China Mobile 4G full band absorbing material, and preparation method and application thereof

A wave-absorbing material, China Mobile's technology, applied in the field of wave-absorbing materials, can solve the problems of poor low-frequency absorption performance and large-spectrum characteristics, etc., achieve excellent wave-absorbing performance, enhance signal-to-noise ratio capability, and achieve the effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

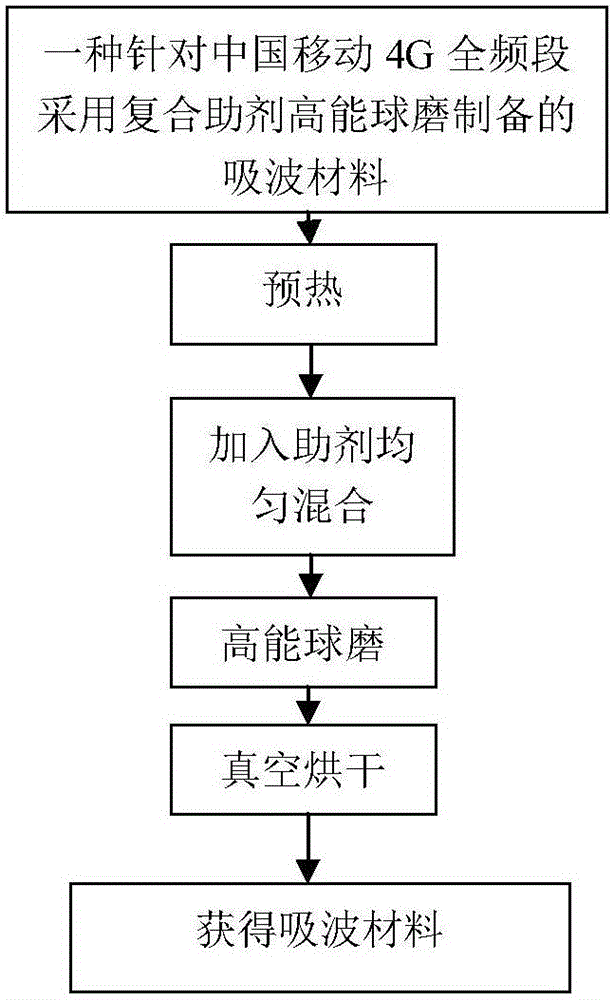

[0035] A preparation method of China Mobile 4G full-band wave-absorbing material, comprising the following steps:

[0036] Get 200g of carbonyl iron powder raw material. Preheat the carbonyl iron powder raw material before high-energy ball milling, and preheat the raw material at 120°C for 3 hours under the protection of argon; add 2ml of silane coupling agent KH-570 and 4.4g of magnesium stearate, and add 150ml of anhydrous ethanol is stirred evenly and mixed, then put into the ball mill tank and sealed, then wet milled, the large ball of stainless steel ball in the planetary ball mill middle ball small ball The weight ratio of the carbonyl iron powder is 10:80:80, the total weight of the three is 1800g, the ball milling time is 15 hours, and the speed is 300r / min; The carbonyl iron powder raw material and the compounding auxiliary agent (silane coupling agent and surfactant stearate) are uniformly mixed, and a dense and uniform organic insulating film is formed on the ...

Embodiment 2

[0039] A preparation method of China Mobile 4G full-band wave-absorbing material, comprising the following steps:

[0040] Get 200g of carbonyl iron powder raw material. Preheat the carbonyl iron powder raw material before high-energy ball milling, and preheat the raw material at 120°C for 3 hours under the protection of argon; add 2ml of silane coupling agent KH-550 and 1g of sodium stearate, and add 150ml Anhydrous ethanol is stirred evenly and mixed, then put into the ball mill tank and sealed, then wet milled, the large ball of stainless steel ball in the planetary ball mill middle ball small ball The weight ratio of the carbonyl iron powder is 10:80:80, the total weight of the three is 1800g, the ball milling time is 15 hours, and the speed is 300r / min; The carbonyl iron powder raw material and the compounding auxiliary agent (silane coupling agent and surfactant stearate) are uniformly mixed, and a dense and uniform organic insulating film is formed on the surface o...

Embodiment 3

[0043] A preparation method of China Mobile 4G full-band wave-absorbing material, comprising the following steps:

[0044] Take 200g of carbonyl iron powder raw material, preheat the carbonyl iron powder raw material before high-energy ball milling, preheat the raw material at 130°C for 4 hours under the protection of argon; add 3ml silane coupling agent KH-550 and 2g Sodium stearate, and add 200ml of absolute ethanol and stir to mix evenly, put it into the ball mill tank and seal it, then carry out wet milling, the large ball of stainless steel ball in the planetary ball mill middle ball small ball The weight ratio of the carbonyl iron powder is 10:60:60, the total weight of the three is 1800g, the ball milling time is 12 hours, and the rotation speed is 100r / min; The carbonyl iron powder raw material and the compounding auxiliary agent (silane coupling agent and surfactant stearate) are uniformly mixed, and a dense and uniform organic insulating film is formed on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com