Bionic light heat insulation sandwich structure and preparation method thereof

A sandwich structure, lightweight thermal insulation technology, applied in ceramic products, other household appliances, layered products, etc., can solve the problems of low structural strength, unfavorable filling of thermal insulation materials, etc., to reduce thermal conductivity and actively save energy Value, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This example prepares a bionic lightweight heat-insulating sandwich material, which mainly includes the following steps:

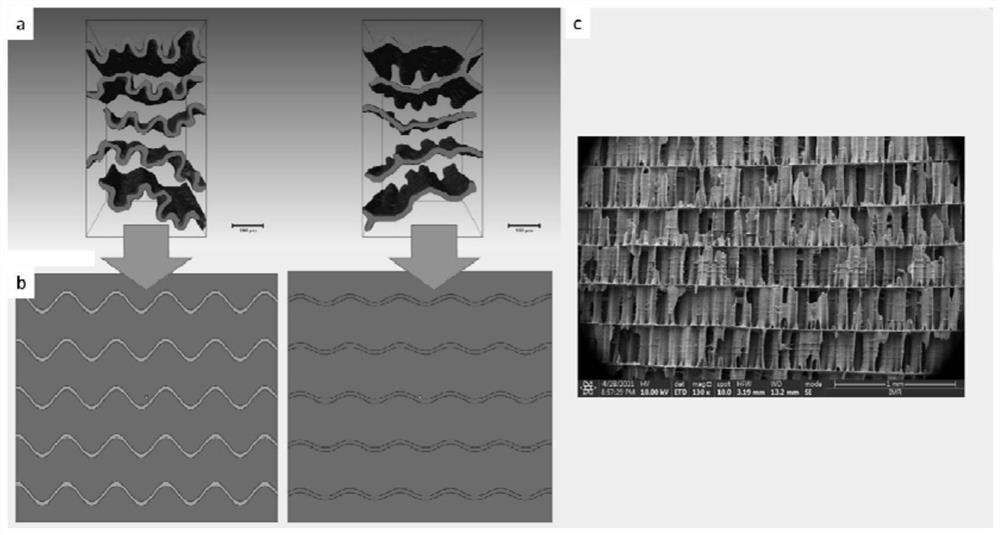

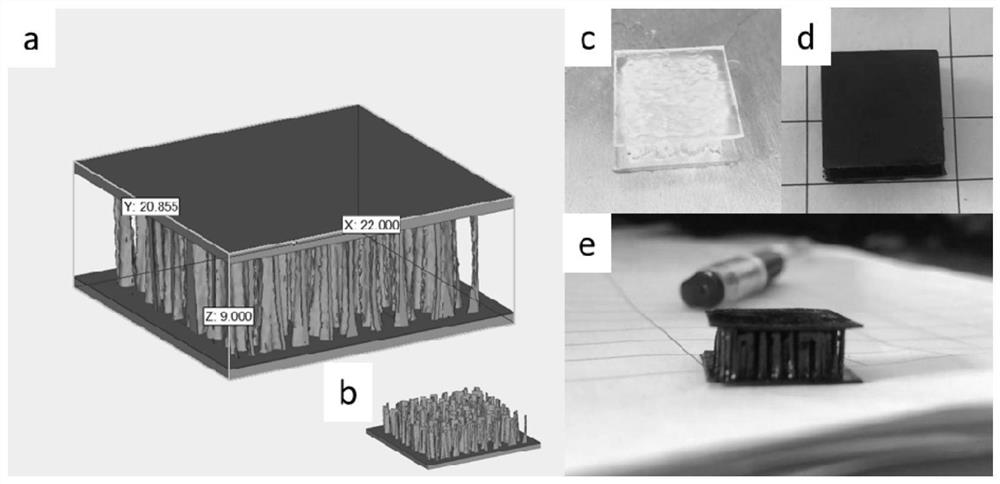

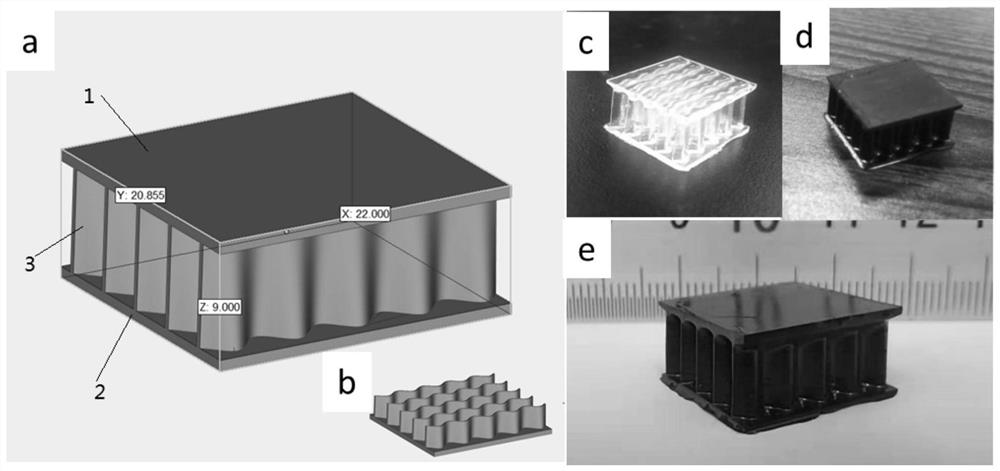

[0069] 1. Reconstruction of the bionic lightweight heat insulation model: Obtain characteristic data through Micro CT, import the 3D design software avizo for reconstruction, obtain a 3D CT model, and enlarge the obtained CT model by 16 times according to the same size, and obtain figure 2 aPrint the model and export it in stl file format for backup; after figure 1 method to get image 3 ;go through figure 1 method of c, get Figure 4 ;

[0070] 2. Preparation of photosensitive ceramic precursor slurry: Weigh 5g of vinylmethyl siloxane, add 1wt% free radical scavenger 2,6-di-tert-butyl-p-cresol, and then ultrasonicate for 10min to obtain a clear solution. After adding 5g of mercaptopropylmethylsiloxane, ultrasonic 10min was added to obtain a clear solution, and then 0.5wt% photoinitiator Omnirad 819 was added and mixed by ultrasonic 10min to ob...

Embodiment 2

[0076] This example prepares a bionic lightweight heat-insulating sandwich material, which mainly includes the following steps:

[0077] 1. Reconstruction of the bionic lightweight heat insulation model: Obtain the characteristic data through Micro CT, import the 3D design software avizo to reconstruct, obtain the CT model, enlarge the obtained CT model by 16 times according to the same size, obtain the printed model, and Export in stl file format for backup;

[0078] 2. Preparation of photosensitive ceramic precursor slurry: Weigh 1g of vinylmethyl siloxane, add 1wt% free radical scavenger 2,6-di-tert-butyl-p-cresol, and ultrasonicate for 10 minutes to obtain a clarified slurry. After adding 9g of mercaptopropylmethylsiloxane, ultrasonic 10min was added to obtain a clarified slurry, and then 0.5wt% photoinitiator Omnirad 819 was added for 10min ultrasonic mixing to obtain a photosensitive ceramic precursor slurry;

[0079] 3. 3D printing of bionic lightweight heat-insulating...

Embodiment 3

[0083] This example prepares a bionic lightweight heat-insulating sandwich material, which mainly includes the following steps:

[0084] 1. Reconstruction of the bionic lightweight heat insulation model: Obtain the characteristic data through Micro CT, import the 3D design software avizo to reconstruct, obtain the CT model, enlarge the obtained CT model by 16 times according to the same size, obtain the printed model, and Export in stl file format for backup;

[0085] 2. Preparation of photosensitive ceramic precursor slurry: Weigh 9g of vinylmethyl siloxane, add 1wt% free radical scavenger 2,6-di-tert-butyl-p-cresol, and then ultrasonicate for 10min to obtain a clarified slurry. After adding 1g of mercaptopropylmethylsiloxane, ultrasonication was performed for 10 minutes to obtain a clarified slurry, and then 0.5wt% photoinitiator Omnirad 819 was added to be ultrasonically mixed for 10 minutes to obtain a photosensitive ceramic precursor slurry;

[0086] 3. 3D printing of bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com