Preparation method of wave absorbing material used in satellite communication uplink frequency band of C wave band

A technology for satellite communication and absorbing materials, applied in chemical instruments and methods, other chemical processes, grain processing, etc., can solve problems such as unsatisfactory impedance matching of materials, and achieve superior absorbing performance, easy availability of raw materials, and absorbing performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

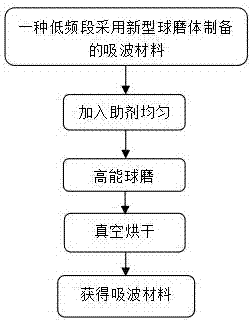

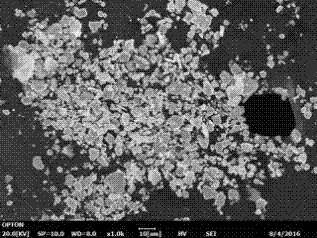

[0028] A preparation method for a wave-absorbing material applied to the satellite communication uplink frequency band in the C-band, comprising the steps of:

[0029] Put carbonyl iron powder (80g), composite coupling agent (2g zinc stearate + 2ml titanate), 100ml absolute ethanol, and 400g bearing steel rollers into a ball mill pot and seal it for ball milling. The horizontal planetary ball mill is 500r / min speed ball mill for 10 hours; 400g bearing steel rollers are composed of three types of large, medium and small cylindrical rollers with diameters and heights of 20mm, 10mm and 6mm. The mass of the large, medium and small cylindrical rollers The ratio is large: medium: small = 10:40:50, and the ratio of the height to diameter of the large, medium and small bearing steel rollers is 1:1.

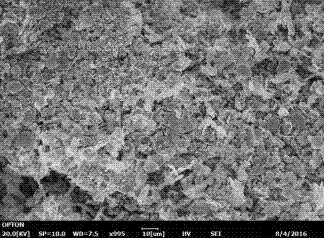

[0030] The slurry after ball milling was taken out, heated at 50° C. for 3 hours and dried to obtain the wave-absorbing material of the present invention. The wave-absorbing material and...

Embodiment 2

[0032] A preparation method for a wave-absorbing material applied to the satellite communication uplink frequency band in the C-band, comprising the steps of:

[0033] Put carbonyl iron powder (100g), composite coupling agent (2g zinc stearate + 4ml titanate), 200ml absolute ethanol, and 800g bearing steel rollers into a ball mill pot and seal it for ball milling. Ball milling at 400r / min for 12 hours; 400g bearing steel rollers are composed of three types of large, medium and small cylindrical rollers with diameters and heights of 20mm, 10mm and 6mm. The mass of large, medium and small cylindrical rollers The ratio is large: medium: small = 5:45:50, and the ratio of the height to diameter of the large, medium and small bearing steel rollers is 0.8:1. The slurry after ball milling was taken out, heated at 60° C. for 2 hours and dried to obtain the wave-absorbing material of the present invention.

Embodiment 3

[0035] A preparation method for a wave-absorbing material applied to the satellite communication uplink frequency band in the C-band, comprising the steps of:

[0036] Put carbonyl iron powder (90g), composite coupling agent (2g zinc stearate + 3ml titanate), 150ml absolute ethanol, and 600g bearing steel rollers into a ball mill pot and seal it for ball milling. 450r / min speed ball mill for 8 hours; 400g bearing steel rollers are composed of three types of large, medium and small cylindrical rollers with diameters and heights of 20mm, 10mm and 6mm. The mass of large, medium and small cylindrical rollers The ratio is large: medium: small = 10:40:50, and the ratio of the height to diameter of the large, medium and small bearing steel rollers is 1.2:1. The slurry after ball milling was taken out, heated at 40° C. for 4 hours and dried to obtain the wave-absorbing material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com