Method of preparing sheet-like carbonyl iron powder with plasma assisted ball milling

A carbonyl iron powder and plasma technology, which is applied to carbonyl iron and other directions, can solve the problems of affecting the performance and product quality of flake carbonyl iron powder, difficult to stabilize product quality, low production efficiency, etc., and achieves reduction of ball milling time and high transformation efficiency. , the effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The indeterminate shape (which can be spherical, ellipsoid or other shapes) carbonyl iron powder with an average particle size of 20 μm is ball-milled with a plasma ball mill under the protection of argon. The ball-milling medium is tungsten carbide balls, and the ball-to-material ratio is 20: 1. The ball milling time is 7h, the working current is 1.5A, and the excitation voltage is 15kV to obtain multi-layer flake carbonyl iron powder with an average particle size of less than 50μm.

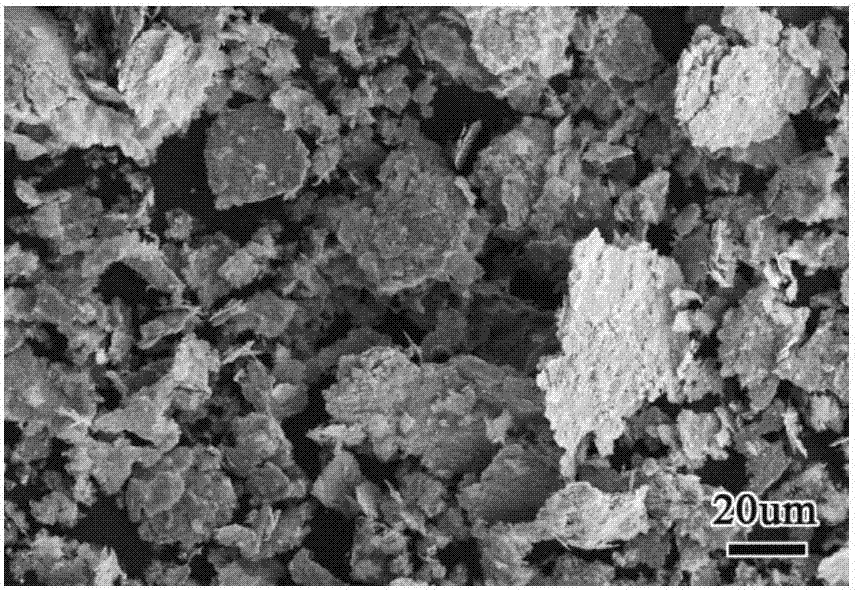

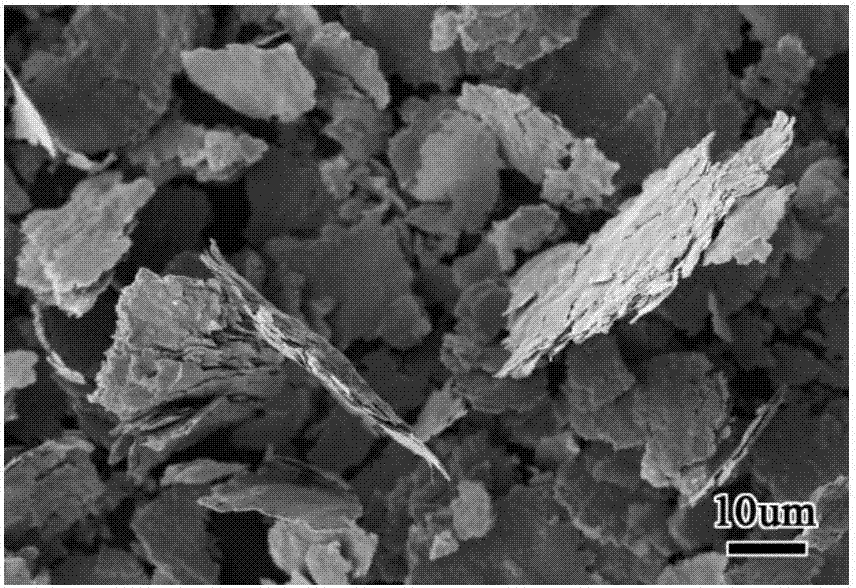

[0036] figure 1 , figure 2 These are the low-magnification and high-magnification SEM images of the multi-layer carbonyl iron powder prepared in this example, respectively.

[0037] (2) The above-mentioned multi-layer flake carbonyl iron powder is refined by a planetary ball mill under the protection of argon. The ball milling speed is 350rpm. The ball milling medium is stainless steel balls. The time is 2 hours, and the secondary flaky carbonyl iron powder with a particle size of ...

Embodiment 2

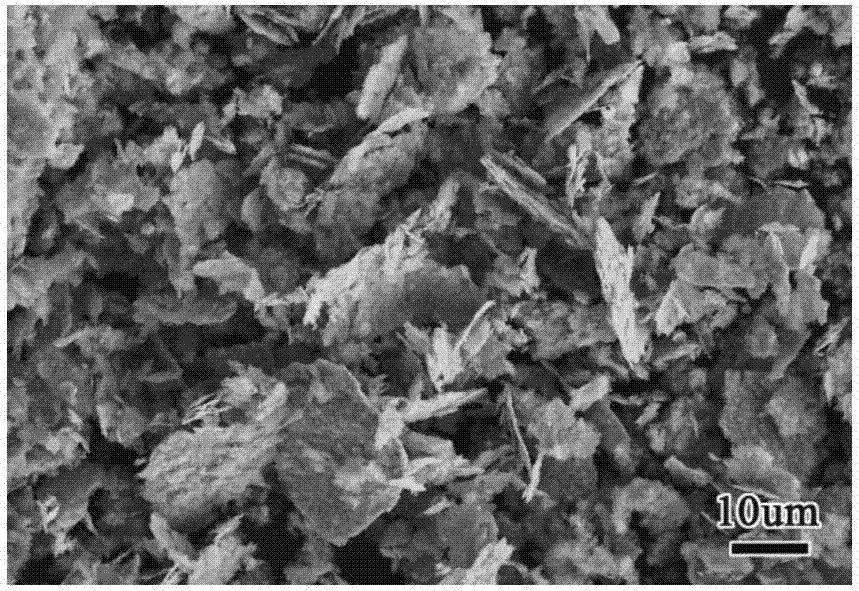

[0039] The steps of this embodiment are basically the same as those of Embodiment 1, except that in step (2), the time for planetary ball milling is 4 hours. Figure 4 SEM image of the secondary flaky carbonyl iron powder prepared in this example. It can be seen from the figure that the particle size of the secondary flaky carbonyl iron powder is less than 15 μm. At the same time, it can be seen that, compared with Example 1, the particle size of the secondary flaky carbonyl iron powder obtained in this example is more uniform.

Embodiment 3

[0041] The steps of this embodiment are basically the same as those of Embodiment 1, except that in step (2), the time for planetary ball milling is 6h. Figure 5 SEM image of the secondary flaky carbonyl iron powder prepared in this example. It can be seen from the figure that the particle size of the secondary flaky carbonyl iron powder obtained by this process is less than 10 μm, and the particle size is relatively uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com