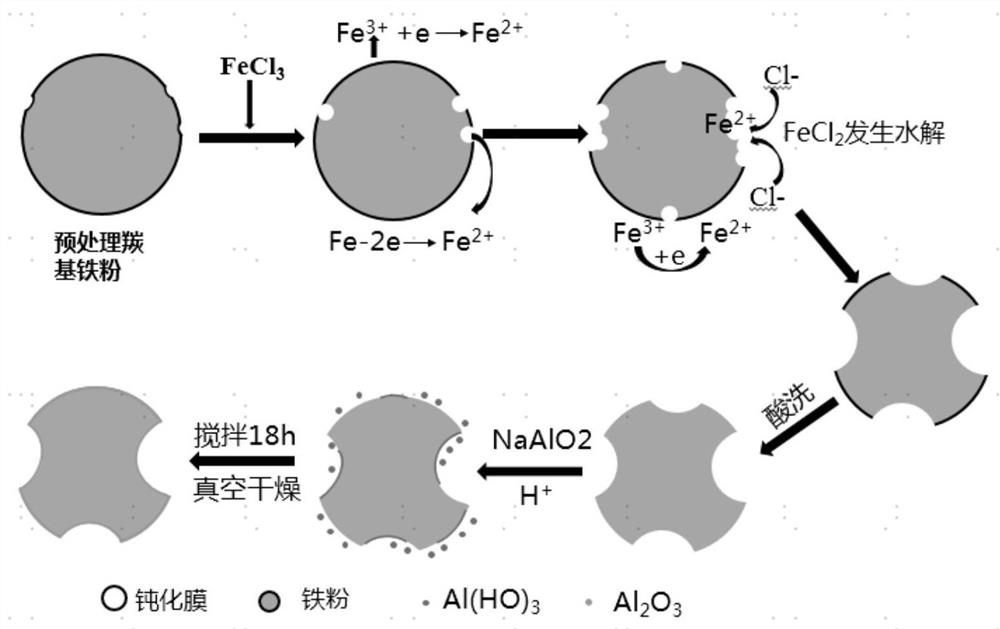

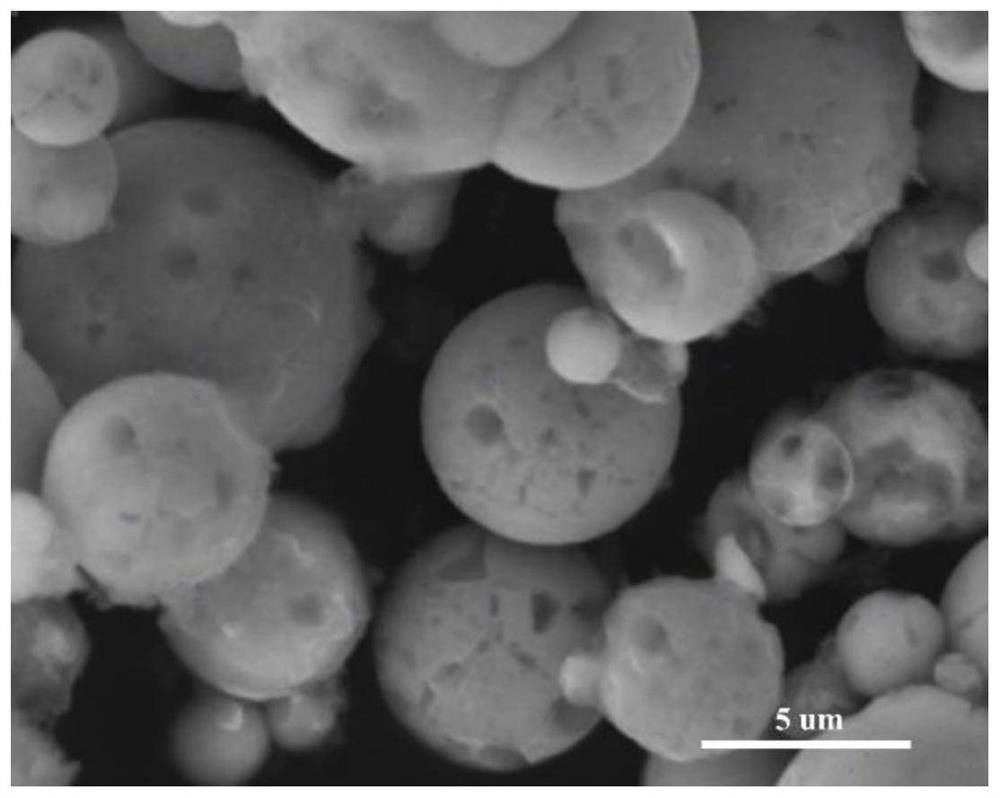

Aluminum oxide-carbonyl iron microsphere wave-absorbing agent and preparation method thereof

PendingCN112744870ASolve the densityImprove permeabilityOther chemical processesIron carbonylsMicrosphereOxidation resistant

The invention provides an Al2O3-carbonyl iron microsphere wave-absorbing agent, which is composed of carbonyl iron microspheres and Al2O3 coated on the surfaces of the carbonyl iron microspheres, and the surfaces of the carbonyl iron microspheres have a porous structure. The invention further provides a preparation method of the Al2O3-carbonyl iron microsphere wave-absorbing agent. In the process of preparing the Al2O3-carbonyl iron microsphere wave-absorbing agent, carbonyl iron microspheres are subjected to porous treatment firstly, then Al2O3 nano layer surface coating is performed, and the novel Al2O3-carbonyl iron microsphere wave-absorbing agent is prepared. According to the Al2O3-porous carbonyl iron microsphere wave-absorbing agent provided by the invention, the density of carbonyl iron microspheres is greatly reduced due to the unique porous and core-shell structure, the wave-absorbing agent is excellent in high temperature resistance and oxidation resistance, the dielectric constant can be reduced, the impedance matching can be improved, the wave-absorbing efficiency can be improved on the premise of keeping the magnetic conductivity basically unchanged, the compatibility with a matrix can also be improved, and the interface bonding force is improved.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Carbonyl iron powder composite wave-absorbing material and preparation method thereof

The invention relates to a carbonyl iron powder composite wave-absorbing material with low dielectric constant and high magnetic loss and a preparation method thereof. The preparation method comprisesthe following steps: using carbonyl iron powder as a modified absorbent, using ethyl orthosilicate as a powder coating silicon source, adding carbonyl iron powder into deionized water to form a mixture, and stirring the mixture to be evenly dispersed and mixed; adding gamma glycidyl ether oxypropyl trimethoxy silane dissolved by ethanol and tetraethoxysilane into the mixture according to a certain ratio, and then carrying out a hydrothermal reaction; filtering and collecting solids after the reaction is finished, and washing with ethanol and distilled water in sequence; and putting the obtained solid product into a vacuum drying oven, and fully drying at a constant temperature to obtain the SiO2-coated carbonyl iron powder. According to the invention, the problems of low overall magneticloss performance of the absorption material prepared based on carbonyl iron powder in each frequency band and magnetic conductivity and magnetic loss mismatch caused by over-high real part and imaginary part of the dielectric constant can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for synthesizing iron pentacarbonyl with middle pressure

InactiveCN101229932ASolve many disadvantages caused by excessive reaction pressureRelieve pressureIron carbonylsSulfurReaction temperature

The invention discloses a method for synthesizing an iron pentacarbonyl under the condition of middle pressure which takes the substance containing iron as the reaction material, carbon monoxide as a reaction gas and the sulfur compounds as a catalyst. Under the operation temperature of 120-250 DEG C and the reaction pressure of 3.0-8.5MPa, the conversion rate of the iron is up to more than 86 percent. The invention shortens the reaction time and reduces the carbonylation pressure.

Owner:JILIN JIEN NICKEL IND +1

Recovery method and application of lithium iron phosphate waste

ActiveCN113264821AHigh recovery rateThe process is simple and easy to controlOrganic compound preparationSolid waste disposalOxalateLithium iron phosphate

The invention belongs to the technical field of battery recovery, and discloses a recovery method and application of lithium iron phosphate waste. The method comprises the following steps: mixing the lithium iron phosphate waste with water to prepare slurry, adding alkali to adjust the pH value to be alkaline, heating to react, filtering and separating to obtain filter residues; dissolving the filter residue in acid, filtering and separating, taking filtrate, adding a solution containing oxalate, reacting, aging, filtering and separating to obtain a filter cake and a precipitation mother solution; and pulping, washing and removing free water from the filter cake to obtain ferrous oxalate. The method comprises the following steps: adding the alkali to adjust the pH value, dissolving the filter residue with acid, carrying out solid-liquid separation, removing the filter residue, adding an oxalate-containing substance into the filtrate, heating and precipitating to obtain the ferrous oxalate precipitate. Compared with the process for synthesizing iron phosphate by using the lithium iron phosphate waste, the process for synthesizing ferrous oxalate by using the lithium iron phosphate waste is easier to control, and the iron recovery rate is higher and can reach 99%.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Preparation method of wave absorbing material used in satellite communication uplink frequency band of C wave band

ActiveCN107352586AImprove absorbing performanceSimple preparation processOther chemical processesIron carbonylsReflection lossArea density

A purpose of the present invention is to provide a preparation method of a wave absorbing material used in the satellite communication uplink frequency band of a C wave band so as to meet the 5.925-6.425 GHz frequency band wave absorbing material used for satellite communication uplink in the C waveband. The method comprises: placing carbonyl iron powder, a composite coupling agent (zinc stearate and titanate), anhydrous ethanol and a bearing steel roller into a ball mill tank, and carrying out ball milling in a horizontal planetary ball mill; and heating the obtained slurry for 2-4 h at a temperature of 40-60 DEG C, and drying to prepare the wave absorbing material for. According to the present invention, the reflection loss is calculated according to a transmission line theory, wherein the reflection loss RL is less than -15 dB at the C waveband of 5.925-6.425 GHz when the thickness of the coating is less than 1.5 mm; and the wave absorbing material has advantages of thin wave absorbing coating, low area density, easily available raw materials, simple production and the like, and the preparation method is suitable for large-scale production.

Owner:安徽璜峪电磁技术有限公司

Passivation method of carbonyl iron powder

The invention discloses a method for passivating carbonyl iron powder. The invention is characterized by passivation course that: trace amount of oxygen is infused into the carbonyl iron powder under the protection of nitrogen, which ensures that passivation takes place at the surface of the carbonyl iron powder with the highest activity so as to reduce the overall activity of the carbonyl iron powder. The method of the invention infuses trace amount of oxygen into the carbonyl iron powder under the protection of nitrogen to ensure that surface oxidation treatment takes place at part of the carbonyl iron powder with the highest activity so as to reduce overall surface activity of the carbonyl iron powder and be convenient to store and transport.

Owner:JINCHUAN GROUP LIMITED

Method for increasing purity of carbonyl iron powder

The invention discloses a method for increasing the purity of carbonyl iron powder, and relates to a method for increasing the purity of the carbonyl iron powder by introducing gas into the common carbonyl iron powder for reduction. The method is characterized in that the process is as follows: reduction treatment is carried out on the carbonyl iron powder under the condition of introducing hydrogen, ammonia or mixed gas of hydrogen and water steam, the reduction temperature is 350 DEG C-850 DEG C, the reduction time is 0.5h-5h, and the use amount of gas is 1.0-50Nm<3> / kg (carbonyl iron powder). In the method for increasing the purity of the carbonyl iron powder, the operation is simple and convenient, the reduction treatment is carried out on the carbonyl iron powder by introducing the gas, detection and analysis are carried out on the obtained carbonyl iron powder, the content of iron in a product is greatly increased, the contents of impurities of carbon, oxygen and nitrogen are obviously reduced, and high-purity carbonyl iron powder is produced. For the carbonyl iron powder treated by the method, the purity is greatly increased, and is increased from 96 percent to more than 98.5 percent.

Owner:JINCHUAN GROUP LIMITED

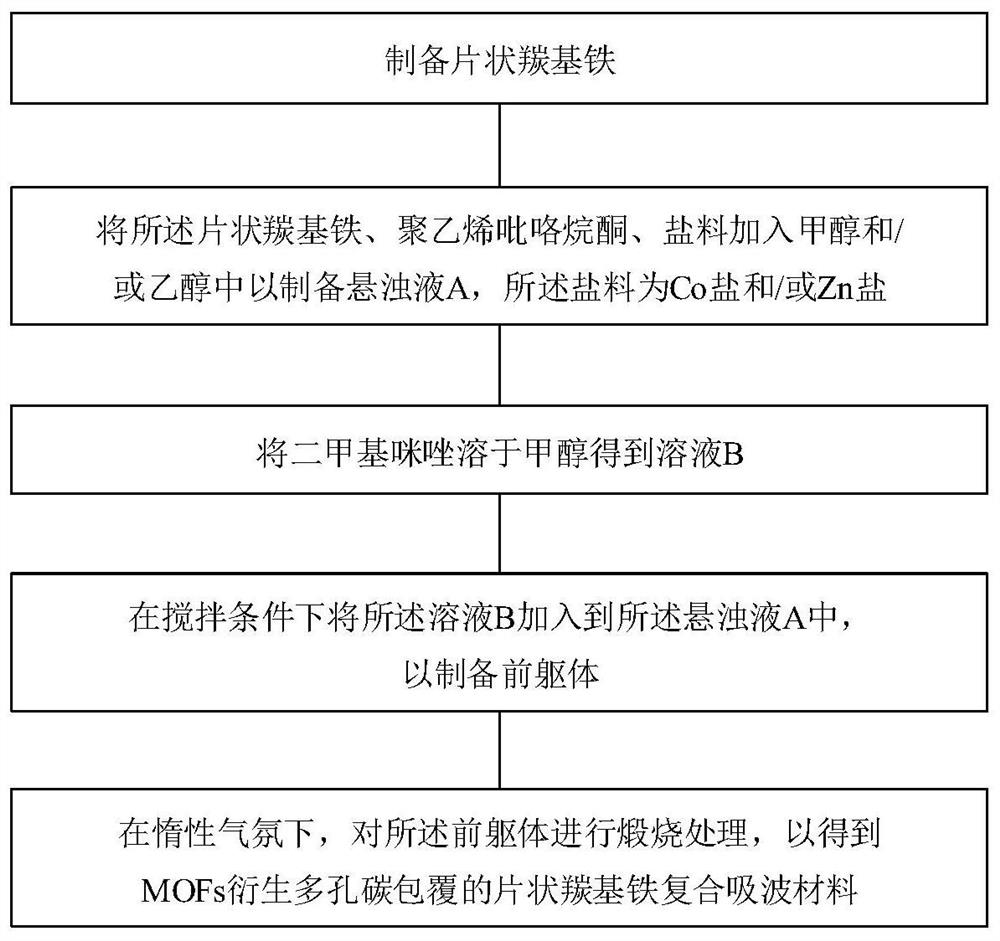

MOFs-derived porous carbon-coated flaky carbonyl iron composite wave-absorbing material and preparation method thereof

ActiveCN112533466AReduce fill ratioLow costMagnetic/electric field screeningCarbon preparation/purificationPorous carbonPyrrolidinones

The invention relates to an MOFs-derived porous carbon-coated flaky carbonyl iron composite wave-absorbing material and a preparation method thereof. The method comprises the following steps: preparing flaky carbonyl iron; adding the flaky carbonyl iron, polyvinylpyrrolidone and a salt material into methanol and / or ethanol to prepare turbid liquid A, wherein the salt material is Co salt and / or Znsalt; dissolving dimethylimidazole in methanol to obtain a solution B; adding the solution B into the turbid liquid A under a stirring condition to prepare a precursor; and calcining the precursor inan inert atmosphere to obtain the MOFs-derived porous carbon-coated flaky carbonyl iron composite wave-absorbing material. The flaky carbonyl iron and an MOFs-derived light porous carbon material arecompounded, the filling proportion of the composite material is reduced, regulation and control of the electromagnetic wave absorption performance of the composite material are achieved by controllingthe components and performance of the porous carbon coating layer, the electromagnetic wave loss capacity is improved, the preparation process is simple, the cost is low, and the composite material is suitable for large-scale batch production.

Owner:中国人民解放军火箭军工程大学

Preparation method of carbonyl ferronickel alloy powder

InactiveCN105948138AImprove stabilityGuaranteed working conditionNickel carbonylsIron carbonylsAlloyFerric

The invention discloses a preparation method of carbonyl ferronickel alloy powder. The method comprises the following steps: respectively introducing CO gas into a carbonyl nickel evaporator and a carbonyl iron evaporator, uniformly mixing the carbonyl-nickel-entrained CO gas and carbonyl-iron-entrained CO gas, introducing the gas mixture into a decomposer, and carrying out thermal decomposition, wherein the temperature of the CO gas introduced into the carbonyl nickel evaporator is 50-60 DEG C, and the temperature of the CO gas introduced into the carbonyl iron evaporator is 75-90 DEG C. The preparation method can enhance the stability of the mixed raw gas components and effectively maintain the operating state of the evaporators and feed pipeline.

Owner:JINCHUAN GROUP LIMITED

Method for removing sulfureted hydrogen from mixture containing iron pentacarbonyl or nickel tetracarbonyl

The invention discloses a method for removing sulfureted hydrogen from mixture containing metal carbonyl (nickel carbonyl or iron carbonyl). The method includes that the catalyst is loaded in a fixed bed reactor; at the temperature of 5-250 DEG C, the CO mixed gas containing the nickel carbonyl or the iron carbonyl is added to the fixed bed reactor; under the air speed of 800-4000h-1, the sulfureted hydrogen in the mixed gas can be removed to below 0.1ppm.

Owner:吉林卓创新材料有限公司 +1

Method for producing carbonyl iron powder

InactiveCN101209864AAvoid the problem that the activity is too large and difficult to useAvoid secondary pollutionIron carbonylsEvaporationCarbonylation

The invention discloses a production method of carbonyl iron powder, which relates to a production method for preparing ultrafine carbonyl iron powder used in powder metallurgy through thermal decomposition of carbonyl iron. The invention is characterized in that the production process is that: carbonyl iron liquid is atomized by carbon monoxide and injected into a resolver to be decomposed. The carbonyl iron liquid generated by carbonylation synthesis is mixed with heated carbon monoxide according to a certain ratio to form gas-liquid mixture through flow and pressure control instead of being subject to carburation and evaporation, the gas-liquid mixture is pumped in the resolver and atomization thermal decomposition is carried out at certain temperature and pressure to obtain the carbonyl iron powder with particle size of 5-12 Mum used in powder metallurgy.

Owner:JINCHUAN GROUP LIMITED

Method for preparing carbonyl nickel iron powder

InactiveCN101209865AQuality improvementSimple and fast operationNickel carbonylsIron carbonylsIron powderFerric

The invention relates to a method for preparing carbonyl ferronickel powder, which is characterized by the preparation course that: carbonyl nickel liquid and carbonyl iron liquid are heated respectively in two evaporators and then mixed with CO gas to be decomposed. The method for preparing carbonyl ferronickel powder of the invention has simple operation and obtains ferronickel powder with design ratio stably by adjusting the mixture ratio of carbonyl nickel to carbonyl iron. The content ratio of ferronickel powder can be adjusted at will according to need. The detection on the obtained carbonyl ferronickel powder shows that the ferronickel content in the product is stable, which realizes stable quality of the produced carbonyl ferronickel powder.

Owner:JINCHUAN GROUP LIMITED

Method for preparing carbonyl iron

InactiveCN104478005ARapid responseLower activation energyIron carbonylsCarbonylationProtein carbonyl

The invention relates to a method for preparing carbonyl iron and relates to improvement of a method for preparing carbonyl ion from sponge iron through carbonylation reaction. The method comprises the following step: enabling raw material sponge iron in a reaction kettle to react with carbon monoxide which passes through the reaction kettle. The method is characterized in that NH3 is adopted as the carbon monoxide gas. The method for preparing carbonyl iron, which is provided by the invention, is simple and convenient to operate, remarkable in effect and easy to implement. The detection result shows that the reaction velocity is remarkably increased in the carbonylation synthesis process, and the carbonylation rate of the sponge iron is ultimately increased.

Owner:JINCHUAN GROUP LIMITED

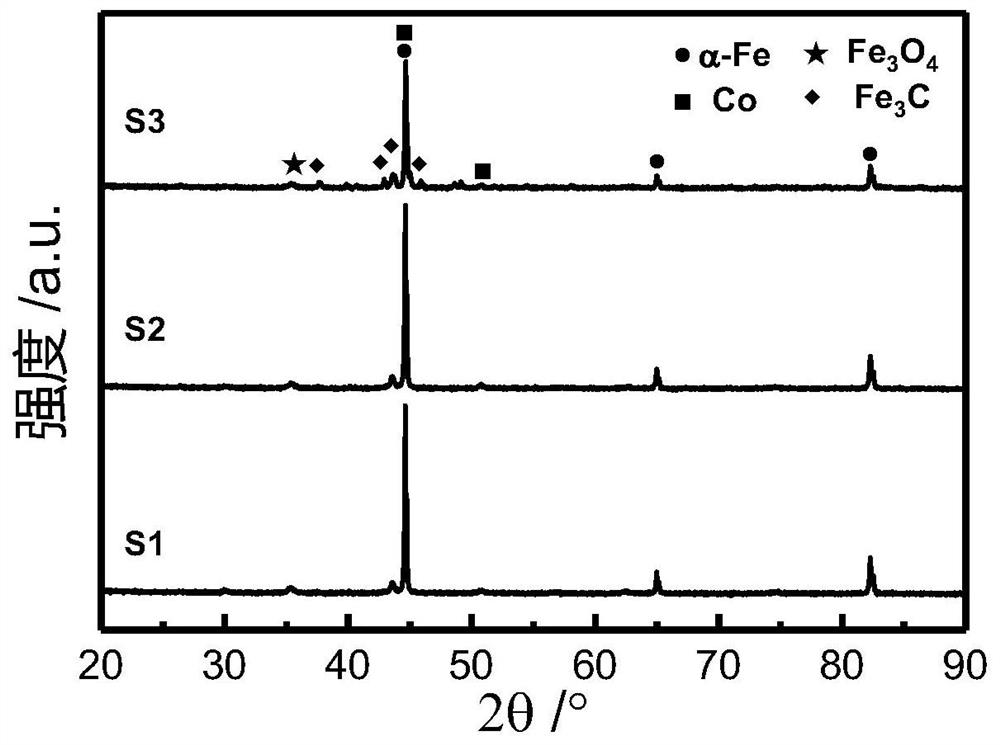

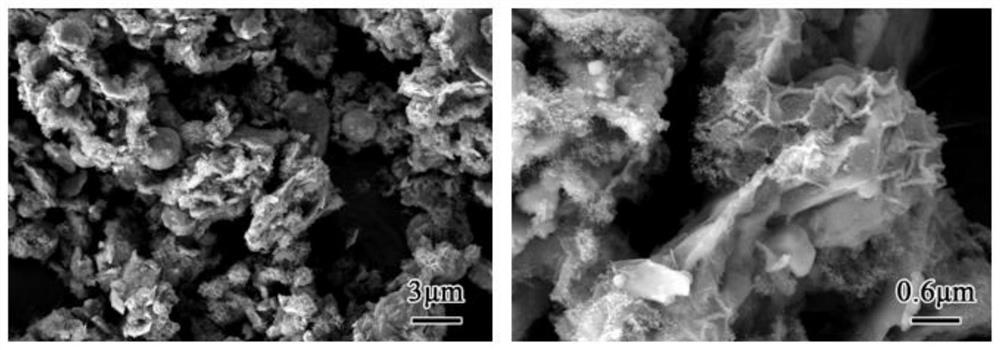

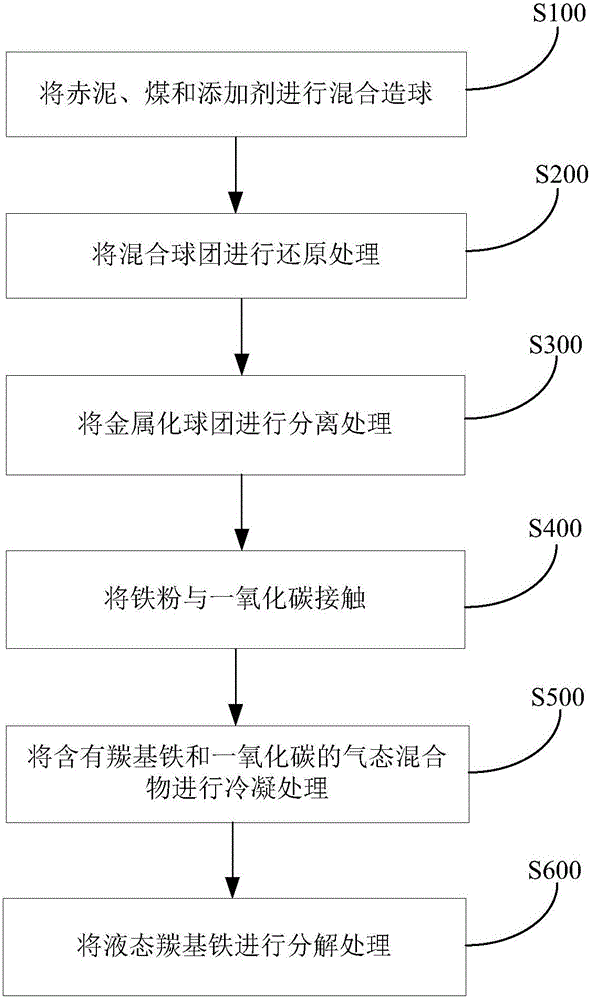

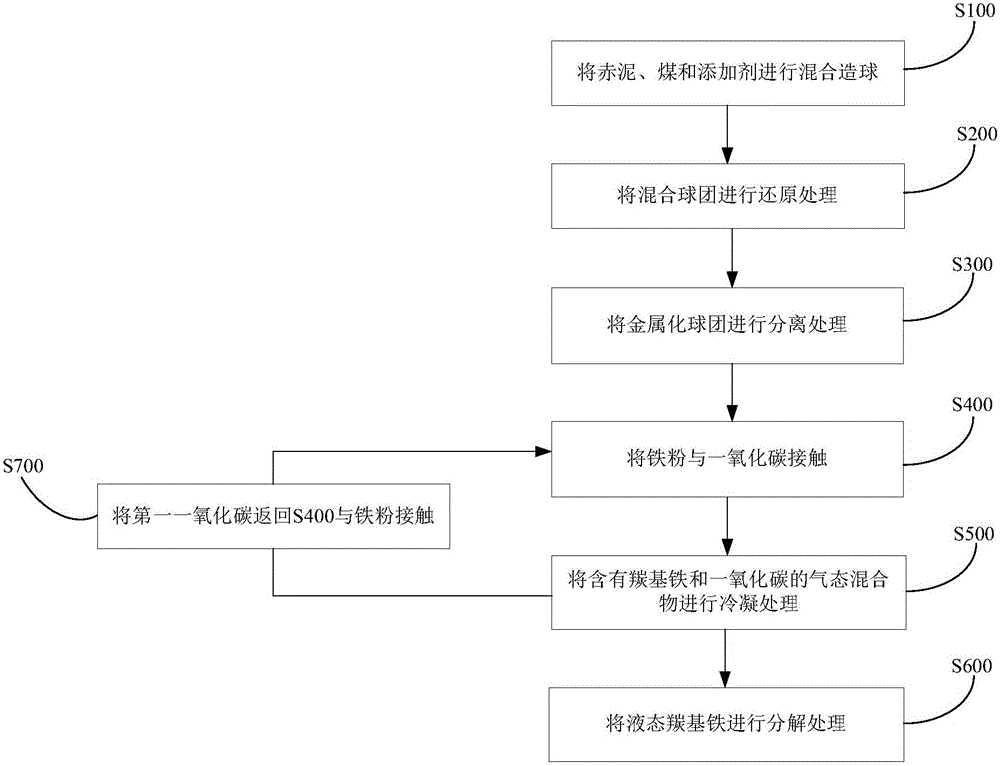

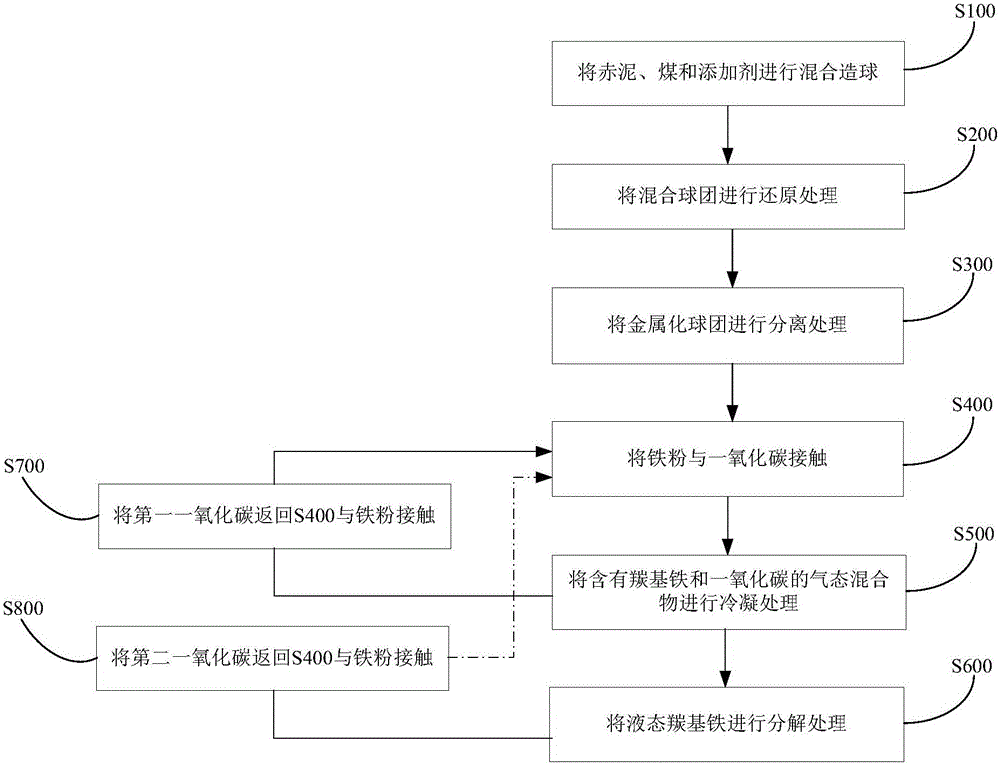

Method and system for preparing carbonyl iron powder by utilizing red mud

PendingCN104986806ASolve UtilizationEfficient use ofSolid waste disposalIron carbonylsIron powderRed mud

The invention discloses a method and system for preparing carbonyl iron powder by utilizing red mud. The method comprises the following steps of: (1) mixing red mud, coal and additives to obtain a mixture, and performing pelletization on the mixture so as to obtain a mixed pellets; (2) performing reduction processing on the mixed pellets so as to obtain metalized pellets; (3) performing separation processing on the metalized pellets so as to obtain iron powder and tailings; (4) enabling the iron powder to be in contact with carbon monoxide so as to obtain a gaseous mixture containing carbonyl iron and carbon monoxide; (5) condensing the gaseous mixture containing the carbonyl iron and the carbon monoxide so as to obtain liquid carbonyl iron and first carbon monoxide; and (6) decomposing the liquid carbonyl iron so as to obtain carbonyl iron powder and second carbon monoxide. Through the adoption of the method, the red mud can be effectively utilized, and carbonyl iron powder with a high additional value can be obtained, so that the difficult problems that the industrial wastes, such as red mud, are low in utilization rate and need to be piled and stored for a long time are fundamentally solved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for preparing carbonyl iron through medium pressure continuous gasification

The invention discloses a method for preparing carbonyl iron through medium pressure continuous gasification, and relates to a method for continuously preparing carbonyl iron from an iron alloy material in a fluidized bed synthetic kettle. The method is characterized in that during the preparation process, iron alloy powder and heated CO are led in from the bottom of the synthetic kettle; the iron alloy powder is driven to flow upwards by CO flow; during the rising process, the iron alloy powder is in reaction with high-temperature CO to obtain carbonyl iron gas; the reaction residue and mixed gas of CO and the carbonyl iron are discharged from the top; the reaction residue is obtained via a separation and dust collecting device; the mixed gas of CO and carbonyl iron is cooled and separated to respectively obtain a carbonyl iron liquid and the mixed gas containing carbonyl iron and CO; carbonyl iron powder and pure CO are prepared from the mixed gas via a pyrolysis device; CO returns to the bottom of the synthetic kettle to be involved in the reaction; the whole production is a long period continuous process. The continuous reaction is realized.

Owner:JINCHUAN GROUP LIMITED

Popular searches

Zinc oxides/hydroxides Gallium/indium/thallium compounds Copper oxides/halides Nickel oxides/hydroxides Chromium oxides/hydrates Cobalt oxides/hydroxides Calcium/strontium/barium oxides/hydroxides Aluminium oxides/hydroxides Grain treatments Alkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com