Modification method for electromagnetic parameters of carbonyl iron powder

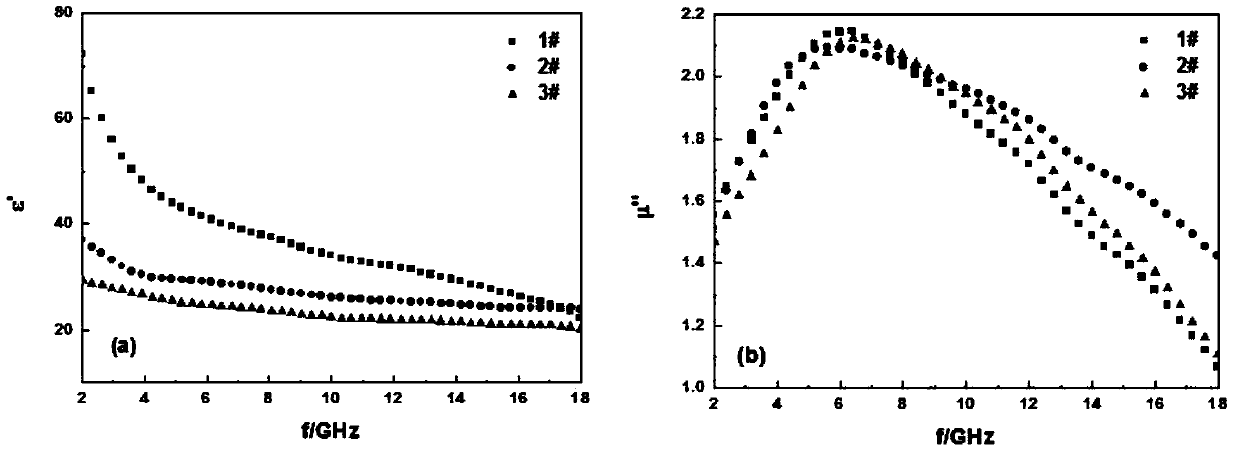

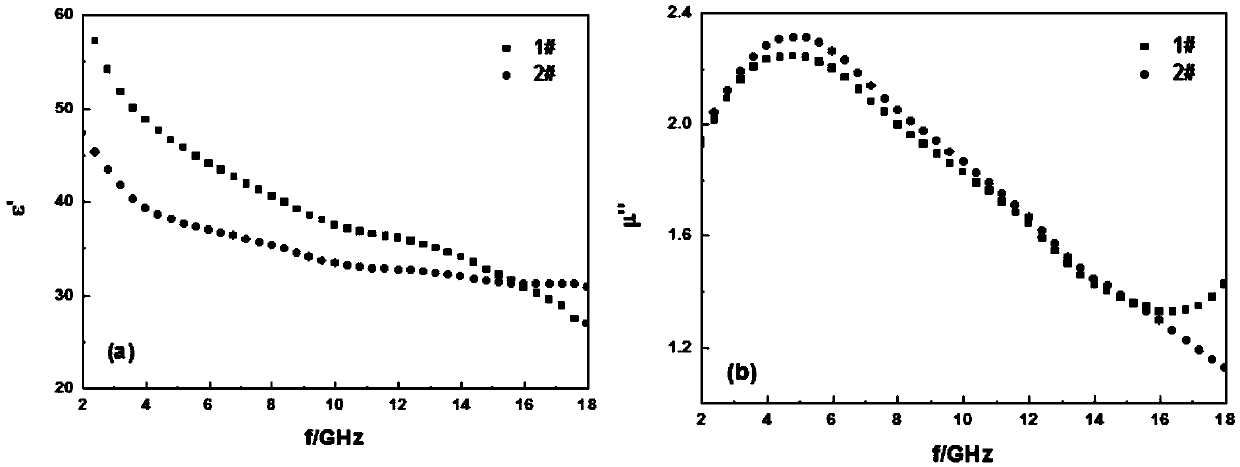

A carbonyl iron powder, electromagnetic parameter technology, applied in the field of absorbent preparation, can solve the problem of dielectric constant and magnetic parameter mismatch, reduce the dielectric constant and other problems, to reduce the dielectric constant, improve the magnetic parameter, change the shape of the problem. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put the carbonyl iron powder produced by Jiangxi Yuean Superfine Metal Material Co., Ltd. without other process treatment into four agate jars of the XQM-2L frequency conversion planetary ball mill of Nanjing Keyan Experimental Instrument Research Institute, and place iron powder in each jar 250g, 10 agate balls with a diameter of 20mm and 25 agate balls with a diameter of 8mm;

[0034] Fix the agate jar on the planetary ball mill, control the rotation speed to 200r / min, change the rotation direction of the ball mill every 0.5 hours, stop the ball mill after 20 hours, and take out the carbonyl iron powder;

[0035] Mix the carbonyl iron powder taken out according to the following formula: (1) Add 0.75ml of analytically pure phosphoric acid dropwise into 200ml of analytically pure acetone and stir well until the mixture is uniform, add 500g of carbonyl iron powder after ball milling and continue stirring until there are no more bubbles Produced, continue to stir at 25-35...

Embodiment 2

[0038] The carbonyl iron powder produced by Jiangxi Lanhai Absorbing Material Co., Ltd. was placed in four vacuum agate jars of the XQM-2L frequency conversion planetary ball mill of Nanjing Keyan Experimental Instrument Research Institute, and 250g of carbonyl iron powder was placed in each jar, with a diameter of 10 20mm agate balls, 25 8mm agate balls;

[0039] The agate jar is fixed on the planetary ball mill, the control speed is 300r / min, and the rotation direction of the ball mill is changed every 0.5 hours. Stop after 10 hours, and the carbonyl iron powder in the jar is taken out;

[0040]Mix the carbonyl iron powder taken out according to the following formula: drop 0.75ml of analytically pure phosphoric acid into 200ml of analytically pure acetone and stir until it is evenly mixed, add 500g of carbonyl iron powder after ball milling and continue stirring until no more bubbles are produced Stirring was continued at -35°C until the solvent evaporated completely. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com