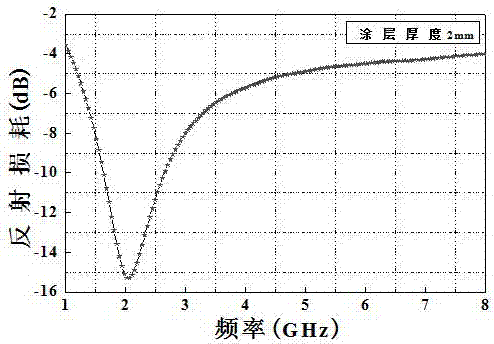

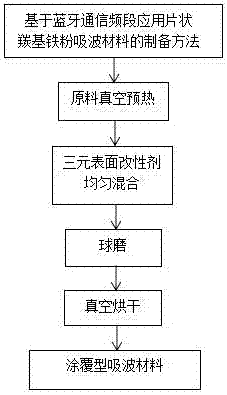

Preparation method of flaky carbonyl iron powder wave-absorbing material based on application of Bluetooth communication frequency band

A technology of carbonyl iron powder and microwave-absorbing materials, which is applied in the field of microwave-absorbing materials, can solve problems such as the research on the preparation method of Bluetooth full-band high-absorbing microwave-absorbing materials, and achieve the effects of low raw material cost, simple preparation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

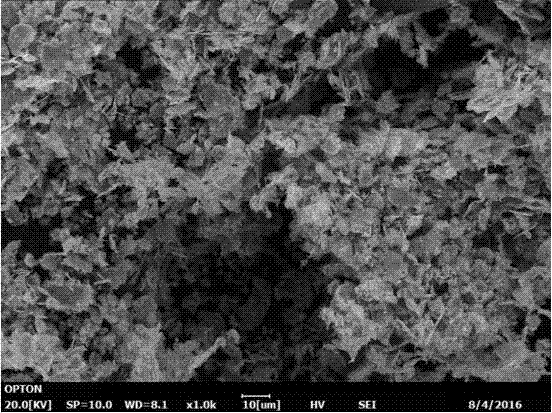

[0036] Before the experiment, the carbonyl iron powder raw material is preheated in a vacuum environment, the preheating temperature is 100-150° C., and the time is 3-5 hours. Put a certain amount of carbonyl iron powder raw materials and stainless steel balls into the ball milling tank according to the ball mass ratio of 1:8, add ternary surface modifier (calcium stearate + KH560 + titanate), absolute ethanol into the ball milling tank As a ball milling medium, the carbonyl iron powder is submerged in anhydrous ethanol, stirred evenly with a glass rod, and then airtightly loaded into a planetary ball mill for ball milling. The grinding body in the planetary ball mill includes three kinds of large, medium and small stainless steel balls with diameters of 16mm, 6mm and 3mm. The mass ratio of the three kinds of stainless steel balls is 10:30:60. The ball milling time is 20 hours and the speed is 200 rpm. / minute. After the wet grinding is completed, put the wet-milled slurry in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com