Preparation method of coated flaky carbonyl iron powder

A carbonyl iron powder and coating technology, which is applied in the field of preparing coated flake carbonyl iron powder, can solve the problems of large complex permittivity, poor spectral characteristics, high density, poor low frequency absorption performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

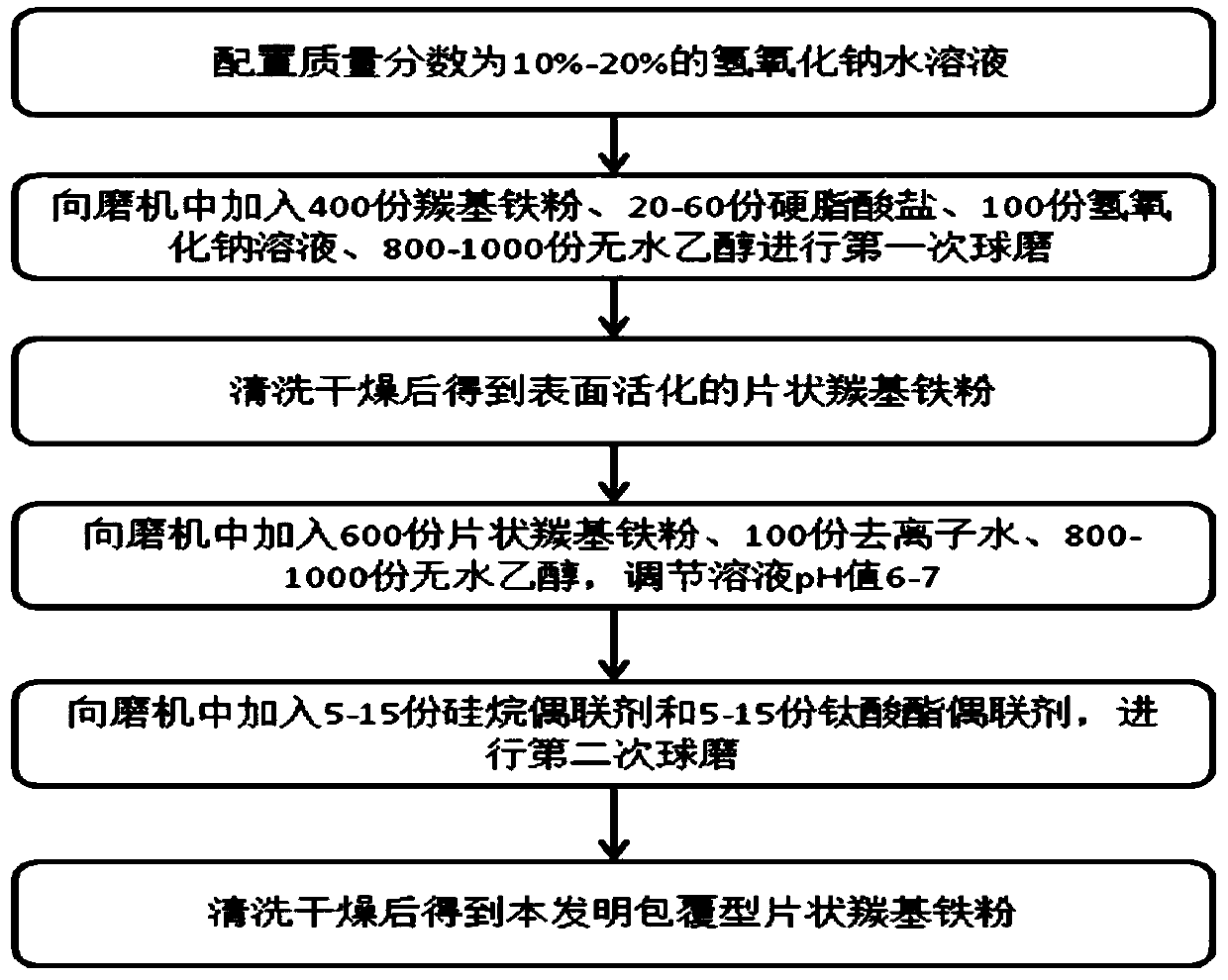

Method used

Image

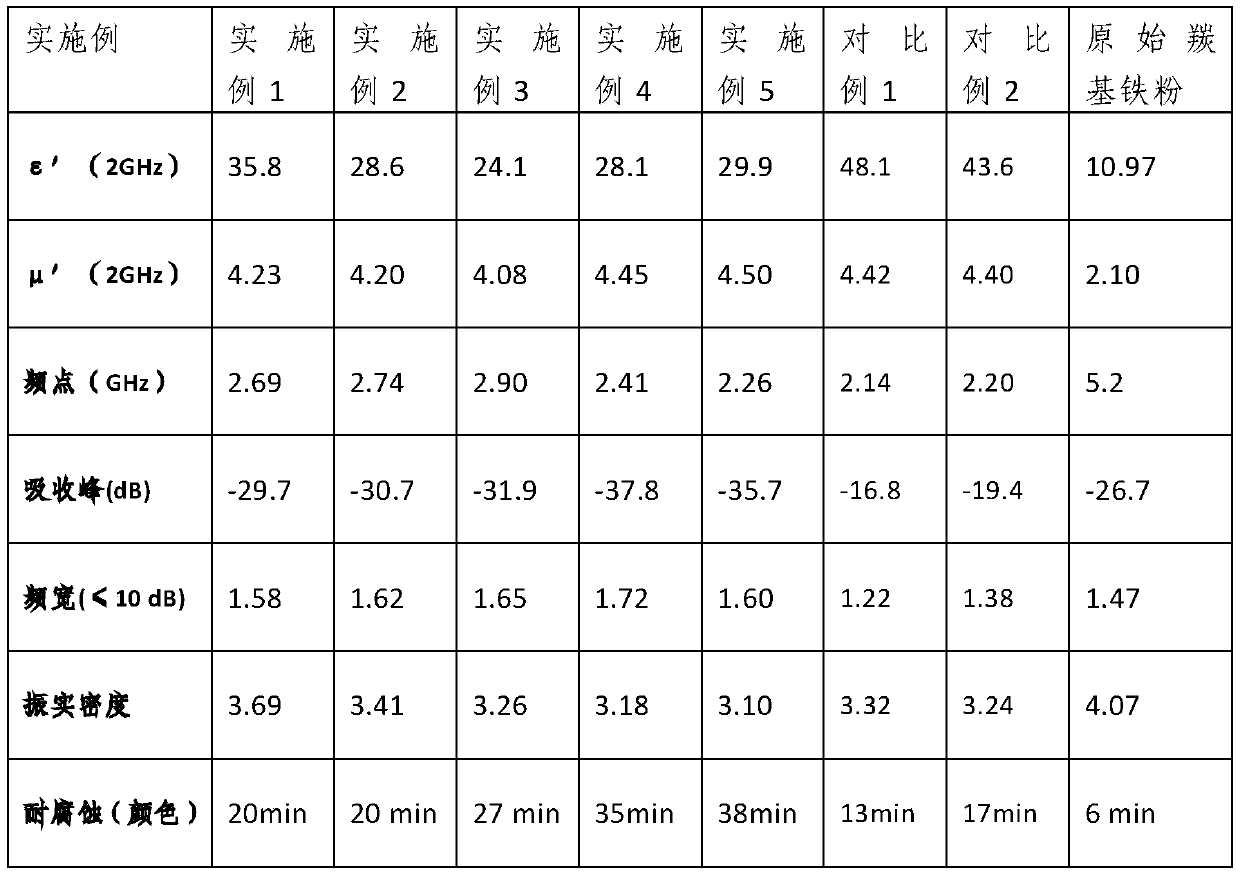

Examples

Embodiment 1

[0023] A method for preparing a low-frequency, light, high-efficiency, high-performance powder, comprising the following steps:

[0024]Firstly, sodium hydroxide was dissolved in deionized water to prepare an aqueous solution of sodium hydroxide with a mass fraction of 10%. Add 400g of calcium stearate, 2L of sodium hydroxide aqueous solution, 8kg of carbonyl iron powder, and 20L of ethanol in the stirring mill for ball milling, set the ball mill speed to 200r / min, and the ball milling time is 10h; wherein zirconium beads and carbonyl iron The ball-to-material ratio of the powder is 8:1. The zirconium beads are composed of large, medium and small zirconium beads with diameters of 12mm, 8mm and 3mm. The masses of the three types of zirconium beads are 3kg, 21kg and 40kg. The total weight is 64kg. After ball milling, the slurry is taken out, washed 4 times, and heated and dried at 50°C for 6 hours to obtain flaky carbonyl iron powder with hydroxyl groups on the surface and high ...

Embodiment 2

[0027] A method for preparing a low-frequency, light, high-efficiency, high-performance powder, comprising the following steps:

[0028] Firstly, sodium hydroxide was dissolved in deionized water to prepare an aqueous sodium hydroxide solution with a mass fraction of 15% for later use. Add 800g of calcium stearate, 2L of sodium hydroxide aqueous solution, 8kg of carbonyl iron powder, and 20L of absolute ethanol into the stirring mill for ball milling, set the ball mill speed to 250r / min, and the ball milling time is 10h; The ball-to-material ratio of the powder is 8:1. The zirconium beads are composed of large, medium and small zirconium beads with diameters of 12mm, 8mm and 3mm. The masses of the three types of zirconium beads are 3kg, 21kg and 40kg. The total weight is 64kg. After ball milling, the slurry is taken out, washed 4 times, and heated and dried at 50°C for 6 hours to obtain flaky carbonyl iron powder with hydroxyl groups on the surface and high surface activity. ...

Embodiment 3

[0031] A method for preparing a low-frequency, light, high-efficiency, high-performance powder, comprising the following steps:

[0032] Firstly, sodium hydroxide was dissolved in deionized water to prepare an aqueous solution of sodium hydroxide with a mass fraction of 20%. Add 1.2kg of calcium stearate, 2L of sodium hydroxide aqueous solution, 8kg of carbonyl iron powder, and 20L of ethanol in the stirring mill for ball milling, set the ball mill speed to 350r / min, and the ball milling time is 10h; wherein the zirconium beads and carbonyl The ball-to-material ratio of the iron powder is 12:1, and the zirconium beads are composed of large, medium, and small zirconium beads with diameters of 12mm, 8mm, and 3mm. The masses of the three types of zirconium beads are 5kg, 31kg, and 60kg. The total weight was 96kg. After ball milling, the slurry was taken out, washed 4 times, and heated and dried at 50°C for 6 hours to obtain flaky carbonyl iron powder with hydroxyl groups on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com