MBBR filler and preparation method thereof

A technology of toughening agent and base material, which is applied in the field of MBBR filler and its preparation, can solve the problems of low COD removal rate, ammonia nitrogen removal rate, poor hydrophilicity and bio-affinity, and high film-hanging amount of MBBR filler, achieving Convenient for long-distance transportation, excellent physical properties, high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

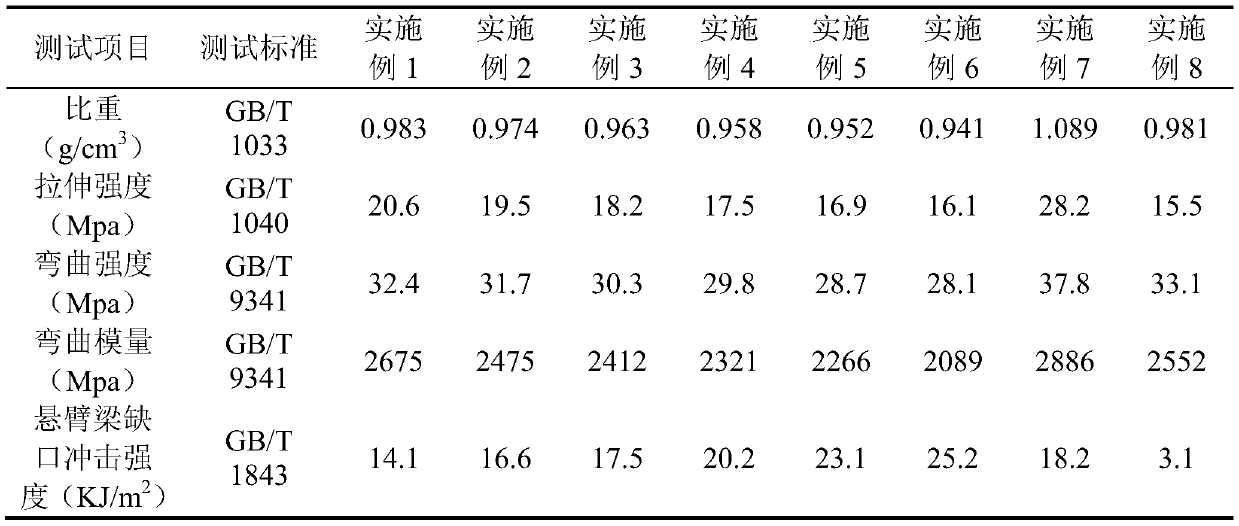

Examples

Embodiment 1

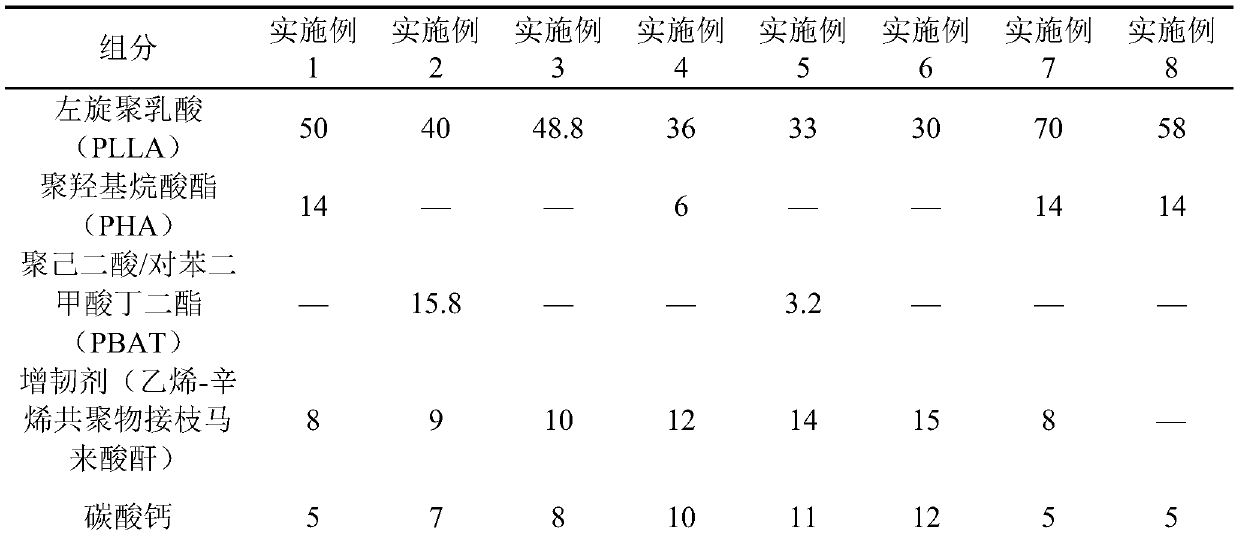

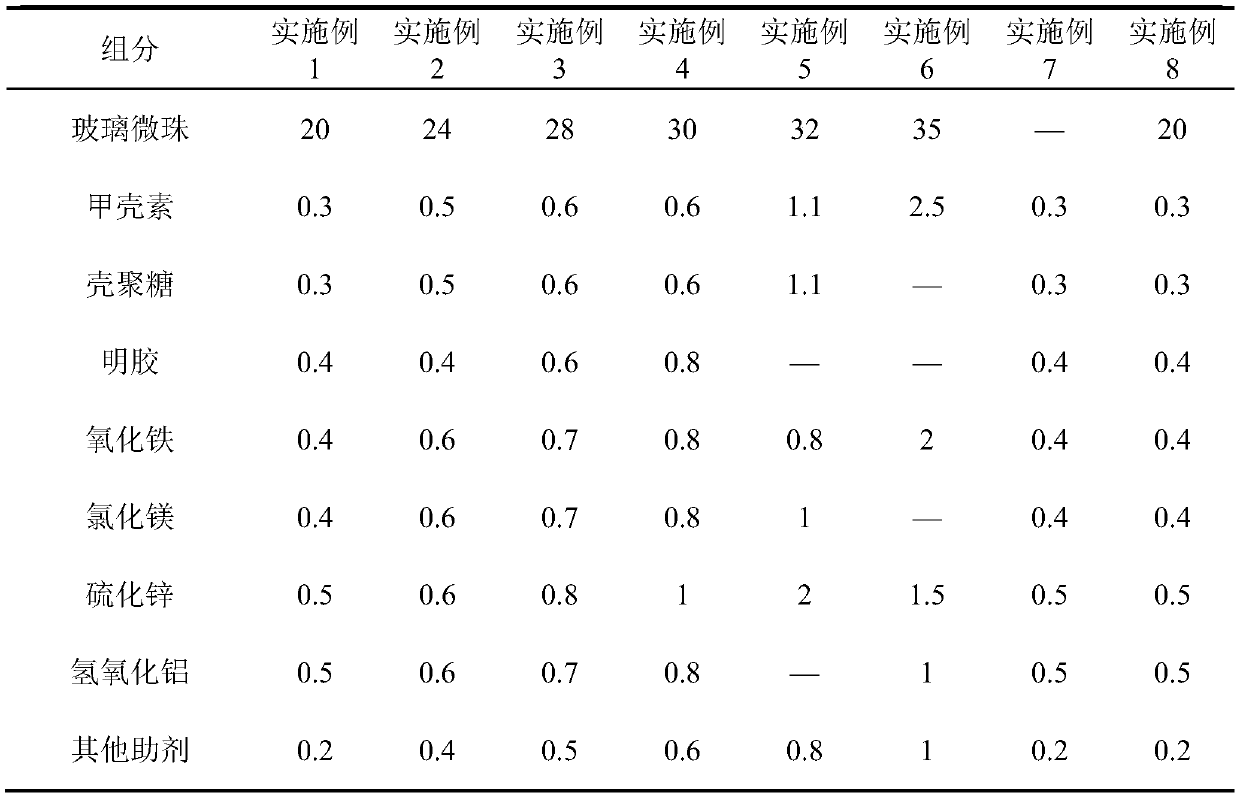

[0034] (1) Take the raw materials according to the components and proportions (parts by weight) of Example 1 in Table 1.

[0035] (2) Mix in high mixer for 5min, mix above-mentioned raw materials evenly, the blend after mixing is extruded and granulated by twin-screw extruder, wherein density regulator is added from side feeding port, the extruder The temperature of each zone is 130°C, 150°C, 165°C, 165°C, 165°C, 170°C, 175°C, 180°C, 180°C and 185°C from the feeding section to the head temperature in sequence. The length-to-diameter ratio of the extruder screw is 40, the extrusion screw speed is 350 rpm.

[0036] (3) The suspended filler base material obtained in step (2) is molded by an extruder, wherein the mouth film of the extruder is in a prescribed structural shape, and then cut to a prescribed length to obtain the final MBBR suspended filler.

Embodiment 2

[0038] (1) Take the raw materials by weighing the components and proportions (parts by weight) of Example 2 in Table 1.

[0039] (2) Mix in high mixer for 10min, mix the above-mentioned raw materials evenly, extrude the mixed blend by twin-screw extruder to granulate, wherein the density modifier is added from the side feeding port, and the The temperature of each zone is 150°C, 165°C, 185°C, 185°C, 185°C, 190°C, 195°C, 200°C, 200°C and 200°C from the feeding section to the head temperature in sequence. The length-to-diameter ratio of the extruder screw is 36. The extrusion screw speed is 350 rpm.

[0040] (3) The suspension filler base material obtained in step (2) is injected into the final MBBR suspension filler by injection molding machine

Embodiment 3

[0042] (1) Take the raw materials by weighing the components and proportions (parts by weight) of Example 3 in Table 1.

[0043] (2) Mix in high mixer for 15min, mix above-mentioned raw materials evenly, the blend after mixing is extruded and granulated by twin-screw extruder, wherein density modifier is added from side feeding port, the extruder The temperature of each zone is 140°C, 160°C, 180°C, 180°C, 180°C, 185°C, 185°C, 190°C, 190°C and 195°C from the feeding section to the die head, and the length-to-diameter ratio of the extrusion screw is 36 , the extrusion screw speed is 300 rpm.

[0044] (3) The suspended filler base material obtained in step (2) is molded by an extruder, wherein the mouth film of the extruder is in a prescribed structural shape, and then cut to a prescribed length to obtain the final MBBR suspended filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com