Aluminum oxide-carbonyl iron microsphere wave-absorbing agent and preparation method thereof

A carbonyl iron and wave absorber technology, applied in the field of wave absorbers, can solve the problems of poor impedance matching, poor oxidation resistance and corrosion resistance, and high density of carbonyl iron microspheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

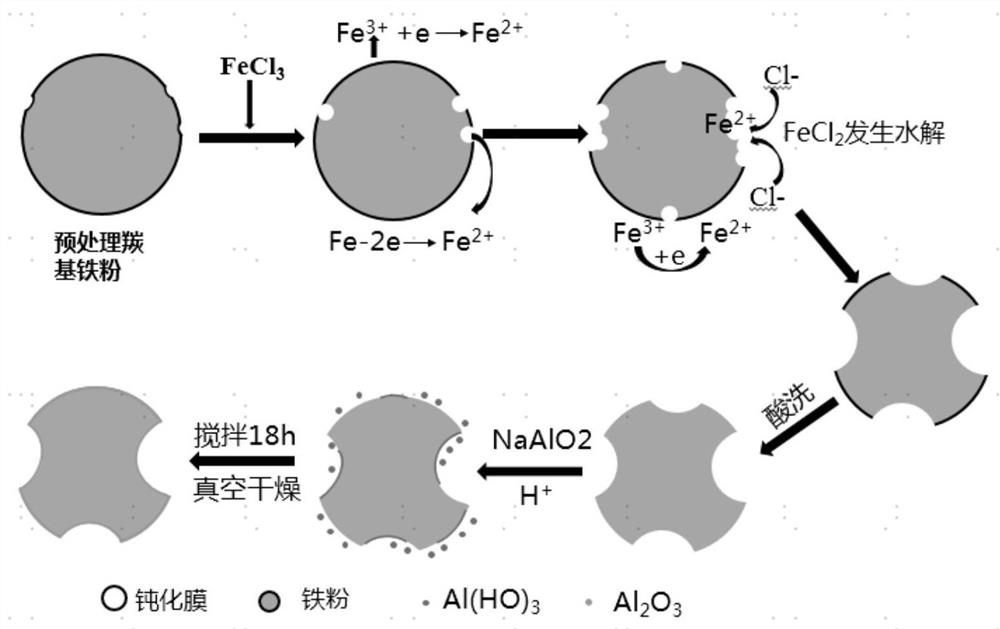

[0028] The application also provides the Al 2 o 3 -The preparation method of carbonyl iron microsphere wave absorbing agent, comprises the following steps:

[0029] A) carbonyl iron microspheres are pretreated in an acid solution, and vacuum-dried to obtain carbonyl iron microspheres with a passivation film on the surface;

[0030] B) reacting the carbonyl iron microspheres obtained in step A) with ferric chloride solution to obtain porous carbonyl iron microspheres;

[0031] C) pickling the porous carbonyl iron microspheres, and vacuum drying to obtain carbonyl iron microspheres without a passivation film on the surface;

[0032] D) react the carbonyl iron microspheres obtained in step C) with the aluminum source and then vacuum dry to obtain Al 2 o 3 -Carbonyl iron microsphere absorber.

[0033] Al was prepared in the above 2 o 3-In the process of the carbonyl iron microsphere wave absorbing agent, the application first pre-treats the carbonyl iron microsphere in an a...

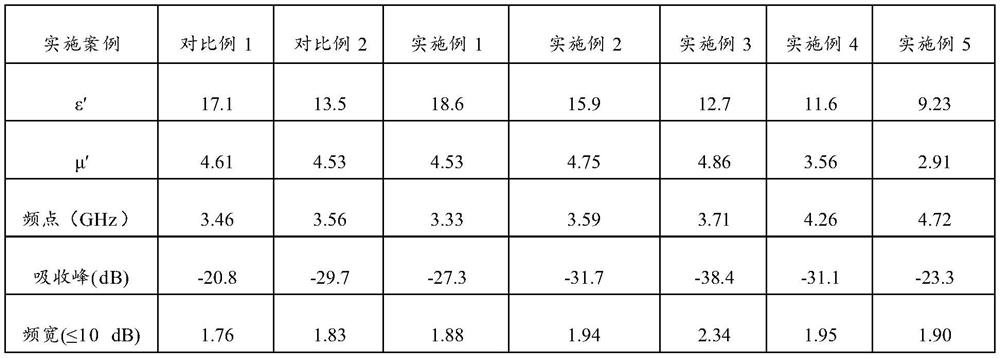

Embodiment 1

[0042] A new type of Al 2 o 3 The preparation method of porous carbonyl iron microsphere wave absorbing agent comprises following two major steps:

[0043] 1. Preparation of porous carbonyl iron microspheres

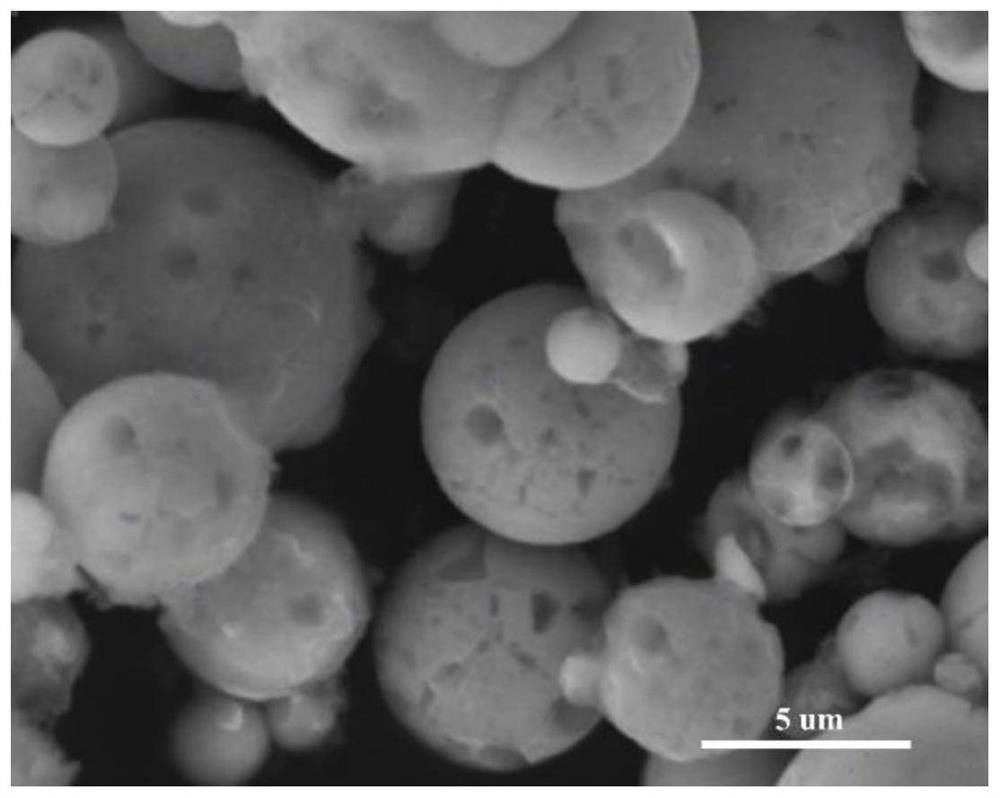

[0044] 1.1 Pretreatment of carbonyl iron surface

[0045] Weigh 4 parts of carbonyl iron microspheres with a particle size of 2-20 μm and place them in a beaker, add 20 parts of dilute hydrochloric acid with a pH of 4, ultrasonicate the beaker for 3 minutes, separate the carbonyl iron microspheres and dilute acid with a magnet, and then use them separately Wash twice with deionized water and absolute ethanol, put into a vacuum drying device and dry in vacuum at 40°C for 30min;

[0046] 1.2 Porosity of carbonyl iron microspheres

[0047] Weigh 4 parts of carbonyl iron microspheres after surface pretreatment into a beaker, add 60 parts of ferric chloride solution, the concentration is 0.1mol / L, ultrasonic treatment for 8min, so that the carbonyl iron microspheres and t...

Embodiment 2

[0053] A new type of Al 2 o 3 The preparation method of porous carbonyl iron microsphere wave absorbing agent comprises following two major steps:

[0054] 1. Preparation of porous carbonyl iron microspheres

[0055] 1.1 Pretreatment of carbonyl iron surface

[0056] Weigh 2 parts of carbonyl iron microspheres with a particle size of 2-20 μm and place them in a beaker, add 30 parts of dilute hydrochloric acid with a pH of 2, ultrasonicate the beaker for 5 minutes, separate the carbonyl iron microspheres and dilute acid with a magnet, and then use them separately Wash twice with deionized water and absolute ethanol, put into a vacuum drying device and dry in vacuum at 40°C for 30min;

[0057] 1.2 Porosity of carbonyl iron microspheres

[0058] Weigh 2 parts of carbonyl iron microspheres after surface pretreatment into a beaker, add 80 parts of ferric chloride solution with a concentration of 0.1mol / L, and ultrasonically treat for 10 minutes to fully react the carbonyl iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com