A kind of monodisperse melamine resin magnetic microsphere and preparation method thereof

A technology of magnetic microspheres and melamine resin, which is applied in the field of magnetic materials, can solve the problems of wide particle size distribution of magnetic microspheres, weak magnetism, complex process, etc., and achieve a simple preparation method, low pollution, and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

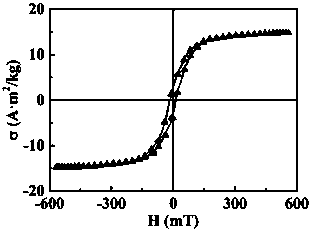

Embodiment 1

[0030] Step 1: Fe 2+ Adsorption of ions

[0031] Take the MF microspheres (dry weight about 1.4 g) after centrifugation and water washing, ultrasonically disperse them in 60 ml water for 5 min, then continue to heat and stir at 60 °C; 4 The solution was slowly added to it, so that the Fe in the solution 2+ The ion concentration is 0.4mol / L, after heating and stirring at 60°C for 1 hour, centrifuge to obtain Fe 2+ Ion-adsorbed MF microspheres.

[0032] Step 2: Fe 2+ Ion Transformation and Chen Hua Process

[0033] Disperse the MF microspheres obtained in step 1 in 60ml of water, adjust the pH to 8.0 with ammonia water, heat the mixture at 40°C for 4 hours, wash the sample after magnetic separation, and repeat 3 times to obtain the desired magnetic microsphere sample.

Embodiment 2

[0035] Step 1: Fe 2+ Adsorption of ions

[0036] Take the MF microspheres (dry weight about 1.4 g) after centrifugation and water washing, ultrasonically disperse them in 50 ml water for 5 min, then continue to heat and stir at 50 °C; 2 The solution was slowly added to it, so that the Fe in the solution 2+ Fe 2+ Ion-adsorbed MF microspheres.

[0037] Step 2: Fe 2+ Ion Transformation and Chen Hua Process

[0038] Disperse the MF microspheres obtained in step 1 in 50ml of water, adjust the pH to 10.0 with ammonia water, heat the mixture at 70°C for 5 hours, wash the sample after magnetic separation, and repeat 5 times to obtain the desired magnetic microsphere sample.

Embodiment 3

[0040] Step 1: Fe 2+ Adsorption of ions

[0041] Take the MF microspheres (dry weight about 1.4 g) after centrifugation and water washing, ultrasonically disperse them in 70 ml water for 5 min, then continue to heat and stir at 70 °C; 4 The solution was slowly added to it, so that the Fe in the solution 2+ Fe 2+ Ion-adsorbed MF microspheres.

[0042] Step 2: Fe 2+ Ion Transformation and Chen Hua Process

[0043]Disperse the MF microspheres obtained in step 1 in 60ml of water, adjust the pH to 11.0 with ammonia water, heat the mixture at 30°C for 6 hours, wash the sample after magnetic separation, and repeat 3 times to obtain the desired magnetic microsphere sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com