Preparation method for flaky carbonyl iron powder with high magnetic permeability

A technology of carbonyl iron powder and high magnetic permeability, which is applied in the field of preparation of high magnetic permeability flaky carbonyl iron powder, can solve the problems of excessive dielectric properties of iron powder, increased magnetic permeability, and adverse effects on overall performance. Achieve the effects of reducing preparation costs, improving magnetic permeability, and excellent electromagnetic absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

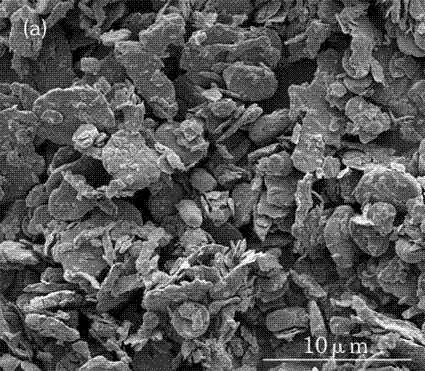

Embodiment 1

[0026] 1) One ball mill

[0027] At room temperature, weigh 100 g of dry and clean steel balls with a diameter of 4 mm, 10 g of carbonyl iron powder and 0.01 g of calcium stearate into a 100 ml ball mill jar, and add 40 ml of acetone solution, and use a planetary ball mill For ball milling, the parameters were set as follows: speed 500 rpm; time 8 h.

[0028] 2) Wet powder drying

[0029] The ball-milled iron powder was taken out and washed 3 times with absolute ethanol. At room temperature, blow dry.

[0030] 3) Secondary ball milling

[0031] Add the dried powder and 4 mm steel balls into the ball mill jar according to the original ratio, and continue ball milling at a speed of 500 rpm for 10 min.

[0032] 4) Separation of iron powder and steel ball

[0033] After the second ball milling, the sample is sieved and separated, and the obtained sample is flaky carbonyl iron powder.

[0034]

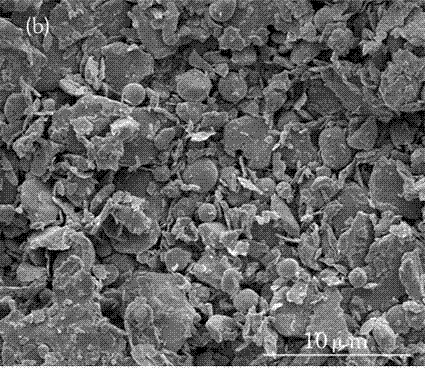

Embodiment 2

[0036] 1) One ball mill

[0037] At room temperature, weigh 50 g of dry and clean steel balls with a diameter of 6 mm, 75 g of 3 mm steel balls, 7.5 g of carbonyl iron powder and 0.05 g of calcium stearate and place them in a 100 ml ball mill jar, and add 50 ml of ethanol solution, A planetary ball mill was used for ball milling, and the parameters were set as follows: speed 400 rpm; time 6 h.

[0038] 2) Wet powder drying

[0039] The ball-milled iron powder was taken out and washed 3 times with absolute ethanol. Dry in a drying oven at 50°C.

[0040] 3) Secondary ball milling

[0041] Put the dried powder and 6 mm and 3 mm steel balls into the ball mill jar according to the original ratio, and continue ball milling at a speed of 400 rpm for 10 min.

[0042] 4) iron powder is separated from steel ball (same as embodiment 1)

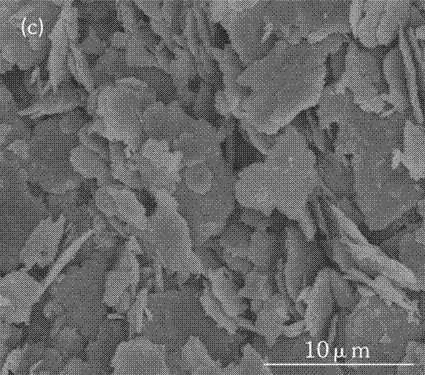

Embodiment 3

[0044] 1) One ball mill

[0045] At room temperature, weigh 50 g of dry and clean steel balls with a diameter of 6 mm, 100 g of 4 mm steel balls, 5 g of carbonyl iron powder and 0.1 g of calcium stearate and place them in a 100 ml ball mill jar, and add 30 ml of n-hexane solution , using a planetary ball mill for ball milling, the parameters are set as follows: speed 600 rpm; time 10 h.

[0046] 2) Wet powder drying

[0047] The ball-milled iron powder was taken out and washed 3 times with absolute ethanol. Dry in a drying oven at 70°C.

[0048] 3) Secondary ball milling

[0049] In this example, secondary ball milling is not used, and the next step is directly entered.

[0050] 4) iron powder is separated from steel ball (same as embodiment 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com